PCB Cooling Systems: Essential Guide to Effective Thermal Management

Behind every high-performance device, there’s a constant battle against heat. It's a quiet force, slowly deteriorating components and risking the very functionality of a system. But what if there was a way to control it, not just fight it? The cooling of a PCB—the brain of your device—doesn't just maintain temperatures; it determines how long your device can endure, how fast it can operate, and whether it will fail prematurely. With the right strategies, heat can be managed, even mastered. This is where innovation in PCB cooling systems come in, turning heat from an inevitable foe into something more manageable—and ultimately, enhancing the life of the entire device.

Introduction to PCB Cooling Systems

Definition and Importance of PCB Cooling

What is PCB cooling and why is it essential?

PCB cooling refers to the process of managing and reducing the heat generated by the electronic components on a printed circuit board (PCB). As devices operate, their components—like microprocessors, memory chips, and power transistors—generate heat. If this heat isn't properly managed, it can cause components to malfunction or even fail. Effective PCB cooling helps ensure that the temperature stays within safe limits, allowing the device to work properly without risk of overheating. Cooling is essential because heat is a primary cause of wear and tear in electronic devices, often leading to permanent damage or failure.

The role of heat management in the longevity and reliability of electronic devices

Heat management is crucial to maintaining the longevity and performance of electronic devices. When components on a PCB get too hot, they can become less efficient, or even fail entirely. Proper cooling systems prevent these problems by regulating the temperature, keeping devices running smoothly for longer periods. Devices with effective cooling systems experience fewer breakdowns and often perform better. By investing in cooling, manufacturers can significantly extend the lifespan of their products and avoid costly repairs or replacements.

Common consequences of poor PCB cooling: overheating, component failure, and reduced device lifespan

When PCB cooling is insufficient, several issues can arise. Overheating is the most obvious, which can cause immediate failure of components. This may result in the device shutting down or not turning on at all. Over time, poor cooling accelerates the aging of components, leading to gradual performance degradation, increased power consumption, and the risk of sudden, unexpected failures. In severe cases, overheating can cause components to burn out, leading to permanent damage. The overall device lifespan is also drastically shortened, which increases maintenance costs and reduces the device’s effectiveness.

Overview of Heat in Electronics

How heat affects electronic components (microprocessors, capacitors, etc.)

Heat affects different components in various ways. Microprocessors, for example, slow down or behave erratically when exposed to high temperatures, which can lead to system crashes or freezes. Capacitors, which store electrical energy, can lose their ability to function properly if they overheat. In extreme cases, they may leak or even burst. Other components, such as resistors and diodes, are also susceptible to heat damage, leading to reduced efficiency and increased failure rates. If heat is not managed effectively, it can cause these parts to degrade much faster, leading to costly repairs or replacements.

The correlation between heat and device failure

Heat is one of the leading causes of device failure. When components overheat, they undergo physical stress. Materials expand and contract, causing connections to weaken and possibly break. This can result in system malfunctions, data loss, or even complete failure of the device. Studies show that heat-related failures account for more than 50% of all electronic breakdowns. Managing heat through proper PCB cooling systems is critical to minimizing these risks and ensuring that devices continue to function reliably over time.

Key statistics on heat-related electronic failures

Statistics from various studies underline the importance of heat management in electronics. Research shows that up to 60% of all electronic failures are directly caused by heat, particularly in high-performance devices like computers, mobile phones, and industrial machinery. Moreover, for every 10°C rise in temperature, the failure rate of electronic components can double. This emphasizes the need for robust thermal management systems, as even a small increase in temperature can significantly affect the reliability and lifespan of the device.

The Fundamentals of PCB Cooling

Heat Transfer Mechanisms in PCBs

Conduction: How Heat Moves Through PCB Materials

Conduction is the process by which heat travels through materials. In a PCB, heat generated by components like microprocessors or voltage regulators moves through the board's materials, such as copper, solder, and PCB substrates. As one part of the material heats up, the heat spreads to adjacent areas, causing the temperature to rise across the entire PCB. This is a key mechanism in transferring heat away from hot components.

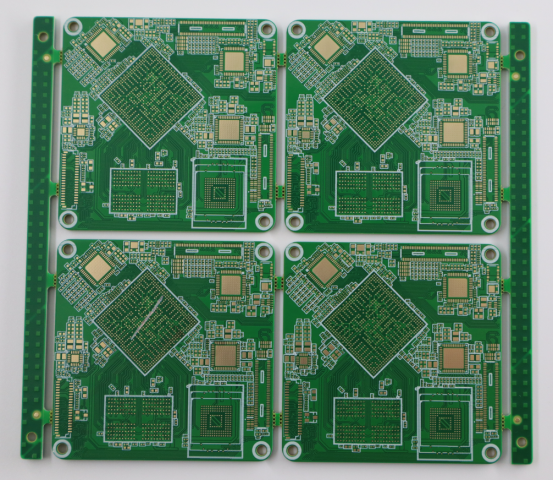

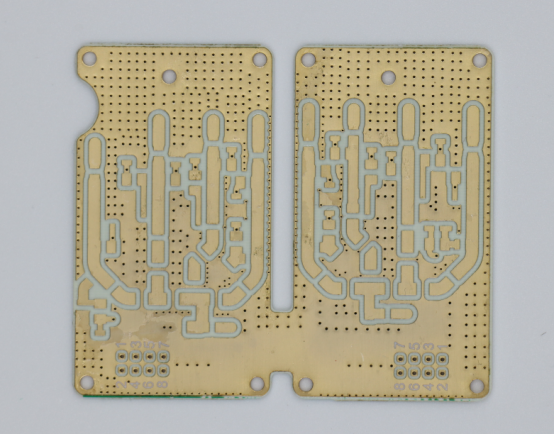

The Role of Copper Layers and Thermal Vias in Heat Conduction

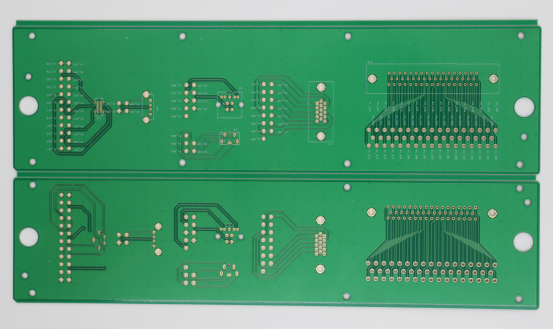

Copper is a highly effective material for heat conduction, which is why it is commonly used in PCBs. Copper layers in the PCB spread the heat generated by components across the board, helping to keep the temperature uniform. Additionally, thermal vias—small holes lined with copper—serve as pathways to move heat from one side of the PCB to the other. Thermal vias enhance heat distribution, allowing it to reach cooler areas or copper planes where the heat can be dissipated more efficiently.

Convection and Radiation: Cooling Through Air and Liquids

While conduction is the primary method of heat transfer within the PCB, convection and radiation also play important roles in PCB cooling. Convection occurs when heat is transferred to air or liquid, which then carries the heat away from the PCB. This is why many devices use fans or liquid cooling systems to actively remove heat. Radiation is another form of heat dissipation, where heat is emitted from the PCB's surface in the form of infrared radiation. Although radiation is not as significant as conduction or convection, it can still help with heat management, especially when the PCB is exposed to an open air environment.

Key Components in PCB Cooling

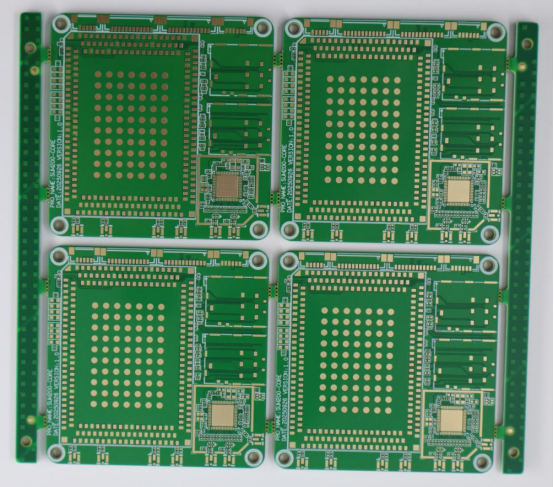

Thermal Vias: Function and Design in PCBs

Thermal vias are small, copper-plated holes drilled through the PCB to allow heat to travel from one layer to another. They play an essential role in moving heat away from hot components to cooler areas of the board. Proper design and placement of thermal vias are critical for effective heat management. When strategically placed beneath heat-sensitive components, thermal vias direct heat to the board’s opposite side, where it can be dissipated more effectively.

Benefits of Effective Via Placement in Heat Distribution

The placement of thermal vias is crucial to ensuring effective heat distribution. For example, multiple thermal vias placed under high-power components, like microprocessors, help spread heat more evenly across the PCB. If the vias are positioned correctly, they help prevent "hot spots"—areas where heat builds up and can damage components. Effective via placement also helps reduce the risk of warping or bending of the PCB caused by uneven heat distribution.

How Filling Vias with Conductive Materials Enhances Heat Transfer

Filling thermal vias with conductive materials, like conductive glue or silver, can significantly improve their heat transfer efficiency. These materials help reduce the resistance to heat flow, allowing the heat to move more quickly through the vias and across the PCB. By using conductive materials, manufacturers can create PCBs that cool down more efficiently, preventing overheating and enhancing the device's overall reliability.

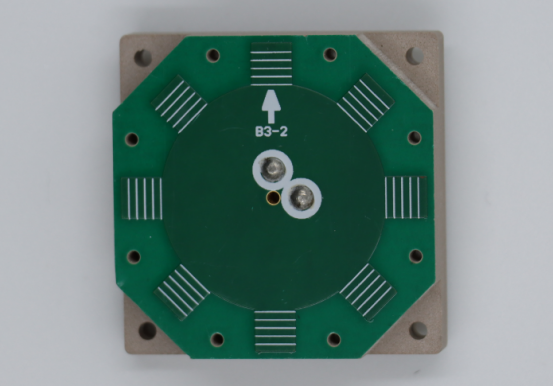

Heat Sinks and Cooling Fans: Heat Dissipation Through Active Cooling

Heat Sink Materials and Their Impact on Heat Dissipation

Heat sinks are devices designed to absorb heat from the components and release it into the surrounding air. Made of materials with high thermal conductivity—like aluminum or copper—heat sinks are attached to hot components to increase the surface area for heat dissipation. The larger the surface area of the heat sink, the more heat it can transfer. These materials are effective because they pull heat away from components and spread it across the fins of the heat sink, where it can be dissipated by air flow.

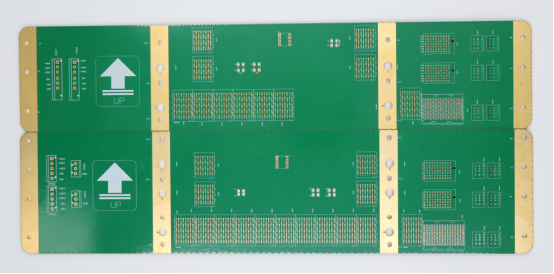

Integration of Fans with PCBs for Active Cooling: Key Design Considerations

Cooling fans are often integrated into PCB designs to provide active cooling by moving air across the PCB and its components. Fans increase the effectiveness of heat sinks by improving airflow, allowing heat to be carried away from the components. When designing PCBs for fan cooling, engineers must consider factors like fan size, airflow direction, and placement to ensure that the airflow is optimal. Poorly placed fans can lead to uneven cooling or create turbulence that reduces cooling efficiency. Fans can also add noise and consume power, so engineers must balance cooling needs with overall system efficiency.

Cooling Methods for PCBs

Passive Cooling Techniques for PCBs

Heatsinks: Types, Materials, and Function

Heatsinks are devices designed to remove heat from electronic components by increasing the surface area exposed to the surrounding air. They are made from materials with high thermal conductivity, such as aluminum and copper, which efficiently transfer heat away from the PCB. Aluminum is lighter and more cost-effective, making it popular for everyday applications, while copper is more efficient but heavier and more expensive.

Heatsinks work by absorbing the heat from components like microprocessors and spreading it across their fins. The larger the surface area of the heatsink, the more heat it can dissipate. By increasing the contact surface between the component and the heatsink, heat is quickly transferred into the surrounding air, reducing the temperature of the component.

Cost-Effective Design Considerations for Passive Cooling

When designing passive cooling solutions, cost-effectiveness is an important consideration. Simple heatsink designs with fewer fins or smaller surfaces are more affordable and work well for devices with moderate heat generation. However, for high-performance systems, larger, more complex heatsinks may be necessary. Passive cooling is especially cost-effective for consumer electronics like LED lights, where moderate heat levels can be managed with minimal expense and power consumption.

Phase Change Materials (PCMs): How They Work and Their Benefits

Phase Change Materials (PCMs) are substances that absorb heat as they melt and release heat as they solidify. In PCB cooling systems, PCMs help maintain a stable temperature by absorbing excess heat when the device gets too hot and releasing it as the temperature drops. This helps prevent overheating and ensures the device operates within safe limits.

Integrating PCMs into PCB cooling systems offers several advantages. First, they can store and release large amounts of heat without the need for active cooling systems like fans or pumps. This makes PCMs ideal for environments where space or energy consumption is a concern. Additionally, they improve thermal stability by smoothing out temperature fluctuations, extending the lifespan of components.

Thermal Vias and Thick Copper Layers: Role in Heat Distribution

Thermal vias are small copper-lined holes drilled through the PCB to help move heat from one side of the board to the other. They act like tiny pipes that channel heat away from hot components to cooler areas or to copper planes where heat can be more efficiently dissipated. The placement and number of thermal vias are crucial for ensuring proper heat distribution.

Thick copper layers are another important feature in effective PCB cooling. Using copper layers that are thicker than normal helps distribute heat more evenly across the board. Thicker copper traces reduce electrical resistance and ensure that heat is spread uniformly, preventing overheating in concentrated areas. This can significantly improve the PCB’s ability to manage heat without needing additional cooling solutions.

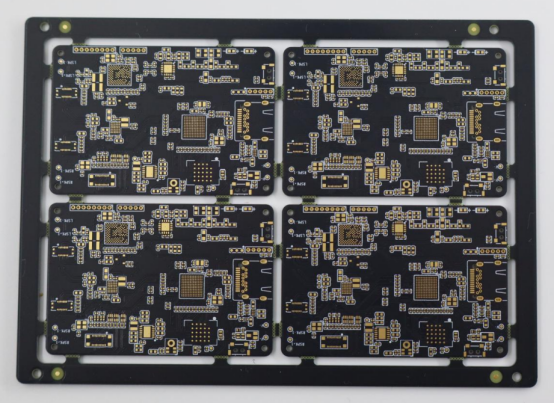

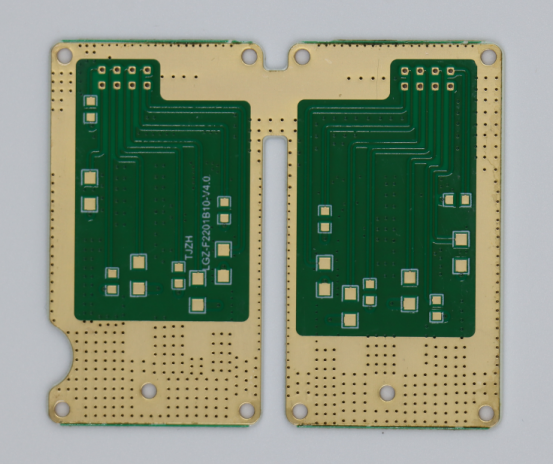

Metal Core PCBs: Improved Heat Management and Board Durability

Metal-core PCBs are designed with a metal base, often aluminum, which improves heat dissipation. These boards are especially beneficial for high-power applications where heat generation is a concern. The metal core acts as a heat sink, quickly transferring heat away from sensitive components. The addition of a metal core also strengthens the board, reducing the risk of warping or bending due to heat stress.

Metal-core PCBs are commonly used in automotive electronics, LED lighting, and power supplies, where the need for efficient thermal management is critical. They are more effective than traditional PCBs at maintaining low temperatures, ensuring better performance and longer device lifespans.

Active Cooling Methods for High-Power PCBs

Cooling Fns and Airflow Management

Cooling fans are a common method for managing heat in high-power devices. Fans work by moving air across the PCB, pushing hot air away from components and bringing in cooler air. This helps maintain a consistent temperature, preventing components from overheating.

Proper fan selection and placement are key to maximizing cooling performance. Engineers must choose fans with the right size, speed, and airflow capacity to ensure efficient cooling. Optimal fan placement can improve airflow and avoid “dead spots” where heat could accumulate. For example, placing fans near high-power components like processors or power transistors helps keep these critical areas cool.

Heat Pipes and Liquid Cooling Systems: Efficient Heat Transfer

Heat pipes are sealed tubes filled with a liquid that evaporates and condenses to transfer heat. When the liquid inside the heat pipe evaporates, it absorbs heat from the component, and when it condenses, it releases the heat to a cooler area. Heat pipes are highly effective in transferring heat away from hot components, especially in compact or tightly packed devices.

Liquid cooling systems take this concept further by circulating a liquid coolant through tubes over the PCB. These systems can dissipate large amounts of heat, making them ideal for high-power devices like gaming computers or industrial machinery. Liquid cooling is more expensive and complex than air cooling, but it offers superior performance in extreme environments where other cooling methods may not be sufficient.

Forced Air and Liquid Cooling: Cost-Benefit Analysis

Forced air cooling uses fans to push air through the device, typically providing a temperature reduction of 20-30°C. It's effective for most medium-heat devices but comes with trade-offs: it can increase the device’s size and power consumption, and fans can generate noise. The cost of forced air cooling is relatively low compared to liquid cooling, making it a good choice for most applications where heat generation is moderate.

On the other hand, liquid cooling systems can reduce temperatures significantly, especially in high-power or critical devices. However, the installation costs are much higher due to the need for pumps, coolant, and sealed systems. Liquid cooling is often necessary for devices that require high-performance cooling, such as gaming PCs, data centers, and high-power industrial equipment.

Situations Where Active Cooling is Necessary

Active cooling methods, like fans and liquid cooling, are essential for devices that generate significant heat. For example, computers, power tools, and critical systems need active cooling to prevent performance issues and component damage. In high-performance devices, such as gaming rigs or servers, heat can accumulate rapidly, and passive cooling methods like heatsinks alone may not suffice. In these cases, active cooling methods are crucial to maintain system stability and reliability.

Designing for Effective PCB Cooling

Optimal Component Placement for Heat Dissipation

Strategic Placement of Heat-Sensitive Components

In PCB design, the placement of components plays a crucial role in managing heat. Power components, such as microprocessors, voltage regulators, and high-power transistors, tend to generate significant heat during operation. To avoid overheating heat-sensitive components like capacitors, sensors, and memory chips, it is essential to position these components away from heat-generating parts. This minimizes the risk of thermal damage and ensures that the device operates efficiently.

Proper placement involves strategically spacing components to prevent heat accumulation in localized areas. Adequate airflow around components and spacing between them helps dissipate heat more effectively. This design consideration is particularly important in high-performance devices where multiple components may generate heat simultaneously. By using thermal management techniques, such as placing heatsinks near heat sources, engineers can optimize the layout for better heat distribution and cooling.

Using Thermal Simulations in PCB Design

Thermal simulations play a key role in identifying potential hot spots in PCB designs before production. Simulation tools help engineers visualize heat flow, pinpoint areas where excessive heat is likely to build up, and adjust the design accordingly. This process allows designers to optimize the layout by adjusting component placement, adding more thermal vias, or integrating heat sinks in areas with high heat concentration.

By using thermal models, engineers can test various design scenarios to predict the thermal performance of the final PCB. These simulations reduce the likelihood of overheating issues, enabling designers to make informed decisions about material choice, cooling methods, and overall design layout. Early detection of heat issues saves both time and cost, ensuring a more reliable final product.

Material Selection for Improved Cooling

High-Tg Laminates vs. Standard FR-4

High-Tg laminates are advanced materials used in PCBs that can withstand higher temperatures compared to standard FR-4 (a commonly used PCB material). The key difference between these two materials lies in their glass transition temperature (Tg). High-Tg laminates have a higher Tg, meaning they can tolerate more heat before the material starts to soften or lose its structural integrity.

Choosing high-Tg laminates can enhance the temperature tolerance of a PCB, especially in high-power applications where heat is a constant concern. These materials improve long-term device reliability, reducing the risk of component failure due to thermal stress. While high-Tg laminates are more expensive than standard FR-4, they offer better performance in demanding environments, making them ideal for high-performance electronics like servers, automotive systems, or military equipment.

Thick Copper Layers and Conformal Coatings

Thicker copper layers are highly effective for managing heat in PCBs. Using copper layers that are thicker than the standard 1 oz/ft² (the typical thickness for many PCBs) allows for better heat distribution, reducing temperature build-up. Thick copper layers also help in reducing electrical resistance, which further enhances thermal performance, particularly in high-current applications like power supplies or LED drivers.

Conformal coatings are protective layers applied to PCBs to shield them from moisture, dust, and corrosive environments. These coatings also offer thermal protection, helping maintain the integrity of components under high heat conditions. Conformal coatings are especially valuable in outdoor electronics or harsh industrial environments where dust, moisture, and heat exposure could otherwise damage the PCB.

Polyimide Substrates and Metal Core PCBs

For high-temperature environments, polyimide substrates are a durable and reliable option. Polyimide is a heat-resistant material that can withstand temperatures well beyond the capabilities of FR-4, making it ideal for aerospace, automotive, and military applications. Polyimide’s superior thermal stability ensures that the PCB remains operational even under extreme conditions.

Metal-core PCBs are another excellent choice for managing heat in demanding applications. These PCBs feature a metal base, typically aluminum, which acts as a heat sink to quickly transfer heat away from the components. Metal-core PCBs are particularly beneficial in LED lighting and power electronics where high heat dissipation is critical. The metal core enhances the PCB's thermal conductivity and prevents the board from warping or bending under high heat stress.

Heat Management Techniques for Specific Applications

Small vs. Large Devices: Cooling Considerations

The cooling requirements for small devices like household electronics, smartphones, and LED lights differ significantly from large, high-power systems such as servers, gaming PCs, and industrial machinery. In small devices, the heat generated is typically low, allowing for passive cooling methods like heatsinks and phase change materials. Compact designs with fewer components also make heat dissipation easier without complex cooling systems.

For larger devices, where heat generation is much higher, active cooling methods like fans, heat pipes, and liquid cooling systems become necessary. The larger the device, the more heat it generates, and as a result, cooling solutions must be scaled accordingly. Engineers must carefully design these systems to ensure that heat is efficiently removed from the device, preventing damage to sensitive components and improving overall performance.

Cooling in Harsh Environments

In extreme heat or challenging environments, such as outdoor electronics or equipment used in high-temperature industrial settings, specialized materials and designs are required. In these environments, standard PCB materials may not provide sufficient heat resistance. High-temperature substrates, like polyimide, and metal-core PCBs are ideal for such conditions.

Furthermore, conformal coatings are often used in these applications to protect the PCB from moisture and dust, which can exacerbate heat retention and accelerate component failure. For example, in automotive electronics or military applications, where extreme temperatures and exposure to dirt and chemicals are common, selecting the right materials and coatings is critical to ensure the PCB continues to function reliably over time.

Advanced Cooling Technologies and Trends

Emerging Cooling Technologies for PCBs

Graphene and Carbon Nanotubes

In recent years, graphene and carbon nanotubes have emerged as potential game-changers in PCB cooling technology. These materials are incredibly lightweight and strong, with outstanding thermal conductivity. Graphene, for example, can conduct heat better than copper, which is traditionally used for heat management in PCBs. This means graphene can potentially replace or enhance the performance of existing materials in heat dissipation.

Using graphene and carbon nanotubes in PCBs could lead to devices that run cooler and more efficiently, especially in high-power applications like computers, mobile devices, or electric vehicles. These materials can also be integrated into PCB traces or heat spreaders to ensure faster heat transfer across the entire board. As these materials are still being researched and tested, their potential for the future of advanced thermal management in PCBs is significant.

Real-world example: In smartphones or laptops, where heat is generated by processors and graphics cards, using graphene could allow for faster, more efficient cooling, enabling devices to stay slimmer without compromising on performance.

Self-Healing Materials

Another exciting development in PCB cooling is the use of self-healing materials, particularly self-healing polymers. These materials can repair themselves when damaged, such as when cracks or gaps form in the PCB due to thermal expansion. In the context of PCB cooling, these polymers can be integrated into the board to repair damage caused by heat stress, ensuring the PCB’s integrity remains intact.

In high-reliability applications, such as aerospace or medical devices, where failure due to overheating can be catastrophic, self-healing materials offer a promising solution. They can automatically restore the functionality of the PCB by healing cracks or gaps that form from temperature fluctuations, reducing the need for manual repair or replacement.

Example: A self-healing PCB in a drone might continue to operate safely even after exposure to high temperatures, as the material repairs itself, ensuring minimal downtime.

Innovations in Thermal Simulation Software

AI and Machine Learning for Thermal Design

Artificial Intelligence (AI) and Machine Learning (ML) are rapidly transforming the way PCB designs are optimized for thermal management. AI-driven thermal simulations help engineers predict how heat will flow through a PCB, enabling them to identify hot spots early in the design process. By using AI, the design can be automatically adjusted to ensure more efficient cooling methods, such as placement of components or adjustment of thermal vias.

Machine learning algorithms can analyze large amounts of thermal data from past designs and learn which configurations work best for different types of devices. Over time, these systems can improve the accuracy of predictions, reducing the need for trial and error and speeding up the design process. AI-enhanced simulations allow engineers to explore multiple cooling strategies and optimize PCB designs based on real-time data.

The future of PCB cooling lies in the integration of these intelligent systems, which will lead to designs that are not only thermally optimized but also more energy-efficient. As AI continues to evolve, it will revolutionize how thermal management is approached in complex electronic devices, making them more reliable and longer-lasting.

Example: In high-performance gaming PCs, AI could be used to optimize the placement of cooling fans and thermal vias, ensuring the system remains cool even during intense use, without the need for bulky, noisy cooling solutions.

The Future of PCB Cooling with Intelligent Systems

Looking ahead, the integration of intelligent systems in PCB cooling design will continue to evolve. With advancements in AI, machine learning, and even quantum computing, PCB designs will become more adaptive, self-optimizing, and able to respond to thermal stress dynamically. Devices may use real-time data to adjust cooling mechanisms based on current conditions, creating a highly efficient, self-regulating cooling system.

For example, smartphones might feature adaptive cooling systems that increase fan speed or activate liquid cooling only when the device is under heavy use, reducing power consumption and noise during light tasks. The implementation of these technologies in wearable electronics, electric vehicles, and high-performance computing could dramatically improve energy efficiency and thermal stability.

Evaluating the Cost and Effectiveness of Cooling Solutions

Comparing Passive vs. Active Cooling Costs

Cost Implications for Different Cooling Methods

When evaluating cooling solutions for PCBs, it’s important to understand the cost differences between passive cooling and active cooling systems. Passive cooling includes methods like heatsinks, thick copper layers, and thermal vias, which typically do not require any power. On the other hand, active cooling systems, such as fans, heat pipes, and liquid cooling, need electrical power and additional components, making them more expensive.

Passive cooling systems are generally more affordable upfront, as they involve simple components like metal-based heatsinks and copper traces. These solutions are ideal for devices that don’t generate excessive heat, such as household electronics or LED lights.

Active cooling methods involve added costs due to fans, pumps, or liquid cooling systems. For instance, installing liquid cooling systems involves additional components like coolant reservoirs and tubes, making the upfront cost significantly higher. These methods are necessary for high-power devices like gaming PCs, servers, or electric vehicles, where the heat generated is too high for passive methods to handle effectively.

Long-Term Cost Savings

While active cooling is more expensive at first, it can offer long-term cost benefits by preventing overheating and extending the lifespan of the device. This can result in fewer repairs and replacements over time. For instance, a high-performance server may initially cost more to cool with active methods, but by maintaining optimal temperatures, it will reduce downtime and prolong its operational life, saving money on maintenance and replacements.

Example:

For a gaming laptop, using passive cooling (e.g., heatsinks) may be sufficient in the short term. However, if the device is subject to heavy use, active cooling (fans or liquid systems) may prevent damage from heat, saving money by extending the laptop’s lifespan and reducing costly repairs in the future.

Cost-Effectiveness of Metal Core PCBs

Are Metal Core PCBs Worth the Investment?

Metal core PCBs (MCPCBs) use aluminum or copper as the base material instead of traditional FR-4 fiberglass. These metal-based PCBs provide superior thermal conductivity, making them ideal for applications that generate significant heat. However, the cost of using metal core materials is generally higher than standard PCB materials.

Pros: Metal core PCBs are excellent at dissipating heat and preventing board warping caused by thermal expansion. This is particularly useful in devices such as LED lighting, power supplies, and automotive electronics, where managing heat is crucial. MCPCBs provide enhanced reliability and longevity due to their efficient thermal management.

Cons: The main downside is the higher manufacturing cost due to the material and processing required to fabricate MCPCBs. The metal layers and specialized designs needed for MCPCBs contribute to a higher initial cost compared to standard PCBs.

Case Studies Demonstrating Cost vs. Benefits

Let’s look at two examples where metal core PCBs might or might not be worth the investment:

1. LED Lighting Applications

In high-power LED lights, where excessive heat can shorten the lifespan of the components, using metal core PCBs ensures that the heat is quickly dissipated, preventing overheating. The increased upfront cost of the MCPCB is justified by the reduced risk of failure and longer lifespan of the LED system. Over time, the lower maintenance and longer usage of the system will offset the higher initial costs.

2. Consumer Electronics (Smartphones)

For consumer devices like smartphones, the cost of metal core PCBs may not always be justified. These devices typically use FR-4 or similar materials as they generate less heat and rely on passive cooling methods (such as heatsinks or copper traces). The additional cost of using metal core PCBs could make the product unnecessarily expensive without providing significant cooling benefits.

Example:

In electric vehicle (EV) systems, where power electronics like inverters generate significant heat, the use of metal core PCBs ensures efficient heat dissipation. The added cost of MCPCBs is outweighed by the longer lifespan of the vehicle's power system and fewer maintenance needs.

The Impact of Effective Cooling on Device Lifespan and Performance

How Cooling Affects Component Reliability

Heat and Component Aging

Heat has a direct impact on the reliability of electronic components. Over time, temperature fluctuations cause stress on materials like solder joints, capacitors, and microprocessors, leading to deterioration. High temperatures can accelerate aging by causing expansion and contraction in the components, which weakens their structural integrity. For example, solder joints—which connect components to the PCB—can crack or even break due to thermal cycling (the repeated heating and cooling of the board). This can lead to poor electrical connections, or even device failure.

Solder Joints: Repeated heating and cooling cycles cause the material to expand and contract, weakening the joints. Over time, this leads to poor connections, signal loss, or complete failure of the component.

Capacitors: Capacitors can dry out or degrade faster when exposed to high temperatures. This leads to voltage instability and potential component failure.

Microprocessors: Excessive heat reduces the lifespan of microprocessors by causing internal damage and decreasing their processing speed over time.

Examples of Common PCB Failures Caused by Inadequate Cooling

Inadequate cooling can result in several types of failures, including:

1. Thermal Fatigue: Repeated heating and cooling can lead to cracks in solder joints due to thermal expansion and contraction. This can result in intermittent failures or permanent damage to the PCB.

2. Warping: Excessive heat can cause the PCB itself to warp or bend, distorting the layout of the components and potentially damaging the circuitry.

3. Component Degradation: Components such as capacitors or resistors degrade faster when exposed to high temperatures. This can result in slower performance, loss of efficiency, or complete failure of the component.

By ensuring effective cooling, these issues can be minimized, leading to more reliable and durable electronics.

Cooling and System Efficiency

Effective cooling plays a critical role in maintaining the efficiency of electronic devices over time. It ensures that heat-sensitive components stay within their optimal operating temperature ranges, preventing thermal damage and improving system reliability.

Improved Performance: By preventing overheating, proper cooling ensures that the device functions at peak performance. For example, cooling systems prevent CPU throttling in computers, ensuring the processor runs at full speed without performance drops due to heat.

Reduced Repairs and Downtime: Devices with proper cooling systems experience fewer thermal failures, reducing the need for repairs and minimizing downtime. This is especially critical in industries where continuous operation is essential, such as in medical devices or server farms.

Longer Lifespan: Consistent cooling helps extend the useful life of components, reducing the frequency of replacements and enhancing overall cost-effectiveness.

In essence, the better the cooling system, the longer the device's lifespan and the more efficient it remains throughout its use.

Real-World Examples of PCB Cooling Solutions

Case Studies of High-Performance Devices

Various industries rely heavily on effective PCB cooling to ensure that their devices run smoothly over time. Below are some real-world examples:

1. Consumer Electronics:

In smartphones, laptops, and gaming consoles, effective cooling is essential to ensure high performance. Overheating can cause slow performance, reduced battery life, or even shutdowns. To manage this, manufacturers use advanced thermal management solutions like heat pipes, copper heat sinks, and liquid cooling. For instance, high-end gaming laptops use thermal solutions that ensure the CPU and GPU remain cool, even during long gaming sessions, ensuring optimal performance.

2. Medical Devices:

In medical electronics, such as MRI machines, pacemakers, and diagnostic equipment, heat management is crucial to maintain the device's accuracy and reliability. Proper PCB cooling in these devices ensures that they operate within specified tolerances and reduces the likelihood of failure during critical procedures. Technologies like metal core PCBs are commonly used in these systems to maintain a stable temperature and ensure patient safety.

3. Automotive:

In electric vehicles (EVs) and automotive control systems, high-performance electronics generate a lot of heat. For example, power inverters and battery management systems need efficient cooling to prevent overheating, which could lead to damage or performance degradation. Metal core PCBs and liquid cooling systems are used in automotive applications to ensure the proper functioning of these critical systems. This cooling ensures that the vehicle’s electronics operate smoothly, enhancing vehicle efficiency and safety.

How Proper PCB Cooling Led to Improved Product Reliability and Market Success

When companies implement effective PCB cooling solutions, it leads to improved product performance and market success:

In the smartphone industry, advanced cooling technologies allowed companies like Apple and Samsung to maintain high processing power while keeping devices slim and lightweight. This has played a significant role in their market success, as users expect performance without sacrificing portability.

In the medical device sector, proper PCB cooling not only ensures device reliability but also enhances patient safety. For instance, MRI machines equipped with efficient cooling systems experience fewer failures, leading to greater customer satisfaction and reduced repair costs.

In automotive applications, thermal management solutions in electric vehicles help reduce risks associated with battery overheating. As a result, these systems perform reliably, increasing consumer confidence in electric vehicles.

These examples show how the right cooling solutions can elevate product reliability, reduce operational costs, and contribute to a company’s competitive advantage.

Conclusion

Effective PCB cooling is essential for ensuring the longevity and reliability of electronic devices. As heat is a primary cause of failure, it is crucial to implement proper cooling systems to prevent overheating, reduce the risk of malfunctions, and extend the lifespan of components. The choice of cooling methods—whether passive techniques like heatsinks or active solutions like fans and liquid cooling—plays a key role in mitigating heat-related failures. Materials like thermal vias, metal core PCBs, and phase change materials contribute significantly to efficient heat dissipation, ensuring optimal performance.

Looking ahead, the importance of advanced cooling technologies will only grow as electronics become more powerful and compact. Innovations such as graphene, carbon nanotubes, and self-healing materials offer exciting possibilities for even more effective thermal management in future devices. As industries continue to push the boundaries of performance, the need for innovative cooling solutions will be essential for maintaining device reliability and efficiency.

If you have further questions or want to learn more about PCB solutions, feel free to reach out to PCBMASTER. As an experienced PCB supplier, we are here to provide you with expert advice and tailored solutions to meet your needs.

FAQs

What happens if a PCB doesn’t have proper cooling?

If a PCB doesn't have proper cooling, several risks arise. Overheating is the primary concern, as excessive heat can cause components to fail. High temperatures can damage solder joints, warp the PCB, and weaken electrical connections, leading to sudden malfunctions. Without efficient heat management, devices become unreliable, often resulting in a shortened lifespan of both the PCB and the overall device. In the worst cases, failure to cool a PCB properly can lead to permanent damage, necessitating costly repairs or replacements.

How do engineers determine which cooling method is right for a PCB?

Engineers consider several factors when selecting the right cooling method for a PCB. First, the amount of heat the device generates is critical. High-power devices such as computers or power tools generate more heat and require more robust cooling systems. Second, the size of the device plays a role—smaller devices may have limited space for cooling solutions, necessitating more compact methods. Lastly, budget constraints are always a factor, as some cooling methods like liquid cooling systems are more expensive than passive solutions. Engineers weigh these factors to choose the most suitable, cost-effective method that ensures optimal thermal management without compromising device performance.

Why is the placement of components critical in PCB cooling?

Strategic component placement is crucial in preventing heat buildup and enhancing overall thermal efficiency. Components that generate significant heat, such as power transistors, should be placed away from heat-sensitive parts, like microprocessors and capacitors. This helps avoid localized overheating, ensuring even temperature distribution across the board. Additionally, proper spacing between components allows for better airflow and heat dissipation. Aligning components effectively and using thermal vias to direct heat away from sensitive areas further improve the PCB's heat management, preventing failures and maintaining reliable performance.

Can the addition of more cooling fans solve overheating issues?

Simply adding more cooling fans may not always solve overheating problems. While fans improve airflow and can help dissipate heat, excessive fans can lead to noise, higher power consumption, and may not effectively cool the entire PCB. An integrated, balanced cooling system is far more effective. Engineers often use a combination of passive and active cooling methods, such as heatsinks, thermal vias, and properly positioned fans, to create a comprehensive solution. Optimizing airflow and ensuring that cooling methods complement each other is essential for long-term thermal efficiency and device reliability.

What is the advantage of using metal-core PCBs in high-power applications?

Metal-core PCBs are highly effective in high-power applications due to their superior thermal conductivity. The metal core, typically made of aluminum, helps to quickly dissipate heat away from critical components. This reduces the risk of overheating and prevents the PCB from warping under high temperatures. The metal layer also enhances the overall structural integrity of the PCB, making it more durable in demanding environments. For high-power devices, such as power supplies and LED lighting, metal-core PCBs ensure better heat management, improved reliability, and longer-lasting performance.