How Mirror Aluminum PCBs Enhance Performance in Optical Modules

Optical modules play a vital role in modern communication systems, ensuring fast and reliable data transfer across networks. From telecommunications to data centers, these components manage high volumes of data, making material choices crucial for performance. Mirror aluminum PCBs are increasingly being used in optical modules for their ability to improve thermal management, signal quality, and overall durability, offering significant advantages in high-speed applications.

Introduction to Mirror Aluminum PCB in Optical Modules

Optical modules are integral to high-speed communication systems, facilitating the fast transfer of data across networks. The materials used to build these modules, such as mirror aluminum PCBs, play a crucial role in improving their performance.

What Are Optical Modules and Why They Matter?

Optical modules are small, yet essential components in modern communication systems. They are responsible for converting electrical signals into optical signals, allowing data to travel through fiber optic cables. These modules are found in various technologies, from telecommunications to cloud computing, enabling high-speed internet, voice communication, and data transmission.

As data volumes continue to grow, especially in areas like 5G networks and cloud storage, the need for fast and reliable communication has never been greater. Optical modules are designed to handle high-bandwidth data transfer with minimal delay, making them critical to maintaining the efficiency and speed of global communication networks.

Why optical modules matter:

They support high-speed data transmission over long distances.

They are key to maintaining network performance in telecommunications, internet services, and data centers.

They help ensure low latency and reduced signal degradation, essential for real-time communication applications.

The Role of Mirror Aluminum PCBs in Optical Modules

PCBs (Printed Circuit Boards) are crucial components in optical modules, providing the structural and electrical foundation for the components that make up these systems. In optical modules, the PCB connects various parts like lasers, photodetectors, and transceivers, ensuring they work together to convert and transmit data.

Mirror aluminum PCB is an advanced PCB material designed to improve the performance of optical modules. As the name suggests, mirror aluminum PCBs have a smooth, highly reflective surface that offers unique advantages in high-speed applications like optical modules.

Superior thermal conductivity: Mirror aluminum efficiently dissipates heat, which is crucial for preventing overheating in optical modules.

High reflectivity: The smooth, reflective surface reduces signal loss in optical modules by minimizing interference and improving signal clarity.

Durability and resistance to corrosion: Mirror aluminum resists oxidation and corrosion, making it ideal for use in harsh environmental conditions such as high humidity or extreme temperatures.

How Do Mirror Aluminum PCBs Improve Heat Management in Optical Modules?

Mirror aluminum PCBs improve heat management in optical modules by offering superior thermal conductivity. Unlike traditional materials like FR-4, mirror aluminum efficiently dissipates heat, preventing overheating and maintaining optimal performance in high-speed data transmission systems. This enhanced thermal performance ensures that optical modules operate reliably, even under heavy data loads, reducing the risk of signal degradation and extending the lifespan of the components.

Thermal Performance in Optical Modules

Heat dissipation is a critical factor in the performance of optical modules. Optical modules, such as those used in high-speed data transmission systems, generate significant heat during operation, especially when handling large volumes of data at high speeds. This heat must be managed effectively to prevent overheating, which could lead to signal loss, reduced efficiency, and even hardware failure.

Why heat management is important:

Prevent overheating: Excessive heat can cause thermal damage to sensitive components, leading to system failure or reduced lifespan.

Ensure consistent performance: High temperatures can increase electrical resistance, which can degrade signal quality and overall module performance.

Maintain operational stability: Proper heat management ensures that the optical module functions optimally over extended periods without unexpected downtime or performance drops.

Quantitative Comparison with Other PCB Materials

Mirror aluminum has significantly better thermal conductivity compared to traditional PCB materials. In optical modules, heat management is one of the most critical performance factors, and choosing the right material can make all the difference.

Thermal conductivity comparison:

FR-4 PCB (a commonly used PCB material) has a thermal conductivity of around 0.3-0.4 W/m·K, which means it can only dissipate heat at a moderate rate. This is acceptable for general electronic applications but not ideal for high-speed, high-power optical modules.

Mirror aluminum PCB, on the other hand, boasts thermal conductivity of around 150-200 W/m·K, which is orders of magnitude higher than FR-4. This high thermal conductivity ensures that heat is spread across the surface more efficiently, allowing the module to stay cooler even during prolonged, intensive data transfers.

Comparison Table

| Material | Thermal Conductivity (W/m·K) | Heat Dissipation Efficiency | Ideal Use Cases |

| FR-4 PCB | 0.3 - 0.4 | Moderate heat dissipation; suitable for general electronic applications. | Standard electronics, low-speed circuits, and non-demanding environments. |

| Mirror Aluminum PCB | 150 - 200 | Superior heat dissipation; ensures efficient cooling, even during high-speed, high-power operations. | High-speed, high-power optical modules, data centers, 5G networks. |

This significant difference in thermal conductivity makes mirror aluminum PCBs a far superior choice for optical modules, especially when managing heat generated from high-speed components like lasers and photodetectors.

How Do Mirror Aluminum PCBs Enhance Signal Integrity in Optical Modules?

Mirror aluminum PCBs enhance signal integrity in optical modules by effectively reducing electromagnetic interference (EMI) and minimizing signal loss. The high conductivity and smooth reflective surface of mirror aluminum help shield sensitive components from external noise, ensuring cleaner signals. Additionally, its low resistance and surface characteristics maintain high signal quality over long distances, making it ideal for high-speed, high-performance optical communication systems.

Electromagnetic Interference (EMI) Shielding

Mirror aluminum PCBs effectively reduce electromagnetic interference (EMI), ensuring cleaner signals in optical modules. EMI is a common issue in high-speed electronic systems, where unwanted electrical signals can interfere with the desired signal, leading to data corruption or performance degradation.

How does mirror aluminum reduce EMI?

Conductivity and Shielding: Mirror aluminum is a conductive material that can reflect and absorb electromagnetic waves. This property helps shield sensitive components in optical modules from external electromagnetic interference.

Reflective Surface: The smooth, highly reflective surface of mirror aluminum acts as a barrier to external EMI, preventing it from interfering with the signals inside the optical module.

Impact on system reliability and performance:

Improved Signal Quality: By blocking or reflecting EMI, mirror aluminum ensures that the signal remains clean, which is critical for maintaining high data integrity in optical communication systems.

Enhanced Reliability: With reduced interference, optical modules can operate more reliably, especially in environments with a lot of electrical noise, such as data centers or industrial settings. This leads to fewer transmission errors, longer system lifespans, and reduced maintenance costs.

Minimizing Signal Loss and Attenuation

Mirror aluminum helps minimize signal loss and attenuation in optical modules, ensuring high signal quality even over long distances. Signal loss refers to the reduction in signal strength as it travels through the optical fiber or PCB, while attenuation refers to the weakening of the signal due to resistance or other factors.

How does mirror aluminum maintain high signal quality?

Lower Resistance: Mirror aluminum has lower electrical resistance compared to other materials like FR-4. This means there’s less energy loss in the form of heat, helping preserve signal strength.

Smooth Surface for Signal Travel: The smooth and reflective surface of mirror aluminum reduces unwanted reflections, which can distort the signal. This is particularly important for high-speed data transmission, where even small disruptions can lead to significant data loss.

Benefits in high-speed optical module applications:

Long-Distance Communication: In long-distance optical communications, such as those used in telecom networks or satellite communications, signal integrity is crucial. Mirror aluminum PCBs can ensure that the signal reaches its destination with minimal degradation.

High-Speed Performance: In applications requiring precise, low-loss transmission, like 5G networks or high-frequency data center connections, mirror aluminum’s properties ensure the signal remains strong and clear throughout the transmission path, reducing the chances of data corruption.

What Are the Durability Benefits of Mirror Aluminum PCBs in Optical Modules?

Mirror aluminum PCBs provide significant durability benefits for optical modules by offering excellent resistance to corrosion, extreme temperatures, and electromagnetic interference. These properties ensure that optical modules remain reliable and efficient over time, even in harsh environmental conditions.

Resistance to Environmental Stress

Mirror aluminum PCBs are highly resistant to environmental stress, making them ideal for optical modules that need to operate in challenging conditions. The durability of mirror aluminum ensures that optical modules can maintain performance over time, even when exposed to factors like humidity, oxidation, and extreme temperatures.

How does mirror aluminum resist corrosion and environmental stress?

Corrosion Resistance: Mirror aluminum has excellent resistance to oxidation and corrosion, which are common issues for electronic components exposed to moisture, humidity, or harsh industrial environments. This is especially important in optical modules used outdoors or in areas with high humidity, where traditional materials like FR-4 might degrade over time.

Durability in Harsh Conditions: Mirror aluminum's resistance to corrosion ensures that the optical module’s components remain intact and functional, preventing costly damage or failures. In comparison, other materials may rust or degrade faster when exposed to environmental factors, leading to decreased performance or total failure of the optical module.

Ability to withstand extreme temperatures and electromagnetic environments:

High-Temperature Tolerance: Optical modules often operate in environments with wide temperature fluctuations. Mirror aluminum’s heat resistance allows it to function effectively in temperatures ranging from freezing to high heat, maintaining its integrity and avoiding performance loss.

Electromagnetic Shielding: Mirror aluminum also helps protect the optical module from electromagnetic interference (EMI) that may occur in industrial settings, where high-power equipment could cause disruptions. This shielding further enhances the module’s reliability.

Long-Term Performance

The durability of mirror aluminum PCBs directly contributes to the long-term performance and reliability of optical modules, reducing the need for frequent maintenance and extending the lifespan of the equipment. This leads to better overall cost-effectiveness for businesses and network operators.

How does mirror aluminum contribute to long-term performance?

Reduced Wear and Tear: Mirror aluminum’s corrosion resistance and high-temperature tolerance allow it to maintain its mechanical and electrical properties for extended periods. Unlike other materials that degrade due to environmental stress, mirror aluminum remains stable, keeping optical modules running smoothly for many years.

Longer Lifespan: Since mirror aluminum PCBs are less prone to environmental damage, optical modules that use this material experience fewer failures, requiring less frequent repairs or replacements. This increases the module’s lifetime and ensures consistent performance over time.

Cost-effectiveness in terms of module lifespan and operational reliability:

Reduced Maintenance Costs: The durable nature of mirror aluminum PCBs results in lower maintenance costs over the lifetime of the optical module. With fewer repairs and replacements needed, businesses can save on labor and part replacement costs.

Increased Operational Reliability: The long-term reliability of mirror aluminum PCBs enhances the overall operational efficiency of optical modules. With reduced downtime and fewer failures, optical modules can run at peak performance for extended periods, making them a wise investment for businesses looking for cost-effective solutions in high-speed communication systems.

What Should Designers Consider When Using Mirror Aluminum PCBs in Optical Modules?

Designers choosing mirror aluminum PCBs for optical modules must carefully consider various design, fabrication, and material selection factors to ensure optimal performance and reliability. By focusing on the right alloys, thicknesses, surface finishes, and cost-to-performance balance, designers can optimize heat management, signal integrity, and durability for their specific application needs.

Design and Fabrication Considerations

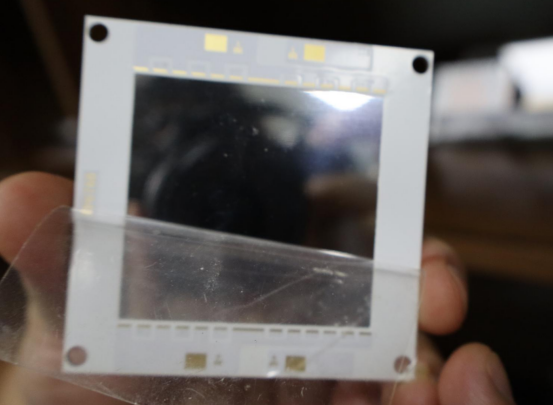

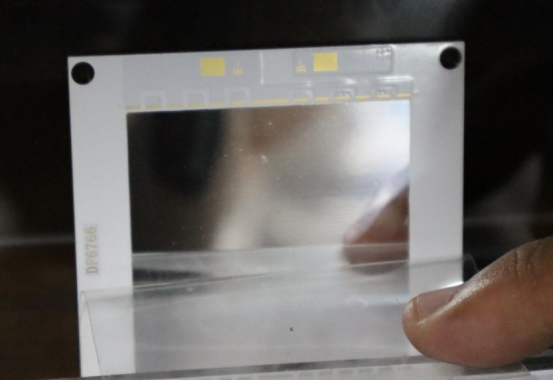

Challenges in handling and manufacturing mirror aluminum PCBs:

Precision Handling: Mirror aluminum requires careful handling during manufacturing due to its reflective surface. Any scratches or imperfections on the surface can significantly impact the signal integrity and heat dissipation capabilities. Specialized tools and techniques are often required to avoid damaging the reflective surface during cutting, drilling, or etching.

Surface Treatment: Mirror aluminum PCBs often undergo specific surface treatments to enhance corrosion resistance and thermal performance. Without proper treatment, the PCB may lose its thermal conductivity or become susceptible to environmental damage. It's crucial to ensure that the surface finish remains smooth and reflective, ensuring both heat dissipation and signal quality are maintained.

Optimal design approaches for integration into optical modules:

Component Placement: Since heat management is crucial, components that generate significant heat should be placed strategically where mirror aluminum can dissipate the heat efficiently. Designing with thermal zones in mind helps distribute heat evenly across the module.

Thermal and Signal Integrity Balance: Mirror aluminum’s high thermal conductivity can be leveraged to create a balanced design where heat dissipation doesn’t come at the cost of signal quality. By optimizing the placement of sensitive components like lasers and photodetectors, designers can prevent overheating while maintaining high signal integrity.

Material Selection within Mirror Aluminum Options

Different aluminum alloys and their specific uses:

1700AGHPSP Alloy: One of the most commonly used alloys for optical modules, 1700AGHPSP provides exceptional thermal conductivity, making it ideal for high-performance applications like telecommunications, data centers, and 5G networks. Its superior strength and corrosion resistance make it suitable for environments with high power demands and exposure to harsh conditions.

Other Alloys: There are various alloys to choose from depending on the required strength, thermal properties, and electrical conductivity. Designers should select the alloy based on the module’s operating environment—for instance, alloys with higher thermal stability may be needed for modules operating at high temperatures.

Factors like thickness, surface finish, and conductivity:

Thickness: The thickness of the PCB plays a significant role in its heat dissipation capabilities. Thicker PCBs generally offer better heat management but may add weight and space limitations. Designers must balance thermal efficiency with size constraints and weight requirements for the optical module.

Surface Finish: The surface finish impacts both signal quality and corrosion resistance. A highly polished surface improves signal integrity by reducing reflection losses and electromagnetic interference (EMI). It also improves the PCB's ability to resist moisture, dust, and other environmental factors.

Thermal and Electrical Conductivity: The higher the thermal conductivity of the alloy, the better the PCB can dissipate heat, which is especially important for high-power optical modules. The electrical conductivity of the material also affects signal quality and power distribution, so it’s crucial to select the right balance of these properties.

Balancing Cost with Performance Needs

Practical considerations for designers when weighing cost vs. performance:

Higher Initial Costs: Mirror aluminum PCBs typically have a higher initial cost than traditional materials like FR-4 due to the quality of the material and the precision required in their manufacturing. While this might make the PCB more expensive initially, the long-term benefits in terms of heat management, signal integrity, and reduced maintenance make it a cost-effective choice over time.

Cost vs. Longevity: Mirror aluminum PCBs, such as those made with 1700AGHPSP, provide longer operational lifespans and reduced failure rates. This reduces the need for frequent replacements or repairs, ultimately providing better cost-effectiveness, especially in high-performance applications like 5G networks and data centers.

When to prioritize performance:

In high-speed, high-power applications, the performance advantages of mirror aluminum—such as its superior thermal management and signal integrity—often justify the additional cost. Optical modules used in environments requiring constant, high-throughput data transmission benefit significantly from the durability and performance of mirror aluminum, especially when compared to other materials.

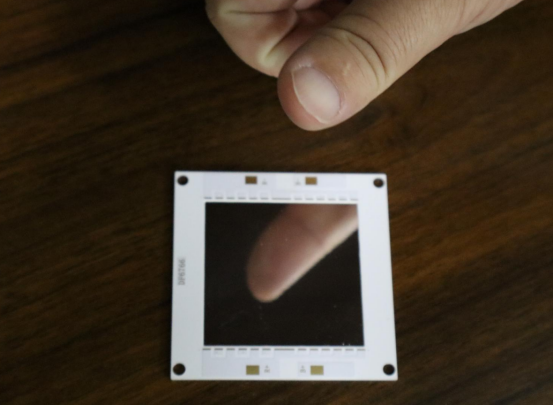

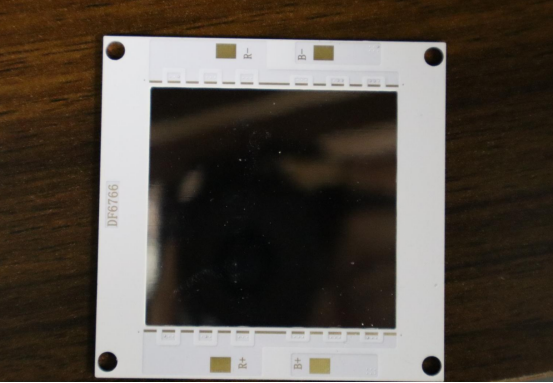

PCBMASTER's Mirror Aluminum PCB (1700AGHPSP 0.7mm) with Nickel Palladium Gold Plating

PCBMASTER offers high-performance mirror aluminum PCBs manufactured with 1700AGHPSP alloy and a 0.7mm thickness, making them an excellent choice for optical modules that demand superior thermal management, signal integrity, and durability. This PCB is designed to meet the requirements of high-speed, high-power optical modules, ensuring reliable performance in demanding environments like 5G networks, telecommunications, and data centers.

Key Features of PCBMASTER's Mirror Aluminum PCB

1700AGHPSP Alloy: The 1700AGHPSP alloy is known for its outstanding thermal conductivity, making it ideal for optical modules where heat dissipation is crucial. This high thermal conductivity helps prevent overheating, which is a common issue in high-power applications, ensuring that the optical module operates efficiently even under heavy data loads.

0.7mm Thickness: With a thickness of 0.7mm, this PCB provides the perfect balance between thermal performance and weight. The moderate thickness allows for effective heat dissipation while maintaining structural integrity and mechanical strength, ensuring long-term durability.

Nickel Palladium Gold Plating: The PCB is finished with Nickel Palladium Gold (NiPdAu) plating, which enhances both its corrosion resistance and signal integrity. This surface treatment is particularly useful in high-frequency applications like optical communication where signal loss and electromagnetic interference (EMI) need to be minimized. The gold plating also improves contact reliability, reducing the risk of signal degradation over time.

Customization Options

PCBMASTER also offers customization options to tailor the mirror aluminum PCB to specific optical module requirements. Customizations can include adjustments to thickness, surface treatments, and component placement to meet the unique needs of your application. This flexibility allows designers to balance heat management, signal integrity, and cost-effectiveness, ensuring the best performance for each optical module design.

Conclusion

Mirror aluminum PCBs offer significant advantages for optical modules, making them a key material in high-performance applications. Their superior heat management ensures that optical modules remain cool even under high power, preventing overheating and ensuring long-term stability. The effective EMI shielding provided by the smooth, reflective surface minimizes electromagnetic interference, preserving signal integrity and improving data transmission reliability. Additionally, their durability, with resistance to corrosion and extreme temperatures, makes them ideal for harsh environments, reducing maintenance costs and extending the lifespan of optical modules.

Looking ahead, advanced materials like mirror aluminum will continue to play an essential role in the evolution of optical technologies. As demands for faster, more reliable communication networks grow, the need for materials that can handle higher speeds, power, and environmental stress will only increase. Mirror aluminum PCBs are well-positioned to meet these future challenges, enabling the next generation of optical modules to operate efficiently and with greater reliability.

FAQs

What are the main advantages of using mirror aluminum PCBs in optical modules?

Mirror aluminum PCBs offer significant advantages for optical modules, particularly in the areas of heat dissipation, signal integrity, and long-term durability:

Superior Heat Dissipation: Mirror aluminum’s high thermal conductivity (150-200 W/m·K) ensures efficient heat transfer, which is crucial for high-speed, high-power optical modules. By efficiently spreading heat across the surface, the PCB prevents overheating, which is essential to maintain stable performance and prolong the life of sensitive components like lasers and photodetectors.

Signal Integrity: The smooth, reflective surface of mirror aluminum minimizes electromagnetic interference (EMI) and signal degradation, allowing for high-quality data transmission. The material’s ability to reflect and shield against EMI ensures that the signals transmitted within the optical module remain clear, reducing the likelihood of data loss or distortion.

Long-Term Durability: Mirror aluminum PCBs are corrosion-resistant, which makes them highly durable in harsh environments. They can withstand extreme temperatures, moisture, and chemical exposure, making them ideal for demanding conditions like 5G networks, data centers, and telecommunications. This durability reduces the frequency of repairs and replacements, leading to long-term cost savings.

Can mirror aluminum PCBs handle high-frequency signals effectively?

Yes, mirror aluminum PCBs are well-suited for handling high-frequency signals in optical modules. Their smooth reflective surface helps to reduce signal loss and electromagnetic interference (EMI), ensuring that high-frequency signals are transmitted with minimal degradation. This is crucial for applications such as fiber-optic communication and high-speed data transmission, where signal integrity is essential.

The thermal conductivity of mirror aluminum also plays a role in maintaining signal quality at high frequencies by preventing the overheating of components. Heat buildup can lead to signal distortion or even module failure, but mirror aluminum’s ability to dissipate heat ensures that high-frequency signals remain stable and reliable.

How does mirror aluminum’s corrosion resistance improve the lifespan of optical modules?

Mirror aluminum’s corrosion resistance significantly improves the lifespan of optical modules by protecting the PCB from environmental factors that can cause damage over time. This is particularly important in harsh environments where exposure to moisture, salt, dust, or extreme temperatures is common.

Moisture Protection: The corrosion-resistant coating on mirror aluminum prevents oxidation and rust, which could otherwise degrade the PCB and affect performance. By shielding the PCB from these elements, mirror aluminum helps maintain both thermal conductivity and electrical conductivity over time.

Longer Lifespan: In high-performance applications like data centers or telecom infrastructure, optical modules must function reliably for extended periods. Mirror aluminum’s resistance to corrosion ensures that the modules can operate effectively for years without significant degradation, reducing the need for frequent maintenance and replacement.

What challenges do designers face when integrating mirror aluminum PCBs into optical modules?

Designers face several challenges when integrating mirror aluminum PCBs into optical modules, primarily related to manufacturing complexity, material handling, and design integration:

Manufacturing Complexity: Mirror aluminum requires specialized processing techniques to maintain its smooth, reflective surface. During drilling, cutting, or etching, designers must take extra care to avoid damaging the surface, which could degrade the PCB’s performance in terms of both thermal management and signal integrity.

Material Handling: The reflective surface can be scratched or damaged during assembly if not handled properly. This necessitates the use of precise equipment and careful assembly techniques to ensure the PCB maintains its properties.

Design Integration: Because mirror aluminum offers such high thermal conductivity, designers must ensure that the module’s components are placed in such a way that heat is evenly dissipated. Improper placement could lead to thermal hotspots, which can negatively impact module performance.

Is mirror aluminum more cost-effective than traditional PCB materials for optical modules?

Mirror aluminum is generally more expensive than traditional PCB materials like FR-4 or CEM1 due to its higher material cost and manufacturing complexities. However, its long-term benefits often outweigh the initial investment:

Upfront Costs: The price of mirror aluminum PCBs is higher because of the specialized manufacturing required to maintain the smooth surface finish, along with the use of high-performance alloys like 1700AGHPSP. Additionally, the Nickel Palladium Gold (NiPdAu) plating commonly used for mirror aluminum adds to the cost.

Long-Term Savings: The long-term reliability and durability of mirror aluminum PCBs result in reduced maintenance and replacement costs. Its superior heat dissipation, signal integrity, and corrosion resistance ensure that optical modules maintain peak performance for longer, which can be more cost-effective in the long run. This is particularly true for high-performance applications in telecom, 5G, and data centers, where module downtime can lead to significant financial losses.

Performance vs. Cost Trade-Off: Designers must weigh the initial cost against the performance and lifespan benefits. For critical applications that require high thermal management, low signal loss, and reliability in harsh environments, the investment in mirror aluminum often proves to be worth the cost.

Author Bio

Hi, I'm Carol, the Overseas Marketing Manager at PCBMASTER, where I focus on expanding international markets and researching PCB and PCBA solutions. Since 2020, I've been deeply involved in helping our company collaborate with global clients, addressing their technical and production needs in the PCB and PCBA sectors. Over these years, I've gained extensive experience and developed a deeper understanding of industry trends, challenges, and technological innovations.

Outside of work, I'm passionate about writing and enjoy sharing industry insights, market developments, and practical tips through my blog. I hope my posts can help you better understand the PCB and PCBA industries and maybe even offer some valuable takeaways. Of course, if you have any thoughts or questions, feel free to leave a comment below—I'd love to hear from you and discuss further!