High-Quality Medical PCB Assembly Services for Healthcare Electronics

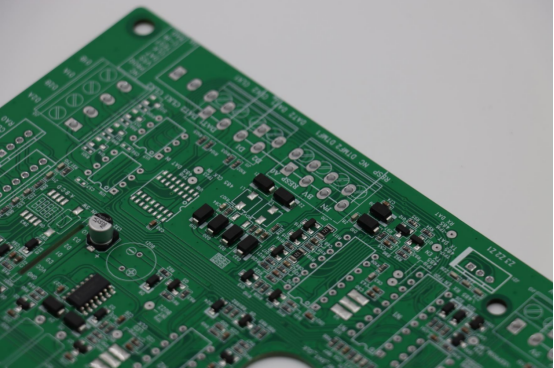

Every medical device you see – from an ECG machine to a small wearable heart monitor – has one thing in common: a printed circuit board (PCB). The PCB is like the “nervous system” of the device. It connects all the electronic parts and makes sure they talk to each other. Without a good PCB, the device simply will not work.

This is why PCB quality is so important. In healthcare, there is no room for failure. If a PCB stops working, a blood test machine might give the wrong result, or a ventilator might stop at a critical moment. A high-quality PCB assembly makes sure every signal is clean, every connection is strong, and every board can run 24/7 without problems.

High-quality assembly also follows strict safety rules, like ISO 13485 and FDA requirements. These rules make sure the boards are safe for patients, free of dangerous materials, and reliable for years of use.

Why High-Quality Medical PCB Assembly Is So Important

When it comes to healthcare, there is no second chance. Medical devices must work perfectly, every time. A single failure could delay treatment or harm a patient. This is why choosing high-quality medical PCB assembly is one of the most important decisions for any healthcare electronics project.

1. Reliability – It Must Work 24/7

Medical devices are not like ordinary gadgets. They often run day and night without a break. Imagine a ventilator in an ICU or a patient monitor in an emergency room — these devices cannot stop even for a minute.

A well-assembled PCB has strong solder joints, precise component placement, and a design that resists heat and vibration. High-quality boards go through stress testing and inspection to ensure they will not fail under real hospital conditions.

This level of reliability saves lives because doctors and nurses can trust the machine to work whenever they need it.

2. Accuracy and Safety – Clean Signals Save Lives

In medicine, even a small error can cause a big problem. PCBs in devices like ECG machines, insulin pumps, or MRI scanners must carry very clean and precise signals.

Poor assembly can create tiny gaps, loose connections, or extra electrical noise. This may lead to wrong readings, delayed diagnoses, or even dangerous mistakes in treatment.

High-quality PCB assembly uses precise soldering, controlled impedance, and careful layout to reduce noise and interference. This ensures the device gives clear, reliable data that doctors can trust, keeping patients safe.

3. Compliance and Standards – Built the Right Way

Medical electronics cannot just “work”; they must also meet strict safety and quality rules. Following recognized standards ensures that PCBs are safe, reliable, and suitable for life-critical applications.

High-quality medical PCB assembly providers follow these key standards:

l ISO 13485 – Requires a controlled manufacturing process with full traceability to ensure consistent quality.

l IPC-610 Class 3 – Defines the highest quality level for soldering and assembly, specifically designed for life-critical products.

l FDA Requirements – Ensure that boards are made from safe materials, fully tested, and approved for use in medical devices.

By following these standards, manufacturers can guarantee that each PCB is safe for hospital use, performs reliably, and passes regulatory audits without issues.

Core Services of Medical PCB Assembly

High-quality medical PCB assembly involves multiple critical services. Each step ensures the boards are reliable, safe, and ready for use in healthcare devices.

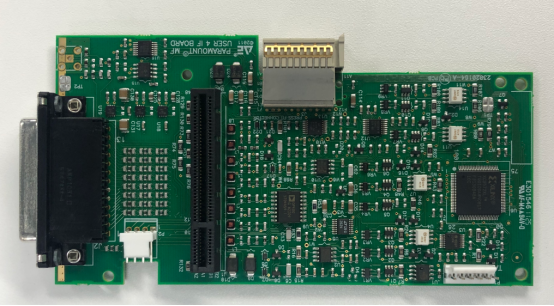

1. PCB Design and Design-for-Manufacturing (DFM) Optimization

The assembly process starts with careful PCB design. Good design ensures the board can be manufactured and assembled without errors. Design-for-Manufacturing (DFM) reviews check that components are placed logically, traces are routed efficiently, and soldering will be reliable.

DFM optimization helps prevent common problems, such as solder bridges, short circuits, or misaligned components. It also improves production yield, reduces defects, and ensures the final device operates correctly from the first unit.

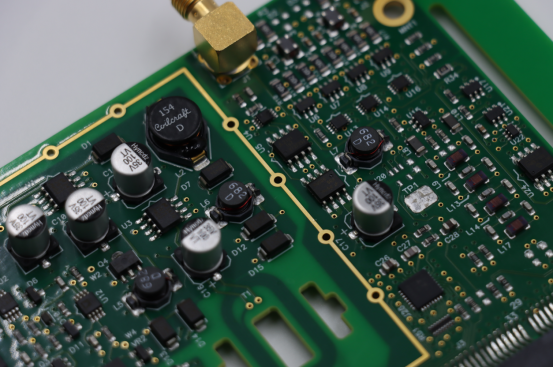

2. High-Precision SMT Placement and THT Insertion

l Surface Mount Technology (SMT) places tiny electronic parts on the board with extreme accuracy. This is important because many medical components are very small and sensitive. Incorrect placement can cause malfunctions or signal errors.

l Through-Hole Technology (THT) inserts components with leads through drilled holes. These connections are mechanically stronger and are often used for components that handle higher current or mechanical stress. Combining precise SMT and THT assembly ensures every component is secure, functional, and reliable for continuous operation.

3. Multi-Layer and HDI PCB Assembly Capability

Modern medical devices often use multi-layer or High-Density Interconnect (HDI) boards to save space and support complex circuits. These boards have many layers of connections stacked together.

Proper assembly ensures all layers are correctly aligned, vias (vertical connections between layers) are reliable, and high-speed signals are transmitted with minimal interference. This is critical for devices like MRI machines, diagnostic analyzers, or patient monitoring systems, where accuracy and signal integrity directly affect performance.

4. Lead-Free Soldering and RoHS-Compliant Material Selection

Safety is paramount in medical electronics. Lead-free soldering and RoHS-compliant components are used to avoid toxic materials.

Careful selection of materials ensures the board is durable, resistant to corrosion, and safe for long-term use in medical environments. Following these standards also ensures the devices meet international regulations and can be approved for hospital and clinical use.

5. Automated Optical Inspection (AOI), X-Ray, and Functional Testing

After assembly, each PCB undergoes rigorous inspection and testing.

l Automated Optical Inspection (AOI) scans the board for missing, misaligned, or poorly soldered components.

l X-Ray inspection checks hidden connections, such as under Ball Grid Array (BGA) components, which cannot be seen with the naked eye.

l Functional testing simulates real device operation, verifying that each circuit performs correctly under normal working conditions.

This comprehensive inspection process ensures that every medical PCB is reliable, safe, and ready for critical applications where failure is not an option.

Medical Electronics Applications for High-Quality PCB Assembly

High-quality medical PCB assembly is used in a wide range of healthcare devices. These devices rely on precise, reliable, and safe PCBs to function correctly and deliver accurate results for patient care.

1. Diagnostic Equipment

PCBs are the heart of many diagnostic devices, including ECG machines, ultrasound (B-mode) machines, and blood analyzers.

l In ECG machines, the PCB processes tiny electrical signals from the heart and converts them into readable waveforms. Accurate PCB assembly ensures that even the smallest signal is detected without noise or interference.

l Ultrasound machines use PCBs to control the probe, process echo signals, and create images of internal organs. High-quality assembly guarantees that the timing, signal processing, and display are precise, producing clear and reliable images for diagnosis.

l Blood analyzers rely on PCBs to manage sensors, pumps, and data-processing circuits. Proper PCB assembly ensures consistent sample handling and accurate chemical analysis, which is critical for patient safety.

2. Therapeutic Devices

Treatment devices, such as ventilators, infusion pumps, and laser therapy machines, depend on highly reliable PCBs.

l Ventilators require PCBs to control airflow, maintain pressure, and trigger alarms when necessary. A well-assembled PCB ensures continuous, accurate operation, even under heavy use in ICU settings.

l Infusion pumps use PCBs to deliver precise medication doses. Any error could be dangerous, so high-quality assembly is essential to maintain dosage accuracy and device reliability.

l Laser therapy machines rely on PCBs to control timing, energy output, and safety interlocks. Accurate PCB assembly ensures the laser operates safely and consistently during treatments.

3. Wearable Medical Monitoring Devices

Wearable devices, such as heart rate monitors, continuous glucose monitors, and smart health patches, require small, compact, and highly reliable PCBs.

These PCBs handle real-time data collection, signal processing, and wireless communication with smartphones or medical systems. High-quality assembly ensures the device works accurately over long periods and remains energy-efficient.

Durable, well-assembled PCBs in wearables also resist shocks, sweat, and temperature changes, which is essential for devices worn daily by patients.

4. Medical Imaging and Data Recording Systems

Advanced imaging systems and data recorders depend on multi-layer, high-speed PCBs for complex operations.

MRI and CT scanners use PCBs to process high-frequency signals and create detailed images of the body. Precise PCB assembly ensures that signals are transmitted accurately, and the images are clear and reliable.

Data recording systems, including patient monitors and electronic health record devices, use PCBs to store and transmit critical patient information. High-quality PCB assembly guarantees secure, fast, and accurate data handling, supporting informed medical decisions.

How to Choose a High-Quality Medical PCB Assembly Supplier

Choosing the right PCB assembly supplier is one of the most important decisions for medical device makers. The supplier’s capabilities affect the safety, reliability, and performance of the final device. High-quality suppliers offer not only reliable PCBs but also support throughout the entire product lifecycle.

1. Certifications and Compliance

Top medical PCB suppliers follow strict international standards to guarantee quality and safety. For example:

l ISO 13485 – This certification ensures that the supplier has a medical device quality management system. It covers design, production, and inspection processes to make sure every board meets the requirements for life-critical applications.

l ISO 9001 – A general quality management certification that demonstrates the supplier can maintain consistent quality across all products and services.

l UL Approval – Ensures that the boards meet safety standards for electrical and environmental compliance.

By working with a certified supplier, medical device makers can be confident that their PCBs meet regulatory requirements and will perform safely in hospitals and clinics.

2. Advanced Manufacturing Capability

High-quality suppliers have advanced assembly skills and equipment. This includes:

l Precision soldering – Ensures every component is attached correctly and can handle vibration, heat, and continuous operation.

l BGA (Ball Grid Array) rework – Allows correction of complex, hidden solder joints, which is crucial for high-density boards.

l Micro and fine-pitch component assembly – Supports modern medical devices with very small or closely spaced parts.

These capabilities are essential for building PCBs that are reliable, compact, and suitable for sophisticated medical electronics. Skilled assembly reduces defects and ensures long-term device performance.

3. Strict Quality Control

Reliable suppliers implement thorough quality checks at every stage. This includes:

l 100% electrical testing – Every board is tested to confirm that circuits are functioning correctly.

l Visual inspection and AOI (Automated Optical Inspection) – Detects misaligned, missing, or damaged components.

l Full traceability – Materials and processes are recorded so any issue can be traced and corrected quickly.

High-quality quality control prevents failures, ensures patient safety, and gives manufacturers confidence in their devices.

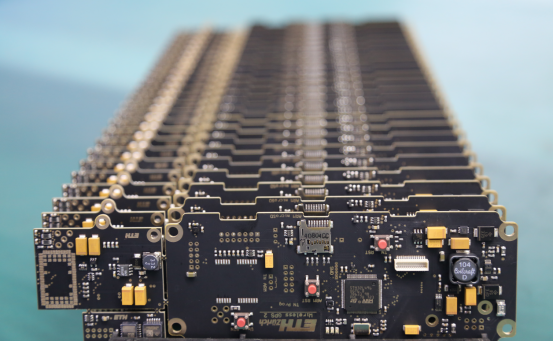

4. Delivery Capability and Flexibility

Medical device projects often require tight schedules and fast response. A strong supplier can provide:

l Rapid prototyping – Quick turnaround for new designs or small batches, allowing testing and validation.

l Scalable production – Smooth transition from prototypes to large-scale manufacturing without quality loss.

l Reliable supply chain management – Ensures timely delivery of boards and components, reducing project delays.

Flexible delivery and dependable logistics help medical companies bring devices to market faster and maintain consistent production.

5. After-Sales and Technical Support

A high-quality supplier provides ongoing support even after the boards are delivered. This includes:

l Technical guidance – Helps optimize designs for manufacturability and future upgrades.

l Problem-solving – Rapid assistance when issues arise during assembly, testing, or operation.

l Long-term partnership – Supports lifecycle maintenance, updates, and repeat orders for consistent quality.

For example, PCB MASTER is a professional PCB supplier that serves multiple industries, including medical electronics. They combine certified processes, advanced manufacturing, strict quality control, fast delivery, and strong technical support to ensure medical devices are reliable, safe, and compliant with standards.

Conclusion

High-quality PCB assembly is the foundation of reliable and safe medical devices. Every ECG machine, ventilator, wearable monitor, or imaging system depends on well-assembled PCBs to perform accurately and consistently. Poor assembly can lead to device failure, incorrect readings, or even risks to patient safety.

Choosing a professional medical PCB assembly service ensures that your devices meet strict safety standards, function reliably, and deliver accurate results. Experts like PCB MASTER provide certified processes, advanced assembly capabilities, and thorough quality control to support medical device manufacturers at every stage.

If you are developing medical electronics, don’t take chances. Contact a trusted PCB assembly provider to ensure your products are safe, compliant, and ready for the demands of healthcare. Your patients and your reputation depend on it.

FAQs

1. What is the difference between a regular PCB and a medical PCB?

A regular PCB is designed for general electronics like computers, TVs, or household devices. A medical PCB is specially made for healthcare devices, so it must meet much higher safety and reliability standards. Medical PCBs often have more precise circuits, use safer materials, and go through stricter testing to make sure they work correctly all the time. This is because even a small mistake can affect patient health, so quality is critical.

2. Why are multi-layer and HDI PCBs important in modern medical devices?

Multi-layer and High-Density Interconnect (HDI) PCBs allow more circuits to fit into a smaller space. This is important for medical devices because many are compact, portable, or wearable. These boards can carry more signals, maintain clean data transmission, and support complex functions without increasing device size. Proper assembly ensures all layers connect correctly, which keeps the device accurate and reliable.

3. How does testing and inspection improve the safety of medical PCBs?

Testing and inspection help catch problems before the board is used in a device. For example, Automated Optical Inspection (AOI) finds missing or misaligned components, while X-Ray checks hidden solder joints under parts like BGAs. Functional testing simulates real device operation to make sure circuits work correctly. This careful checking prevents failures, ensures patient safety, and guarantees the device performs exactly as intended.