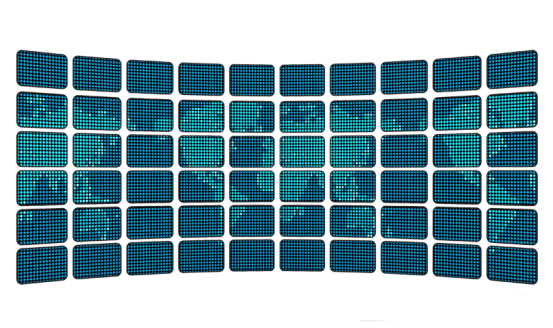

How LED Printed Circuit Boards Improve Lighting Efficiency

Lighting has come a long way since the days of incandescent bulbs and fluorescent tubes. Today, as we push toward more sustainable, cost-effective, and efficient solutions, LED lighting is at the forefront of this revolution. But what makes LED lighting so much more efficient than its predecessors? A key factor lies in the underlying technology—LED printed circuit boards (PCBs). These specialized components are crucial for optimizing performance, reducing energy consumption, and extending the lifespan of LED systems. As we delve deeper into how LED PCBs drive these advancements, it becomes clear that they are not just a part of the lighting system, but the cornerstone of modern lighting efficiency.

Introduction to LED Printed Circuit Boards (PCBs) and Their Role in Lighting

What Are LED Printed Circuit Boards?

LED printed circuit boards (PCBs) are specialized substrates that provide the essential foundation for mounting and connecting LEDs in a lighting system. Essentially, they function as the backbone of LED lighting technology, allowing the individual light-emitting diodes to work efficiently by managing power distribution, heat dissipation, and signal transmission.

The primary function of an LED PCB is to connect the LED chips to the power source while also ensuring that electrical signals are transmitted seamlessly. These PCBs are designed to withstand the high temperatures generated by LEDs and are equipped with heat dissipation mechanisms that prevent overheating and improve the longevity of the entire lighting system.

Common materials used in LED PCBs include:

Aluminum: Known for its excellent thermal conductivity, aluminum-based PCBs are commonly used in high-power LED applications where heat management is critical.

Copper: Copper PCBs offer even better thermal dissipation than aluminum, making them ideal for applications requiring superior heat control.

FR4 (Fiberglass): A less expensive alternative, used in low-power applications where thermal management is less of a concern.

Unlike traditional PCBs, which are often used for a wide variety of electronics, LED PCBs are specifically designed to handle the unique demands of LED lighting systems. Traditional PCBs generally use materials like FR4 to create rigid, flat circuits, but LED PCBs prioritize heat management and power regulation, making them more suited for high-performance and energy-efficient lighting solutions.

The Importance of Lighting Efficiency

Lighting efficiency refers to the ability of a lighting system to produce the maximum amount of light output with the least amount of energy input. It’s a measure of how effectively energy is converted into usable light rather than wasted as heat. In the context of LED PCBs, lighting efficiency is not only about the amount of light generated but also about how well the system manages power, dissipates heat, and extends the lifespan of the LEDs.

Energy-efficient lighting is crucial for several reasons:

Environmental Impact: Reducing energy consumption directly lowers greenhouse gas emissions, helping to combat climate change. LED lighting, in particular, is one of the most eco-friendly solutions available, consuming up to 75% less energy than incandescent bulbs.

Cost Savings: Energy-efficient lighting reduces electricity bills, providing both short-term and long-term savings. In commercial and industrial settings, these savings can be significant, making the upfront investment in LED technology worthwhile.

Sustainability: With the growing global emphasis on sustainability, energy-efficient solutions like LED lighting are becoming essential in industries seeking to reduce their carbon footprint and operate in a more environmentally responsible manner.

By integrating LED PCBs, lighting systems become more energy-efficient due to the optimized management of power distribution and heat, enabling them to last longer and consume less electricity. This combination of improved performance and reduced environmental impact makes LED PCBs a vital component in the future of lighting.

How LED PCBs Enhance Lighting Efficiency

Superior Heat Dissipation

Heat management is a critical factor in the performance and efficiency of LED lighting systems. LEDs generate significant heat during operation, and if not effectively dissipated, this heat can lead to reduced brightness, faster degradation, and even failure of the lighting system. This is where LED PCBs come into play.

LED PCBs are specifically designed to manage heat, ensuring that the LEDs remain within optimal operating temperatures. One of the most common ways this is achieved is through metal-core PCBs (MCPCBs), which use materials like aluminum or copper to conduct heat away from the LED chips. These materials have high thermal conductivity, allowing heat to be efficiently transferred from the LED to the surrounding environment, preventing overheating.

Example:

Traditional PCBs typically use FR4 material, which offers limited heat dissipation capabilities. In contrast, an LED PCB with a metal-core design, such as an aluminum PCB, can dissipate heat much more effectively, keeping the LEDs cool and extending their lifespan. This difference in heat management can be particularly noticeable in high-power LED applications, like streetlights or industrial lighting, where excessive heat is a common issue.

Energy Savings with LED PCBs

One of the primary advantages of LED PCBs is their ability to reduce power consumption compared to traditional lighting systems. LED technology is inherently more energy-efficient than incandescent or fluorescent lighting, but the design of LED PCBs further optimizes energy usage.

The circuit design of LED PCBs plays a key role in lowering energy consumption. For example, LED PCBs often incorporate voltage regulation and optimized power distribution to ensure that the LEDs receive the correct voltage and current for their operation. This minimizes power wastage and maximizes light output.

Voltage regulation: Ensures that the LED receives a steady, controlled amount of power, preventing fluctuations that could waste energy.

Optimized power distribution: Ensures that energy is distributed efficiently across the entire PCB, reducing unnecessary power loss.

Longer Lifespan of LED Lighting Systems

The longevity of an LED lighting system is another key benefit that LED PCBs provide. The efficient heat dissipation and power management offered by LED PCBs directly contribute to the extended lifespan of the LEDs. When LEDs are kept at lower temperatures and powered optimally, their degradation rate is slowed, allowing them to last much longer than traditional lighting technologies.

Improved thermal management: Effective heat dissipation prevents thermal stress, which is a leading cause of LED failure.

Lower degradation: By maintaining stable operating conditions, LED PCBs reduce the risk of performance degradation over time.

The extended lifespan of LED lighting not only means fewer replacements and lower maintenance costs, but it also results in greater sustainability. In commercial and residential lighting applications, the reduced need for replacement bulbs leads to less waste and lower environmental impact.

Example:

A typical incandescent bulb lasts about 1,000 hours, while a fluorescent bulb lasts around 10,000 hours. In comparison, an LED lighting system with a high-quality PCB can last anywhere from 25,000 to 50,000 hours—up to 50 times longer than an incandescent bulb. This significant increase in lifespan leads to reduced waste and long-term cost savings, making LED PCBs an investment that pays off over time.

In summary, LED PCBs play a vital role in improving the efficiency of lighting systems. Their superior heat dissipation, energy-saving designs, and ability to extend the lifespan of LEDs make them a cornerstone of modern, sustainable lighting technology.

The Technical Design Aspects of LED PCBs for Enhanced Efficiency

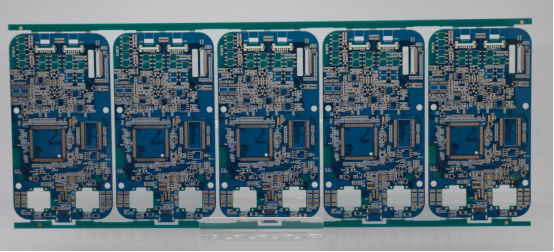

Multi-layer PCB Designs for Improved Performance

In LED PCB design, multi-layer PCBs are often used to significantly enhance both thermal conductivity and overall performance. Multi-layer PCBs consist of multiple conductive layers stacked on top of one another, with each layer performing specific functions, such as power distribution, signal routing, or heat dissipation. This structure helps optimize the efficiency of the entire system, especially in high-performance lighting applications.

The role of multi-layer designs in enhancing thermal conductivity is particularly important. With multiple layers, the heat generated by the LEDs can be spread across a greater area, reducing the likelihood of heat buildup that can damage the components. Multi-layer PCBs often incorporate metal-core materials, such as aluminum, within the layers to provide superior heat dissipation, allowing LEDs to run cooler and perform better.

Benefits of using multi-layer LED PCBs:

Enhanced heat dissipation: Multiple layers allow for more effective heat spread across the PCB, lowering the operating temperature of the LEDs.

Improved signal integrity: In more complex lighting systems, multi-layer designs can separate power and signal layers, preventing electrical noise and signal interference.

Higher power capacity: Multi-layer PCBs can handle higher currents and voltages, making them ideal for high-power LED applications such as streetlights or industrial lighting.

Example:

In a comparison between single-layer vs. multi-layer LED PCBs, a multi-layer PCB can dissipate heat much more efficiently. For instance, an LED lighting system using a multi-layer PCB with an aluminum core will experience less thermal stress, ensuring that the LED chips remain at an optimal temperature. In contrast, a single-layer PCB, with its limited heat dissipation capacity, may cause overheating and a decrease in performance or lifespan.

Integrated Power Regulation Systems

An essential aspect of optimizing energy use in LED lighting systems is the integration of power regulation circuits within the LED PCB design. These circuits control the amount of power supplied to the LEDs, ensuring that they receive the correct voltage and current, preventing waste, and improving overall energy efficiency.

The integrated power regulation systems in LED PCBs help to:

Optimize energy use: Power regulation prevents energy loss by maintaining steady and controlled energy delivery to the LEDs, ensuring they perform at their best without drawing excess power.

Reduce waste: By regulating the power supplied to each LED, these systems minimize the chances of energy being wasted as heat or inefficiency, contributing to both energy savings and prolonged lifespan.

Step-by-step explanation of power regulation in a typical LED PCB:

1. Power input: The system receives power from the main source (e.g., AC or DC power supply).

2. Power conversion: A power converter (often a buck or boost converter) adjusts the incoming voltage to a level appropriate for the LEDs.

3. Voltage regulation: The voltage regulator ensures that the LEDs receive a consistent and optimal voltage, regardless of fluctuations in the power supply.

4. Current control: Current control circuits ensure the LEDs receive just the right amount of current to maintain efficiency while preventing overcurrent, which can cause damage.

Example:

In a smart lighting system, power-regulated LED PCBs can adjust the light intensity based on ambient lighting conditions. By integrating power regulation, the system ensures that LEDs only consume as much power as needed, further optimizing energy savings. For instance, if the system detects that it’s daytime and the natural light is sufficient, the power-regulated PCB may reduce the brightness of the LEDs, thus conserving energy without compromising lighting quality.

The Impact of LED PCB Materials on Lighting Efficiency

Aluminum-based LED PCBs

Aluminum is one of the most commonly used materials for LED PCBs due to its excellent thermal conductivity and durability. When it comes to LED lighting, effective heat dissipation is crucial for maintaining performance and extending the lifespan of the LEDs. Aluminum’s high thermal conductivity allows it to quickly transfer heat away from the LED chips, ensuring that they remain at optimal operating temperatures.

The durability of aluminum also makes it an ideal material for PCBs used in various environments, including outdoor and industrial applications where exposure to moisture, temperature fluctuations, and physical stress is common. This helps maintain the integrity of the LED system over time.

Benefits of aluminum-based LED PCBs:

Efficient heat dissipation: Aluminum effectively pulls heat away from the LED chips, preventing overheating and performance degradation.

Lightweight and cost-effective: Aluminum is relatively inexpensive compared to other metals and provides a lightweight solution for various applications.

Specific examples:

Streetlights: Many modern streetlights use aluminum-based LED PCBs for improved heat management in high-power applications, where heat dissipation is crucial to prevent system failure.

Industrial lighting: In factories and warehouses, aluminum-based PCBs are often used in high-bay lighting systems, where durability and efficient heat dissipation are essential.

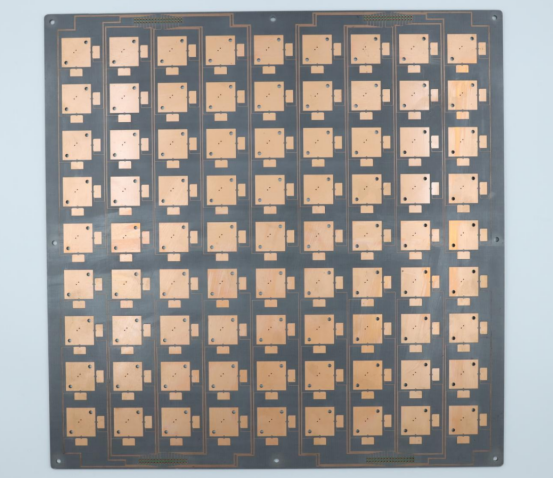

Copper-based LED PCBs

Copper is another popular material for LED PCBs, particularly when dealing with high-heat environments or high-power LEDs. Copper has superior thermal conductivity compared to aluminum, which makes it an excellent choice for applications that demand the highest level of heat management. Copper is also more durable in extreme conditions, maintaining its performance under high electrical loads.

The key benefit of copper-based LED PCBs is their ability to handle higher heat levels without sacrificing performance. This makes them ideal for applications where the LED system needs to operate at maximum capacity for extended periods.

Benefits of copper in LED PCB construction:

Superior heat dissipation: Copper's thermal conductivity allows it to efficiently transfer heat, which is critical for high-power LEDs.

Higher power capacity: Copper PCBs can handle higher current and voltage levels, making them suitable for more demanding applications.

Use cases:

High-power LEDs: Copper PCBs are often used in lighting systems for industrial or commercial settings, such as high-intensity floodlights or automotive headlights, where high-power LEDs generate more heat.

LEDs in high-temperature environments: Copper-based PCBs are ideal for use in environments with extreme temperatures, such as outdoor lighting systems or areas where the lighting operates continuously.

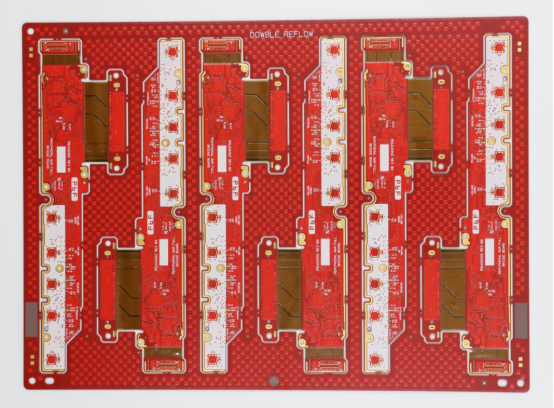

Flexible LED PCBs for Custom Lighting Solutions

Flexible LED PCBs offer unique advantages in lighting design, particularly when customization is key. Unlike rigid PCBs, flexible PCBs can be bent or shaped to fit unique or irregular spaces, making them ideal for applications that require curvable or adaptable lighting solutions. This flexibility allows for more creative and versatile lighting designs, enhancing both performance and aesthetics.

The key advantage of flexible LED PCBs is their ability to conform to a variety of shapes and sizes, enabling designers to create custom solutions that are not possible with traditional, rigid PCBs.

Benefits of flexible LED PCBs:

Adaptable design: Flexible PCBs can be shaped to fit around corners, curved surfaces, or even integrated into specific product designs, opening up new possibilities for lighting.

Space-saving: Flexible PCBs can be compactly designed, reducing the need for large, bulky components in tight spaces.

Use cases in lighting:

Curvable LED strip lights: Flexible LED PCBs are commonly used in LED strip lights, where the ability to bend and wrap around objects is essential. These strips can be used in both residential and commercial settings for accent lighting, under-cabinet lighting, and architectural designs.

Custom-shaped lighting installations: In creative lighting designs, such as in theaters, museums, or art installations, flexible LED PCBs allow for unique and dynamic lighting solutions that are tailored to the space.

In summary, the materials used in LED PCBs—whether aluminum, copper, or flexible substrates—play a crucial role in enhancing lighting efficiency. Each material offers distinct advantages depending on the application, such as superior heat dissipation with aluminum and copper or the design flexibility provided by flexible PCBs. These materials enable LED lighting systems to perform at their best while meeting specific functional and aesthetic requirements.

Applications of LED PCBs in Lighting Efficiency

Commercial and Industrial Lighting

LED PCBs are revolutionizing commercial and industrial lighting by enhancing efficiency, reducing energy consumption, and lowering maintenance costs. Whether it's for streetlights, office buildings, or factories, LED PCBs provide significant improvements over traditional lighting systems, particularly in environments where performance and longevity are critical.

The key benefits of using LED PCBs in commercial and industrial lighting include energy savings and superior heat dissipation. By integrating efficient power regulation and heat management systems, LED PCBs ensure that lighting systems remain operational for longer periods with reduced energy consumption, all while maintaining optimal performance.

Residential Lighting Solutions

In residential settings, LED PCBs play a vital role in making home lighting systems more energy-efficient. From smart home lighting systems to energy-efficient bulbs, LED PCBs ensure that homes are lit with minimal energy waste. These systems are designed to deliver the same, or even superior, brightness compared to traditional lighting, but with a fraction of the energy consumption.

One of the most notable advantages of LED PCBs in residential lighting is their ability to integrate with smart home systems, offering users greater control over their lighting environments. These systems can adjust lighting based on time of day, occupancy, or environmental conditions, contributing to further energy savings.

Examples of energy savings:

A typical LED bulb using an LED PCB consumes about 80% less energy than an incandescent bulb while providing the same level of brightness.

In a smart home system, lights equipped with LED PCBs can automatically dim or turn off based on motion sensors or user preferences, leading to additional savings on electricity bills.

Automotive and Specialty Lighting

The use of LED PCBs is growing rapidly in the automotive industry, particularly in headlights, tail lights, and interior lighting. These systems demand high-intensity lighting with consistent performance, even under extreme conditions such as varying temperatures and vibrations. LED PCBs provide the ideal solution due to their superior thermal management and energy efficiency.

In automotive lighting, LED PCBs are preferred because they offer better light output with lower power consumption, contributing to longer battery life and better overall efficiency. In high-intensity applications like headlights, LED PCBs ensure that the lights remain bright and durable over time, even with the heat generated by continuous use.

How LED PCBs provide efficiency in high-demand environments:

Headlights and taillights: LED PCBs are increasingly used in automotive lighting due to their ability to produce bright, focused light while consuming less power. This is particularly important for electric vehicles, where energy efficiency is key.

Interior lighting: Flexible LED PCBs allow for sleek, custom lighting designs in vehicle interiors, offering both aesthetic appeal and energy efficiency.

In summary, LED PCBs are transforming lighting systems across commercial, residential, and automotive sectors, improving energy efficiency, performance, and sustainability. Whether in streetlights, home lighting setups, or vehicle lighting, the adoption of LED PCBs is driving significant advances in how we illuminate our world.

Conclusion

LED PCBs have proven themselves to be a game-changer in the lighting industry by significantly enhancing efficiency through superior heat dissipation, energy savings, and longer lifespans. Their ability to manage heat effectively ensures that LEDs perform optimally, reducing the risk of overheating and extending the life of the lighting system. With lower power consumption, LED PCBs help reduce energy bills while contributing to environmental sustainability. Furthermore, their durability means fewer replacements and less maintenance, offering long-term cost savings.

As lighting systems continue to evolve, LED PCBs are positioned to remain at the forefront of efficient lighting solutions. The ongoing advancements in materials, integration with smart technology, and superior thermal management ensure that LED PCBs will continue to meet the growing demands for energy-efficient and high-performance lighting. The long-term advantages of adopting LED PCBs are clear—cost savings, sustainability, and enhanced performance.

At PCBMASTER, we specialize in designing and manufacturing high-quality LED PCBs that meet the diverse needs of modern lighting systems. Our expertise ensures that every LED PCB is optimized for efficiency, durability, and performance, helping businesses and individuals make the most of their lighting solutions. Whether for residential, commercial, or industrial applications, PCBMASTER is committed to driving the future of lighting efficiency with cutting-edge technology and expert craftsmanship.

FAQs

What are the main advantages of using LED PCBs over traditional lighting systems?

LED PCBs offer several key advantages over traditional lighting systems. First and foremost, they provide superior energy efficiency, reducing electricity consumption by up to 80% compared to incandescent and fluorescent bulbs. This results in lower energy bills and a reduced carbon footprint. LED PCBs also deliver better heat dissipation, ensuring the LEDs remain cool and perform at optimal levels, leading to a longer lifespan—often lasting up to 50,000 hours or more. Additionally, they are compact and can be easily integrated into a wide range of lighting applications, offering more design flexibility and allowing for custom lighting solutions.

How does the material choice of a PCB affect the performance of LED lighting?

The material used in LED PCBs plays a critical role in determining the thermal conductivity and overall efficiency of the lighting system. Materials like aluminum and copper are commonly used due to their excellent heat dissipation properties. Aluminum-based PCBs help maintain lower operating temperatures, preventing LEDs from overheating and thereby improving their performance and lifespan. On the other hand, copper-based PCBs offer even better thermal conductivity, making them ideal for high-power LED applications where excessive heat can degrade performance. The choice of material impacts not only energy efficiency but also the durability and maintenance costs of the lighting system.

What are the environmental benefits of LED PCBs in lighting applications?

LED PCBs provide several environmental benefits compared to traditional lighting systems. Since they use significantly less energy, they contribute to lower carbon emissions, helping to combat climate change. LED lights also contain no harmful substances like mercury, which is found in fluorescent lights, making them safer to dispose of. The long lifespan of LED lights reduces the frequency of replacements, cutting down on waste. Furthermore, the efficiency of LED PCBs minimizes energy consumption, leading to a reduction in overall electricity demand, further decreasing the environmental impact of lighting systems.

How do multi-layer PCB designs improve lighting efficiency in high-power applications?

Multi-layer PCB designs are especially beneficial for high-power LED applications, such as streetlights and industrial lighting, where heat management is crucial. These designs allow for better thermal conductivity, as heat can be spread more evenly across the layers, preventing overheating. Multi-layer PCBs also improve the stability and performance of the system by allowing for more efficient power distribution and signal routing. In high-power settings, where LEDs generate significant heat, multi-layer PCBs enable the system to maintain optimal performance, ensuring that energy is not wasted and that the lights last longer without degrading.

What are the cost implications of using LED PCBs in lighting systems?

While the initial cost of LED PCBs may be higher than traditional lighting systems, the long-term savings they offer make them a more cost-effective choice. LED PCBs reduce energy consumption significantly, leading to lower electricity bills. They also have a longer lifespan, which means fewer replacements and reduced maintenance costs over time. Additionally, the energy efficiency of LED PCBs contributes to lower operational costs for both residential and commercial lighting systems. Overall, the initial investment in LED PCBs is offset by the savings on energy and maintenance, making them a more economical option in the long run.