Choosing the Best Materials for RF Circuit Boards: Impact on Signal Integrity

RF (Radio Frequency) circuit boards are essential for high-frequency applications like 5G networks, satellite communications, and radar systems. These boards are designed to handle the transmission of RF signals, ensuring clear, stable communication without signal loss or distortion.

As the demand for faster and more reliable communication grows, particularly with the rise of 5G, RF circuit boards have become increasingly crucial. The global RF circuit board market is expected to grow from $6.28 billion in 2025 to $10.9 billion by 2035, with a 5.7% compound annual growth rate (CAGR), reflecting the increasing reliance on advanced RF technologies.

The performance of these boards depends heavily on material selection. The right materials ensure high signal integrity by minimizing loss and interference, making material choice a critical factor in optimizing the performance of modern RF applications.

The Impact of Material Selection on RF Circuit Board Performance

Electrical Properties and Signal Transmission

The electrical properties of materials used in RF circuit boards are critical to signal transmission. Two key properties—dielectric constant (Dk) and loss factor (Df)—play a direct role in determining how efficiently signals travel through the material.

Dielectric constant (Dk) measures how well a material can store electrical energy in an electric field. A material with a high Dk will slow down the signal more than one with a low Dk. This affects signal propagation speed, which is especially important for high-speed communication systems such as 5G and satellite communications.

Loss factor (Df) refers to how much signal energy is lost as it travels through a material. A lower Df means less energy loss, resulting in a cleaner, stronger signal. High Df materials lead to signal attenuation, which can degrade performance, especially in high-frequency applications.

The combination of Dk and Df directly influences the signal stability of RF circuit boards. In high-frequency applications like 5G, satellite communications, and radar systems, maintaining a stable signal without significant distortion or loss is critical for reliable performance.

High-Frequency Signal Transmission and Material Interaction

In high-frequency applications, signals interact with the material's electrical properties, leading to potential issues such as signal distortion, reflection, and attenuation.

Signal distortion occurs when the material’s Dk causes the signal to travel at inconsistent speeds, leading to errors in data transmission.

Reflection happens when the signal encounters a material with poor impedance matching, causing part of the signal to bounce back toward the source instead of continuing along the transmission path. This can result in signal loss or even interference with other signals.

Attenuation refers to the gradual loss of signal strength as it travels through the material. Materials with high Df contribute to greater attenuation, which compromises signal integrity, particularly in long-distance transmissions or high-frequency signals.

For example, in 5G networks, which rely on millimeter-wave frequencies, materials with low Dk and Df are essential to minimize signal degradation over short distances, ensuring high-speed data transmission with minimal interference. Conversely, in satellite communication systems, where signals travel over much longer distances, signal integrity is especially crucial, and materials with low loss and stable dielectric properties are chosen to prevent signal loss and delay.

The Importance of Low Dielectric Constant (Dk) and Low Loss Factor (Df)

Advantages and Applications of Low Dielectric Constant (Dk) Materials

Low dielectric constant (Dk) materials are essential in RF circuit boards, especially for high-speed signal transmission. Dk represents a material's ability to store electrical energy in an electric field. Lower Dk values result in faster signal propagation speeds. This is crucial for modern communication systems, such as 5G networks, where speed and efficiency are paramount.

Materials with low Dk reduce the signal delay, allowing signals to travel more quickly through the circuit. For example, in high-frequency applications like radar systems or 5G, faster signal transmission directly correlates with better system performance and reduced latency. This makes low Dk materials essential for any high-speed or long-range RF communication, where speed is a critical factor in maintaining data integrity.

Impact of Low Loss Factor (Df) Materials

Low loss factor (Df) is another key material property that affects RF signal integrity. Df measures how much signal energy is lost as it travels through a material. Materials with low Df help reduce signal attenuation, which is the gradual loss of signal strength over distance. In RF applications, especially at high frequencies, signal attenuation can be a significant problem.

By using low Df materials, RF circuit boards can maintain signal strength and clarity, even over longer distances. This is particularly important in satellite communications, where signals must travel vast distances without losing power. In high-frequency applications like 5G, the impact of signal loss is amplified, so minimizing Df is critical to ensuring high-quality communication with minimal interference.

Relationship Between Df and Signal Integrity in High-Frequency Applications

In high-frequency systems, such as 5G and satellite communications, signal integrity is highly sensitive to losses. A high Df material results in higher signal loss and distortion, leading to a degradation in the overall system performance. Low Df materials help maintain signal integrity by minimizing these losses, ensuring that the transmitted signal remains as close to its original form as possible.

For example, in 5G communications, where millimeter-wave frequencies are used, the need for low Dk and Df materials is even more pressing. The higher frequencies involved in 5G are more susceptible to attenuation and interference, so using materials with low loss properties ensures that the signals travel over long distances without degradation.

Examples: Rogers RO4350B and PTFE-Based Materials

Rogers RO4350B is a widely used material with a Dk of 3.66 and a very low Df of 0.004. These properties make it ideal for high-frequency applications where performance, signal integrity, and reliability are crucial. RO4350B is commonly used in 5G network equipment, satellite communications, and radar systems, where minimal signal loss and high-speed transmission are required.

On the other hand, PTFE-based materials (Polytetrafluoroethylene) have an exceptionally low Dk and Df, making them ideal for extreme environments like aerospace and military applications. These materials perform well under high temperatures and in environments subject to high levels of electromagnetic interference. PTFE-based materials are often used in military-grade RF circuits and space communications, where maximum signal integrity and minimal loss are non-negotiable.

Analysis of Common RF Circuit Board Materials

Rogers RO4350B Material Analysis

Advantages:

Rogers RO4350B is a high-performance RF circuit board material known for its excellent dielectric properties, making it ideal for high-frequency applications. It offers a low dielectric constant (Dk) of 3.66 and a low loss factor (Df) of 0.004, ensuring minimal signal loss and high signal integrity. This makes it suitable for 5G networks, satellite communications, and radar systems, where maintaining strong, stable signals is essential.

Another advantage of Rogers RO4350B is its environmental stability. The material is resistant to moisture absorption and temperature fluctuations, which is critical for reliability in demanding environments, such as aerospace and industrial applications.

Disadvantages:

The primary drawback of Rogers RO4350B is its cost. Compared to standard PCB materials, such as FR4, Rogers RO4350B is significantly more expensive. This makes it less suitable for cost-sensitive projects or applications where budget is a primary concern. Additionally, while it performs exceptionally well in high-frequency environments, the higher cost may make it less appealing for everyday, low-cost applications.

PTFE-Based Materials Analysis

Advantages:

PTFE (Polytetrafluoroethylene)-based materials are known for their extremely low Dk and Df, making them ideal for ultra-high-frequency signal transmission. With Dk values as low as 2.1 and Df as low as 0.001, PTFE-based materials offer minimal signal loss and superior performance at microwave frequencies and high-speed data transfer. This makes them ideal for critical applications such as military-grade RF circuits, aerospace, and satellite communications, where signal integrity and performance are non-negotiable.

Another advantage of PTFE-based materials is their excellent thermal stability and chemical resistance, making them capable of withstanding extreme environmental conditions, including high temperatures and exposure to harsh chemicals. These properties make PTFE the material of choice for applications in harsh environments, like space and defense systems.

Disadvantages:

However, PTFE-based materials come with some significant downsides. The manufacturing complexity of PTFE materials is higher, requiring specialized processing techniques. This can lead to higher production costs and may limit its applicability in less demanding or cost-sensitive projects. Additionally, PTFE’s poor machinability makes it more difficult to work with compared to other materials, further increasing processing times and costs. As a result, PTFE is best suited for specialized applications rather than general-purpose use.

Other Common RF Materials

FR4 Material:

FR4 is the most commonly used PCB material, known for its low cost and availability. While it is widely used in consumer electronics, FR4 is not ideal for high-frequency applications due to its relatively high Dk (around 4.5) and Df (typically around 0.02). As a result, it suffers from greater signal loss and poor performance in high-speed, high-frequency systems. Despite these limitations, FR4 remains popular for low-cost, low-frequency applications, where signal integrity is not as critical.

Aluminum Nitride (AlN):

Aluminum Nitride is a high-performance material often used in high-power RF applications due to its exceptional thermal conductivity and electrical insulation properties. It is ideal for environments that require efficient heat dissipation, such as high-power RF circuits or 5G base stations. However, AlN is more challenging to process and has a higher manufacturing cost than other materials like FR4. Due to these factors, it is typically used in specialized applications where performance outweighs cost concerns.

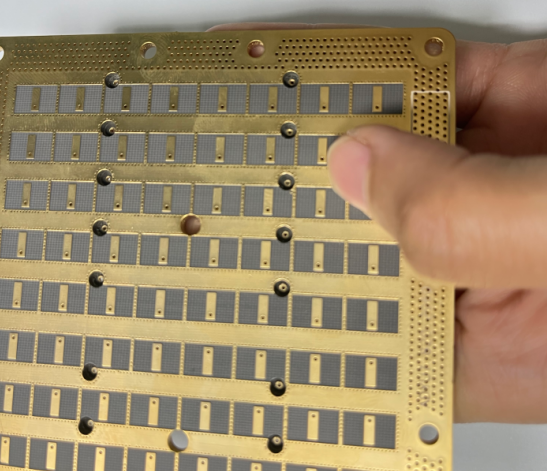

The Impact of Copper Foil Quality on RF Circuit Board Performance

Impact of Copper Foil Smoothness on Signal Transmission

The smoothness of copper foil used in RF circuit boards plays a significant role in signal transmission quality, especially at high frequencies. Smooth copper foil helps minimize signal loss, particularly by reducing skin effect losses. Skin effect occurs when high-frequency signals tend to travel along the surface of the conductor, rather than through its entire cross-section. With rougher copper surfaces, the signal encounters more resistance, leading to higher attenuation.

In contrast, smooth copper foil allows the signal to travel more efficiently along the conductor’s surface, reducing losses. This becomes crucial in high-frequency RF applications, such as 5G, where signal loss can degrade the performance of the system. By using higher-quality copper foil, designers can maintain a stable signal, which is essential for fast and reliable communication.

Moreover, the smoothness of copper is important when designing fine trace lines. Microstrip lines and thin traces are commonly used in RF circuit boards for precise signal routing. If the copper foil is rough, it can cause irregularities in the traces, leading to signal instability. Higher-quality copper ensures that microstrips and fine traces can maintain consistent impedance, thereby preserving signal integrity.

The Effect of Copper Foil Roughness on Impedance Matching

Copper foil roughness can significantly affect the impedance matching of RF circuit boards, which is crucial for signal quality and performance. Impedance matching ensures that the signal flows smoothly without reflections, reducing loss and improving overall transmission efficiency. If the copper foil is too rough, it can cause variations in the trace width and the dielectric material, leading to impedance mismatch. This mismatch results in signal reflection, distortion, and even complete loss of the signal in severe cases.

For optimal performance, it is essential to control copper foil roughness within tight limits, such as ±10%. This ensures consistent trace width and maintains precise impedance values, which are vital for high-frequency applications like 5G, radar systems, and satellite communications. When impedance is mismatched, part of the signal reflects back toward the source, which can create interference and degrade the overall system performance.

By using high-quality copper foil with controlled roughness, designers can ensure that the signal travels through the circuit board without significant loss or distortion. Proper impedance matching is particularly important in high-speed communication systems, where even minor variations can lead to significant performance issues.

Real-World Application: Improving Signal Integrity

In 5G networks, where high-frequency signals are transmitted over short and long distances, maintaining signal integrity is crucial. A smooth copper foil can dramatically improve the efficiency of the transmission by minimizing attenuation and ensuring stable signal propagation. For instance, 5G base stations rely on precise impedance matching to ensure that the signals are accurately transmitted to mobile devices. High-quality copper foil plays a central role in achieving this.

Similarly, in satellite communication systems, where signals travel over vast distances, any loss or distortion can severely impact data transmission. The copper foil's smoothness and roughness control directly influence the quality of the received signals, making it vital for high-frequency RF circuit boards used in these systems to employ superior copper materials.

Copper Foil Selection and Material Optimization in Practical RF Circuit Board Design

How to Choose the Right Copper Foil Quality

Selecting the appropriate copper foil for RF circuit boards depends on several factors, including the frequency range, signal strength, and cost requirements of the application.

Frequency Range: For high-frequency RF applications (such as 5G or satellite communication systems), it is crucial to choose copper foil with high smoothness and low roughness. This helps minimize signal loss and impedance mismatch, ensuring reliable signal transmission. For lower-frequency applications, the copper foil’s smoothness may be less critical.

Signal Strength: Stronger signals require higher-quality copper to maintain signal integrity, as higher-quality copper foil reduces attenuation and signal distortion. For weaker signal applications, such as low-power RF systems, less expensive copper foil may suffice without significantly compromising performance.

Cost Considerations: Higher-quality copper foil comes with increased costs due to its manufacturing complexity and superior performance characteristics. In applications where cost is a limiting factor, a balance must be struck between performance and budget. For instance, FR4 boards with standard copper foil might be suitable for less demanding applications, while high-performance systems may require Rogers or PTFE-based materials.

In practice, selecting the appropriate copper foil involves balancing these factors to optimize both performance and cost-effectiveness.

How to Balance Copper Foil Quality with Cost to Optimize RF Circuit Board Performance

Balancing copper foil quality with cost is a common challenge in RF circuit board design. High-quality copper foil offers better signal transmission, lower attenuation, and more consistent impedance matching, but these benefits come at a higher cost. The key to optimizing performance while staying within budget lies in understanding the specific requirements of the application.

High-Performance Applications: In high-frequency and high-power systems like 5G, military communications, or aerospace applications, investing in premium copper foil is often essential to ensure signal integrity and reliable performance. The higher cost is justified by the need for stable signals and minimal interference.

Cost-Sensitive Applications: For less demanding applications, such as low-frequency consumer electronics, opting for standard copper foil can reduce costs without significantly impacting performance. In these cases, the trade-off between cost and performance may be more acceptable.

Ultimately, copper foil quality must be chosen based on the specific needs of the project, weighing the importance of signal integrity against budget constraints.

Methods to Optimize Copper Foil Surface Smoothness

The surface smoothness of copper foil plays a crucial role in signal quality and transmission performance, especially at high frequencies. Copper foils with smoother surfaces reduce skin effect losses and minimize signal distortion. Here are methods for optimizing copper foil smoothness:

Electrolytic Copper Foil: Electrolytic copper foil is one of the most commonly used types, produced through an electrolytic process that provides a relatively smooth surface. While it offers good performance for most RF applications, its surface smoothness can be enhanced further by applying additional treatments. The smoother the copper surface, the better the signal transmission, especially in high-frequency systems like 5G.

Electroplated Gold Copper Foil: Gold-plated copper foil (often referred to as electroplated gold copper foil) offers superior smoothness and corrosion resistance compared to traditional copper foil. The gold layer provides an extremely smooth surface, reducing signal attenuation and improving overall signal quality. This type of copper foil is particularly beneficial for high-performance RF and microwave circuits, where every bit of signal integrity matters.

ENIG (Electroless Nickel Immersion Gold) Surface Treatment: One of the most effective methods for improving copper foil smoothness is the use of ENIG (Electroless Nickel Immersion Gold) surface treatment. ENIG involves depositing a thin layer of nickel followed by a layer of gold on the copper surface. This treatment not only improves smoothness but also increases durability, prevents corrosion, and provides excellent solderability. ENIG-treated copper foil is commonly used in high-frequency RF designs where both performance and long-term reliability are essential.

In RF circuit board design, applying ENIG surface treatment to copper foil helps maintain high signal integrity by minimizing surface imperfections, making it ideal for advanced RF applications like 5G base stations, satellite communications, and high-speed data transmission systems.

Conclusion

In conclusion, the selection of materials is crucial to the performance of RF circuit boards. Low dielectric constant (Dk) and low loss factor (Df) materials are essential for minimizing signal losses and maintaining signal integrity, especially in high-frequency applications like 5G and satellite communications. Choosing the right materials ensures stable transmission, reduced interference, and efficient power usage.

As high-frequency technologies continue to evolve, innovations in PCB materials will play a key role in improving performance. PCBMASTER, a leader in RF PCB design and manufacturing, is committed to meeting these needs. They provide high-performance solutions using advanced substrates, such as Rogers RO4350B, and ensure precise signal transmission and impedance control. With expertise in material selection and process optimization, PCBMASTER supports clients across industries like 5G, aerospace, and automotive, delivering reliable, high-quality RF circuit boards for cutting-edge applications.

FAQs

Why are Low Dielectric Constant (Dk) and Low Loss Factor (Df) Critical for RF Circuit Boards?

Low Dk and low Df materials are essential for maintaining signal integrity in RF circuit boards, especially in high-frequency applications. A low Dk reduces the signal delay by allowing the signal to travel faster through the material, which is crucial for high-speed data transmission in 5G and other wireless technologies. Similarly, a low Df minimizes the signal attenuation, ensuring that signals are transmitted with minimal energy loss. This reduces power consumption and enhances the overall performance and reliability of the RF circuit. In high-frequency applications, maintaining the quality of the signal is essential, and low Dk and Df materials help preserve the integrity of the signal over long distances, reducing distortion, reflection, and signal degradation.

What are the Selection Criteria for Rogers RO4350B vs. PTFE Materials?

Choosing between Rogers RO4350B and PTFE materials depends on specific application requirements such as frequency, environmental conditions, and cost considerations. Rogers RO4350B is a popular choice for high-frequency applications due to its excellent dielectric properties (Dk = 3.66, Df = 0.004), making it suitable for high-speed signal transmission. It offers good thermal stability and low signal loss, but it can be more expensive, making it suitable for performance-driven applications like RF communication, satellite systems, and 5G infrastructure.

On the other hand, PTFE (Polytetrafluoroethylene)-based materials are chosen for applications requiring extremely low Dk and Df values, especially in industries like aerospace and military, where performance and environmental resistance are critical. PTFE offers lower dielectric constants (around 2.2–2.5) and very low loss factors, making it ideal for ultra-high-frequency systems. However, PTFE materials are more difficult to process and have higher manufacturing costs compared to Rogers RO4350B. Thus, PTFE is typically selected for applications where signal integrity is paramount and budget is less of a concern.

How Does Copper Foil Smoothness Affect RF Circuit Board Performance?

The smoothness of copper foil plays a critical role in the signal transmission performance of RF circuit boards. Smooth copper foil reduces signal loss, especially in high-frequency applications, by minimizing skin effect loss. The skin effect is a phenomenon where high-frequency signals tend to travel along the surface of the conductor, and any surface roughness can impede this efficient signal flow. High-quality, smooth copper foil ensures that the signals are transmitted more efficiently with minimal resistance, reducing overall signal attenuation. Achieving a smoother copper surface, through processes like electrolytic copper plating or gold-plating, helps in maintaining signal integrity, enabling faster and more reliable transmission in high-frequency RF designs.

How Does Copper Foil Roughness Affect Impedance Matching?

Copper foil roughness directly impacts impedance matching, which is crucial for ensuring stable signal transmission and minimizing signal reflections. When copper foil is rough, it increases the surface irregularities, leading to inconsistent impedance characteristics. This irregularity can cause signal reflection, where the reflected signals interfere with the transmitted signals, resulting in degraded signal quality and instability. Precise control of copper foil roughness, typically within ±10% of the target roughness, helps achieve accurate impedance matching, ensuring that the signal experiences minimal loss and distortion during transmission. Maintaining stable impedance is especially important in RF circuits, as any mismatch can lead to increased reflection, power loss, and overall system inefficiency.