Top Advantages of Polyimide Material in Flexible Circuit Design

In today’s era of ultra-thin electronics and wearable innovation, flexibility and reliability are no longer optional—they’re fundamental. Behind many of these breakthroughs lies a material engineered to endure heat, stress, and constant motion: polyimide. Known for its exceptional thermal stability, strength, and insulating performance, polyimide has become the backbone of flexible circuit design, enabling electronic systems to bend, fold, and perform in places rigid boards simply can’t. Its versatility continues to push the limits of what engineers can create, from next-generation medical devices to space-grade technology.

Introduction to Polyimide Material

What Is Polyimide Material?

Polyimide is a high-performance polymer known for its exceptional thermal stability, chemical resistance, and mechanical strength. Chemically, it is composed of imide groups (–CO–NH–CO–) that form a rigid molecular backbone. This molecular structure gives polyimide its ability to maintain strength and flexibility even under extreme conditions—qualities that make it indispensable in modern electronics.

The material was first developed in the mid-20th century as engineers sought alternatives to conventional plastics that could withstand higher temperatures. Over time, polyimide films became essential in the electronics industry, especially for flexible printed circuit boards (FPCBs), where traditional rigid materials like FR4 could not perform.

Common commercial versions of polyimide include Kapton® (DuPont), Upilex® (UBE), and Apical® (Kaneka). These trade names represent film types designed for different industrial uses—from aerospace wiring to advanced PCB manufacturing. For example, Kapton® films are widely used in spacecraft insulation and high-density flex circuits because they retain their properties across a temperature range of –200°C to +300°C.

In short, polyimide is not just another insulating material—it is a key enabler of high-performance and high-reliability electronic systems.

Why Polyimide Is Crucial for Flexible Circuits

Polyimide is the preferred substrate material for flexible circuit design because it offers a unique balance of flexibility, durability, and heat resistance that few other polymers can match. Unlike rigid PCB materials such as FR4, polyimide can bend or twist thousands of times without cracking or losing electrical insulation. This property allows it to serve as the foundation for wearable devices, foldable displays, and compact medical sensors where constant motion is required.

Its high thermal stability ensures that flexible circuits made from polyimide can endure soldering and reflow processes that exceed 250°C without deformation. This resistance to heat also makes it suitable for automotive and aerospace electronics, where circuits must perform reliably under harsh temperature cycles.

Moreover, as high-density interconnect (HDI) and miniaturized devices become the norm, polyimide’s dimensional stability and excellent dielectric properties make it indispensable. It prevents signal loss in high-speed applications and maintains circuit accuracy during multilayer lamination and microvia drilling.

In essence, polyimide’s unique combination of flexibility, heat endurance, and electrical reliability positions it as the backbone material for next-generation flexible electronic designs—bridging the gap between mechanical adaptability and electronic precision.

Key Properties That Make Polyimide Ideal for Flex Circuits

Excellent Thermal Stability

One of the most defining properties of polyimide material is its exceptional thermal stability. It can reliably operate in a temperature range from –200°C to +300°C, far beyond what most polymer films can endure. This stability means that flexible circuits built on polyimide maintain their mechanical and electrical integrity even during extreme thermal cycles.

During PCB manufacturing, components are exposed to soldering and reflow processes that often exceed 250°C. While materials such as PET (polyester) or FR4 epoxy glass may soften, warp, or delaminate under these conditions, polyimide remains dimensionally stable and resistant to thermal degradation.

In high-reliability applications—like aerospace, and automotive electronics—this heat resistance ensures consistent performance over time. Simply put, polyimide’s ability to resist melting, burning, and shrinking under heat makes it the gold standard for high-temperature flexible circuits.

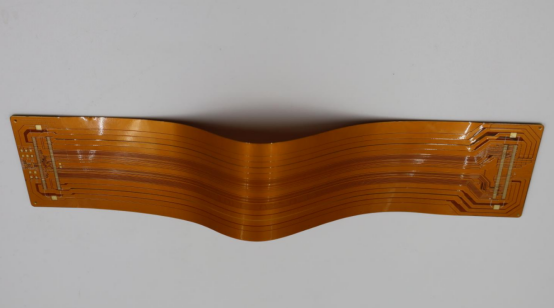

Outstanding Mechanical Flexibility

Polyimide film is engineered to withstand repeated bending, folding, and twisting without cracking or losing its insulating properties. It combines high tensile strength with exceptional elasticity, allowing circuits to flex thousands of times while maintaining stable performance.

This flexibility is crucial for wearable electronics, foldable smartphones, and compact medical devices, where circuits must bend with the device’s movement. For example, in a flexible display, the copper traces on a polyimide substrate can move and stretch without fracturing.

How this works step by step:

1. The polyimide base layer bends under mechanical stress.

2. The copper traces slightly stretch but remain supported by the flexible substrate.

3. The stress is distributed evenly across the film instead of concentrating at a single point.

4. As a result, cracks and delamination are prevented, even after thousands of flex cycles.

This combination of mechanical endurance and flexibility is what allows polyimide-based circuits to outperform rigid materials in dynamic or compact electronic designs.

Superior Chemical and Moisture Resistance

Polyimide is highly resistant to chemicals, solvents, acids, and humidity, which makes it exceptionally durable in challenging operating environments. Unlike some plastic substrates that absorb moisture and degrade over time, polyimide maintains its insulation and dimensional stability even after prolonged exposure to corrosive agents or humid conditions.

This property is particularly valuable in aerospace and automotive applications, where electronic systems often face oil, fuel vapors, and temperature fluctuations. By protecting copper circuits from oxidation and corrosion, polyimide ensures long-term reliability and stable electrical performance, even in harsh industrial environments.

Electrical Insulation Performance

From an electrical standpoint, polyimide offers outstanding insulation and dielectric properties. It features a high dielectric strength (typically above 200 kV/mm) and a low dielectric constant (around 3.4 at 1 MHz), meaning it can effectively separate electrical signals without significant interference or loss.

These properties are essential in high-speed or high-frequency circuits, where signal integrity is critical. In comparison, PET films have higher dielectric losses and lower temperature stability, which can lead to signal distortion or material breakdown over time.

For advanced applications—such as high-density interconnect (HDI) PCBs and RF circuits—polyimide ensures that signals remain clean, consistent, and free from cross-talk, even under demanding electrical loads.

In short, polyimide combines electrical reliability with mechanical and thermal endurance, making it the preferred choice for engineers designing the next generation of flexible, high-performance electronics.

Design and Manufacturing Advantages

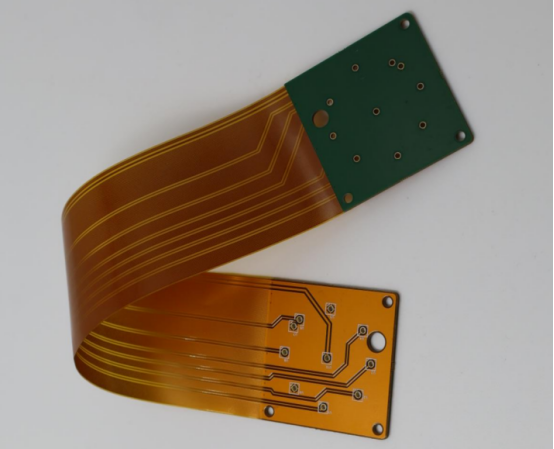

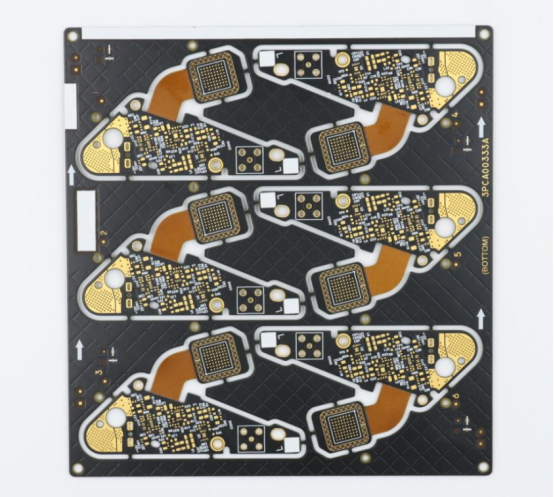

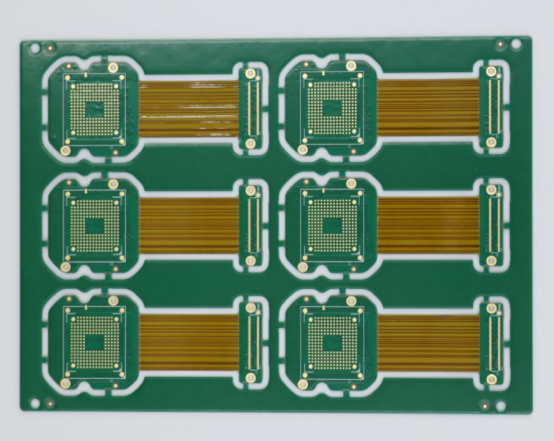

Compatibility with High-Density Interconnect (HDI) Designs

Polyimide material is highly compatible with high-density interconnect (HDI) PCB designs, thanks to its exceptional dimensional stability. During key manufacturing steps—such as etching, lamination, and drilling—polyimide maintains precise thickness and minimal expansion or contraction. This stability allows engineers to achieve fine trace spacing, tight registration, and accurate microvia alignment, all essential for high-performance, compact electronic assemblies.

For instance, in multilayer flex PCBs, where traces and vias are closely packed, even slight distortion during processing can cause misalignment. Polyimide’s low coefficient of thermal expansion (CTE) ensures that layers remain perfectly aligned, even under repeated heat cycles. This makes it the preferred choice for HDI boards used in smartphones, communication modules, and aerospace systems, where precision and reliability are non-negotiable.

In short, polyimide supports the miniaturization and signal integrity demands of HDI designs better than conventional materials like PET or FR4, which tend to warp or expand under thermal stress.

Lightweight and Space-Saving Benefits

Another key advantage of polyimide is its lightweight and thin profile, which directly supports the miniaturization of modern electronic devices. Flexible circuits made with polyimide can replace bulky rigid boards, reducing both weight and overall PCB stack-up thickness without sacrificing performance.

In smartphones, tablets, and medical implants, this reduction translates to more internal space for batteries, sensors, or cooling systems. For example, a flexible polyimide substrate may measure as little as 25–50 micrometers thick, while providing equivalent or superior electrical performance compared to a 0.8–1.6 mm rigid FR4 board.

This space-saving property enables engineers to design slimmer, lighter, and more integrated electronic systems. In wearable devices, for instance, a polyimide-based flex circuit allows the entire system to conform to curved surfaces, improving both comfort and functionality.

Ease of Processing and Adhesion

From a manufacturing perspective, polyimide’s strong adhesion and processability make it ideal for flex PCB fabrication. It bonds effectively with copper foils, coverlays, and adhesives, ensuring structural stability even during repeated bending or exposure to heat.

Here’s a simplified step-by-step overview of how polyimide is processed in flex circuit manufacturing:

1. Copper Lamination: A thin layer of copper foil is laminated onto the polyimide film using heat and pressure, forming a stable copper-clad substrate.

2. Circuit Etching: Fine circuit patterns are etched into the copper layer with high precision, enabled by the film’s excellent dimensional control.

3. Adhesive Application or Coverlay Lamination: Polyimide-based adhesives or coverlays are applied to protect the circuit and maintain flexibility.

4. Drilling and Plating: Microvias or through-holes are drilled and plated, connecting multiple conductive layers.

5. Final Curing and Finishing: Controlled curing strengthens the adhesive bonds and stabilizes the final flex PCB structure.

Because polyimide tolerates high processing temperatures and aggressive chemicals, manufacturers can achieve consistent quality and yield in advanced PCB production. Its natural affinity for copper also minimizes delamination risks, a key advantage over less robust polymers.

In essence, polyimide simplifies fabrication while enabling the precision and durability needed for complex flex circuit architectures—a combination that continues to drive innovation in next-generation electronics.

Application Areas of Polyimide-Based Flex Circuits

Consumer Electronics

Polyimide-based flexible circuits are widely used in consumer electronics, where compact design, lightweight construction, and mechanical flexibility are essential. Devices such as smartphones, cameras, laptops, and wearable technology rely on polyimide flex circuits to connect components in tight, foldable, or curved spaces.

Common use cases include battery interconnects, camera sensors, display modules, and touch interfaces. For instance, foldable smartphones use polyimide films to allow display ribbons and hinge circuits to bend repeatedly without cracking. Similarly, in digital cameras, polyimide substrates support flexible ribbon cables connecting image sensors to main boards, maintaining stable electrical performance under frequent movement.

Polyimide’s thermal stability and dimensional consistency also enable it to withstand soldering processes and daily operation, ensuring long-term reliability in consumer devices.

Automotive Electronics

In the automotive industry, polyimide flex circuits are valued for their reliability in high-temperature and vibration-prone environments. They are commonly used in engine control units (ECUs), LED lighting modules, airbag systems, and sensor arrays.

A practical example is under-the-hood control units, where temperatures can exceed 150°C. Unlike PET or other conventional substrates, polyimide maintains both mechanical and electrical stability under these conditions. This ensures continuous operation of temperature sensors, pressure monitors, and power distribution circuits.

Additionally, polyimide’s flexibility supports compact designs for in-vehicle infotainment systems and advanced driver-assistance systems (ADAS), helping reduce space and weight while maintaining reliable electrical performance.

Aerospace Applications

Polyimide flex circuits are extensively used in aerospace electronics due to their ability to perform under extreme temperature fluctuations, mechanical stress, and vibration. They are used in satellites, spacecraft, and avionics systems, where weight reduction and reliability are critical.

For example, polyimide-based flexible harnesses and interconnects in satellites provide durable, lightweight connections that can withstand the harsh environment of space. Its thermal stability from –200°C to +300°C ensures circuits remain operational during launch, orbit, and re-entry.

This combination of lightweight design, mechanical resilience, and thermal endurance makes polyimide indispensable in high-reliability aerospace systems.

Medical Devices

In the medical field, polyimide’s flexibility and biocompatibility make it ideal for wearable and implantable devices. Applications include hearing aids, pacemakers, diagnostic sensors, and miniature imaging tools.

Polyimide circuits can conform to curved or irregular surfaces, allowing electronics to fit seamlessly on or inside the human body. For instance, wearable ECG patches use polyimide-based flex circuits to monitor heart activity continuously while remaining thin and comfortable.

Its chemical and moisture resistance ensures devices can endure sterilization and contact with bodily fluids without degrading, making polyimide a reliable material for next-generation biomedical electronics.

In summary, polyimide-based flexible circuits support innovation across consumer electronics, automotive systems, aerospace, and medical devices, delivering lightweight, reliable, and high-performance solutions for applications where traditional rigid boards cannot perform.

Comparing Polyimide with Other Flexible Substrates

Polyimide vs. PET (Polyester)

Polyimide and PET (polyester) are both used in flexible circuits, but they differ significantly in temperature tolerance and mechanical fatigue resistance. Polyimide can withstand –200°C to +300°C, making it suitable for high-temperature soldering and harsh environments. In contrast, PET typically operates below 150°C, limiting its use in demanding applications.

Mechanically, polyimide endures thousands of bending cycles without cracking, whereas PET degrades faster under repeated flexing. This makes polyimide the preferred choice for high-reliability electronics, wearable devices, and aerospace applications.

Feature | Polyimide | PET (Polyester) |

|---|---|---|

Max Operating Temp | 300°C | 150°C |

Flexibility | High | Moderate |

Mechanical Fatigue | Excellent | Limited |

| Cost | Higher | Lower |

Typical Applications | Aerospace, Wearables, HDI Flex | Consumer-grade devices, Displays |

Polyimide vs. PEN (Polyethylene Naphthalate)

PEN offers better temperature resistance than PET (up to ~180–200°C) and slightly improved mechanical stability. However, it still falls short of polyimide’s performance, especially in high-temperature or high-flexibility applications.

The trade-off is cost and mid-range performance: PEN is generally cheaper than polyimide, making it attractive for consumer electronics or mid-range flex circuits where extreme thermal or mechanical demands are not critical. For example, lightweight display modules or printer flex circuits may use PEN, but polyimide is required for foldable phones or automotive sensors.

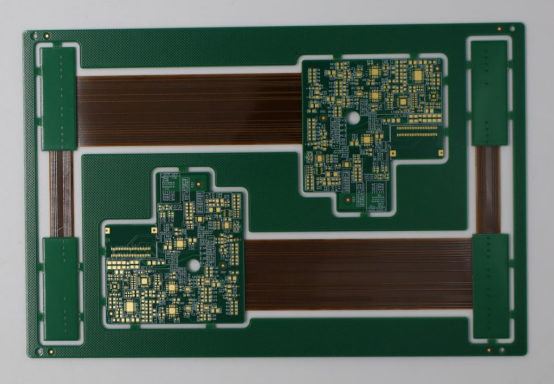

Polyimide vs. FR4 (Rigid Substrate)

FR4 is a rigid, glass-reinforced epoxy substrate commonly used in standard PCBs. Compared with FR4, polyimide provides flexibility, high-temperature tolerance, and lightweight construction. This allows engineers to design bent, folded, or compact circuits that rigid FR4 cannot accommodate.

When to use polyimide over FR4:

Flexible interconnects: Devices require bending or folding, such as foldable displays, wearable electronics, or medical sensors.

High-density interconnects (HDI): Polyimide maintains dimensional stability during microvia drilling and multilayer lamination.

Weight-sensitive applications: Aerospace or portable electronics benefit from the lighter polyimide substrate.

While FR4 remains suitable for rigid, cost-sensitive, or standard PCB applications, polyimide is the material of choice when mechanical flexibility, heat endurance, and space efficiency are critical.

In summary, polyimide outperforms PET and PEN in thermal stability and bending endurance, while offering flexibility and lightweight advantages over FR4, making it the preferred material for advanced flexible circuits in demanding applications.

Environmental and Reliability Advantages

Long-Term Durability

Polyimide-based flexible circuits are known for their long-term durability, maintaining performance under repeated bending, flexing, and thermal cycling. Unlike many conventional polymer substrates, polyimide can endure thousands of mechanical cycles without cracking, delaminating, or losing electrical integrity.

For example, in a 10,000-cycle bending test, polyimide circuits retained full conductivity and mechanical stability, whereas PET-based circuits began to show microcracks and signal degradation after fewer cycles. This reliability makes polyimide ideal for applications that require continuous motion, such as wearable electronics, foldable devices, and flexible sensor arrays.

Its thermal endurance further contributes to long-term durability. Even after repeated exposure to temperatures ranging from –200°C to +300°C, polyimide maintains dimensional stability and insulation properties, ensuring consistent performance over the product’s lifespan.

Resistance to Harsh Operating Conditions

Polyimide exhibits excellent resistance to environmental stressors, including high humidity, ultraviolet (UV) radiation, and chemical exposure. Unlike PET or PEN, which may degrade under moisture or prolonged UV exposure, polyimide maintains both mechanical integrity and electrical insulation.

In automotive or aerospace electronics, where circuits are exposed to oils, fuels, vibration, and temperature extremes, polyimide ensures long-lasting functionality. Its chemical resistance protects against solvents, acids, and other contaminants, preventing corrosion of copper traces and degradation of insulating layers.

This combination of thermal, chemical, and moisture resistance makes polyimide-based flexible circuits highly reliable in demanding industrial and environmental conditions.

Sustainability Considerations

While polyimide offers exceptional performance, recycling and sustainability remain challenges due to its high thermal stability and chemical resistance. The polymer’s durability, which makes it excellent for electronics, also complicates conventional recycling processes.

However, ongoing research focuses on eco-friendly processing methods and polyimide alternatives or blends that reduce environmental impact without sacrificing performance. Manufacturers are exploring mechanical recycling, chemical depolymerization, and reuse of copper foils to enhance sustainability.

By balancing long-term reliability with environmental responsibility, polyimide continues to play a key role in advanced flexible electronics while gradually moving toward greener production methods.

In summary, polyimide’s durability, resistance to harsh conditions, and potential for sustainable processing make it a reliable and environmentally conscious choice for high-performance flexible circuits, ensuring devices operate effectively over extended lifespans.

Conclusion

Polyimide continues to stand out as a foundational material for flexible electronics, offering unmatched heat resistance, mechanical flexibility, electrical insulation, and long-term reliability. These properties make it the ideal choice for advanced applications, from consumer devices and medical sensors to aerospace and automotive electronics. By enabling compact, lightweight, and durable circuits, polyimide empowers engineers to push the boundaries of design and functionality in ways that traditional materials cannot.

Looking ahead, innovations in low-dielectric-constant (low-Dk) and transparent polyimide films are expanding possibilities for high-speed signal integrity and optical applications. Additionally, the industry is moving toward hybrid multilayer flexible-rigid PCBs, combining the best of both flexible and rigid substrates for next-generation electronics. Companies like PCBMASTER are at the forefront of these developments, providing high-performance polyimide solutions that meet the evolving demands of modern electronic design.

In short, polyimide’s combination of performance, adaptability, and future-ready innovations ensures it will remain a critical material for cutting-edge flexible circuits, enabling the next wave of technological advancement.

FAQs

What are the main advantages of using polyimide in flexible circuit design?

Polyimide offers excellent heat resistance, mechanical flexibility, electrical insulation, and long-term reliability. It can bend or fold thousands of times without cracking, withstand high temperatures during soldering, and maintain performance under harsh environmental conditions. These qualities make polyimide ideal for high-density, compact, and durable flexible circuits in modern electronics.

How does polyimide compare to PET or FR4 materials in performance and cost?

Compared to PET, polyimide has a much higher temperature tolerance (up to 300°C vs. PET’s ~150°C) and superior mechanical fatigue resistance, making it more suitable for demanding applications like wearable devices or aerospace electronics. FR4 is a rigid substrate that is cheaper and suitable for standard PCBs, but it cannot bend or fold like polyimide. While polyimide is generally more expensive than PET or FR4, its performance benefits in flexibility, thermal endurance, and reliability justify the higher cost for advanced applications.

Can polyimide flex circuits withstand high-temperature soldering processes?

Yes. Polyimide is highly thermally stable and can endure soldering and reflow processes exceeding 250°C without deformation or loss of electrical performance. This makes it suitable for high-reliability electronics, automotive sensors, aerospace modules, and consumer devices that require exposure to high temperatures during manufacturing.

What industries commonly use polyimide-based flex PCBs?

Polyimide flex circuits are widely used in consumer electronics (smartphones, cameras, wearables), automotive electronics (engine control units, LED modules, sensors), aerospace applications (satellites, spacecraft, avionics systems), and medical devices (wearable ECG monitors, implants, diagnostic tools). In each of these sectors, polyimide’s flexibility, heat resistance, and durability are critical for device performance and longevity.

Are there any environmental concerns with manufacturing polyimide materials?

Yes. Polyimide’s high thermal stability and chemical resistance make it difficult to recycle using conventional methods. This can create challenges in sustainable disposal or material recovery. However, ongoing research is exploring eco-friendly processing, chemical recycling, and reuse of copper foils, which aim to reduce the environmental impact of polyimide-based electronics while maintaining their performance and reliability.