7 Reasons to Choose Full Turnkey PCB Assembly for Quality Manufacturing

Full turnkey PCB assembly is a manufacturing service where a single provider manages every step of building a printed circuit board — from PCB fabrication and component sourcing to assembly, testing, and delivery. Instead of coordinating multiple suppliers for each stage, companies work with one trusted partner who takes responsibility for the entire process.

This approach is especially important for businesses focused on quality manufacturing. Managing multiple vendors often leads to communication gaps, delayed shipments, and inconsistent quality standards. With a full turnkey solution, all steps are integrated under one workflow, which helps maintain consistent quality control, accurate component sourcing, and better traceability.

For example, imagine you are launching a new electronic device. If you source PCBs from one vendor, buy components from another, and ship them to a separate assembly house, each handoff creates opportunities for error — a missing part, a mismatched component, or a schedule delay. A full turnkey provider eliminates those handoffs, reducing risk and speeding up production.

In this article, we’ll explore seven compelling reasons to choose full turnkey PCB assembly if you want a faster, more reliable, and cost-effective path to high-quality electronics manufacturing. By the end, you’ll know exactly why many engineering teams, startups, and OEMs prefer this model over partial turnkey or DIY procurement.

Reason 1: Simplified Supply Chain Management

One Vendor, Complete Solution

Full turnkey PCB assembly means one provider manages the entire production workflow — including PCB fabrication, component sourcing, assembly, and functional testing. Instead of contacting different vendors for each step, you work with a single partner who is responsible for delivering a finished, tested board.

This approach eliminates the need to manage multiple supplier relationships. A typical electronics company might have to coordinate with:

l A PCB manufacturer for bare boards

l A component distributor for parts

l A logistics provider for shipping

l An assembly house for soldering and mounting

l A separate testing lab

Each of these vendors requires separate purchase orders, emails, and follow-ups. With a full turnkey solution, those five separate vendors are consolidated into one supplier contract and one project manager, greatly reducing complexity.

Example:

Company A uses five different suppliers. When one shipment is delayed, their team must email each vendor to identify where the issue occurred. This takes time and can push the project off schedule.

Company B uses a turnkey provider. Their single point of contact quickly locates the bottleneck, resolves it, and keeps production on track — saving hours of coordination work.

Minimized Communication Overhead

Centralizing the supply chain also reduces communication overhead. Instead of dozens of email threads across multiple suppliers, you have one project manager who keeps you updated on progress.

Here’s how a single point of contact streamlines order tracking step-by-step:

1. Place one order — You submit your BOM and Gerber files to the turnkey provider.

2. Automatic coordination — The provider orders components, schedules PCB fabrication, and reserves assembly slots.

3. Receive consolidated updates — You get a single progress report rather than tracking multiple shipments.

4. Resolve issues faster — If a part is out of stock, the provider suggests alternatives immediately, without waiting for multiple vendors to respond.

5. Approve and receive final product — The completed, tested boards arrive in one shipment.

This centralized communication model helps prevent misunderstandings, reduces lead times, and allows engineering teams to focus on product development instead of supplier management.

Reason 2: Faster Time-to-Market

Parallel Processes Reduce Lead Times

One of the biggest advantages of full turnkey PCB assembly is that fabrication, component procurement, and assembly preparation can run in parallel. Instead of waiting for each step to finish before starting the next, the turnkey provider begins ordering components while the PCB boards are being manufactured.

This parallel workflow significantly reduces total lead time. For example, a company managing the process themselves might spend:

l 3 weeks on PCB fabrication

l 2 weeks sourcing components

l 3 weeks waiting for assembly and testing

Total: 8 weeks before a final product is ready.

With turnkey assembly, those steps overlap. Components are ready by the time boards come off the production line, and assembly begins immediately. This can cut lead time to just 5 weeks, helping new products hit the market sooner.

For businesses launching new electronics, a faster time-to-market can mean beating competitors, capturing early demand, and reducing development costs.

Real-Time Status Updates

Turnkey providers often offer real-time project tracking through online dashboards or ERP system integration. This visibility allows engineering and purchasing teams to check progress at any time without sending multiple emails.

Example:

l The dashboard shows PCB fabrication is 70% complete

l Component sourcing is fully confirmed, with no stock shortages

l Assembly is scheduled to start in three days

This level of transparency allows teams to plan product launches, allocate resources, and make design changes if needed — all without waiting for status reports from multiple suppliers. It also reduces last-minute surprises, ensuring smoother production cycles and faster deliveries.

Reason 3: Cost Efficiency and Better Pricing

Bulk Purchasing Power

Full turnkey PCB assembly can significantly reduce your overall production cost because turnkey providers source components in large volumes across multiple projects. Their purchasing power often allows them to negotiate lower prices than what a single company could get buying parts individually.

For example, if your Bill of Materials (BOM) lists a microcontroller at $2.50/unit when bought in small quantities, a turnkey provider may get it for $2.10/unit due to bulk orders. For a run of 5,000 units, that saves $2,000 just on one component. Multiply that across dozens of parts, and the savings add up quickly.

Hypothetical BOM Cost Comparison:

| Component Type | DIY Purchase Cost | Turnkey Cost | Savings (%) |

|---|---|---|---|

| Microcontroller | $2.50 | $2.10 | 16% |

| Resistors (per set) | $0.05 | $0.04 | 20% |

| Connectors | $1.20 | $1.00 | 17% |

| Total (per unit) | $10.00 | $8.70 | 13% overall |

This bulk purchasing advantage helps keep unit costs lower, making turnkey assembly ideal for both prototypes and mass production.

Fewer Hidden Costs

When companies manage PCB procurement and assembly themselves, they often overlook the indirect costs:

l Shipping components from multiple suppliers

l Paying for customs clearance separately

l Administrative hours spent coordinating vendors

l Extra inventory storage fees

Turnkey services consolidate shipping into one shipment, simplify customs paperwork, and save engineering teams time on coordination.

Cost Comparison (Example):

| Cost Item | Multiple Vendors | Full Turnkey |

|---|---|---|

| Component Shipping | $300 | Included |

| Customs Brokerage | $150 | Included |

| Admin Labor (8 hrs) | $200 | $0 (provider manages) |

| Total Extra Costs | $650 | $0 |

By reducing these hidden costs, companies can reallocate resources to product design and R&D rather than logistics and vendor management.

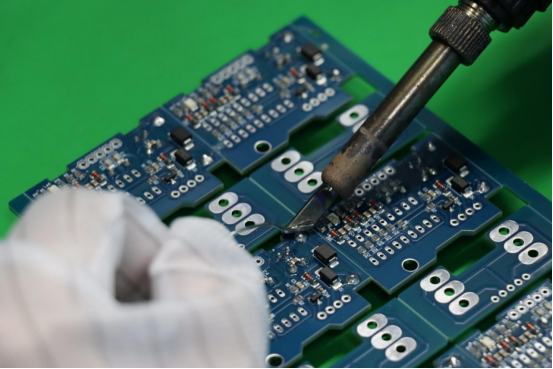

Reason 4: Higher Product Quality

Integrated Quality Control

Full turnkey PCB assembly helps companies achieve higher product quality because a single provider oversees every stage of production — from PCB fabrication and component sourcing to assembly and final testing. This integration reduces the chance of defects and ensures consistent standards across all boards.

For example, many turnkey providers follow IPC-A-610 standards, the widely recognized benchmark for electronics assembly quality. By maintaining these standards throughout production, defects like cold solder joints, misaligned components, or missing parts are minimized. Continuous in-process inspections catch issues early, avoiding costly rework or product recalls.

Step-by-step quality process in turnkey assembly:

1. Incoming Inspection: Verify all components and PCBs meet specifications.

2. Assembly Monitoring: Inspect soldering and placement during production.

3. Functional Testing: Test boards for electrical performance and reliability.

4. Final Audit: Ensure finished boards meet customer requirements and industry standards.

Better Traceability

Another key advantage of full turnkey PCB assembly is traceability. Each component, PCB batch, and assembly process is tracked within a single system. This single chain of custody makes it easy to identify the source of any issues if defects are detected later.

Traceability is crucial for industries that require regulatory compliance, such as medical devices, telecommunications, and industrial electronics. For example:

l If a faulty microcontroller is discovered, the provider can quickly trace which boards contain it.

l This enables targeted recalls or repairs rather than scrapping entire production runs, saving time and costs.

With integrated quality control and traceability, full turnkey PCB assembly ensures consistent, reliable, and compliant products, giving companies confidence in every board they ship.

Reason 5: Access to Professional Expertise

Engineering Support and DFM Review

Full turnkey PCB assembly providers often offer engineering support, including Design for Manufacturability (DFM) reviews. A DFM review examines your PCB design to ensure it can be manufactured efficiently and reliably, identifying potential issues before production begins.

For example, a common issue in PCB assembly is a solder bridge, where solder accidentally connects two adjacent pads, causing short circuits. During a DFM review, engineers may notice that component spacing is too tight, or pad sizes are inconsistent, and recommend adjustments. Fixing these issues before fabrication prevents costly errors during assembly and ensures higher first-pass yield.

Troubleshooting and Continuous Improvement

Turnkey providers also provide dedicated engineering support during production, enabling fast troubleshooting of any issues. This is especially valuable for prototypes or complex boards, where minor defects can halt production.

Step-by-step example: Debugging a faulty prototype within 48 hours:

1. Problem Detection: Functional testing identifies intermittent power failures.

2. Analysis: Engineers review assembly data and schematic layout.

3. Root Cause Identification: A misaligned capacitor is causing voltage drops.

4. Corrective Action: The assembly process is adjusted, and faulty units are replaced.

5. Verification: Final testing confirms the issue is resolved.

By having experienced engineers embedded in the process, full turnkey PCB assembly ensures issues are resolved quickly, production quality improves over time, and designs are optimized for repeatable manufacturing.

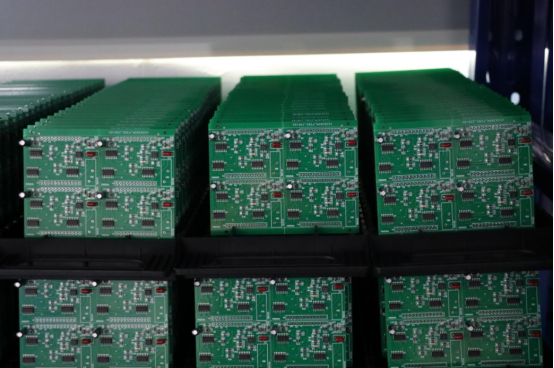

Reason 6: Flexibility for Prototypes and Mass Production

Seamless Scaling

Full turnkey PCB assembly offers flexibility to scale production from small prototype runs to large-volume manufacturing without changing suppliers. This ensures continuity, maintains quality standards, and reduces the risk of errors during supplier transitions.

Example:

A start-up develops a new IoT device and begins with a 50-unit prototype. Using a turnkey provider, the company later scales to 10,000+ units for mass production without switching vendors. The same team, processes, and quality checks remain consistent, eliminating the learning curve and delays that often occur when onboarding a new supplier.

Rapid Iteration

Turnkey services also enable rapid iteration of PCB designs. If a design modification is needed, the provider can implement changes quickly between production runs. This flexibility is critical for innovation and fast product development.

Comparison with non-turnkey processes:

l Non-turnkey: Updating a design may require contacting a new assembly house, resubmitting BOMs, and coordinating separate component sourcing, which can add weeks of delay.

l Turnkey: The same provider adjusts the existing workflow, updates the BOM and assembly instructions, and implements the new design without restarting the entire supply chain.

Step-by-step rapid iteration workflow:

1. Submit updated design files to the turnkey provider.

2. Provider reviews the design for manufacturability and compatibility with existing processes.

3. Adjust component sourcing and assembly instructions accordingly.

4. Implement changes in the next production batch.

5. Test and validate updated boards before full-scale production.

This combination of seamless scaling and rapid iteration allows companies to bring products to market faster, innovate efficiently, and reduce costs associated with supplier transitions or repeated onboarding.

Reason 7: Reduced Risk and Greater Accountability

Clear Responsibility

A major advantage of full turnkey PCB assembly is that one partner takes full responsibility for deadlines, quality, and delivery. With multiple vendors, it’s common for errors or delays to trigger “blame games,” where each supplier points fingers instead of solving the problem.

Example:

Company X was producing a batch of complex PCBs using three separate vendors: a PCB manufacturer, a component supplier, and an assembly house. When a shipment was delayed, each vendor blamed another, and the project timeline slipped.

By switching to a turnkey provider, the company had a single point of accountability. The turnkey team tracked the entire workflow, resolved delays immediately, and delivered the boards on time, eliminating confusion and stress.

Lower Risk of Component Mismatch

Centralized Bill of Materials (BOM) management is another way turnkey assembly reduces risk. When one provider manages all components, the chance of ordering incorrect parts or using incompatible substitutes is greatly reduced.

Mini Case Study:

A medical device manufacturer needed 1,000 units of a PCB with over 200 components. In a previous project with separate suppliers, a single resistor of incorrect value caused a full batch failure, delaying the product launch by two weeks.

With a turnkey provider, the BOM was centrally managed and cross-checked against the design files. Any potential mismatch was flagged before production. The result: zero component errors and on-time delivery.

By combining clear responsibility and centralized component management, full turnkey PCB assembly provides companies with lower risk, higher reliability, and greater accountability, giving engineering teams confidence that their projects will stay on schedule and meet quality standards.

Conclusion

Full turnkey PCB assembly offers clear advantages for companies seeking high-quality electronics manufacturing. Throughout this article, we explored seven key reasons to choose turnkey services:

1. Simplified Supply Chain Management – One vendor handles PCB fabrication, component sourcing, assembly, and testing, reducing complexity and vendor coordination.

2. Faster Time-to-Market – Parallel workflows and real-time updates help companies launch products more quickly.

3. Cost Efficiency and Better Pricing – Bulk component sourcing and fewer hidden costs lower overall production expenses.

4. Higher Product Quality – Integrated quality control and traceability ensure consistent, reliable, and compliant products.

5. Access to Professional Expertise – DFM reviews, engineering support, and rapid troubleshooting improve yields and prevent design errors.

6. Flexibility for Prototypes and Mass Production – Turnkey services allow seamless scaling and rapid design iteration without supplier transitions.

7. Reduced Risk and Greater Accountability – Single-point accountability and centralized BOM management reduce errors, delays, and production risks.

By leveraging a full turnkey PCB assembly provider, companies can streamline production, maintain high quality, reduce costs, and accelerate product development. Whether you are producing prototypes or scaling to mass production, turnkey solutions help minimize risk and optimize efficiency.

Talk to a turnkey PCB assembly provider, such as PCBMASTER, a professional PCB supplier that excels at turnkey PCB assembly, to see how much time, cost, and effort you could save on your next project.

FAQs

1. What does “full turnkey PCB assembly” include compared to partial turnkey?

Full turnkey PCB assembly covers all steps of production, including PCB fabrication, component sourcing, assembly, testing, and final delivery. Partial turnkey assembly may only include assembly and testing, requiring the customer to source PCBs or components separately.

Example: A company using partial turnkey must order components and PCBs from different vendors, increasing coordination complexity and risk of delays. Full turnkey consolidates everything with one provider.

2. How does full turnkey assembly reduce lead time?

Turnkey providers enable parallel workflows, meaning PCB fabrication, component procurement, and assembly preparation happen simultaneously rather than sequentially. This reduces the overall production timeline.

Example: A project that takes 8 weeks using separate vendors can be completed in 5 weeks with full turnkey assembly because components are ready when PCBs arrive, and assembly starts immediately.

3. Is full turnkey assembly suitable for low-volume prototype runs?

Yes. Turnkey providers are flexible, supporting small prototype runs as well as large-scale production. They maintain the same quality standards and processes regardless of volume.

Example: A startup producing 50 prototype units can later scale to 10,000+ units without changing suppliers, ensuring continuity and consistent quality.

4. How do turnkey providers ensure quality standards are met?

Turnkey providers implement integrated quality control and follow standards such as IPC-A-610. They perform in-process inspections, functional testing, and final audits, maintaining traceability for all components and boards.

Step-by-step:

1. Inspect incoming components and PCBs

2. Monitor assembly process

3. Perform functional and reliability testing

4. Validate final product before delivery

5. What are common mistakes companies make when not using turnkey assembly?

Companies managing separate vendors often face:

l Communication gaps leading to delayed deliveries

l Component mismatches due to multiple BOMs

l Inconsistent quality from different assembly houses

l Increased administrative costs from managing multiple suppliers

Example: A project delayed two weeks because a single wrong resistor was used, which would have been avoided under a full turnkey provider with centralized BOM management.