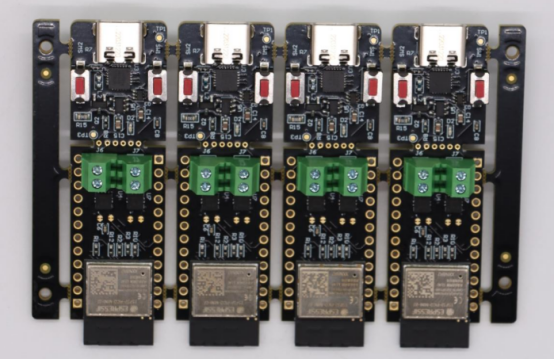

Cheap Printed Circuit Boards for Prototypes and Small Batch Production

For startups, product developers, and small electronics projects, managing costs is critical. Cheap printed circuit boards (PCBs) offer an affordable way to prototype and produce small batches without compromising performance or reliability. By making smart design choices, selecting cost-effective materials, and partnering with a reliable manufacturer, ideas can move from concept to working product quickly while keeping production budgets under control.

Understanding the key factors that influence PCB costs, applying cost-saving strategies, and ensuring quality are essential for successful prototypes and small batch production.

Introduction to Cheap Printed Circuit Boards

What Are Cheap Printed Circuit Boards?

A printed circuit board (PCB) is a flat board used to mechanically support and electrically connect electronic components through conductive tracks, pads, and other features. PCBs are the backbone of nearly all modern electronic devices, from consumer gadgets to industrial equipment.

In industry terms, “cheap printed circuit boards” refers to PCBs that are manufactured with cost-efficient materials, simplified designs, and optimized production processes. This can include standard FR-4 substrates, fewer layers, minimized vias, and design adjustments that streamline assembly.

It’s important to note that low cost does not automatically mean low quality. Many affordable PCBs still meet high reliability and performance standards when designed and manufactured properly. The key is balancing material choice, design efficiency, and production techniques to achieve both cost savings and dependable functionality.

Why Cheap PCBs Matter for Prototypes and Small Batches

For startups, product developers, and low-volume electronics, cheap PCBs play a crucial role in managing budgets and accelerating development cycles.

The primary benefits include:

Lower upfront costs, which reduces financial risk during early-stage product development.

Faster iteration, allowing multiple design revisions without prohibitive expense.

Reduced financial risk, as small batches minimize the investment tied up in unused or defective boards.

Example: Prototyping 10 units of a new IoT device might cost $500–$700, while producing 100 units in a small batch might cost only $2,000–$2,500. By optimizing batch size and leveraging low-cost PCB options, developers can significantly reduce the per-unit cost while still testing and refining their designs effectively.

Cheap PCBs provide a flexible, cost-effective solution for early-stage development and small-scale production, making them an essential tool for modern electronics projects.

Key Cost Factors in PCB Prototyping and Small Batch Production

Design Complexity

The complexity of a PCB design directly affects manufacturing cost. Key factors include:

Layer count: More layers require additional materials, longer fabrication time, and increased risk of defects.

Trace width and spacing: Narrow traces demand precise fabrication, which can raise cost.

Via density: More vias mean more drilling and plating, adding both time and expense.

Example: A 2-layer prototype PCB may cost $50 per unit, while a 4-layer board with similar dimensions could cost $120 per unit due to extra materials and processing.

Tip: Simplify routing, minimize unnecessary vias, and keep trace widths standard to reduce both material and labor costs while maintaining functionality.

Material Selection

PCB substrate choice is another major cost factor. Common materials include:

FR-4: Standard fiberglass epoxy laminate, widely used for cost-effective PCBs.

High-TG FR-4: Offers higher thermal stability, suitable for applications with elevated temperatures.

Aluminum: Excellent for heat dissipation but significantly more expensive, often used for LED or power circuits.

Cost vs. performance: Standard FR-4 provides a balance of low cost, mechanical strength, and reliability, making it ideal for most prototypes and small batches. High-TG or aluminum should only be used if the design specifically requires thermal or mechanical advantages.

Guideline: Choose standard FR-4 for prototypes and low-volume production to save costs without compromising basic performance.

Component Sourcing

The cost and availability of components can dramatically influence PCB assembly budgets:

In-stock vs. custom parts: Readily available components are cheaper and faster to source; custom or obsolete parts increase cost and lead time.

Local vs. international suppliers: Local sourcing reduces shipping and lead time but may be more expensive; overseas suppliers can offer lower prices but carry longer delivery times and potential communication challenges.

Example: If a preferred component is back-ordered internationally, selecting an alternative in-stock part from a verified supplier can prevent delays and additional costs.

Tip: Maintain a flexible alternative parts list in the BOM to avoid production slowdowns.

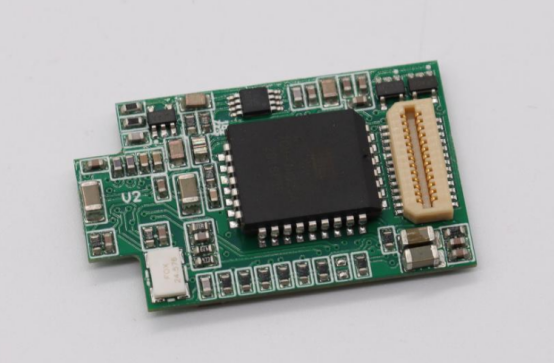

Assembly Process

Different assembly methods affect both cost and feasibility:

SMT (Surface Mount Technology): Efficient for high-density, small components; works well with automated pick-and-place.

Through-hole: More expensive due to manual insertion, often used for connectors or mechanical strength.

Mixed assembly: Combines SMT and through-hole, balancing cost and functionality.

Cost implication: Automated processes reduce labor costs, improve consistency, and increase throughput. Manual assembly is slower and more expensive for small batches.

Example: Using an automated pick-and-place machine for a small prototype batch can cut labor costs by 30–50% compared to manual placement.

Testing and Quality Assurance

Testing ensures that prototypes and small batches function correctly, but it also adds cost:

Essential tests: Automated Optical Inspection (AOI), functional testing, X-ray inspection for hidden defects.

Trade-offs: More extensive testing increases upfront cost but reduces long-term risk of failure and rework.

Recommendation: Optimize testing coverage rather than eliminating it. Focus on critical circuits and high-risk areas to balance cost and reliability, ensuring prototypes and small batches meet quality expectations.

Strategies to Reduce Costs Without Sacrificing Quality

Optimize Design for Manufacturability (DFM)

Design for Manufacturability (DFM) helps reduce errors, scrap, and rework by ensuring the PCB layout is easy to produce. By considering production constraints during the design phase, you can prevent costly mistakes later.

Example: Standardizing hole sizes and pad spacing to match common assembly line specifications reduces the risk of misalignment and soldering defects.

Tools: Many PCB design software platforms offer built-in or free DFM checks that automatically highlight potential manufacturability issues before production, helping designers make informed adjustments early.

Batch Production and Panelization

Producing multiple units together can significantly lower per-unit costs by spreading setup and handling expenses.

Example: Combining prototype orders with a small batch production run reduces tooling and setup fees compared to running separate jobs.

Step-by-step process:

1. Panel layout: Arrange multiple PCBs on a single panel to optimize space and production efficiency.

2. Assembly: Produce all units together using automated or semi-automated lines.

3. Depanelization: Separate individual boards after assembly, ready for testing or shipment.

This approach maximizes efficiency while maintaining consistent quality across all units.

Partner With a Reliable PCB Manufacturer

Choosing an experienced PCB supplier is crucial for cost control and quality assurance.

Benefits: Experienced manufacturers reduce hidden costs such as low yield rates, production delays, and rework. They also provide engineering guidance to optimize design and assembly.

Checklist for selecting a low-cost partner:

Verify manufacturing certifications (ISO, UL).

Check previous sample builds for quality and consistency.

Assess engineering support and transparent pricing policies.

Brand example: PCBMASTER offers an 80,000-square-meter in-house factory with one-stop PCBA design, production, and assembly services, enabling efficient cost management while delivering high-quality results.

Efficient BOM Management

Efficient management of the Bill of Materials (BOM) ensures cost-effectiveness and reduces delays.

Strategies:

Avoid end-of-life (EOL) or hard-to-source components.

Maintain alternative parts lists for critical components to improve flexibility.

Work with EMS partners to source cost-efficient parts without compromising quality.

Proper BOM management reduces supply chain risks and prevents unnecessary production downtime, keeping prototype and small-batch costs under control.

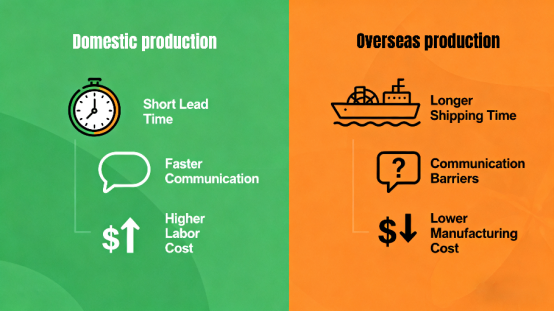

Comparing Domestic vs. Overseas Production for Small Batches

Cost, Lead Time, and Communication Differences

When producing small batches of PCBs, the choice between domestic and overseas manufacturing has a direct impact on cost, lead time, and communication efficiency.

Domestic production:

Offers faster communication due to shared time zones and language familiarity.

Enables shorter lead times, ideal for rapid prototypes or urgent revisions.

Higher labor costs can increase per-unit price, especially for small batches.

Overseas production:

Provides lower labor and manufacturing costs, reducing overall project expense.

Often involves longer shipping times and potential customs delays.

Communication challenges may arise due to time zone differences or language barriers.

Understanding these trade-offs helps businesses balance cost savings with speed and reliability for low-volume PCB production.

When to Choose Domestic or Overseas

Selecting between domestic and overseas manufacturing depends on several factors:

Project size: Small prototypes may not justify overseas production costs due to shipping and setup fees.

Urgency: Tight deadlines favor domestic suppliers who can respond quickly.

Risk tolerance: Overseas production carries higher risks of miscommunication, delays, and logistics complications.

Example:

For a prototype or urgent design iteration, using a local facility ensures rapid turnaround and easier collaboration.

For small batch production where cost reduction is critical, overseas suppliers can provide affordable manufacturing without sacrificing quality if timelines allow for shipping.

By evaluating project requirements, lead time, and cost priorities, businesses can choose the most efficient production location for their small-batch PCBs.

Using Online PCB Assembly Services

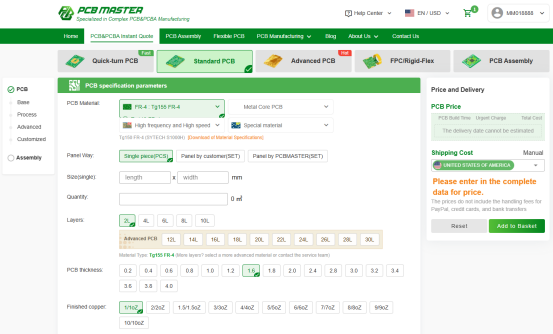

Benefits of Automation and Instant Quotation

Online PCB assembly services leverage automation to simplify the ordering and production process. Instant quotation tools provide accurate cost estimates in real time, reducing the need for back-and-forth communication and saving administrative time.

Transparent pricing ensures that businesses can plan budgets accurately, avoiding unexpected costs during small-batch or prototype production. Automation also improves production consistency, reducing human errors and enhancing the overall reliability of assembled boards.

Overall, online PCB assembly platforms streamline the ordering process while maintaining cost efficiency and high-quality results.

Suitable Scenarios

Online PCB assembly is particularly advantageous for:

Prototypes, where rapid iteration and quick turnaround are essential.

Small batch production, which benefits from automated processes and panelization to reduce per-unit costs.

Rapid design iterations, allowing engineers to test multiple versions of a board quickly and efficiently.

Example: An online PCB service can panelize multiple small orders from different prototypes into a single production run. This approach minimizes setup costs, shortens assembly time, and reduces shipping complexity, while still ensuring each board meets quality standards.

By using online PCB assembly services, businesses gain speed, flexibility, and cost transparency, making them ideal for modern electronics development and small-scale manufacturing.

Conclusion

Producing low-cost PCBs does not mean compromising on quality. By focusing on efficient design, smart material selection, batch production, and partnering with a reliable manufacturer, businesses can control costs while maintaining high performance and reliability.

Small businesses and startups can take advantage of these strategies to create high-quality prototypes and small-batch production runs affordably. Trusted partners, such as PCBMASTER, offer one-stop PCBA design, production, and assembly services in their 80,000-square-meter in-house factory, helping clients manage budgets effectively while ensuring consistent quality.

With careful planning, optimized processes, and the right support, achieving cost-effective, reliable PCB assembly is not only possible—it is practical and repeatable for any project.

FAQs

1. How can startups minimize PCB prototyping costs?

Startups can reduce PCB prototyping costs by optimizing design for manufacturability (DFM), choosing cost-effective materials, and ordering small batches or panelized prototypes to spread setup costs. Partnering with a reliable PCB manufacturer helps prevent hidden expenses like low yields or rework. Efficient BOM management—using in-stock components and alternatives—also reduces procurement delays and extra costs. For example, producing 10 units with optimized design and panelization may cost significantly less per unit than ordering them individually.

2. What is the best material choice for cheap prototype PCBs?

For most prototypes, standard FR-4 is the most cost-effective choice. It offers a good balance of mechanical strength, electrical performance, and affordability. High-TG FR-4 or aluminum PCBs are more expensive and should only be used when higher thermal stability or heat dissipation is required. By using standard FR-4, startups can reduce material costs while still achieving reliable performance for prototypes and small-batch production.

3. Are online PCB assembly services reliable for small batch production?

Yes, online PCB assembly services can be reliable for prototypes and small batches, especially when using platforms with automation and quality control standards. They provide instant quotations, transparent pricing, and panelized assembly, which reduces administrative overhead and ensures consistent production quality. Automation minimizes human errors, and verified suppliers follow proper assembly standards, making online services suitable for low-volume production and rapid iterations.

4. How does panelization reduce PCB assembly costs?

Panelization combines multiple small PCBs into a single production panel. This approach reduces setup and handling costs because multiple units are assembled, soldered, and tested together. After assembly, boards are depaneled into individual units. For example, combining several prototype boards in one panel spreads machine setup time across all units, reducing per-board cost while maintaining high-quality assembly.

5. What design practices help prevent errors in low-volume PCB production?

Key design practices include:

Design for Manufacturability (DFM): Standardize hole sizes, pad spacing, and trace widths to match common assembly capabilities.

Minimize unnecessary vias and complex routing: Simplifies production and reduces defect risk.

Early prototype testing and simulation: Catch errors before full production.

Alternative component planning: Use in-stock or widely available parts to prevent delays.

These strategies help prevent rework, scrap, and assembly errors, ensuring small-volume PCBs are produced reliably and cost-effectively.