Printed Circuit Board Drill Bits: Types, Uses, and Buying Guide

Every hole on a printed circuit board affects its performance, and using the right drill bit ensures accuracy and reliability. With a wide range of materials, sizes, and tip shapes available, each board and design presents unique drilling requirements. From delicate microvias to complex multi-layer layouts, mastering these differences is crucial for achieving professional results.

Introduction to Printed Circuit Board Drill Bits

What Are PCB Drill Bits?

Printed circuit board (PCB) drill bits are specialized cutting tools designed to create precise holes in PCB materials. These holes serve as pathways for electrical connections, allowing components to be mounted and signals to travel between layers. Unlike standard drill bits used for wood or metal, PCB drill bits are engineered for high accuracy and minimal damage to delicate substrates.

Most PCB drill bits are made from tungsten carbide or cobalt steel, materials chosen for their hardness, wear resistance, and ability to maintain sharp cutting edges at high speeds. For example, tungsten carbide drill bits are commonly used for microvias in high-density interconnect (HDI) boards, because they can handle extremely small diameters without breaking. In contrast, cobalt steel bits are often applied to less dense boards where flexibility and lower cost are priorities.

PCB drill bits also vary in tip design, coating, and size to match different board thicknesses and materials. Using the right combination ensures clean, precise holes with minimal burrs or delamination.

Importance of Choosing the Right Drill Bit

Selecting the correct drill bit is critical for PCB quality and performance. Using an inappropriate bit can cause a variety of problems, such as:

Broken holes: A brittle drill bit may snap during high-speed drilling, ruining the PCB.

Burrs or rough edges: Poorly suited bits can leave rough holes that interfere with component placement or soldering.

Delamination: Excessive pressure or incorrect tip design may separate layers in multi-layer boards.

For example, drilling a 0.2mm microvia with a standard metal drill instead of a tungsten carbide micro drill can lead to broken holes or oversized vias, which compromise electrical connectivity. By choosing a bit matched to the PCB material, hole size, and drilling speed, manufacturers can ensure precision and reliability, reduce waste, and extend the life of both the drill bit and the PCB.

Understanding the types, materials, and proper applications of PCB drill bits forms the foundation for producing high-quality boards and avoiding common manufacturing issues.

Types of Printed Circuit Board Drill Bits

By Material

Tungsten carbide drill bits are extremely hard and wear-resistant, making them ideal for high-precision PCB drilling. They can maintain sharp edges even at very small diameters, which is essential for microvias in high-density boards. However, tungsten carbide is brittle and can break if used improperly or with excessive force.

High-speed steel (HSS) drill bits are less brittle and more flexible than tungsten carbide, which makes them suitable for less dense or single-layer boards. They are generally more affordable but wear out faster, requiring more frequent replacement during high-volume production.

Diamond-coated drill bits are used for specialized applications involving very hard substrates or ultra-precise drilling. The diamond layer improves cutting efficiency and prolongs drill life, particularly in ceramics or advanced PCB materials. They are typically more expensive and are reserved for critical applications.

By Tip Shape

The standard point tip usually has an angle between 118° and 130° and is suitable for general PCB drilling tasks. In contrast, a split point tip is designed to reduce walking at the start of drilling and improve accuracy on hard or delicate substrates.

Special shapes include step drills, which can create multiple hole sizes in one pass; micro drills, which are used for microvias and HDI boards; and countersinks, which create beveled edges for flush component mounting. Each shape is optimized for specific PCB requirements and helps minimize defects like burrs or delamination.

By Coating

Titanium nitride (TiN) coatings and other advanced coatings enhance wear resistance and reduce friction during drilling. Coated drill bits generally last longer and perform better on hard substrates.

When to choose coated vs. uncoated bits: Coated bits are recommended for high-volume production, hard materials, or frequent drilling of small holes. Uncoated bits may suffice for prototyping or softer materials where cost efficiency is a priority.

By Size

PCB drill bits come in a wide range of sizes, typically from 0.15mm to 3mm, to accommodate different hole diameters. Smaller, miniaturized drills are essential for HDI boards and microvias, while larger bits are used for through-holes and mounting holes.

Step-by-step guidance for matching drill size to PCB holes:

1. Determine the required hole diameter based on the component lead or via design.

2. Check the PCB layer count and material type to ensure compatibility with the drill bit.

3. Select a drill bit material and coating that balances precision, durability, and cost.

4. Adjust drilling speed and feed rate according to the bit size and PCB substrate.

Using the right size drill bit for each application ensures accurate holes, clean edges, and long tool life, which ultimately improves PCB reliability and performance.

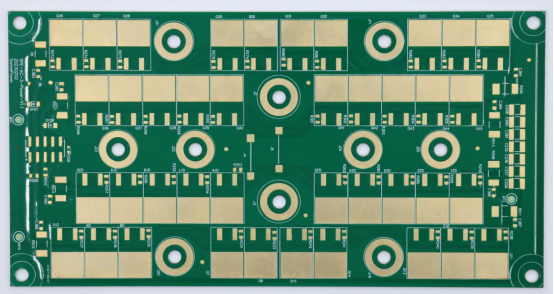

Applications and Uses

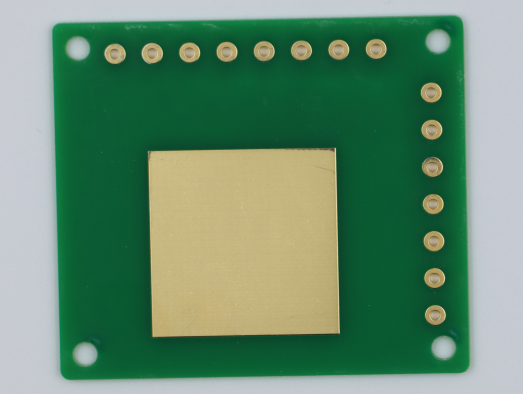

Through-Hole vs. Blind/Buried Vias

Through-hole vias are drilled all the way through the PCB, connecting every layer from top to bottom. Blind vias connect an outer layer to one or more inner layers, while buried vias exist entirely within inner layers. The choice of drill bit significantly affects the quality of these holes. For example, micro drills or tungsten carbide bits are often required for blind or buried vias because the holes are smaller and more delicate. Using an incorrect bit can cause misalignment, broken holes, or delamination, especially in high-density boards.

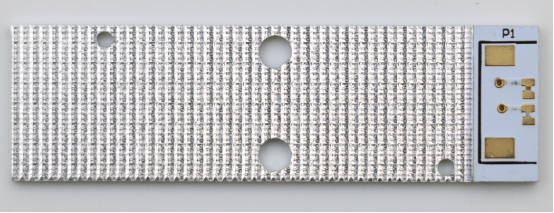

Prototyping vs. Mass Production

For rapid prototyping, flexibility and cost efficiency are important. High-speed steel (HSS) or affordable coated bits are often preferred because they can handle varied board types and smaller production runs without excessive cost.

In high-volume manufacturing, durability and precision are critical. Tungsten carbide or diamond-coated bits are commonly used because they maintain sharp edges longer and reduce the risk of breakage. Other considerations include consistent drill speed, feed rate, and tool life monitoring to prevent defects across thousands of boards.

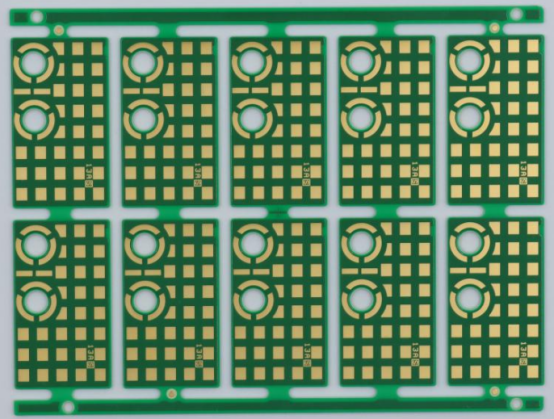

Specialized PCB Materials

Different PCB substrates require specific drill bit types:

FR-4: Standard glass-reinforced epoxy; compatible with HSS, tungsten carbide, or coated bits for general-purpose drilling.

Rogers material: High-frequency laminate; use tungsten carbide or coated bits to maintain clean holes and avoid delamination.

Flexible PCBs: Polyimide or thin substrates; small-diameter tungsten carbide micro drills prevent tearing and maintain flexibility.

Ceramic PCBs: Hard, brittle materials; diamond-coated bits are preferred to achieve precise holes without cracking.

Selecting the right drill bit for each material ensures clean cuts, minimal burrs, and reliable electrical connections.

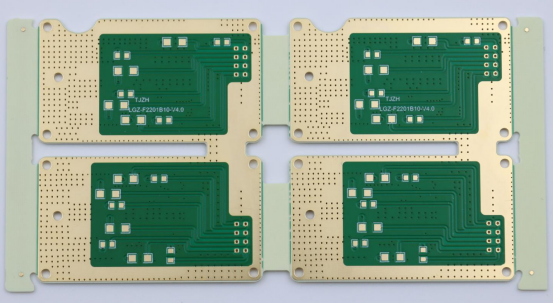

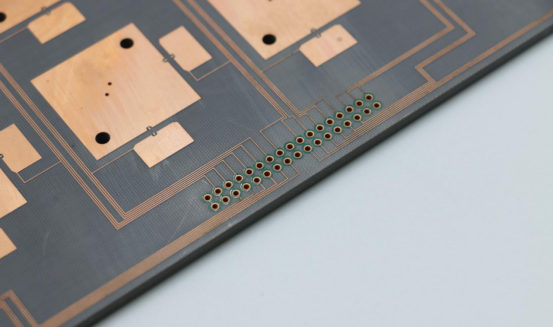

Multi-Layer PCB Drilling

Drilling multi-layer PCBs presents unique challenges due to the complexity and number of layers. Common issues include misalignment, delamination, and excessive heat generation.

Strategies for precision drilling in multi-layer boards:

1. Use high-precision tungsten carbide or coated micro drills designed for small diameters.

2. Optimize spindle speed and feed rate to reduce thermal stress on the board.

3. Employ step drilling or peck drilling techniques to gradually remove material and prevent delamination.

4. Regularly inspect drill bits for wear to maintain consistent hole quality across all layers.

Following these strategies helps maintain structural integrity, electrical performance, and overall reliability in complex PCB designs.

How to Choose the Right PCB Drill Bit

Factors to Consider

Selecting the right PCB drill bit starts with understanding the material hardness and substrate type. Hard materials like ceramic or Rogers laminates require durable bits such as tungsten carbide or diamond-coated tools, while standard FR-4 boards can be drilled with HSS or coated carbide bits.

Hole size and tolerance requirements are equally important. Microvias and fine-pitch holes demand micro drills with precise diameters, while larger through-holes can use standard bits. Choosing a drill bit too large or small for the intended hole can cause misalignment, oversized vias, or structural defects.

Drill machine compatibility and RPM limits must also be considered. Each drill bit material and size has an optimal rotational speed and feed rate. For example, micro tungsten carbide drills require higher RPMs but low feed pressure to prevent breakage. Using an incompatible machine or speed can shorten bit life and damage the PCB.

Drill Life and Maintenance

Knowing when a drill bit needs replacement is essential for consistent PCB quality. Signs include worn or rounded edges, rough hole walls, excessive burrs, or frequent breakage.

Cleaning, sharpening, and proper storage extend bit life. After drilling, remove resin or debris buildup, store bits in protective cases to avoid chipping, and consider professional sharpening for premium carbide bits. Routine maintenance ensures accurate, clean holes and reduces production downtime.

Cost vs. Performance Trade-offs

PCB drill bits vary widely in price. Low-cost bits are suitable for prototyping or small runs where occasional replacement is acceptable. They are less durable and may wear out faster, but they reduce upfront expenses.

Premium drill bits, such as coated tungsten carbide or diamond-coated bits, offer superior durability, precision, and consistent hole quality. Investing in high-quality bits is worthwhile in high-volume production or when drilling complex PCBs with tight tolerances. The trade-off balances initial cost against reduced downtime, fewer defects, and longer tool life.

For example, using a diamond-coated micro drill on a multi-layer HDI board reduces breakage and ensures clean microvias, whereas a cheaper uncoated bit may fail quickly, causing wasted boards and production delays.

Best Practices and Tips

Drilling Techniques

A clean and precise hole starts with the correct drilling process. Follow these steps for reliable results:

1. Secure the PCB on the drill table or fixture to prevent movement.

2. Select the appropriate drill bit for the substrate, hole size, and layer count.

3. Align the bit with the target location to prevent misalignment or walking.

4. Start drilling at low speed to reduce initial stress on the material.

5. Gradually increase feed rate while monitoring bit penetration for smooth hole formation.

Feed rate and speed adjustments depend on material hardness and hole size. For example, microvias in FR-4 require high RPM but low feed pressure, while larger holes in rigid ceramic PCBs need slower speeds with steady feed to prevent cracking. Adjusting speed and feed ensures minimal burrs, accurate holes, and prolonged drill bit life.

Avoiding Common Issues

Common drilling problems include burr formation, cracks, and bit breakage. To minimize these:

Use sharp, properly coated drill bits suitable for the substrate.

Apply gradual, controlled feed pressure rather than forcing the bit through the PCB.

Peck drilling or step drilling can reduce heat buildup and stress in multi-layer boards.

Preventing thermal damage is critical, especially for high-density or multi-layer boards. Excessive heat can delaminate layers or warp the board. Using the right speed, intermittent drilling, and proper lubrication (if applicable) protects PCB integrity and ensures consistent electrical performance.

Safety Guidelines

PCB drilling involves small, sharp tools and high-speed rotation, so safety is essential.

Personal protective equipment (PPE): Wear safety glasses, gloves, and dust masks to prevent injury from flying debris or fine dust.

Proper handling of drill bits: Store bits in protective cases, handle with care to avoid chipping, and never touch the cutting edge directly.

Work environment: Ensure the drill station is stable and free from clutter to prevent accidents.

Following these safety practices reduces risk of injury and protects both the operator and the PCB from damage.

Buying Guide for PCB Drill Bits

Where to Buy

PCB drill bits can be purchased from online suppliers or local distributors. Online stores offer a wider selection of materials, sizes, and specialty bits, often with user reviews to guide selection. Local suppliers allow hands-on inspection and immediate availability, which can be useful for urgent prototyping needs.

When choosing a supplier, consider trusted brands and manufacturers known for quality and consistency. Established names typically provide specifications, material certifications, and customer support, ensuring reliability for professional PCB fabrication.

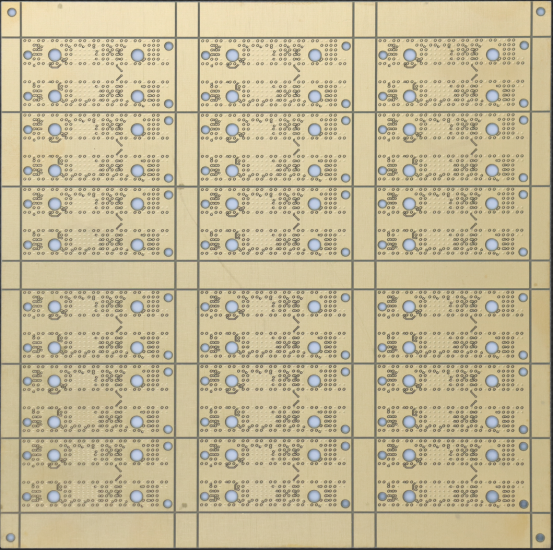

Packaging and Bulk Buying

Drill bits are available as kits or individual pieces. Kits usually include a range of sizes and types, which is convenient for prototyping or small-scale work. Individual bits allow precise selection for specific hole sizes or specialized applications.

Advantages of bulk purchases become clear in production environments. Buying in bulk reduces cost per bit, ensures consistent quality, and minimizes downtime caused by frequent reordering. For example, a manufacturer producing thousands of multi-layer PCBs may invest in bulk tungsten carbide bits to maintain efficiency and reduce tool replacement frequency.

Evaluating Quality

Before purchasing, it is important to inspect drill bits visually. Look for smooth, uniform cutting edges, consistent diameter, and absence of chips or cracks.

Check specifications and certifications such as material grade, coating type, and recommended RPM. High-quality drill bits often come with documentation that confirms their suitability for microvias, HDI boards, or multi-layer PCB applications. Using verified bits reduces defects and ensures reliable, repeatable performance.

Cost Considerations

PCB drill bit prices vary based on material, size, and coating. Low-cost bits are suitable for prototyping or small batches but wear out faster. Premium bits like coated tungsten carbide or diamond-coated bits cost more upfront but provide long-term durability and consistent hole quality.

Balancing budget with performance needs is essential. For example, a hobbyist creating a small batch of FR-4 boards may prioritize affordability, while a manufacturer producing HDI boards will benefit from investing in high-quality bits to minimize defects and production downtime.

Conclusion

Selecting the right PCB drill bit is crucial for achieving precise, reliable, and high-quality circuit boards. Understanding the different types of drill bits—based on material, tip shape, coating, and size—helps ensure the best fit for each application, from simple prototyping to complex multi-layer HDI boards. Applying proper drilling techniques, maintaining drill life, and following safety practices further enhances performance and reduces defects. For hobbyists, choosing affordable bits with careful handling can yield excellent results, while prototypers and manufacturers benefit from investing in premium, durable bits to maintain consistency and efficiency in production. If you have questions or want to learn more about PCB solutions, PCBMASTER, as an experienced PCB supplier, is ready to provide expert guidance and support tailored to your needs

FAQs

How can I extend the life of my PCB drill bits?

To extend drill bit life, use the correct bit for the substrate and hole size, maintain proper feed rate and spindle speed, and avoid excessive pressure. Regularly clean debris and resin from the bit, store them in protective cases, and sharpen high-quality carbide bits when needed. Using coated bits for harder materials can also reduce wear and prolong usage.

What is the difference between micro drills and standard PCB drills?

Micro drills are extremely small, typically below 0.3 mm, designed for microvias and high-density interconnect (HDI) boards. They require higher RPM and careful handling to avoid breakage. Standard PCB drills are larger, used for through-holes or general component mounting, and are more robust and easier to handle. The main differences are size, precision, and application.

Can I use a standard drill bit for flexible PCBs?

Standard drill bits are generally not recommended for flexible PCBs. Flexible substrates are thin and prone to tearing, so small-diameter tungsten carbide micro drills or specialized flexible PCB bits are preferred. They provide clean holes without damaging the material.

How do I prevent drill bit breakage when drilling multi-layer boards?

To prevent breakage, use high-precision carbide or coated bits suited for small diameters, optimize spindle speed and feed rate, and consider step or peck drilling to gradually remove material. Regularly inspect bits for wear and avoid applying excessive pressure. This helps maintain clean holes across all layers and reduces the risk of delamination or bit snapping.

Are coated drill bits always better than uncoated ones?

Not always. Coated drill bits, like titanium nitride (TiN) or diamond coatings, offer greater wear resistance and longer life, especially in hard substrates or high-volume production. However, for prototyping, softer materials, or low-volume work, uncoated bits may be sufficient and more cost-effective. The choice depends on material, hole size, production volume, and budget.