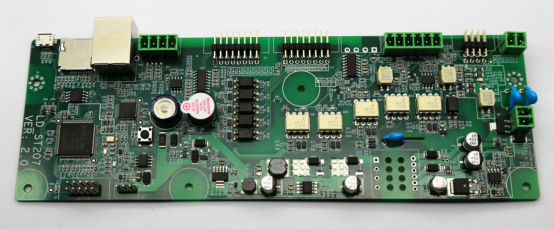

Power Supply PCB: Types & Design Optimization for High Efficiency

Behind every device that powers our world, from the simplest gadgets to the most complex machines, is a silent, yet vital, player: the power supply PCB. Its role isn’t just to deliver energy—it ensures that each component, from microchips to motors, receives exactly what it needs to perform reliably and safely. With increasing demands for efficiency and miniaturization, the design of power supply PCBs has become more crucial than ever.

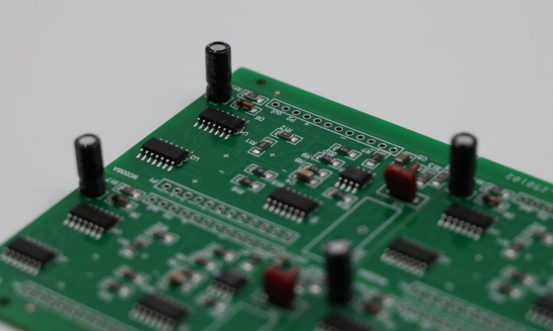

Understanding Power Supply PCBs

A Power Supply PCB (Printed Circuit Board) is a specialized type of circuit board that is responsible for managing electrical power in electronic devices. It doesn’t just distribute power— it actively converts, regulates, and protects the power that reaches the different parts of an electronic device. Essentially, a Power Supply PCB ensures that every component in a device (like microchips, sensors, or motors) gets the exact voltage and current it needs to function properly.

For example, in a smartphone, the power supply PCB is the part that converts the power from the battery and regulates it to ensure each part of the phone gets the right voltage.

Functions of Power Supply PCB

Power Conversion

One of the key functions of a Power Supply PCB is power conversion. In most devices, the incoming power from the wall outlet (AC power) needs to be converted into DC power, which is what most electronic circuits require. This is typically achieved using rectifiers, which change AC into DC. Sometimes, the power also needs to be adjusted, for instance, lowering or boosting the voltage. This adjustment ensures that every component receives the right amount of power.

For example, a 12V DC input might be converted to a 5V DC output to power a microchip. This process is done by the power supply module on the PCB.

Voltage Regulation and Stabilization

Another critical function of the power supply PCB is voltage regulation. Voltage regulation ensures that the electrical voltage remains steady, even when there are fluctuations in the power source. If the voltage fluctuates too much, it can damage sensitive components like microchips or sensors.

For example, in a medical device like a heart rate monitor, maintaining stable power is crucial. A voltage regulator on the PCB ensures that even if there are changes in the power supply, the device’s components receive a steady voltage, preventing potential malfunctions.

Protection Mechanisms

Power supply PCBs also integrate several safety mechanisms to protect the device from overvoltage, overcurrent, and short circuits. These protections are built into the circuit to automatically cut off or limit power if unsafe conditions are detected.

For instance, if a surge in voltage occurs, the PCB will cut off the power to prevent damage to sensitive electronics. Similarly, if the device tries to draw too much current, the PCB will limit the flow to avoid overheating or fire hazards.

Core Components of a Power Supply PCB

Power Supply Modules

Power supply modules are the heart of the PCB. They convert and regulate the power according to the device’s needs. Each module is designed with specifications such as output voltage, current rating, and efficiency. For instance, a module for a smartphone might output 5V and 2A, with an efficiency of over 90%, meaning very little power is wasted as heat.

These modules come in different types, such as buck (step-down) or boost (step-up) converters, depending on whether the voltage needs to be lowered or raised.

Transformers & Rectifiers

A transformer is used to either step up or step down the AC voltage coming from the wall outlet. For example, if a device needs 5V, but the input is 110V AC, a transformer will reduce the voltage accordingly. Once the voltage is adjusted, rectifiers convert the AC voltage to DC so that it can be used by the electronic components. Without rectifiers, many devices would not function properly.

Capacitors and Inductors

Capacitors help to filter out noise and smooth the DC voltage, ensuring a steady power supply. Inductors, on the other hand, help control the flow of current and store energy. Together, they play a critical role in reducing electrical noise (unwanted signals) and stabilizing the power supply.

In an audio amplifier, for example, capacitors are crucial to ensure that there is minimal noise in the power supply, which could affect the sound quality.

Thermal Management Solutions

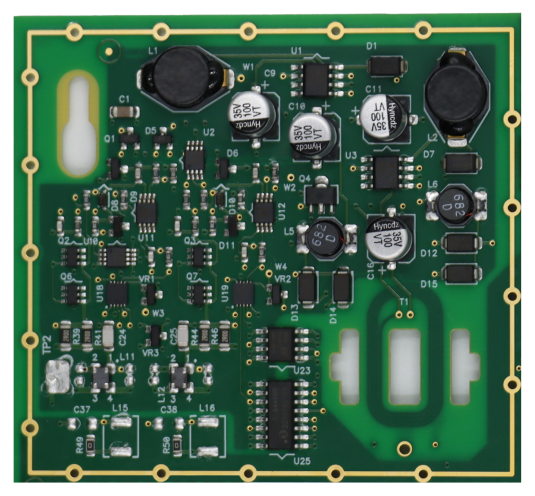

Thermal management is an essential part of designing Power Supply PCBs. As power supply modules convert and regulate power, they generate heat. If this heat isn’t properly managed, it can cause the PCB to fail or components to burn out.

To manage heat, designers use thermal vias (small pathways for heat to travel through the PCB) and copper pours (large areas of copper that help dissipate heat). In high-power devices like electric cars or servers, thermal management is crucial to ensure the power supply operates safely without overheating.

EMI Suppression Components

Electromagnetic Interference (EMI) can cause devices to malfunction. Power supply PCBs often include components such as ferrite beads and common-mode chokes to suppress EMI. These components help reduce the noise that may interfere with nearby sensitive electronics, ensuring that devices work properly without causing interference with other devices.

For example, in medical devices like MRI machines, even the smallest interference can disrupt measurements, so EMI suppression components are crucial to ensure clear and accurate results.

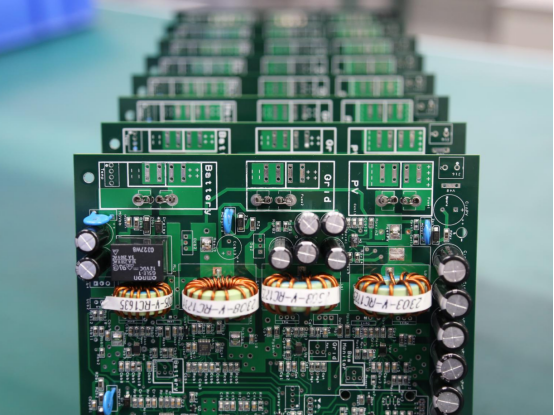

Types of Power Supply PCBs

Power supply PCBs can be classified in different ways based on their structure and layer count. Choosing the right type is crucial for ensuring efficiency, reliability, and safety in electronic devices. Below, we break down the two primary categories of power supply PCBs: structure-based and layer count-based types.

Power Supply PCB Types Based on Structure

Rigid PCBs

Key Traits: Rigid PCBs are made from strong, mechanical materials, usually FR-4 (a common material for printed circuit boards). These boards are stiff, durable, and easy to manufacture. They have good mechanical strength, making them ideal for applications that require physical stability.

Best Applications: Rigid PCBs are widely used in servers, industrial machinery, and desktop PCs where stability and durability are important. They are commonly found in large systems that require a reliable power supply to run continuously and handle higher power demands without failure. For example, a server in a data center would use rigid PCBs for its power supply due to the need for high strength and reliable performance.

Flexible PCBs

Key Traits: Flexible PCBs are thin, bendable, and lightweight. Made from polyimide or similar materials, these boards can be folded or bent without losing functionality. Flexible PCBs are compact and often used in devices where space and weight are crucial.

Best Applications: These PCBs are perfect for wearables, such as smartwatches and fitness trackers, where flexibility and compactness are needed. They are also used in foldable devices (like smartphones) and medical tools (such as endoscopes), which require small, lightweight, and flexible power solutions. For instance, a smartwatch uses flexible PCBs to manage the power supply while maintaining a compact design.

Rigid-Flex PCBs

Key Traits: A rigid-flex PCB combines the benefits of both rigid and flexible PCBs. They have sections that are rigid and sections that are flexible, offering a hybrid solution for applications that need both strength and flexibility in specific areas.

Best Applications: Aerospace, automotive, and portable medical devices are ideal applications for rigid-flex PCBs. These types of PCBs are used in satellite components or automotive dashboard sensors, where reliability is key, but some parts of the board need to be flexible to fit in tight spaces or be folded for installation. A portable medical tool, like a handheld ultrasound device, might use rigid-flex PCBs for both stability and flexibility.

Comparison Table

| PCB Type | Key Traits | Best Applications |

| Rigid PCBs | Made from strong, mechanical materials (e.g., FR-4), providing durability and stability. | Servers, industrial machinery, desktop PCs (where stability is important). |

| Flexible PCBs | Thin, bendable, lightweight, made from flexible materials like polyimide. | Wearables (smartwatches), foldable devices (smartphones), portable medical tools. |

| Rigid-Flex PCBs | Combines both rigid and flexible layers for hybrid applications, offering strength and flexibility. | Aerospace (satellite components), automotive (dashboard sensors), medical tools. |

Power Supply PCB Types Based on Layer Count

Single-Sided PCBs

Characteristics: Single-sided PCBs have copper traces on only one side of the board, making them the simplest and most cost-effective type. The design is straightforward, with fewer components and a basic structure. Single-sided PCBs are ideal for low-power applications where cost is a major concern.

Best Use: These PCBs are commonly used in basic power supplies like small chargers, remote controls, or any low-power electronics where a simple design is sufficient. For example, a calculator charger might use a single-sided PCB because it doesn't require complex routing or multiple power paths.

Double-Sided PCBs

Characteristics: Double-sided PCBs have copper traces on both sides of the board, allowing for more components and better routing of the electrical paths. This enables a higher component density, allowing for more complex circuits in a compact space. Double-sided PCBs also allow more efficient use of space in devices.

Best Use: These boards are used in consumer electronics like smart TVs, automotive sensors, and mid-power supplies. For instance, a smart TV power supply would use a double-sided PCB to handle more complex routing and higher power, ensuring the TV runs efficiently.

Multi-Layer PCBs

Characteristics: Multi-layer PCBs contain four or more layers, with each layer serving a specific purpose. These layers typically include power planes, ground planes, and signal layers. This high-density design helps reduce impedance, allows more components to be placed, and enables better heat dissipation.

Best Use: High-power applications such as data centers, electric vehicles, and medical devices like MRI machines require multi-layer PCBs. These PCBs can manage the power demands of high-performance electronics. For example, electric cars use multi-layer PCBs to efficiently handle power distribution for the motor, sensors, and battery systems.

Comparison Table

| PCB Type | Characteristics | Best Use |

| Single-Sided PCBs | Copper traces on one side, simple, cost-effective, and basic design. | Basic, low-power applications like small chargers (e.g., calculator chargers). |

| Double-Sided PCBs | Copper traces on both sides, allowing more components and better routing. | Consumer electronics (e.g., smart TVs), automotive sensors, mid-power supplies. |

| Multi-Layer PCBs | 4 or more layers, including power/ground planes and signal layers, used for high-density designs. | High-power devices like data centers, electric vehicles, medical devices (e.g., MRI). |

Key Considerations When Designing Power Supply PCBs

Designing a reliable and efficient power supply PCB involves many factors, including selecting the right materials, managing heat dissipation, controlling electromagnetic interference (EMI), and choosing high-quality components. Let’s explore the key considerations that will help you create effective power supply PCBs.

Choosing the Right PCB Material

Substrate Material Choices: Comparison of FR4, Polyimide, and Other Materials

The substrate material is the foundation of any PCB, as it provides both mechanical support and thermal management. The material choice depends on the device's performance needs, operating conditions, and cost.

FR4: FR4 is the most common substrate material used for PCBs. It is made of fiberglass and epoxy resin, offering good mechanical strength and insulation properties. It is inexpensive, durable, and works well for most standard applications, including low to moderate-power designs.

Polyimide: This material is used in flexible PCBs. Polyimide is more expensive than FR4 but offers greater flexibility and heat resistance, making it ideal for applications where the PCB needs to bend or where high temperatures are involved. Wearables and medical devices often use polyimide substrates due to their flexibility and lightweight nature.

Other Materials: For high-power applications, such as in electric vehicles or data centers, you may find ceramic or metal-core substrates. These materials offer superior heat dissipation and better performance under high-temperature conditions. Metal-core PCBs, for instance, are commonly used in LED lighting where heat dissipation is critical.

Designing for Efficiency and Thermal Management

Trace Width and IPC-2152 Standards: The Importance of Selecting Appropriate Trace Widths for Power Handling

The trace width on a PCB is directly related to the amount of current it can carry. If the trace width is too narrow, it can cause excessive heat buildup and potentially damage the PCB. To avoid this, it’s crucial to choose the right trace width based on the amount of current that needs to be handled.

IPC-2152 Standards: These standards provide guidelines for calculating the trace width for specific current ratings. Following these standards ensures that the traces on the PCB will not overheat, and the power supply will run efficiently.

For example, a PCB designed to handle 5A of current would need a wider trace compared to one designed for 1A. By using the IPC-2152 standards, you can ensure the PCB is designed with the correct trace width, reducing the risk of heat-related failures.

Thermal Via and Heat Sink Design: Steps to Ensure Effective Heat Dissipation

Heat dissipation is a critical aspect of power supply PCB design. As power supply modules convert and regulate energy, they generate heat. If this heat isn’t properly managed, it can lead to component failure or decreased performance.

Thermal Vias: These are small holes in the PCB that allow heat to travel from the top layer to the bottom layer of the board. By placing thermal vias in high-power areas, heat can be directed away from sensitive components.

Heat Sinks: A heat sink is an external device that helps draw heat away from the power supply PCB. These are often attached to power transistors or MOSFETs, which are components that generate a lot of heat during operation.

Together, thermal vias and heat sinks help ensure that the PCB remains cool and that power supply components work efficiently.

Electromagnetic Interference (EMI) Control

EMI Filters: Best Practices for Integrating Ferrite Beads, Capacitors, and Chokes to Reduce Noise

EMI can cause unwanted electrical noise that interferes with the performance of other electronic devices. In a power supply PCB, EMI filters are essential to reduce this noise.

Ferrite Beads: These components absorb high-frequency noise and are often used in power input lines to filter unwanted signals. They are simple, cost-effective, and widely used in consumer electronics.

Capacitors: Capacitors can filter out low-frequency noise and help smooth the power supply output. By placing them in parallel with the power lines, they reduce ripple and noise.

Chokes: A choke is an inductive component that blocks high-frequency noise. It is typically used in SMPS (Switch-Mode Power Supplies) to ensure that the power supply operates without creating interference.

Together, these EMI filtering components help improve the power supply's performance by preventing noise from disrupting other parts of the device or external equipment.

Shielding and Grounding: Techniques to Minimize EMI in Sensitive Electronic Devices

To further reduce EMI, power supply PCBs must incorporate shielding and grounding techniques.

Shielding: Shielding involves placing a conductive barrier around sensitive components to block external electromagnetic waves. This is especially important in devices like medical instruments or audio equipment, where even small amounts of EMI can interfere with their function.

Grounding: Proper grounding is essential to ensure that any unwanted electrical noise is safely directed away from the device’s critical circuits. A single ground plane is often used in high-power designs to avoid the effects of EMI.

Together, shielding and grounding ensure that sensitive electronics work correctly without external interference, making the power supply more reliable and efficient.

Component Selection for Reliability

Capacitors with Low ESR and High Ripple Current Rating

Capacitors play a critical role in filtering out noise and ensuring smooth power supply. When selecting capacitors for a power supply PCB, focus on two key specifications:

Low ESR (Equivalent Series Resistance): Capacitors with low ESR help reduce heat generation and power loss. Low ESR capacitors are crucial for high-performance circuits that handle large currents, as they minimize heat buildup.

High Ripple Current Rating: Capacitors with a high ripple current rating can handle fluctuations in the power supply without degrading over time. This is essential in power supplies for devices like servers or LED lighting, where the power input can fluctuate.

Inductors with High Saturation Current

Inductors are used to filter current and control energy flow in power supply circuits. When selecting an inductor, consider the saturation current rating. An inductor with a high saturation current rating can handle higher currents before it starts to lose its inductance, ensuring the power supply operates efficiently without failure.

For instance, in a SMPS (Switch-Mode Power Supply), a high saturation current inductor ensures that the power supply can efficiently step down or boost voltage without risking component failure.

MOSFETs with Low On-Resistance

MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) are key components in regulating the flow of current in power supply circuits. When selecting MOSFETs, focus on their on-resistance (Rds(on)):

Low On-Resistance: MOSFETs with low on-resistance offer less resistance to current flow, resulting in less power loss and lower heat generation. This improves the efficiency of the power supply and reduces the chances of overheating.

For example, in high-performance applications like data center servers, low on-resistance MOSFETs ensure that the power supply operates efficiently while maintaining thermal stability.

Types of Power Supplies Used in Power Supply PCBs

When designing power supply PCBs, one of the key decisions is selecting the appropriate power supply type. Power supplies are essential for converting electrical energy and distributing it efficiently within an electronic device. The two main types of power supplies are Linear Power Supplies (LPS) and Switch-Mode Power Supplies (SMPS). Each type has its advantages and disadvantages, depending on the application. In this section, we will explore these power supply types, their working principles, pros and cons, and best uses.

Linear Power Supplies (LPS)

Working Principle: How Linear Power Supplies Work and Their Advantages

A Linear Power Supply (LPS) operates by converting AC voltage to DC and then regulating the DC voltage. It uses a transformer to step down the AC voltage and a linear regulator to maintain a steady output voltage. The regulator adjusts the voltage by dissipating excess energy as heat. The simplicity of the design is one of the main reasons for its popularity, particularly in sensitive applications that demand low-noise power.

Key Advantage: LPS provides an extremely stable and clean output, making it ideal for applications where low noise and stable voltage are critical.

Pros and Cons: Low Noise, but Inefficient with Heat Dissipation

Pros:

Low Noise: LPS generates minimal electrical noise, which is important for audio equipment, medical devices, and laboratory tools where signal accuracy is vital.

Simple Design: The straightforward design with fewer components makes it easy to repair and maintain.

Stable Output: Provides a constant and stable output voltage, ensuring no fluctuation that could damage sensitive components.

Cons:

Inefficient: Linear power supplies are less efficient compared to switch-mode supplies, with efficiency typically ranging between 30% and 60%. The rest of the energy is dissipated as heat.

Heat Generation: Because they waste energy as heat, LPS requires large heat sinks or cooling solutions to manage the temperature. This makes them less ideal for high-power applications.

Best Use: Audio Equipment, Medical Devices, and Lab Tools

Linear power supplies are particularly suited for audio equipment like amplifiers and microphones, where noise reduction is a priority. Medical devices, such as MRI machines and ECG monitors, also rely on LPS to avoid interference and maintain precision. Laboratory equipment like oscilloscopes or signal generators, which require stable and noise-free power, also commonly uses linear power supplies.

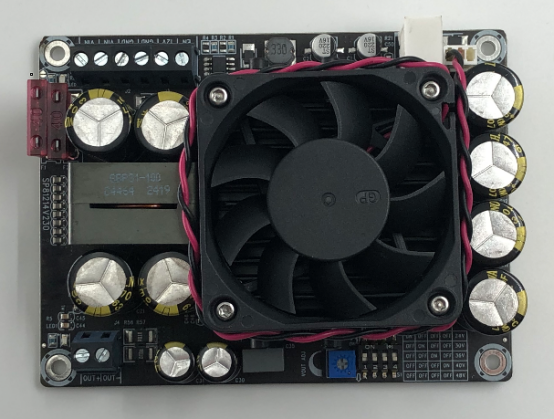

Switch-Mode Power Supplies (SMPS)

Working Principle: Efficient Voltage Conversion Using MOSFETs and Inductors

A Switch-Mode Power Supply (SMPS) works differently from an LPS. It uses MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) to rapidly switch the input voltage on and off at a high frequency. This switching process stores energy in inductors or capacitors and releases it in controlled bursts to regulate the output voltage. Because of this high-frequency switching, SMPS is much more efficient than linear supplies, often achieving efficiencies between 70% and 95%.

Key Advantage: SMPS can step up or step down voltage efficiently, providing compact, lightweight designs ideal for high-power applications.

Pros and Cons: High Efficiency but Higher Noise and Complexity

Pros:

High Efficiency: SMPS is highly efficient due to the rapid switching of voltage. As a result, less energy is lost as heat, making it ideal for applications where energy efficiency and small form factor are essential.

Compact Size: The ability to use smaller components allows SMPS to be designed into more compact, lighter units, which is crucial for portable and consumer electronics.

Multiple Output Voltages: SMPS can provide different voltage levels from a single input, making it versatile for multi-output power supplies in applications like smartphones or data centers.

Cons:

Higher Noise: The rapid switching in SMPS generates electromagnetic interference (EMI), resulting in higher noise levels. This noise can disrupt sensitive circuits unless carefully controlled with EMI filters.

Complexity: SMPS circuits are more complex than linear supplies, requiring more components like inductors, transformers, and MOSFETs. This can increase design complexity and costs.

Thermal Management: While more efficient, SMPS still generates heat, especially in high-power applications, requiring proper thermal management.

Best Use: Consumer Electronics, Data Centers, and Automotive Applications

SMPS is commonly used in consumer electronics, such as smartphones, laptops, and televisions, due to its compact size and efficiency. Data centers rely on SMPS for servers and networking equipment to ensure high power efficiency and low operating costs. In the automotive industry, SMPS is used for electric vehicles, battery chargers, and sensors, where space and power efficiency are key factors.

Comparison of Linear vs. SMPS

To help decide which power supply to use, let's compare Linear Power Supplies (LPS) and Switch-Mode Power Supplies (SMPS) based on key factors such as efficiency, size, noise, and cost.

| Aspect | Linear Power Supply (LPS) | Switch-Mode Power Supply (SMPS) |

| Efficiency | 30%–60% (inefficient, energy lost as heat) | 70%–95% (efficient, low energy loss) |

| Size/Weight | Larger, bulkier (requires heat sinks and transformers) | Smaller, lighter (compact design) |

| Noise | Very low (ideal for noise-sensitive applications) | Higher (requires EMI filters to reduce interference) |

| Cost | Lower cost for low-power designs | Higher upfront cost but cheaper in high-power applications |

| Heat Dissipation | Requires large heat sinks due to low efficiency | Requires careful thermal management but less heat overall |

| Best Applications | Audio equipment, medical devices, lab tools | Consumer electronics, data centers, automotive applications |

Key Takeaways:

Choose LPS if low noise and stable voltage are critical for your application, such as in audio equipment or medical devices.

Opt for SMPS if you need high efficiency, small size, and multiple output voltages for applications like smartphones, laptops, or electric vehicles.

Advanced Power Supply PCB Design Techniques

In designing power supply PCBs, advanced techniques play a crucial role in optimizing performance, minimizing size, ensuring safety, and managing heat. This section delves into the best practices for designing power supply PCBs for both high-power applications and small devices, as well as the critical safety considerations that must be addressed in any design.

Designing for High Power Applications

High Power PCBs: Understanding the Need for Multi-Layer PCBs in High-Power Devices

When dealing with high-power devices like electric vehicles (EVs) or MRI machines, the power supply requires careful management of heat, voltage stability, and current distribution. As power demands increase, the complexity of the PCB design also grows.

Multi-layer PCBs are essential for high-power devices because they provide dedicated power and ground planes, which help reduce noise and ensure stable power distribution. The layers also allow the PCB to handle larger currents without overheating.

In high-power applications, power needs to be carefully regulated, and multi-layer designs help manage impedance and electromagnetic interference (EMI), making the system more efficient and reliable. Devices like electric vehicles and MRI machines need multi-layer PCBs to ensure that power is distributed efficiently across all components without causing damage or signal disruption.

Reducing Impedance and Heat: Techniques to Reduce Impedance and Manage Thermal Dissipation for Power Supplies Over 50W

For power supplies exceeding 50W, two critical factors must be considered: impedance and heat dissipation.

Reducing Impedance: Impedance affects how power flows through the PCB. High impedance can cause signal distortion, loss of power, and inefficiency. To reduce impedance:

Thicker traces should be used to ensure low resistance.

Optimal trace width is necessary to handle higher current without excessive voltage drop.

Via structures should be designed carefully to minimize resistance at through-holes and vias.

Thermal Dissipation: As power increases, more heat is generated. Effective heat management is critical to prevent overheating and component failure.

Thermal vias and copper pours are commonly used to conduct heat away from sensitive areas.

Heat sinks or metal-core PCBs (MCPCBs) are used to dissipate heat effectively, especially in high-power devices.

Active cooling solutions, such as fans or liquid cooling in extreme cases, are often required in power supplies over 100W.

By reducing impedance and managing heat efficiently, power supply PCBs ensure that high-power devices operate safely, reliably, and efficiently.

Optimizing Power Supply PCBs for Small Devices

Miniaturization Strategies: How Compact Power Supply Designs Fit into Modern Wearables and Smartphones Without Compromising Efficiency or Safety

As technology advances, the demand for compact, efficient power supplies in devices like smartphones and wearables continues to grow. These devices need high power efficiency in a small, lightweight package.

Miniaturization is achieved by using smaller components and high-density designs. This includes integrating SMPS (Switch-Mode Power Supply) technology, which allows for smaller, more efficient power conversion.

Power supply designers use multi-layer PCBs even in small devices to separate power and signal planes. This keeps the circuit more organized, reduces noise, and ensures stable power delivery to all components.

Component choices also play a key role in miniaturization. Designers opt for low-profile capacitors, integrated inductors, and compact MOSFETs to reduce space while maintaining performance.

For example, in a smartwatch, the power supply PCB needs to handle varying power levels, be as small as possible, and still provide the required voltage stability. Designers use flexible PCBs in these applications, allowing the power supply to bend and fit the compact form factor.

Safety Considerations in Power Supply PCB Design

Overvoltage, Overcurrent, and Thermal Protection: Essential Safety Features to Protect Sensitive Electronics from Power Fluctuations

When designing power supply PCBs, safety features are critical to ensure that the device is protected from overvoltage, overcurrent, and thermal overload. These protections help safeguard sensitive electronics and prevent failures that could damage the device or cause safety hazards.

Overvoltage Protection: This protects the circuit when the input voltage exceeds the maximum voltage rating of the components. Zener diodes or crowbar circuits are commonly used to clamp the voltage and protect against surges.

Overcurrent Protection: Fuses or current-limiting resistors can be incorporated into the design to ensure that the circuit doesn’t exceed its current rating. If the current exceeds safe levels, the fuse blows, preventing damage to the PCB.

Thermal Protection: Excess heat is a common issue in power supplies, especially in high-power designs. Thermal shutdown circuits are designed to turn off the power supply if temperatures exceed a safe threshold, preventing components from overheating and sustaining damage.

For example, in a medical device like an ECG monitor, overvoltage and overcurrent protection circuits ensure that the device continues to operate safely, even during power surges or faults.

Conclusion

Choosing the right power supply PCB is key to ensuring efficiency, reliability, and safety in electronic devices. The structure and layer count of the PCB should match the application needs—high-power devices require multi-layer designs for better heat management, while small devices benefit from compact, efficient power supplies.

Proper selection of materials, components, and safety features like overvoltage and thermal protection is crucial. These decisions help create power supply PCBs that perform optimally and protect sensitive electronics. For quality and reliability, PCBMASTER offers top-notch power supply PCBs, designed to meet the demands of diverse applications.

FAQs

What is the main difference between rigid and flexible power supply PCBs?

Rigid PCBs are more robust, offering greater mechanical strength and lower cost, making them ideal for standard applications. Flexible PCBs, on the other hand, are designed to be lightweight and bendable, making them perfect for wearables or devices where flexibility is essential.

Why are multi-layer PCBs preferred for high-power applications?

Multi-layer PCBs are preferred for high-power applications because they help reduce impedance, enhance heat dissipation, and ensure voltage stability. The multiple layers allow better management of power distribution, which is critical for high-demand electronics like electric vehicles and MRI machines.

How can thermal management be optimized in power supply PCBs?

Thermal management can be optimized by using thermal vias, copper pours, and appropriate heat sinks. These methods help dissipate heat efficiently, preventing overheating and ensuring that high-power designs remain stable and functional.

What are the benefits of using switch-mode power supplies (SMPS) in modern electronics?

SMPS are highly efficient, compact, and can handle multiple voltage outputs. These features make them ideal for consumer electronics, data centers, and automotive applications, where space, efficiency, and versatility are key considerations.

What should I look for in a power supply component to ensure longevity and reliability?

For longevity and reliability, choose high-quality components like capacitors with low ESR, inductors with high saturation current, and MOSFETs with low on-resistance. These components help ensure the power supply can handle high loads without failure and extend the overall lifespan of the device.

Author Bio

Hi, I'm Carol, the Overseas Marketing Manager at PCBMASTER, where I focus on expanding international markets and researching PCB and PCBA solutions. Since 2020, I've been deeply involved in helping our company collaborate with global clients, addressing their technical and production needs in the PCB and PCBA sectors. Over these years, I've gained extensive experience and developed a deeper understanding of industry trends, challenges, and technological innovations.

Outside of work, I'm passionate about writing and enjoy sharing industry insights, market developments, and practical tips through my blog. I hope my posts can help you better understand the PCB and PCBA industries and maybe even offer some valuable takeaways. Of course, if you have any thoughts or questions, feel free to leave a comment below—I'd love to hear from you and discuss further!