PCBA vs PCB: Which One Do You Need for Your Electronics Project?

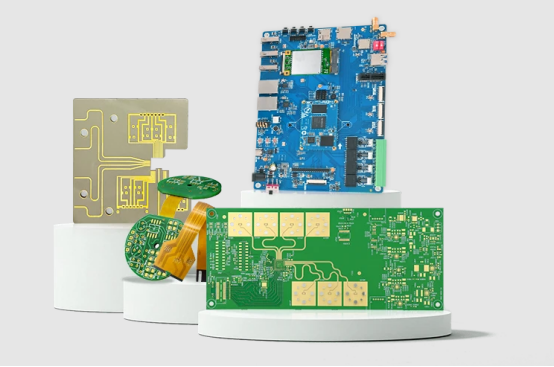

In the world of electronics, knowing the difference between a PCB (Printed Circuit Board) and a PCBA (Printed Circuit Board Assembly) can make or break your project. While both terms are often used interchangeably, they represent very different stages of an electronic device’s life—from a bare board waiting for components to a fully functional circuit ready for deployment. Choosing the right option impacts cost, time, and project success, whether you’re prototyping a DIY gadget or manufacturing a commercial product.

Introduction — Understanding PCBs and PCBAs

Definition of PCB (Printed Circuit Board)

A Printed Circuit Board (PCB) is a bare board that provides the physical platform for electronic circuits. It consists of copper traces, insulating layers, and drilled holes or pads where components can later be mounted.

Typical materials used in PCB manufacturing include:

FR4: A common fiberglass-reinforced epoxy laminate.

CEM-1 and CEM-3: Composite epoxy materials often used in low-cost or single-layer boards.

Flexible boards: Made from polyimide or other flexible substrates for bendable or compact applications.

Importantly, a PCB alone does not perform any electronic functions. Without components such as resistors, capacitors, or integrated circuits, it serves only as a structural and conductive framework.

Definition of PCBA (Printed Circuit Board Assembly)

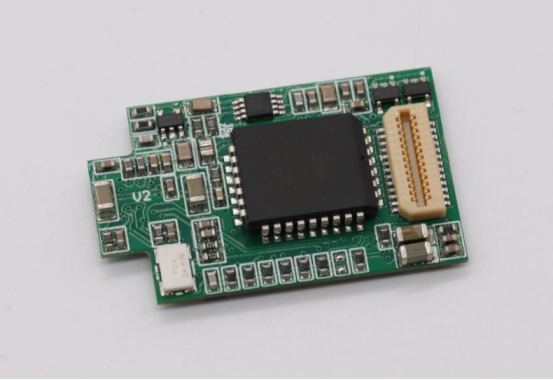

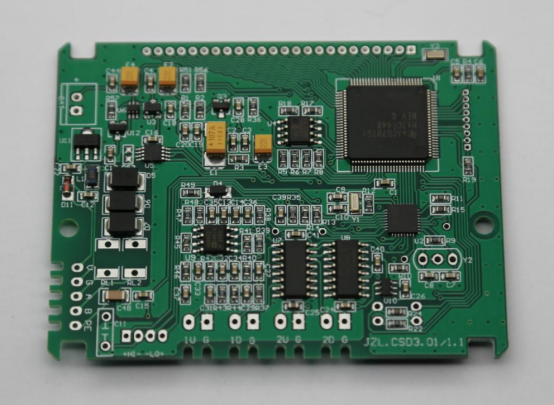

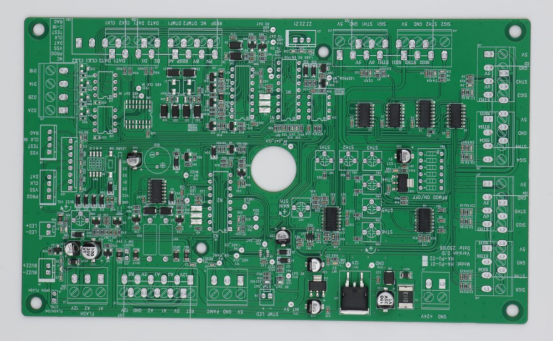

A Printed Circuit Board Assembly (PCBA) is a PCB that has been populated with electronic components, making it a fully functional circuit. Components such as resistors, capacitors, integrated circuits (ICs), connectors, and LEDs are soldered onto the board using specialized techniques.

Common manufacturing processes include:

Soldering: Joining components to copper pads using solder paste and heat.

Surface Mount Technology (SMT): Mounting small components directly onto the surface of the board.

Through-Hole Technology (THT): Inserting component leads through holes in the PCB and soldering them on the opposite side.

A PCBA is therefore ready to perform its intended electronic functions, whether it’s powering a consumer device, controlling industrial equipment, or enabling IoT applications.

Why the Distinction Matters

Understanding the difference between PCB and PCBA is essential for engineers, hobbyists, and procurement teams. A simple analogy helps:

PCB = “Blank Canvas”: Provides the structure and connectivity but is not functional on its own.

PCBA = “Painted Artwork”: Fully assembled and operational, ready to perform electronic tasks.

This distinction impacts project planning, cost estimation, manufacturing decisions, and supply chain management. Choosing between a bare PCB or a fully assembled PCBA ensures that resources are used efficiently and that the electronics project meets functional requirements from prototyping to production.

Key Differences Between PCBA and PCB

Understanding the differences between a PCB (Printed Circuit Board) and a PCBA (Printed Circuit Board Assembly) is crucial for electronics design, manufacturing, and procurement. These differences span structure, function, manufacturing processes, cost, and applications.

Structural Differences

PCB: A bare board featuring copper layers, insulation, drilled holes, and pads for component placement. It serves as the foundational platform for electronic circuits.

PCBA: A PCB that has mounted electronic components such as resistors, capacitors, and integrated circuits, forming functional circuitry capable of performing tasks.

Example: A smartphone PCB alone is just a layered board with traces; once populated with chips, connectors, and sensors, it becomes a fully functional PCBA.

Functional Differences

PCB: Non-functional by itself. It cannot perform any electronic operations until components are added.

PCBA: Fully functional, able to execute tasks such as processing data, controlling devices, or interfacing with other electronics.

Comparison: Think of PCB as an empty motherboard framework and PCBA as the complete motherboard installed with CPU, RAM, and chips ready to run.

Manufacturing Process Differences

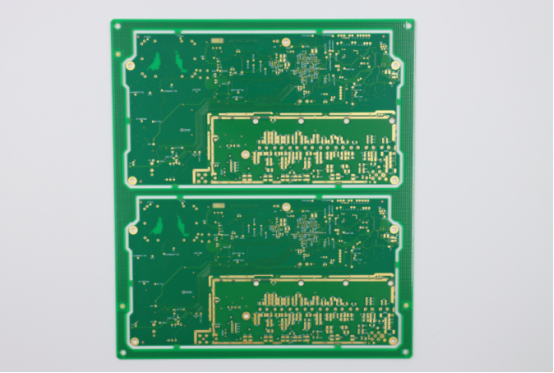

PCB Manufacturing: Involves layering, etching copper traces, drilling holes, applying solder masks, and surface coating. The result is a bare board ready for assembly.

PCBA Manufacturing: Adds solder paste application, automated or manual component placement, reflow or wave soldering, and functional inspection/testing. The board transitions from a physical structure to a working electronic device.

Step-by-step example:

1. PCB is fabricated and tested for defects.

2. Components are placed using SMT machines.

3. Soldering bonds components to the board.

4. Final inspection ensures the PCBA works as intended.

Cost and Lead Time Differences

PCB: Generally lower cost since it’s just a bare board, with faster production times. Ideal for prototyping or initial testing.

PCBA: Higher cost due to added components and assembly labor. Lead time is longer, especially for complex or multi-layer boards with many components.

Example: A single-layer PCB may be produced in a few days, while a fully assembled PCBA with hundreds of components could take weeks to manufacture and test.

Application Differences

PCB: Primarily used for prototyping, testing, or as a base for final assemblies in larger electronic devices. It is also used in educational kits or small DIY projects.

PCBA: Found in ready-to-use electronic products such as smartphones, industrial controllers, IoT devices, medical instruments, and consumer electronics.

Comparison: If a PCB is a blank sheet of music, the PCBA is the full orchestra playing the composition.

How to Decide Between Using a PCB or PCBA

Choosing between a PCB (Printed Circuit Board) and a PCBA (Printed Circuit Board Assembly) depends on several factors, including project type, technical capabilities, costs, and reliability requirements. Understanding these considerations ensures that your electronics project is both cost-effective and functional.

Project Type Consideration

Prototype vs Final Product:

Prototyping: Bare PCBs are often preferred because they allow for modifications, component testing, and iterative design changes.

Final Product: PCBAs are necessary for fully functional products that are ready for deployment, such as smartphones, IoT devices, or industrial controllers.

Low-Volume vs High-Volume Production:

Low-volume or experimental projects can use bare PCBs to reduce costs and maintain flexibility.

High-volume manufacturing benefits from pre-assembled PCBAs for consistency, quality control, and faster deployment.

Example: A hobbyist designing a custom sensor might start with a bare PCB for testing, while a company producing 10,000 units of a smart thermostat would require PCBA for efficiency and reliability.

Technical Capability and Resources

In-House Assembly vs Contract Manufacturing:

Companies with soldering equipment, pick-and-place machines, and experienced technicians may assemble PCBAs internally.

Smaller teams or startups may outsource assembly to specialized PCB assembly services for higher precision and reduced risk.

Availability of Equipment:

SMT machines, reflow ovens, and functional testing stations are necessary for producing reliable PCBAs.

Lack of proper equipment makes bare PCBs more practical until contract manufacturing or assembly resources are available.

Cost and Time Analysis

Upfront Costs:

Bare PCBs are generally cheaper since they exclude components and assembly labor.

PCBAs include component costs, labor, testing, and packaging, leading to higher initial expenses.

Lead Time Implications:

Bare PCBs can be produced in a matter of days.

PCBAs may require weeks to source components, assemble, solder, and perform quality testing.

Comparison: For rapid prototyping, bare PCBs save both time and money, while PCBAs are more cost-effective in large-scale production when factoring in labor and error reduction.

Risk and Reliability Factors

Testing and Component Failure:

Bare PCBs require assembly and testing before functionality can be ensured.

Professionally assembled PCBAs often undergo functional testing and quality inspection, reducing the risk of component failure.

High-Reliability Applications:

Industries such as medical devices, automotive, or aerospace rely on PCBAs to meet stringent reliability and safety standards.

Step-by-step example:

1. Evaluate project scale and complexity.

2. Assess internal assembly capabilities and resources.

3. Compare cost vs lead time for bare PCB vs PCBA.

4. Factor in testing requirements and reliability needs.

5. Make an informed decision based on the balance of flexibility, cost, and performance.

Examples and Case Studies

Understanding the difference between PCB and PCBA becomes clearer when we look at real-world examples and applications. These cases highlight how choice of board type affects functionality, cost, and project outcomes.

DIY Electronics Projects

Hobbyist kits: Many DIY kits use bare PCBs with minimal surface mount technology (SMT) components. This approach allows learners to solder components themselves and understand circuit design.

Low-complexity projects: Simple devices like LED blinkers, basic sensors, or microcontroller experiments can often rely on bare PCBs, as they require few components and are easy to modify.

Example: A beginner Arduino project may use a PCB with headers and pads only, allowing the user to populate resistors, LEDs, and ICs manually.

Key takeaway: Bare PCBs offer flexibility and cost savings for educational or experimental purposes, while still providing a structural foundation for electronics learning.

Commercial Electronics Products

High-functionality devices: Smartphones, industrial machinery, automotive ECUs, and medical instruments require fully assembled PCBAs.

Why full assembly is critical: PCBAs ensure consistent electrical connectivity, component placement accuracy, and functional reliability, which are essential for devices that must operate without failure.

Example: A smartphone motherboard includes hundreds of tiny SMT components and ICs. Without professional PCBA, these devices would not function correctly or meet quality standards.

Key takeaway: PCBAs are necessary for complex, high-reliability, and large-scale commercial products where functional integrity cannot be compromised.

Prototype vs Mass Production Example

Early-stage testing: Engineers often start with prototype PCBs populated with temporary components. This allows rapid iteration, testing of circuit behavior, and easy modifications before committing to full production.

Large-scale manufacturing: Once the design is finalized, manufacturers produce fully assembled PCBAs, ready for shipment and integration into end products.

Step-by-step scenario:

1. Prototype PCB is fabricated and components temporarily installed.

2. Circuit functionality is tested and adjusted.

3. Design finalized and sent for full-scale PCBA production.

4. PCBAs undergo automated assembly, soldering, and inspection before distribution.

Key takeaway: The choice between PCB and PCBA depends on project stage, scale, and functionality requirements.

Advantages and Limitations

Choosing between a PCB (Printed Circuit Board) and a PCBA (Printed Circuit Board Assembly) involves balancing cost, functionality, flexibility, and project requirements. Understanding the advantages and limitations of each helps engineers, hobbyists, and manufacturers make informed decisions.

Advantages of Using a PCB

Lower cost: Bare PCBs are cheaper because they exclude components and assembly labor.

Easier modifications during prototyping: Engineers can quickly change component placement, trace routing, or board design without discarding an assembled board.

Simpler logistics and storage: Bare boards are lighter, easier to store, and have longer shelf life compared to fully populated PCBAs.

Example: A startup designing a new sensor can use bare PCBs to iterate multiple design versions at minimal cost before committing to assembly.

Limitations of a PCB

Non-functional until assembled: A PCB cannot perform any electronic operations without soldered components.

Requires assembly expertise and equipment: Soldering, component placement, and testing must be performed either in-house or through a contract manufacturer.

Step-by-step implication: Using a bare PCB means the team must:

1. Source components.

2. Assemble them using SMT or through-hole techniques.

3. Test the functionality before deployment.

Advantages of Using a PCBA

Ready-to-use and functional: A PCBA is fully assembled and capable of performing its intended electronic operations immediately.

Tested and reliable: Professional assembly includes quality checks, reducing the risk of faulty circuits.

Reduces assembly risk for end-users or OEMs: Outsourcing assembly ensures consistent soldering quality and functional integrity.

Example: A smartphone motherboard delivered as a PCBA is immediately operational, eliminating assembly challenges for device manufacturers.

Limitations of a PCBA

Higher initial cost and longer lead times: PCBAs include components, assembly labor, and quality testing, which increases upfront expenses.

Less flexible for modifications during prototyping: Once components are soldered, changes are costly and complex, making iterative design adjustments difficult.

Comparison: For experimental projects, a bare PCB allows rapid iteration, whereas a PCBA is ideal for finalized designs requiring reliability and ready-to-use functionality.

Conclusion — Making the Right Choice

Choosing between a PCB (Printed Circuit Board) and a PCBA (Printed Circuit Board Assembly) requires careful consideration of project type, available resources, cost, and reliability needs. Bare PCBs are ideal for prototyping, learning, or low-volume experimentation, offering flexibility, lower costs, and faster production times. In contrast, PCBAs are best suited for ready-to-use, high-reliability products, where professional assembly ensures consistent functionality and quality, especially for industrial, automotive, or consumer electronics applications.

Project resources play a key role in the decision. Teams with limited soldering expertise or testing equipment may benefit from working with PCBAs, while in-house assembly capabilities make bare PCBs a viable option for iterative design. Cost and lead time should also be weighed carefully: although PCBAs have higher upfront costs, they reduce assembly risk and save time in large-scale production.

Collaborating with experienced suppliers, such as PCBMASTER, can streamline this process. Suppliers provide valuable guidance on assembly methods, component sourcing, and design optimization, helping engineers and manufacturers select the right board type while balancing efficiency, cost, and reliability. By evaluating your project’s purpose, scale, and technical requirements, you can make an informed choice between PCB and PCBA, ensuring both successful development and long-term performance.

FAQs

Can a PCB be converted into a PCBA at home?

Yes, a PCB can technically be converted into a PCBA at home with soldering skills, proper tools, and components. Simple hobbyist boards can be assembled using a soldering iron or reflow oven for surface-mount devices (SMDs). However, complex multilayer boards or fine-pitch components are difficult to assemble at home and usually require professional equipment or contract assembly. DIY assembly works for learning and simple prototypes, but professional PCBAs are recommended for high-density or high-reliability circuits.

What factors affect the cost difference between PCB and PCBA?

The main factors include component costs, assembly labor, testing and quality control, and production scale. PCBAs are more expensive because they include components like resistors, ICs, and connectors, require labor-intensive assembly, and undergo functional testing and inspections. Large production batches can reduce per-unit costs, but small or custom orders generally remain costlier than bare PCBs.

Are there standard testing procedures for PCBAs?

Yes, standard procedures ensure functionality and reliability. Common methods include visual inspection, Automated Optical Inspection (AOI), In-Circuit Testing (ICT), functional testing, and X-ray inspection for hidden solder joints. These tests reduce failures, especially in high-reliability applications like industrial or medical electronics.

How do PCBA lead times vary for small vs large orders?

Lead times depend on order size, complexity, and component availability. Small orders have shorter setup times but may take longer per unit and cost more due to limited batch efficiencies (typically a few days to two weeks). Large orders require more preparation but benefit from automated production, reducing per-unit time (usually 2–6 weeks depending on board complexity and components).

What types of projects benefit most from using a bare PCB instead of a PCBA?

Bare PCBs are ideal for prototyping, educational kits, DIY projects, and low-volume experimental designs. They allow rapid iteration, cost savings, and design flexibility since components can be manually placed or adjusted. Projects where flexibility and learning are more important than immediate functionality gain the most benefit from bare PCBs.