Low Cost PCB Assembly: How to Save Money Without Sacrificing Quality

In the world of electronics manufacturing, balancing performance and cost is a constant challenge. Low cost PCB assembly doesn’t have to mean cutting corners—it’s about making smart choices at every stage of production. From design optimization to material selection and supplier collaboration, small decisions can lead to significant savings while maintaining high standards of quality and reliability.

Understanding how to reduce assembly costs without compromising quality can give your business a true competitive edge in an increasingly price-sensitive market.

Introduction to Low Cost PCB Assembly

What Is Low Cost PCB Assembly?

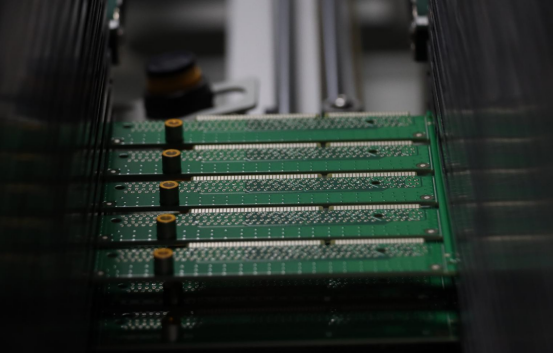

PCB assembly (PCBA) is the process of soldering and mounting electronic components onto a printed circuit board (PCB) to create a functional electronic device. It involves several key steps—such as stencil printing, pick-and-place, soldering, inspection, and testing—each contributing to the final performance and reliability of the product.

In the context of electronics manufacturing, “low cost PCB assembly” refers to methods and strategies used to reduce overall production costs without lowering quality standards or reliability. The goal is to streamline processes, use cost-effective materials, and optimize design to make manufacturing more efficient.

It’s important to understand that low cost does not mean low quality. Many high-performing electronics are built using optimized, budget-conscious assembly techniques. The difference lies in how intelligently the production workflow is managed—from smart design decisions to strategic supplier partnerships.

Typical cost components in PCB assembly include:

Materials: PCB substrate, copper thickness, solder paste, and components.

Labor: Skilled technicians, assembly setup, and handling.

Equipment: Automated pick-and-place machines, reflow ovens, and inspection systems.

Testing and Quality Control: AOI, functional testing, and final inspection.

By analyzing each of these elements, manufacturers can identify areas for savings while keeping product performance and consistency intact.

Why Cost Optimization Matters in PCB Manufacturing

Cost optimization in PCB manufacturing has become increasingly important due to the rising demand for affordable, high-performance electronics. Companies across industries face intense pressure to shorten development cycles and reduce time-to-market while staying within tight budgets.

For startups and small to medium-sized OEMs, every production dollar matters. Efficient PCB assembly can determine whether a product reaches profitability or becomes unsustainable. For small batch or prototype runs, smart cost control allows teams to iterate designs faster and allocate more resources toward innovation rather than manufacturing overhead.

There is a direct link between design efficiency and assembly savings. A well-optimized design—using standard component sizes, simplified layouts, and manufacturable geometries—reduces assembly time, minimizes errors, and lowers rework rates. For example, designing a board with fewer layer transitions or avoiding unnecessary vias can significantly reduce both fabrication and assembly expenses.

Ultimately, cost optimization is not about spending less—it’s about spending smarter. When implemented strategically, it helps manufacturers achieve reliable performance, shorter lead times, and a sustainable competitive advantage in a cost-sensitive market.

Key Factors That Influence PCB Assembly Costs

PCB Design Complexity

The complexity of a PCB design is one of the most significant factors that determine assembly cost. A simple 2-layer board is much easier and cheaper to manufacture than a complex 8-layer multilayer PCB. More layers require additional lamination cycles, precise registration, and longer production time—all of which increase expenses.

Other design parameters, such as trace width, spacing, and via density, also have a direct impact. For instance, narrow traces and microvias demand advanced fabrication techniques and higher precision equipment.

To manage costs effectively, engineers can:

Simplify routing to minimize unnecessary vias and layer transitions.

Use standard trace widths compatible with most assembly lines.

Group components logically to reduce long interconnections.

By designing with manufacturability in mind, you reduce both material waste and assembly time, leading to lower overall production costs.

Component Sourcing

Component selection and sourcing play a critical role in total PCB assembly cost. The price of components can fluctuate due to availability, demand, and sourcing channels. Using readily available, in-stock parts is typically much more cost-effective than ordering custom or long lead-time components.

For example, choosing a resistor or capacitor from a verified local distributor can cut lead times and shipping costs, while sourcing from a global supplier may reduce unit cost but increase logistics complexity.

To control costs:

Prioritize components with stable supply and multiple sourcing options.

Avoid parts nearing end-of-life (EOL) or those with limited availability.

Collaborate with your assembly partner for BOM optimization and cost comparison.

Smart sourcing doesn’t just reduce immediate expenses—it also helps prevent production delays and redesign costs caused by part shortages.

Assembly Process Type

The assembly process type—whether Surface Mount Technology (SMT), through-hole, or mixed assembly—has a major influence on both cost and efficiency.

SMT assembly uses automated pick-and-place machines to mount components directly on the board’s surface. This method is faster, more precise, and ideal for high-volume production.

Through-hole assembly, which requires inserting component leads into drilled holes and soldering them manually or by wave soldering, tends to be more labor-intensive and costly.

Mixed assembly combines both techniques and is typically used when certain components, like connectors or transformers, cannot be mounted via SMT alone.

Automation plays a key role in cost reduction. Automated pick-and-place systems significantly reduce labor hours and improve consistency, while automated reflow soldering offers uniform results and less rework compared to manual soldering.

In short, the more automation involved in the assembly line, the lower the per-unit cost—especially for medium and high-volume orders.

Testing and Quality Assurance

Testing and quality control are essential to ensure that every assembled PCB performs as intended. However, they also represent a meaningful portion of total assembly cost.

Common testing methods include:

AOI (Automated Optical Inspection): Detects soldering and component placement issues.

X-ray inspection: Used for checking hidden joints, especially in BGAs or multilayer boards.

ICT (In-Circuit Testing): Verifies electrical performance and circuit integrity.

While it may be tempting to skip or reduce testing to save money, this often leads to higher long-term costs due to defective boards, rework, or warranty claims. Instead of eliminating testing, manufacturers should optimize test coverage—focusing on high-risk areas while maintaining essential inspection steps.

Balancing testing depth and production efficiency ensures that cost savings don’t come at the expense of reliability or customer satisfaction.

Strategies to Reduce PCB Assembly Costs Without Losing Quality

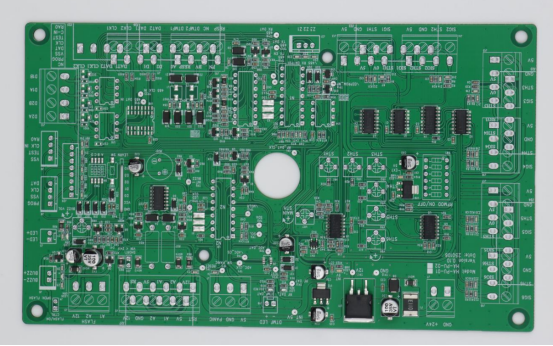

Optimize Design for Manufacturability (DFM)

Design for Manufacturability (DFM) means designing a PCB so it can be produced efficiently, with minimal rework and scrap. A DFM-optimized layout helps manufacturers assemble boards faster and with fewer errors, which directly reduces overall cost.

For example, standardizing hole sizes and pad spacing allows your board to fit seamlessly into common assembly processes. This eliminates the need for special tooling or manual adjustments, both of which increase labor costs.

Even small design decisions—like grouping components logically, maintaining consistent trace widths, or aligning parts for automated pick-and-place—can significantly improve yield rates.

Before sending your design for production, it’s wise to perform a DFM check. Many manufacturers, including online PCB services, provide free DFM tools that automatically detect potential issues such as spacing violations, missing solder masks, or incompatible footprints. Early detection prevents costly rework later in the process.

Select Cost-Effective Materials

Choosing the right PCB base material has a major impact on total assembly cost and long-term reliability. The three most common options are:

FR-4: The industry-standard fiberglass epoxy laminate. It offers a strong balance of cost, durability, and performance—ideal for most consumer and industrial applications.

High-TG FR-4: Designed for higher thermal stability. It’s more expensive than standard FR-4 but necessary for boards that experience elevated operating temperatures.

Aluminum substrates: Commonly used for LED or power applications where heat dissipation is critical, though they come at a higher cost.

In most cases, standard FR-4 is the most cost-effective choice unless your design has special mechanical or thermal requirements.

Material Type | Approximate Cost | Thermal Performance | Best Use Case |

|---|---|---|---|

Standard FR-4 | Low | Moderate | General electronics |

High-TG FR-4 | Medium | High | Power or high-temp circuits |

Aluminum | High | Excellent | LED, power modules |

By aligning material selection with actual performance needs, you can achieve both cost savings and stable product reliability.

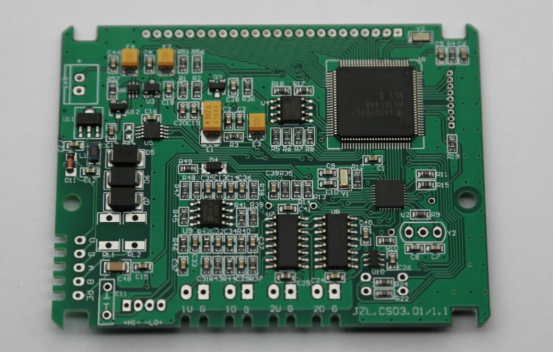

Partner With a Reliable PCB Manufacturer

A reliable PCB manufacturing partner can help you save money in ways that go beyond unit pricing. Experienced suppliers reduce hidden costs by improving yield, optimizing component sourcing, and preventing design-to-production mismatches.

When evaluating a low-cost assembly provider, verify the following:

Certifications: Look for ISO 9001, UL, and RoHS compliance to ensure consistent quality.

Technical capabilities: Check supported layer counts, minimum trace width, and testing options.

Sample builds: Request prototypes to evaluate workmanship and communication efficiency.

A trustworthy partner will also provide engineering support and transparent pricing—two factors that prevent costly surprises during production. For example, PCBMASTER is a reliable PCB assembly supplier, offering consistent quality and dependable service.

Tip: The cheapest supplier isn’t always the most economical. A slightly higher upfront quote can actually result in lower overall costs if the manufacturer maintains higher yields and fewer production errors.

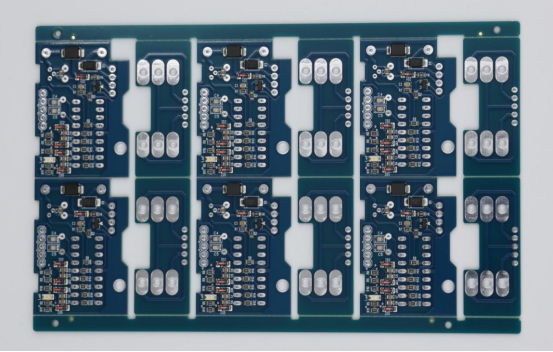

Order in Batches or Combine Orders

One of the simplest ways to reduce per-unit cost is to order PCBs in batches or combine multiple designs into one production run (a process known as panelization).

Batch production helps spread setup and tooling costs across more boards, significantly lowering the cost per piece. For instance, producing 1,000 boards in a single run may cost only 20–30% more than producing 100 boards—an effective way to scale efficiently.

Case example:

A startup producing prototype IoT devices reduced its PCB cost by 25% by combining multiple small orders into one panelized batch. The manufacturer only had to run the machines once, saving time and labor on setup.

If you anticipate multiple revisions or steady demand, plan ahead to consolidate orders rather than placing them piecemeal.

Manage BOM (Bill of Materials) Efficiently

An optimized Bill of Materials (BOM) can make or break the budget of your PCB assembly. Each part on the BOM influences both material cost and assembly complexity.

To keep costs under control:

Avoid end-of-life (EOL) or hard-to-find components, which can cause expensive sourcing delays.

Maintain an alternative parts list (APL) with equivalent replacements in case of shortages.

Work with an experienced EMS (Electronics Manufacturing Services) partner who can recommend cost-effective substitutes or consolidate sourcing for better pricing.

Efficient BOM management not only reduces procurement costs but also ensures consistent lead times and smoother assembly runs. It’s a proactive step that minimizes supply chain risks while keeping production costs predictable.

Quality Assurance Practices That Keep Costs Under Control

Preventing Defects Early

Identifying potential issues early in the design and prototyping stage is one of the most effective ways to control PCB assembly costs. Conducting design reviews and prototype testing ensures that errors are caught before mass production, reducing scrap, rework, and wasted components.

For example, performing early Automated Optical Inspection (AOI) on prototypes can detect soldering defects, misaligned components, or missing parts. By correcting these issues before full-scale assembly, manufacturers can significantly reduce the scrap rate and overall production costs.

Using Reliable Assembly Standards

Following recognized assembly standards, such as IPC-A-610 Class 2 or Class 3, helps maintain consistent quality throughout production. Class 2 is typically used for general electronic products, while Class 3 is applied to high-reliability boards where failure is not an option.

Compliance with these standards ensures that solder joints, component placement, and board finishes meet established criteria. This reduces long-term costs by minimizing failures in the field, lowering warranty claims, and preventing expensive rework.

Continuous Feedback Between Design and Assembly Teams

Cross-functional collaboration between design engineers and assembly teams is essential for reducing miscommunication, rework, and material waste. Continuous feedback loops allow issues to be addressed before they escalate into costly problems.

A step-by-step example of this process:

1. Design Revision: Engineers update the PCB layout based on performance or functional feedback.

2. DFM Check: The revised design is analyzed for manufacturability, identifying potential assembly issues.

3. Assembly Adjustment: The production team implements changes to optimize placement, soldering, or component handling.

By maintaining this iterative workflow, manufacturers ensure higher yield, fewer errors, and more predictable production costs.

Comparing Low Cost PCB Assembly Options

Domestic vs. Overseas Assembly

When selecting a PCB assembly provider, choosing between domestic and overseas manufacturing affects cost, lead time, and communication.

Domestic assembly usually offers faster turnaround times and easier communication due to proximity and shared time zones. Labor costs tend to be higher, but shipping is faster and intellectual property risks are lower.

Overseas assembly, commonly in regions like China or Southeast Asia, often provides lower labor and material costs. However, it may involve longer shipping times, additional customs procedures, and potential communication challenges.

Example comparison table:

Factor | U.S. | China | Southeast Asia |

|---|---|---|---|

Labor Cost | High | Low | Low-Medium |

Lead Time | Short | Medium-Long | Medium |

Communication | Easy | Moderate | Moderate |

Quality Control | High | Medium-High | Medium |

Shipping Costs | Low | Medium-High | Medium |

Choosing the right location depends on budget, project urgency, and quality requirements.

Prototype vs. Mass Production Pricing

Prototypes often appear more expensive per unit because setup, tooling, and testing costs are spread across fewer boards. Despite higher per-unit prices, prototypes are crucial for validating design and preventing costly errors in mass production.

Strategies to reduce prototype costs:

Batch prototypes: Produce multiple prototype boards at once to spread setup costs.

Quick-turn production lines: Use rapid-turn assembly services designed for prototypes, which reduce lead time and cost without sacrificing quality.

Panelization: Combine multiple small designs into one production panel for efficiency.

By managing prototypes effectively, companies can reduce overall development costs and accelerate time-to-market.

Online PCB Assembly Services

Online PCB assembly platforms provide instant quotations, automated ordering, and streamlined communication, which help reduce both time and cost.

Automation: Online systems use automated processes for quoting, component sourcing, and order management, minimizing manual errors and labor costs.

Transparent pricing: Clients can compare costs immediately and adjust design parameters to fit their budget.

Convenience: These services are ideal for small batches, prototypes, or projects requiring quick turnarounds.

By leveraging online assembly services, companies can achieve low cost PCB assembly with reliable quality and predictable delivery times.

Conclusion

Reducing PCB assembly costs does not mean compromising on quality. By focusing on smart design, efficient material selection, optimized assembly processes, and rigorous quality assurance, manufacturers can achieve low cost PCB assembly without sacrificing performance or reliability.

Collaboration with professional PCB partners is key. PCBMASTER, with its 80,000-square-meter in-house factory, provides one-stop PCBA design, production, and assembly services. This integrated approach allows for efficient cost control while ensuring high-quality output, helping clients meet both budget goals and product excellence.

With the right strategies and a trusted partner, achieving affordable, high-quality PCB assembly is not only possible—it is practical, repeatable, and scalable for any project.

FAQs

1. How can I assemble a PCB cheaply without sacrificing quality?

You can reduce PCB assembly costs without lowering quality by making smart decisions throughout the process. Focus on designing for manufacturability (DFM) to minimize errors and rework. Use cost-effective materials like standard FR-4 unless your project requires specialized substrates. Partnering with a reliable PCB manufacturer ensures consistent quality and fewer defects. Ordering in batches or panelizing multiple designs helps spread setup costs, and efficiently managing your BOM with readily available components keeps procurement costs low.

2. How does DFM help lower PCB assembly costs?

Design for Manufacturability (DFM) makes a PCB easier to produce, which reduces assembly errors, scrap, and labor time. Standardizing hole sizes, pad spacing, and trace widths helps boards fit common assembly lines. Performing early DFM checks can catch issues before production begins, saving time and money. Overall, DFM increases production yield, shortens lead times, and makes assembly more efficient.

3. Are low cost PCB assembly services reliable for mass production?

Yes, low cost does not automatically mean lower quality. Reliable manufacturers follow industry standards such as IPC-A-610 Class 2 or Class 3 and use proper quality assurance testing like AOI, X-ray, and in-circuit testing. Experienced suppliers maintain high yields, consistent quality, and predictable results, making low cost PCB assembly suitable for both prototypes and mass production.

4. What are the main factors that drive PCB manufacturing costs?

The biggest cost drivers in PCB assembly include:

Design complexity: More layers, narrow traces, and dense vias increase fabrication and assembly costs.

Component sourcing: Part availability, lead time, and unit cost impact overall expenses.

Assembly type: SMT, through-hole, or mixed assembly, and whether soldering is automated or manual.

Materials: PCB substrate, copper thickness, and other consumables.

Testing and QA: AOI, functional testing, and inspection add costs but reduce long-term risks.

5. How can small businesses or startups save on PCB assembly?

Small businesses can cut costs by optimizing designs for manufacturability to reduce scrap and errors. Choosing standard, readily available components lowers material expenses. Working with a trustworthy, cost-effective PCB assembly partner helps prevent hidden costs. Consolidating orders or using batch production reduces per-unit cost, and online PCB assembly services offer fast quotes, automated ordering, and transparent pricing—ideal for prototypes or small runs.