Box Build Printed Circuit Board Assembly Services: Complete Solutions for Your Projects

In today’s fast-paced electronics industry, bringing a product from concept to market requires more than just designing a circuit board. Companies need solutions that integrate every component, every wire, and every enclosure into a fully functional system—reliably and efficiently. Box build PCB assembly services have emerged as the answer, offering a seamless path from individual parts to complete, ready-to-use electronic products. Whether for complex industrial machinery, consumer gadgets, or cutting-edge IoT devices, these services are transforming how products are manufactured, tested, and delivered.

Introduction to Box Build PCB Assembly Services

Definition and Overview

Box build PCB assembly, often referred to as “system assembly” or “turnkey assembly,” is a comprehensive process that goes beyond standard printed circuit board (PCB) assembly. While traditional PCB assembly focuses on soldering components onto a bare board, box build services integrate all necessary parts—including PCBs, wiring harnesses, enclosures, connectors, and mechanical components—into a fully functional electronic system.

In simple terms, a box build service delivers a complete, ready-to-use product rather than just the circuit board. For example, a medical device manufacturer might receive a fully assembled diagnostic unit with its PCB, sensors, housing, and connectors already installed, ready for testing or shipping. Similarly, consumer electronics companies rely on box build services to receive finished devices rather than handling the labor-intensive process of assembly in-house.

The main difference between standard PCB assembly and box build lies in scope and integration. Standard assembly stops at the populated PCB; box build extends to system integration, enclosure assembly, wiring, and sometimes even final testing. Turnkey solutions—where the manufacturer handles every step from sourcing components to full assembly—are a common form of box build, providing businesses with convenience, reduced risk, and faster time-to-market.

Importance in Modern Electronics

Box build PCB assembly plays a critical role in today’s electronics industry by simplifying complex manufacturing processes. By combining multiple assembly steps into one coordinated service, companies can reduce production complexity, avoid errors during manual integration, and streamline logistics.

For OEMs (Original Equipment Manufacturers) and startups, this means focusing more on design and innovation while leaving labor-intensive assembly tasks to specialized service providers. Startups, for instance, can bring a prototype to market without investing in large-scale assembly facilities. Similarly, industrial machinery companies can rely on box build services to manage intricate systems with numerous interconnected components, ensuring consistent quality and reliability.

Consider the difference between consumer electronics and industrial equipment. A smartphone assembly requires precise integration of tiny PCBs, connectors, and housing into a sleek device, while industrial machinery may involve larger boards, heavy-duty connectors, and robust enclosures. In both cases, box build services provide a turnkey solution that ensures each system functions correctly upon delivery, minimizing post-assembly errors and accelerating deployment.

Components of Box Build PCB Assembly

Printed Circuit Boards (PCBs)

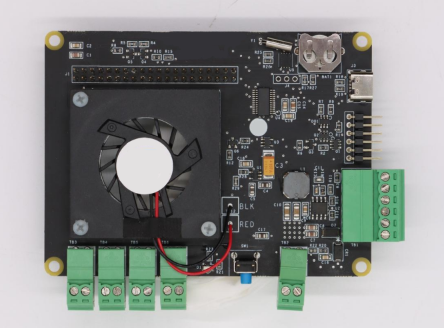

The PCB is the foundation of any electronic system in a box build assembly. PCBs can come in several types: rigid, flexible, and rigid-flex. Rigid PCBs are the most common and provide a stable platform for standard electronics. Flexible PCBs can bend or fold, making them ideal for compact devices or applications with moving parts. Rigid-flex PCBs combine both characteristics, offering the structural stability of rigid boards with the flexibility where needed.

Materials also play a critical role in performance. FR4 is widely used for general-purpose electronics, while high-Tg materials withstand higher temperatures in industrial applications. Metal-core PCBs provide excellent heat dissipation for high-power devices. Choosing the right PCB type and material impacts the assembly process, affecting component placement, soldering methods, and overall product durability. For example, flexible PCBs may require specialized handling during enclosure integration, while metal-core PCBs may influence thermal management in the final product.

Electronic Components

Electronic components form the functional heart of a box build assembly. These include surface-mount devices (SMD) and through-hole components. SMD components are mounted directly onto the PCB surface and are suitable for compact, high-density designs. Through-hole components, which require leads to pass through the PCB, provide stronger mechanical connections for high-stress applications.

Modern assemblies often integrate microcontrollers, sensors, connectors, and communication modules to enable advanced functionality. For instance, in an IoT device, the PCB may include a microcontroller for processing, sensors to capture environmental data, and connectors for power and network connectivity. Proper component selection and placement ensure the final product performs reliably and efficiently, reducing the need for post-assembly adjustments.

Enclosures and Mechanical Parts

Enclosures and mechanical parts are essential for protecting electronics and ensuring proper assembly. This includes housing, brackets, connectors, and fasteners. The design of the enclosure can significantly impact the assembly workflow. For example, tight-fitting housings require precise PCB placement, accurate alignment of connectors, and careful routing of wiring harnesses.

A typical step-by-step integration looks like this:

1. Place and secure the PCB within the enclosure.

2. Attach wiring harnesses and connect modules or subassemblies.

3. Mount brackets or fasteners to stabilize components.

4. Ensure connectors align with external interfaces.

5. Close the enclosure and verify that all mechanical and electrical connections are secure.

Proper coordination between PCB design, component layout, and enclosure specifications ensures a smooth assembly process, minimizes errors, and results in a reliable final product.

Key Steps in Box Build PCB Assembly Process

Design and Prototyping

The first step in any box build PCB assembly is design verification and prototyping. This begins with confirming that the schematic and PCB layout accurately reflect the intended design. Engineers check component placement, trace routing, and layer stack-up to ensure signal integrity and mechanical compatibility.

Once the PCB design is validated, a prototype is assembled to test functionality. Prototype testing includes verifying electrical connections, checking signal performance, and ensuring the device operates under expected conditions. For example, an IoT sensor prototype might undergo temperature and connectivity tests to confirm reliability before scaling up production. Early prototyping helps identify design issues, reducing costly errors during full-scale assembly.

Component Sourcing and Procurement

After design validation, components must be sourced from reliable suppliers. Choosing suppliers with proven quality and consistent delivery reduces the risk of defective parts or delays.

Managing lead times and supply chain risks is crucial. Components with long lead times or high demand can impact production schedules. A practical approach is to maintain a preferred supplier list, use verified distributors, and have backup options for critical parts. For example, if a microcontroller faces shortages, having an alternative from a certified supplier ensures the assembly line continues without interruption.

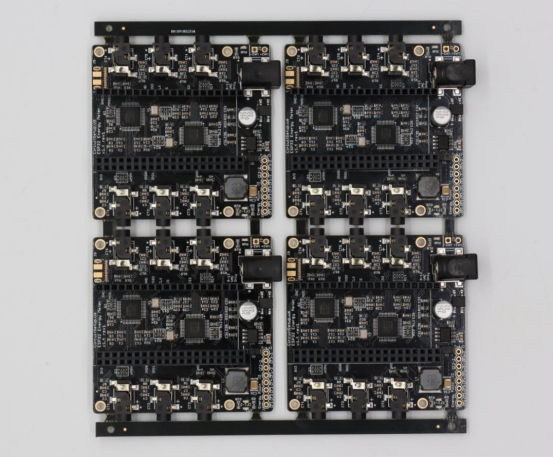

PCB Assembly

PCB assembly is the stage where design meets reality. It typically involves both surface-mount (SMT) and through-hole assembly processes. Surface-mount assembly places tiny components on the board surface with precision soldering, while through-hole assembly ensures mechanical stability for heavier components.

Quality control checkpoints are integrated throughout this stage. Common checks include solder joint inspections, automated optical inspection (AOI), and verifying component orientation. These measures reduce defects and ensure the PCB meets design specifications before system integration.

System Integration

System integration is the core of box build assembly, combining all components into a fully functional system.

Steps include:

1. Mount the assembled PCB into the enclosure securely.

2. Connect wiring harnesses and ensure proper routing to avoid interference.

3. Attach connectors and fasteners according to mechanical design.

4. Integrate subassemblies or modules, ensuring alignment and mechanical stability.

5. Perform preliminary operational checks to confirm everything is connected correctly.

Proper system integration ensures the final product is reliable, compact, and ready for functional testing.

Testing and Quality Assurance

The final step is comprehensive testing and quality assurance. This includes in-circuit testing (ICT) to verify electrical continuity and functionality, as well as full functional testing to simulate real-world operation.

Compliance with standards such as CE, UL, and RoHS is verified to ensure the product meets regulatory requirements. For example, a complex industrial controller might undergo step-by-step testing: power-up checks, signal verification, load testing, and final environmental stress testing. Documenting these tests ensures traceability and product reliability.

Selecting the Right Box Build PCB Assembly Partner

Capabilities to Look For

When choosing a box build PCB assembly partner, it’s important to assess their technical capabilities. A qualified partner should handle multi-layer PCB assembly, advanced components such as microcontrollers and sensors, and full system integration including wiring, connectors, and mechanical assembly.

Look for providers offering turnkey services, where they manage the entire process—from component sourcing to enclosure assembly and final testing. For example, a partner capable of integrating a multi-layer PCB into a compact IoT device, complete with connectors, housing, and functional testing, simplifies the supply chain and reduces potential errors. Ensuring the partner has experience with both small-scale prototypes and high-volume production increases confidence in their adaptability.

Certifications and Standards

Certifications are a key indicator of quality and reliability. Trusted assembly partners often comply with ISO standards, IPC standards, UL, and RoHS regulations.

These certifications ensure that the assembly processes meet industry benchmarks for quality, safety, and environmental compliance. For instance, ISO 9001 demonstrates a consistent quality management system, while IPC-A-610 ensures electronic assemblies meet industry-accepted workmanship standards. Working with a certified partner reduces the risk of defects, ensures regulatory compliance, and provides peace of mind for both OEMs and end-users.

Cost, Lead Time, and Scalability

Evaluating cost, lead time, and scalability is essential when selecting a partner. Compare quotes and service levels carefully, considering not only price but also included services such as testing, enclosure integration, and post-assembly support.

Scalability is another critical factor. A strong partner can handle small prototype runs for early-stage product development and seamlessly scale to mass production without compromising quality. For example, a startup may initially require a batch of 50 units but later need thousands of devices for market launch; choosing a partner capable of supporting both ensures continuity and reduces the need to switch suppliers.

For companies seeking a reliable and experienced box build PCB assembly partner, PCBMASTER stands out as a top choice. With expertise in high-performance multi-layer PCB assembly, turnkey integration, advanced component handling, and rigorous quality standards, PCBMASTER enables businesses to streamline production, ensure compliance, and bring products to market efficiently, whether for prototypes or large-scale manufacturing.

Common Challenges and Solutions

Component Shortages

One of the most frequent challenges in box build PCB assembly is component shortages. These occur when critical parts are unavailable due to high demand, supply chain disruptions, or obsolescence.

To manage this, companies should implement BOM (Bill of Materials) flexibility. This means maintaining alternative components that are compatible in function, size, and electrical characteristics. For example, if a specific microcontroller faces a long lead time, a certified equivalent from another supplier can be substituted without delaying production. Alternate sourcing strategies include dual-sourcing key components, working with multiple distributors, or keeping safety stock for critical parts. These approaches help maintain production continuity and reduce project risk.

Design Compatibility Issues

Design compatibility issues often arise when the PCB, components, or enclosure do not align correctly. Common problems include improper component spacing, connector misalignment, or enclosure fit conflicts.

Resolving these issues requires early verification during the design phase and close collaboration between design engineers and assembly teams. Tools like 3D mechanical modeling, PCB layout simulation, and prototype fitting tests can identify potential conflicts before mass production. For example, adjusting trace placement or relocating connectors in the design stage can prevent mechanical interference when the PCB is installed into its enclosure.

Testing Failures

Testing failures are another common challenge in box build assembly. They can result from solder defects, incorrect component placement, wiring errors, or environmental factors such as heat or vibration.

Troubleshooting involves step-by-step identification of the root cause:

1. Conduct visual inspection to identify obvious defects.

2. Perform in-circuit testing (ICT) to verify electrical continuity and component functionality.

3. Execute functional testing to simulate real-world operation.

4. Isolate and correct defects such as cold solder joints, misaligned connectors, or wiring mistakes.

5. Re-test to confirm the issue is resolved before proceeding to final assembly.

Implementing systematic testing and troubleshooting protocols ensures reliability and reduces costly rework, particularly in complex multi-layer assemblies or industrial-grade devices.

Future Trends in Box Build PCB Assembly

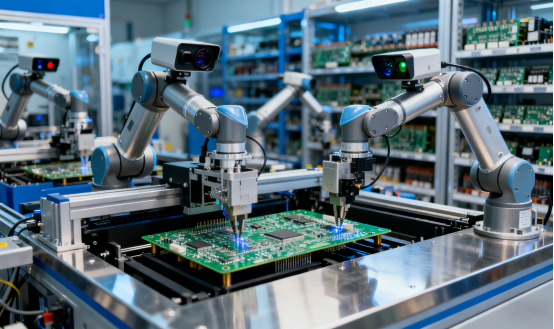

Advanced Automation and Robotics

The future of box build PCB assembly is increasingly driven by advanced automation and robotics. AI-powered assembly lines are capable of precision soldering, automated component placement, and real-time quality inspections, reducing human error and increasing production efficiency.

For example, robotic arms can assemble high-density multi-layer PCBs with consistent accuracy, while AI algorithms detect soldering defects instantly. This trend not only accelerates production but also allows manufacturers to handle complex assemblies that would be difficult or error-prone with manual labor.

Smart and IoT-Enabled Devices

As electronics become more connected and intelligent, box build assemblies face new integration challenges. IoT-enabled devices often require multiple sensors, microcontrollers, wireless modules, and real-time data processing within compact enclosures.

The trend emphasizes co-design of hardware and firmware to ensure seamless integration. For instance, assembling a smart thermostat involves precise placement of temperature sensors, Wi-Fi modules, and power management circuits, while maintaining enclosure aesthetics and thermal performance. Adapting box build processes for smart devices ensures reliability and faster time-to-market for connected products.

Sustainable Manufacturing

Sustainability is emerging as a key consideration in modern box build PCB assembly. Manufacturers are adopting green materials, recyclable enclosures, and energy-efficient processes to reduce environmental impact.

Examples include using lead-free solder, biodegradable plastics for housings, and optimizing production lines to minimize energy consumption and material waste. Companies that implement sustainable practices not only comply with regulatory standards like RoHS but also appeal to eco-conscious customers and reduce long-term operational costs.

Conclusion

Box build PCB assembly provides turnkey solutions that combine PCB assembly, component integration, enclosure installation, and final testing into a single, seamless process. This approach ensures consistent quality, reduces errors, and improves overall cost efficiency. Complex devices, from industrial controllers to compact IoT products, can be delivered fully assembled and ready for deployment, eliminating the need for multiple vendors or in-house assembly expertise. The result is faster time-to-market, fewer production delays, and a more reliable final product.

When selecting a box build partner, it is important to consider capabilities, certifications, and scalability. Choosing a provider like PCBMASTER, which specializes in high-performance PCB solutions and turnkey box build assembly, ensures access to multi-layer PCB assembly, advanced component integration, and comprehensive system-level testing. By defining project requirements, evaluating prototype and production needs, and verifying certifications such as ISO, IPC, UL, and RoHS, companies can leverage professional services to focus on design and innovation while leaving assembly and testing to experienced experts. Partnering with a trusted provider like PCBMASTER simplifies production, guarantees quality, and accelerates market readiness, turning design concepts into fully functional electronic systems efficiently and reliably.

FAQs

What is the difference between standard PCB assembly and box build assembly?

Standard PCB assembly focuses on assembling components onto a bare printed circuit board, typically stopping once the PCB is populated and soldered. Box build assembly goes a step further by integrating the assembled PCB into a complete system, including wiring, connectors, enclosures, and mechanical parts. Essentially, standard PCB assembly delivers just the board, while box build delivers a fully functional, ready-to-use electronic device.

How does box build assembly reduce manufacturing time and costs?

Box build assembly reduces manufacturing time by consolidating multiple steps into a single process, eliminating the need to coordinate different vendors for PCB assembly, wiring, enclosure integration, and testing. It also reduces costs by minimizing labor, avoiding redundant handling, and enabling bulk component sourcing. Companies receive a finished product faster and with fewer production errors, which improves efficiency and accelerates time-to-market.

What types of products benefit most from box build PCB assembly services?

Products that involve complex assemblies, multiple components, or compact enclosures benefit most from box build services. This includes industrial machinery, medical devices, IoT gadgets, consumer electronics, and automotive electronics. Essentially, any product where integrating PCBs, mechanical components, and enclosures is time-consuming or requires specialized expertise is ideal for box build assembly.

How do I ensure quality and compliance in box build assemblies?

Ensuring quality and compliance requires working with a partner that follows standardized procedures and holds relevant certifications, such as ISO 9001, IPC-A-610, UL, and RoHS. Quality is maintained through systematic inspections, in-circuit testing (ICT), functional testing, and adherence to design specifications. Early prototyping and careful verification of PCB layout, component placement, and enclosure fit also help prevent defects and ensure regulatory compliance.

Can small businesses or startups use box build services effectively?

Yes, small businesses and startups can benefit significantly from box build services. By outsourcing assembly, wiring, enclosure integration, and testing, they avoid the need to invest in expensive production facilities and specialized labor. This allows them to focus on design, innovation, and market development while receiving fully assembled, tested, and compliant products, even in small prototype runs or limited production batches.