High-Temperature Kapton Polyimide Materials for Aerospace and Industrial Applications

In environments where electronics are pushed to their thermal and mechanical limits, few materials can endure what Kapton polyimide can. This amber-colored film has become a quiet enabler behind aerospace missions, industrial automation, and next-generation power systems—offering unmatched stability, flexibility, and insulation even in extreme heat or vacuum. From the wiring of satellites to the flexible circuits in high-performance machinery, Kapton’s resilience continues to redefine what is possible when materials meet innovation.

Introduction to Kapton Polyimide

What Is Kapton Polyimide?

Kapton Polyimide is a high-performance polymer film originally developed by DuPont. It belongs to the family of aromatic polyimides, known for their outstanding thermal, mechanical, and electrical stability. Unlike standard plastics, Kapton maintains its physical and chemical integrity even when exposed to extreme temperatures or harsh environments.

Chemically, Kapton is made up of aromatic imide linkages—bonds that give the material its exceptional heat resistance and molecular rigidity. These linkages prevent the film from melting or decomposing under high heat, making it suitable for long-term use in demanding conditions.

Kapton’s temperature resistance range is one of its most remarkable features. It can perform reliably from −269°C (−452°F)—near absolute zero—up to +400°C (752°F) without losing flexibility or electrical insulation. This unique stability allows Kapton to function in environments that would cause most polymers to become brittle, deform, or fail.

Because of these properties, Kapton Polyimide is widely used in aerospace, automotive, electronics, and energy systems where conventional materials cannot survive.

Why Kapton Is Preferred for High-Temperature Environments

Kapton Polyimide stands apart from other insulation films such as PET (polyethylene terephthalate) and PTFE (polytetrafluoroethylene) due to its ability to balance thermal endurance, flexibility, and dielectric strength in a single material.

Compared with PET: PET films typically degrade or shrink at temperatures above 150°C, while Kapton retains its shape and electrical properties well above 300°C.

Compared with PTFE: PTFE can resist high temperatures but lacks the same mechanical strength and dimensional stability as Kapton, especially in thin-film applications.

This combination of strength and adaptability makes Kapton ideal for use in flexible circuits, insulation tapes, sensors, and aerospace wiring, where components must operate under wide temperature swings or mechanical stress.

Industries such as aerospace, automotive electronics, and semiconductor manufacturing rely heavily on Kapton films to ensure reliability in critical applications. For example, spacecraft wiring and electric vehicle batteries often use Kapton insulation to prevent heat damage and electrical breakdown.

In short, Kapton Polyimide is not just another high-temperature material—it is a precision-engineered solution designed to thrive where other polymers fail.

Key Material Properties and Performance Advantages

Thermal Stability

Kapton Polyimide is recognized for its outstanding thermal stability, which allows it to perform continuously in extreme temperature ranges without degrading. It can operate continuously between −269°C and +400°C, with short-term exposure tolerances up to 450°C, depending on the grade and application. This makes it ideal for components that experience rapid or repeated heating and cooling cycles.

During thermal cycling, Kapton maintains both its physical dimensions and insulation properties. Unlike many polymers that crack or deform after repeated expansion and contraction, Kapton’s molecular structure resists thermal fatigue. This ensures long-term reliability in high-stress environments, such as the vacuum of space or the interior of jet engines.

A practical example is Kapton insulation on spacecraft wiring. NASA and other aerospace organizations have used Kapton films to wrap cables and circuit assemblies, as the material can survive both intense solar radiation and deep-space cold without failure.

Electrical and Mechanical Strength

Kapton Polyimide combines excellent electrical insulation with superior mechanical toughness, making it suitable for both static and dynamic electronic applications. Its dielectric constant typically ranges from 3.2 to 3.5, and its insulation resistance exceeds 10¹⁶ ohms, ensuring stable performance even under high voltage or high-frequency conditions.

Mechanically, Kapton offers tensile strengths of 165–231 MPa and high elongation at break (up to 70%), meaning it can stretch and recover without tearing. Its creep resistance—the ability to resist deformation under prolonged stress—is significantly higher than that of most polymer films.

Comparison of Kapton vs. Other Insulation Films:

Property | Kapton Polyimide | PET Film | PI Composite Film |

|---|---|---|---|

Continuous Temp. | −269°C to +400°C | up to 150°C | up to 300°C |

Dielectric Constant | 3.2–3.5 | 3.0–3.3 | 3.3–3.6 |

Tensile Strength | 165–231 MPa | 150 MPa | 170 MPa |

Flexibility | Excellent | Moderate | Good |

This combination of high voltage endurance and mechanical resilience is why Kapton remains a preferred choice for flexible printed circuits, insulation tapes, and precision sensors.

Chemical and Radiation Resistance

Kapton Polyimide shows strong resistance to a wide range of chemicals, including solvents, oils, and oxidizing agents. It maintains structural integrity even after long-term exposure to hydrocarbons, acids, and cleaning solvents that typically degrade conventional plastics.

Another major advantage is its radiation resistance. Kapton does not embrittle or lose dielectric strength when exposed to UV, gamma, or electron radiation, making it highly suitable for spacecraft, satellites, and nuclear instrumentation. Its performance under these harsh conditions ensures uninterrupted operation where material failure could be catastrophic.

Dimensional Stability and Flexibility

Kapton’s dimensional stability means it retains its shape and size even after extreme temperature variations. The coefficient of thermal expansion (CTE) is low—typically around 20 ppm/°C—which prevents warping or delamination in multilayer assemblies.

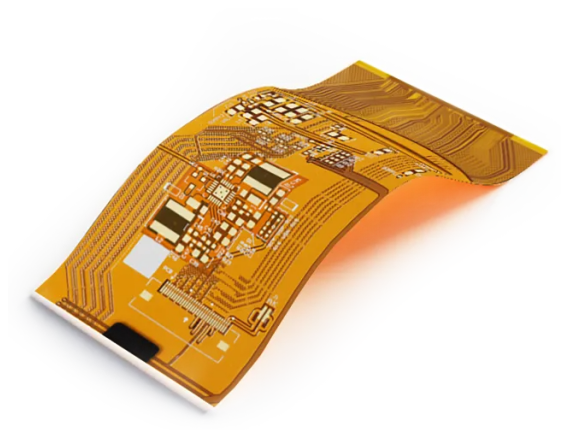

At the same time, Kapton remains highly flexible. Unlike rigid high-temperature materials, it can bend, fold, and flex without cracking, even after prolonged exposure to heat. This property is crucial in Flexible Printed Circuits (FPCs) and rigid-flex PCB assemblies, where repeated movement or vibration is common.

For example, in advanced aerospace control systems, Kapton films are used as the dielectric substrate for flexible circuits that connect sensors and processors. These circuits endure both extreme heat and mechanical strain—conditions under which conventional polymers would fail.

Kapton Polyimide’s unique combination of thermal stability, electrical insulation, mechanical strength, chemical resistance, and flexibility makes it one of the most reliable materials for demanding aerospace and industrial applications.

Kapton Polyimide in Aerospace Applications

Use in Spacecraft and Satellites

Kapton Polyimide is one of the few materials proven to survive the extreme conditions of space. It serves as thermal insulation, electrical protection, and structural support in spacecraft and satellite systems. Its ability to perform across a temperature range from −269°C to +400°C makes it indispensable in environments that alternate between direct sunlight and deep-space cold.

One of its primary uses is in multi-layer insulation (MLI)—the gold-colored thermal blankets that wrap around satellites and spacecraft. These layers of Kapton help minimize heat loss and protect onboard systems from radiation and temperature fluctuations. The film is also used to insulate spacecraft wiring and flexible circuits, ensuring that electrical signals remain stable even under radiation or vacuum conditions.

A historic example of Kapton’s reliability is NASA’s Apollo Lunar Module, which used Kapton films extensively to shield critical instruments and wiring from lunar temperature extremes. This legacy continues today, as Kapton remains a material of choice for modern satellites, Mars rovers, and orbital telescopes where consistent thermal management and insulation are vital.

Aircraft Wiring and Sensors

In modern aviation, weight reduction and reliability are crucial to both performance and safety. Kapton Polyimide provides lightweight yet durable insulation for aircraft wiring harnesses and temperature sensors. Compared to conventional PVC or Teflon insulation, Kapton offers superior heat resistance and long-term flexibility, even after thousands of flight hours.

Kapton-insulated cables can endure continuous exposure to temperatures above 200°C, making them suitable for wiring routed through engine bays or high-temperature zones. Its low outgassing and excellent dielectric strength help prevent short circuits and insulation failure at high altitudes.

The use of Kapton in temperature and pressure sensors enhances precision by maintaining electrical stability under rapid temperature changes. For aircraft manufacturers, the benefits are tangible:

Reduced overall cable weight, improving fuel efficiency.

Enhanced safety, due to consistent insulation performance.

Extended service life, minimizing maintenance and replacement costs.

Engine and Structural Components

Kapton Polyimide is not limited to insulation—it also contributes to thermal protection in aircraft engines and structural assemblies. When used as a coating or composite layer, Kapton acts as a thermal barrier, protecting sensors, electronics, and adjacent materials from heat exposure.

In turbine engines, Kapton-based composites are applied to control modules, sensor housings, and electrical connectors, where they must resist continuous high temperatures and mechanical vibration. The material’s ability to remain stable and flexible ensures that these critical systems continue operating even in high-heat zones exceeding 300°C.

Additionally, Kapton films are incorporated into aerospace-grade adhesives and laminates, reinforcing structural components while minimizing added weight. This combination of thermal endurance, low density, and mechanical stability allows aircraft and spacecraft designers to achieve higher performance without compromising safety or efficiency.

In essence, Kapton Polyimide enables aerospace systems to function reliably in environments that push the limits of materials science—from the vacuum of space to the high-pressure heat of jet engines. Its enduring performance continues to make it an essential material in both legacy missions and next-generation aerospace innovations.

Industrial and Manufacturing Applications

High-Temperature Electrical Insulation

Kapton Polyimide plays a vital role in industrial electrical systems that demand continuous operation under high thermal stress. It is widely used in motors, transformers, and generators, where insulation materials must endure both heat and voltage without degrading.

In electric motors, Kapton films insulate winding wires and slot liners, ensuring stable performance during continuous high-load operation. Unlike polyester or paper insulation, which can deteriorate above 150°C, Kapton maintains its dielectric integrity even at temperatures exceeding 250°C. This allows equipment to run longer with fewer failures, improving reliability and reducing maintenance costs.

In power transformers and high-voltage generators, Kapton is often used as an interlayer insulation film or adhesive tape backing. It resists thermal aging, corona discharge, and mechanical vibration, making it suitable for both heavy industrial machinery and compact high-efficiency systems. The result is longer operational life and safer performance in demanding electrical environments.

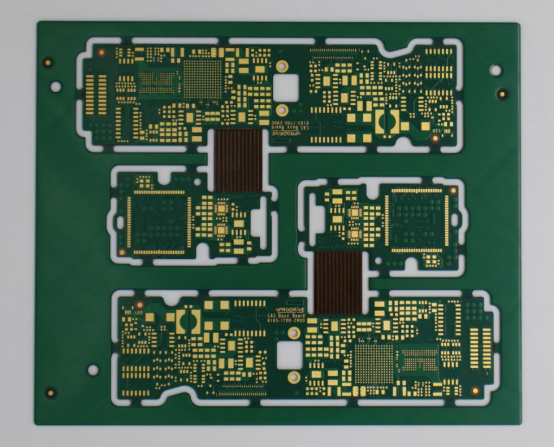

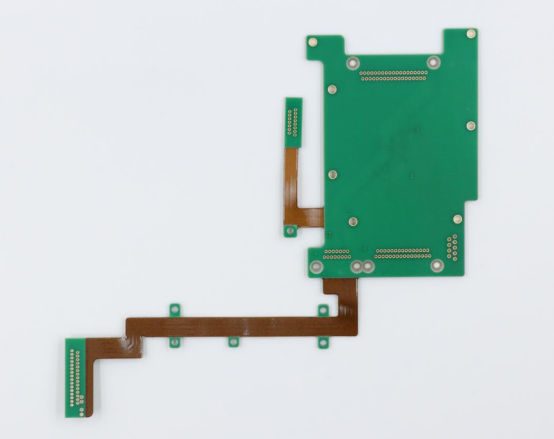

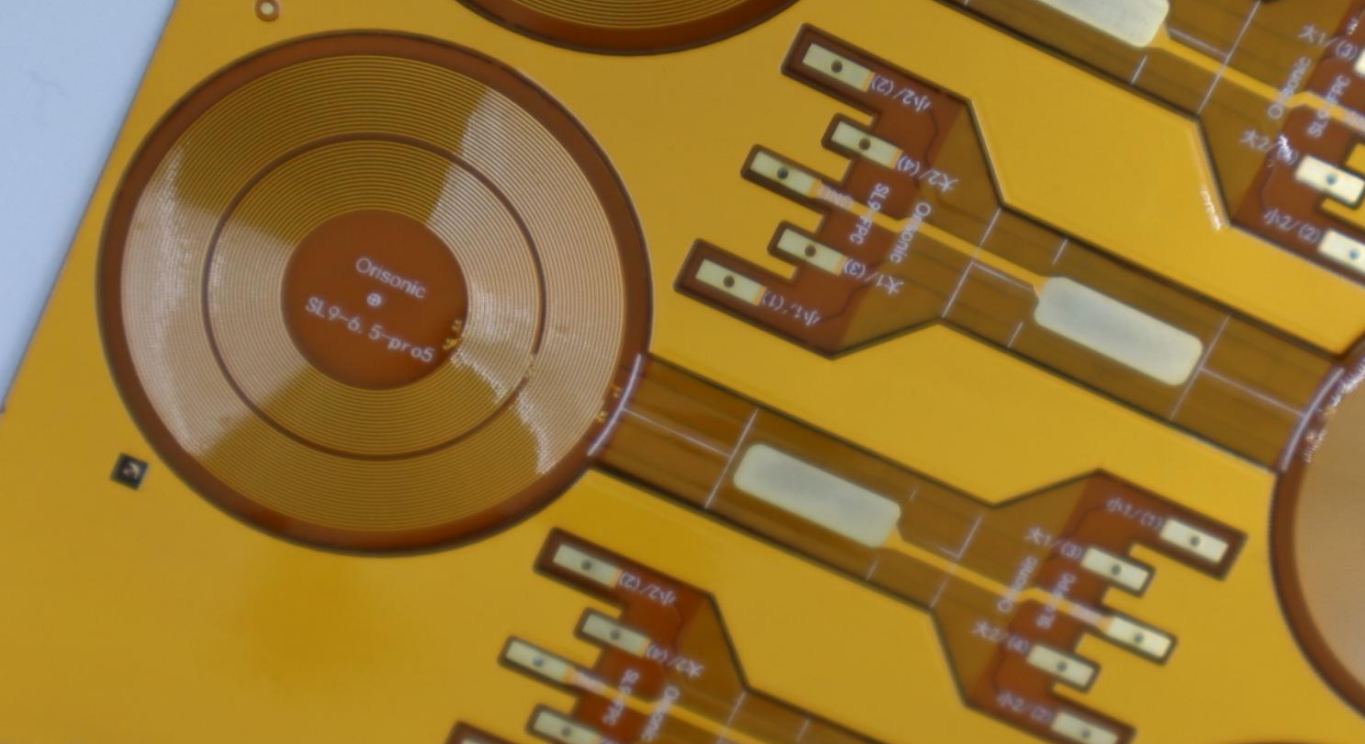

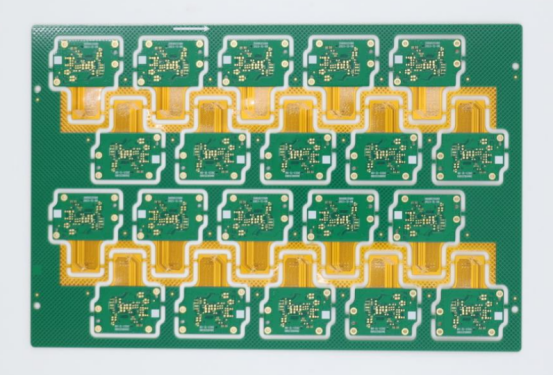

Flexible PCB and Electronics Assembly

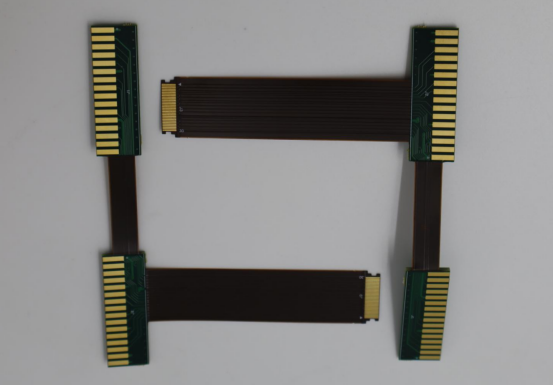

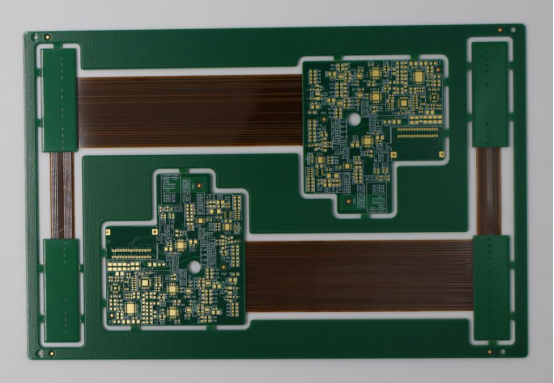

Kapton Polyimide is a foundational material in flexible printed circuit boards (FPCBs) and electronics manufacturing, where durability and miniaturization are critical. Its thin, heat-resistant structure supports fine-line copper circuits, polyimide heaters, and rigid-flex PCB assemblies that bend or fold without cracking.

Common applications include:

Flexible circuits in wearable devices, cameras, and aerospace controls.

Heaters used in 3D printers, sensors, and thermal management systems.

Rigid-flex assemblies that connect multiple PCB layers through flexible joints.

Step-by-step example: How Kapton layers are laminated in flexible PCBs:

1. Base film preparation – A Kapton film is cleaned and treated to enhance adhesion.

2. Copper foil bonding – A thin layer of copper is laminated onto the Kapton surface using heat and pressure.

3. Etching and circuit formation – Circuit traces are etched into the copper using photolithography.

4. Coverlay application – Another Kapton layer, often with adhesive, is applied to protect the circuitry.

5. Final curing and inspection – The laminated structure is heat-cured to ensure mechanical and electrical stability.

This process results in a lightweight, flexible, and thermally stable PCB that can withstand soldering temperatures and repeated bending cycles—qualities essential for modern electronics, from satellites to consumer devices.

Automotive and Energy Systems

Kapton Polyimide is increasingly used in electric vehicles (EVs), hybrid systems, and renewable energy equipment, where it supports both performance and safety.

In EV and hybrid batteries, Kapton serves as a thermal and electrical insulator between cells, preventing short circuits and enhancing battery safety. Its high dielectric strength and low outgassing make it ideal for compact, high-energy battery packs that operate under heavy load and fluctuating temperatures.

In automotive engine compartments, Kapton films protect wiring, sensors, and connectors from exposure to oil, fuel vapors, and high voltage. The material’s resistance to chemicals, vibration, and thermal stress ensures consistent performance in conditions that would quickly degrade conventional insulation materials.

Beyond vehicles, Kapton films are used in solar panels, power inverters, and wind turbines, where high-temperature endurance and electrical reliability are essential. These qualities help energy systems achieve longer lifespans and improved efficiency, even under constant exposure to heat, UV radiation, or environmental contaminants.

Kapton Polyimide’s combination of thermal endurance, flexibility, chemical resistance, and electrical strength makes it a cornerstone material in industrial and manufacturing systems—from high-voltage insulation to next-generation electronics and sustainable energy technologies.

Grades and Forms of Kapton Polyimide Materials

Common Grades

Kapton Polyimide films are available in several grades, each designed to meet specific performance or processing requirements. The most widely used types include Kapton HN, Kapton F, Kapton CR, and Kapton FN, each offering unique thermal, electrical, and mechanical characteristics.

Kapton HN: The standard all-purpose grade used across electronics, aerospace, and industrial applications. It offers balanced thermal stability, dielectric strength, and mechanical durability, making it suitable for insulation tapes, flexible circuits, and transformers.

Kapton F: Features a fluoropolymer coating that enhances surface smoothness and chemical resistance. This coating provides better release and moisture resistance, making Kapton F ideal for composite molding and insulation where clean surfaces are critical.

Kapton CR: A chemical-resistant grade specifically formulated for environments exposed to solvents, fuels, and corrosive agents. It is commonly used in automotive and aerospace wiring harnesses that must resist harsh fluids.

Kapton FN: A composite film consisting of Kapton HN coated with FEP (fluorinated ethylene propylene) on one or both sides. The FEP layer allows heat sealing and lamination, which is valuable for producing insulation sleeves, conformal wraps, and bonded circuit layers.

Each grade differs slightly in film thickness, coating composition, and processing behavior, allowing engineers to select the best match for temperature, chemical exposure, or assembly method.

Customization Options

Kapton Polyimide materials can be customized to fit a wide range of technical and manufacturing needs. Standard thicknesses typically range from 25 to 125 micrometers (µm), though thinner and thicker variants are available for specialized applications such as microelectronics or heavy-duty insulation.

Manufacturers can provide surface-treated or adhesive-backed Kapton films to improve adhesion during lamination or bonding. Treatments such as plasma etching or chemical roughening increase surface energy, ensuring stronger adhesion with metals, adhesives, or resins. Adhesive-backed Kapton—often paired with silicone or acrylic adhesives—is widely used for tapes, flexible circuits, and thermal insulation layers.

Below is a simplified comparison of Kapton film types and their typical application suitability:

Grade / Type | Key Feature | Temperature Resistance (°C) | Typical Applications |

|---|---|---|---|

Kapton HN | General-purpose | −269 to +400 | Electrical insulation, FPCs, transformers |

Kapton F | Fluoropolymer-coated | −269 to +300 | Molding release film, composite fabrication |

Kapton CR | Chemical resistant | −269 to +350 | Fuel systems, aerospace harnesses |

Kapton FN | FEP-laminated, heat-sealable | −269 to +250 | Heat-sealed insulation, bonded laminates |

Custom Thickness (25–125 µm) | Tailored mechanical strength and flexibility | Application dependent | Custom industrial and electronics projects |

These customization options enable Kapton Polyimide to serve a broad spectrum of industries—from precision electronics to high-temperature energy systems—while maintaining consistent performance and reliability.

The versatility of Kapton Polyimide lies not only in its inherent material strength but also in its diverse grades and modifiable forms, which allow engineers to optimize both thermal performance and processing efficiency for specific high-demand applications.

Manufacturing and Processing Guidelines

Handling and Storage Recommendations

Proper handling and storage are critical to maintaining the performance and longevity of Kapton Polyimide films. Kapton is hygroscopic, meaning it can absorb moisture from the air, which may affect adhesion, dielectric properties, and dimensional stability. To prevent this, films should be stored in cool, dry environments—ideally below 30°C and with relative humidity under 50%. Sealed packaging with desiccants is recommended for long-term storage.

When working with Kapton, careful attention should be given to cutting, laminating, and bonding:

Cutting: Use sharp blades or laser cutting to prevent edge fraying and micro-cracks.

Laminating: Apply uniform heat and pressure to avoid bubbles or wrinkles that compromise insulation.

Bonding: Ensure clean, dry surfaces and compatible adhesives to achieve strong adhesion with metals or other polymers.

Following these guidelines reduces material waste and ensures consistent performance in high-temperature and high-voltage applications.

Thermal Processing and Adhesion

Kapton Polyimide can withstand high-temperature processing, but proper thermal control is essential during curing, bonding, or lamination. Recommended curing temperatures generally range from 200°C to 400°C, depending on film grade and application, with times varying between 30 minutes and 2 hours to achieve optimal mechanical and electrical properties.

Kapton films exhibit excellent adhesion compatibility with common conductive and structural materials, including copper, aluminum, and epoxy. For example:

1. Copper foils in flexible PCBs bond well to Kapton using heat and pressure.

2. Aluminum coatings can be laminated with Kapton for shielding applications.

3. Epoxy resins used in composites adhere reliably to Kapton surfaces after surface preparation.

Step-by-step thermal processing ensures that the film maintains its dimensional stability, dielectric strength, and flexibility, even after repeated thermal cycles.

Quality and Testing Standards

Kapton Polyimide materials are subject to rigorous quality and testing standards to ensure reliability in critical applications. Common industry benchmarks include:

ASTM standards for mechanical, thermal, and electrical properties.

IPC standards for printed circuit materials and flexible circuits.

MIL-SPEC standards for aerospace and defense-grade films.

Key testing parameters often measured include:

Dielectric breakdown voltage – determines insulation performance under high voltage.

Tensile strength and elongation – ensures mechanical durability during handling and operation.

Shrinkage and dimensional stability – evaluates behavior under heat or thermal cycling.

Compliance with these standards provides assurance that Kapton films will perform reliably in aerospace, industrial, and electronics applications, even under extreme conditions.

Proper handling, thermal processing, and quality testing are essential to maximize the benefits of Kapton Polyimide films. Following these guidelines ensures consistent mechanical strength, electrical insulation, and thermal reliability, enabling successful deployment in high-performance and high-temperature applications.

Environmental and Sustainability Considerations

Longevity and Reusability

Kapton Polyimide is highly valued not only for its performance but also for its long-term stability, which directly contributes to environmental sustainability. Because the material resists thermal, chemical, and mechanical degradation, components made from Kapton last significantly longer than those using conventional polymers such as PVC, PET, or standard polyimides.

This extended service life reduces material turnover and waste in industrial and aerospace applications. For example, Kapton-insulated wiring in satellites or aircraft may remain functional for decades, minimizing the need for replacement and reducing associated manufacturing and disposal impacts.

A lifecycle comparison illustrates the benefit: while PET insulation may need replacement every 5–10 years under high-temperature conditions, Kapton can reliably operate for 20–30 years without performance loss. This durability translates to fewer resources consumed and a smaller environmental footprint over the lifetime of the system.

Recycling and Safe Disposal

Despite its advantages, Kapton presents challenges in recycling. The aromatic polyimide structure that gives it high-temperature and chemical resistance also makes it difficult to break down using conventional recycling methods. Currently, there are limited industrial-scale processes for polyimide recycling, and most used Kapton films are disposed of according to specialized waste management protocols.

For aerospace-grade or high-performance Kapton, safe handling and disposal are critical. Guidelines recommend:

1. Segregating Kapton waste from standard polymer waste streams.

2. Avoiding incineration without proper controls, as polyimides can release toxic fumes if burned improperly.

3. Using certified disposal or recycling facilities that can safely process high-performance films.

Manufacturers and engineers can also extend Kapton’s lifecycle by reusing scrap films in prototyping or secondary insulation layers, maximizing resource efficiency.

While Kapton Polyimide offers exceptional longevity and reusability, which reduce waste and environmental impact compared with conventional polymers, recycling remains a challenge. Proper handling, reuse, and certified disposal ensure that the environmental footprint of Kapton remains manageable, even in high-performance aerospace and industrial applications.

Choosing the Right Kapton Polyimide for Your Application

Factors to Consider

Selecting the appropriate Kapton Polyimide grade and form requires careful evaluation of several key factors. Operating temperature is the first consideration, as different grades handle heat differently. For applications exposed to continuous high temperatures or thermal cycling, higher-temperature grades such as Kapton HN or Kapton CR are recommended.

Mechanical stress is another critical factor. Flexible circuits or components that will bend, fold, or vibrate frequently require Kapton films with high tensile strength and elongation to prevent cracking or delamination. For static insulation, mechanical flexibility may be less critical, allowing for more cost-effective grades.

Chemical exposure must also be evaluated. Components exposed to fuels, oils, solvents, or oxidizing agents benefit from chemically resistant grades like Kapton CR or FEP-coated Kapton FN.

Finally, consider the cost-performance balance. Aerospace and high-end industrial applications often prioritize reliability and long-term durability over cost, while standard industrial uses may allow slightly lower grades to optimize budget efficiency without compromising essential performance.

How to Source from Trusted Manufacturers

When sourcing Kapton Polyimide, it is crucial to rely on certified and reputable suppliers. Key elements to check in datasheets and certifications include:

Material grade and specifications (temperature range, dielectric strength, thickness).

Compliance with ASTM, IPC, or MIL-SPEC standards relevant to the intended application.

Batch traceability and quality assurance certifications to ensure consistent performance.

For example, engineers can rely on PCBMASTER to provide 6–20 layer rigid-flex PCBs with flexible board sections as small as 0.8 mm, built with materials like Kapton to ensure high-temperature stability, dielectric strength, and flexibility. Their experience in handling advanced PCBs ensures that circuits perform reliably under extreme temperatures, mechanical stress, and electrical loads.

Partnering with PCBMASTER allows teams to confidently translate Kapton Polyimide’s material advantages into finished PCBs and assemblies, achieving precise, high-performance solutions for aerospace, industrial, and electronics applications.

Conclusion

Kapton Polyimide stands out as a high-performance material due to its exceptional thermal stability, electrical insulation, mechanical strength, chemical resistance, and flexibility. These properties make it ideal for demanding applications in aerospace, industrial, and high-temperature electronics, where conventional polymers often fail.

Its long-term reliability and versatility have enabled innovations from satellite wiring and flexible circuits to electric vehicle battery insulation and industrial transformers. By maintaining performance under extreme temperatures, chemical exposure, and mechanical stress, Kapton continues to advance technology in environments where safety and precision are critical.

For engineers and designers seeking tailored solutions, consulting certified Kapton manufacturers and suppliers (like PCBMASTER) ensures that the chosen grade, thickness, and coating meet specific operational requirements. Leveraging expert guidance helps maximize both performance and durability in high-demand aerospace and industrial systems.

FAQs

What temperature range can Kapton Polyimide withstand?

Kapton Polyimide can reliably operate across a wide temperature range, from −269°C (−452°F) up to +400°C (752°F). Short-term exposure may tolerate slightly higher temperatures depending on the specific grade. This makes it suitable for environments with extreme heat or cold, such as spacecraft, high-temperature motors, and industrial electronics.

How does Kapton compare to other high-temperature films like PET or PTFE?

Kapton outperforms PET and PTFE in several ways:

Compared with PET: PET typically degrades above 150°C, while Kapton remains stable up to 400°C.

Compared with PTFE: PTFE can handle high heat but lacks Kapton’s mechanical strength and dimensional stability, especially in thin-film applications.

Kapton’s combination of thermal endurance, flexibility, and dielectric strength makes it ideal for demanding aerospace and industrial uses.

Is Kapton suitable for flexible PCB applications?

Yes. Kapton is widely used in flexible printed circuits (FPCs), rigid-flex PCBs, and heaters. Its thin, flexible, and heat-resistant structure allows it to bend and fold without cracking, making it perfect for applications where circuits must withstand repeated mechanical movement or high soldering temperatures.

What are the most common thicknesses and grades of Kapton Polyimide?

Kapton films are commonly available in thicknesses from 25 µm to 125 µm, though custom thicknesses are also possible. Common grades include:

Kapton HN: General-purpose, balanced thermal and electrical performance.

Kapton F: Fluoropolymer-coated for chemical resistance and smooth surfaces.

Kapton CR: Chemical-resistant for harsh fluids and fuels.

Kapton FN: FEP-laminated, heat-sealable for bonding and insulation applications.

Can Kapton be recycled or reused in industrial settings?

Recycling Kapton is challenging due to its aromatic polyimide structure, which resists conventional recycling methods. However, it can often be reused in prototyping or secondary insulation layers to extend its lifecycle. Safe disposal is recommended for aerospace-grade materials, typically through certified recycling or waste management facilities.