High-Frequency & High-Speed PCBs Explained: PCBMASTER Technical Guide

As devices get faster and more compact, PCB performance has become a bottleneck for many industries. High-frequency and high-speed PCBs are now the key to unlocking next-gen communications, aerospace systems, and high-performance computing. Unlike traditional PCBs, their design focuses on three critical dimensions: Signal Integrity (SI), Power Integrity (PI), and Electromagnetic Compatibility (EMC) — ensuring reliability at gigahertz speeds.

Core Objective: Signal Integrity as the Top Priority

In high-frequency (≥1 GHz) and high-speed (≥1 Gbps) applications, even tiny signal losses or interferences can turn into major problems — causing communication failures, data corruption, or unstable system performance. This is why Signal Integrity (SI) becomes the absolute core of high-frequency and high-speed PCB design.

To achieve reliable transmission, every design decision and manufacturing step must focus on four key aspects:

l Signal Attenuation Control – Reduce energy loss along the transmission path by optimizing conductors, dielectrics, and minimizing radiation.

l Crosstalk Suppression – Prevent electromagnetic interference between neighboring signal traces, addressing both Near-End (NEXT) and Far-End (FEXT) crosstalk issues.

l Jitter Optimization – Stabilize signal timing and edge transitions to avoid sampling errors and maintain data integrity.

l Impedance Alignment – Maintain consistent impedance across the source, transmission line, and load (e.g., 50 Ω single-ended, 100 Ω differential) to eliminate reflections and ensure clean signal flow.

By optimizing these four areas, high-frequency and high-speed PCBs can deliver clean, reliable signals — the foundation for stable, high-performance systems.

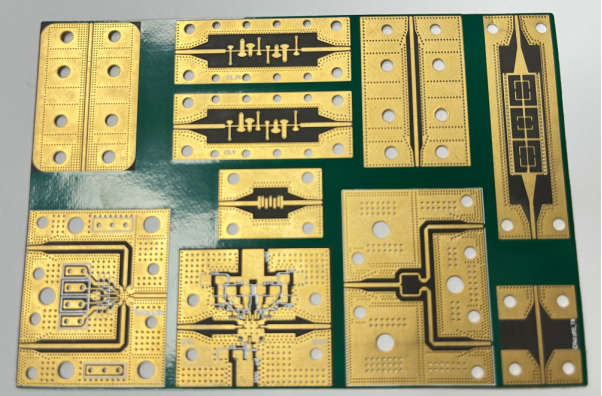

Substrate Selection: Low-Loss, High-Stability Special Materials

Substrates directly determine signal transmission quality. Standard FR-4 substrates cannot meet requirements due to high dielectric loss and unstable parameters. PCBMASTER prioritizes high-frequency special substrates, focusing on the following core parameters:

| Key Parameter | Definition | Impact on High Frequency & High Speed |

|---|---|---|

| Dielectric Constant (Dk) | The ability of a dielectric material to store electric field energy. | Should be low and stable (ideally 2.0–3.5), with minimal variation over frequency and temperature. A higher Dk slows down signal propagation and makes impedance consistency more difficult to maintain. |

Dissipation Factor (Df) | The ability of a dielectric material to dissipate electric field energy. | Should be extremely low (ideally ≤0.005). At higher frequencies, Df has a more significant impact on signal attenuation — for example, at 10 GHz, the attenuation difference between Df = 0.002 and Df = 0.02 can be several times. |

| Thermal Stability | The stability of a material’s parameters under temperature variations. | Should maintain stable Dk and Df across a wide temperature range (e.g., –55 °C to 125 °C) to prevent impedance drift. |

Selecting the optimal substrate is critical for high-frequency and high-speed PCB performance. PCBMASTER commonly uses the following materials:

l PTFE (Polytetrafluoroethylene) – Offers excellent high-frequency performance with Dk≈2.1 and Df≈0.0002, ideal for microwave applications such as radar and satellite communications.

l Rogers RO4000 Series – Balances performance and cost with Dk≈3.38 and Df≈0.0027, making it the mainstream choice for communication equipment.

l Modified FR-4 (High Tg) – High thermal stability (Tg≥170℃) and moderate loss (Df≈0.008), suitable for mid-to-low-end high-frequency and high-speed scenarios, such as USB 3.0/4.0 applications.

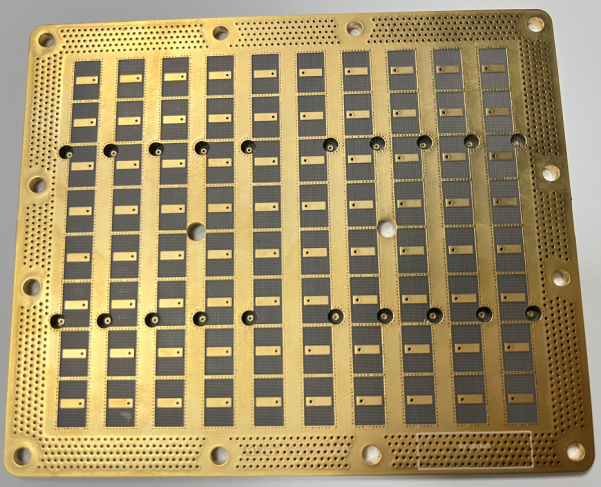

Stack-Up Design: Precise "Signal-Power-Ground" Layout

The stack-up of high-frequency and high-speed PCBs is critical for reducing interference and optimizing signal loops. PCBMASTER typically implements the following design principles:

l Ensure Signal Layers are Adjacent to Reference Planes – Place each high-speed signal layer close to a ground (GND) or power (PWR) plane to form microstrip or stripline structures, minimizing radiation and crosstalk.

l Pair Power and Ground Layers – Position power and ground planes next to each other to create a low-impedance Power Distribution Network (PDN), suppressing power noise.

l Maintain Multi-Layer Symmetry – Design with 8 or more layers (server motherboards often 12–20 layers) in a symmetrical layout (e.g., “Signal-Ground-Power-Ground-Signal”) to prevent PCB warping.

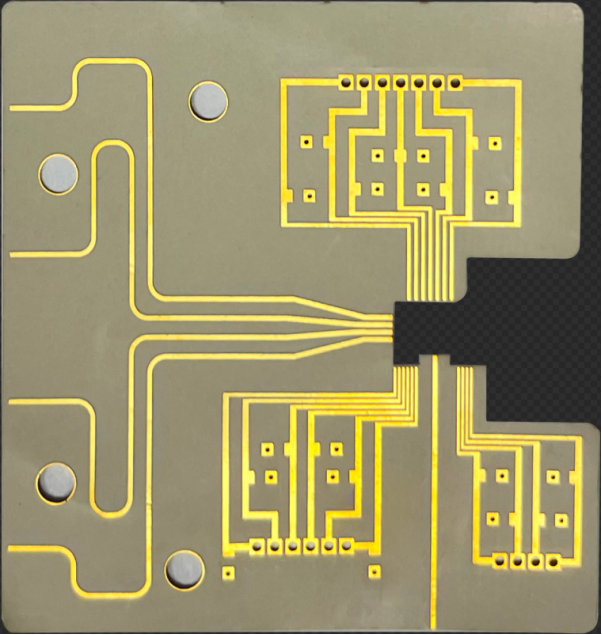

Routing Design: Strict Physical Rules and Topology Optimization

Routing is the foundation of signal integrity in high-speed PCBs. PCBMASTER follows these core rules to ensure reliable signal transmission:

l Ensure Differential Pair Routing – For signals such as USB and PCIe, maintain equal length, width, and spacing (tolerance ≤5 mil) with full parallelism to guarantee differential transmission performance.

l Control Length Matching – DDR buses require careful length control (tolerance ≤20 mil) to avoid timing mismatches.

l Apply the 3W Principle – Maintain signal line spacing at least three times the line width to suppress crosstalk.

l Reduce Via Usage – Prefer blind and buried vias over through vias to minimize parasitic effects and signal reflections.

l Adopt Topology Optimization – Use star, point-to-point, or fly-by layouts (e.g., DDR5) to balance delay and load across the PCB.

Electromagnetic Compatibility (EMC): Proactive Interference and Radiation Suppression

High-frequency and high-speed signals are prone to electromagnetic interference and radiation, which can affect device performance. PCBMASTER implements the following EMC measures:

l Ensure a Continuous Ground Plane – Use large-area, uninterrupted ground planes to provide shielding and reduce interference.

l Apply Shielding Design – Implement shielding covers or cavities for RF links and wrap sensitive signals (e.g., clock) with ground to minimize radiation.

l Implement Filtering and Decoupling – Place high-frequency filter capacitors at power inlets, and use 0.1μF + 10μF decoupling capacitor combinations near chips to stabilize power and suppress noise.

Manufacturing Process: High Precision and Consistency

High-frequency and high-speed PCBs demand strict process precision to maintain signal integrity and impedance stability. PCBMASTER follows these core process standards:

l Maintain High-Precision Line Widths – Keep line width tolerance within ±5 μm to ensure consistent impedance.

l Use Fine Drilling Techniques – Achieve blind/buried via diameters as small as 0.1 mm, with hole position accuracy ≤ ±25 μm using laser or mechanical drilling.

l Prioritize Surface Finish – Use Electroless Nickel Immersion Gold (ENIG) or Immersion Silver instead of HASL to avoid impedance instability.

l Test Impedance Carefully – Verify each batch using a Time Domain Reflectometer (TDR) to ensure impedance remains within the target range (e.g., 50 Ω ±10%).

Thermal Management: Addressing High-Power Dissipation Challenges

High-frequency and high-speed chips such as CPUs and FPGAs can dissipate tens to hundreds of watts. Effective thermal management is crucial to maintain performance and prevent failures. PCBMASTER implements the following solutions:

l Use Thickened Copper Layers – Apply 2 oz or thicker copper on power and ground planes to improve thermal conductivity.

l Implement Thermal Structures – Add thermal vias (Via-in-Pad) under heat-generating components and integrate large-area heat sinks.

l Apply Auxiliary Cooling – Optionally use heat sinks, heat pipes, or metal-based PCBs (aluminum or copper substrates) to enhance heat dissipation.

Summary

High-frequency and high-speed PCBs require systematic optimization across materials, design, manufacturing, and testing. With years of technical expertise, PCBMASTER ensures full-process control from substrate selection to final product delivery, guaranteeing signal integrity, system stability, and reliable performance for your applications.

About PCBMASTER

PCBMASTER specializes in the R&D and manufacturing of high-end PCBs, including high-frequency, high-speed, and RF boards. We provide customized solutions for industries such as communications, aerospace, and industrial control.

For technical consultation or sample requests, our team is ready to assist — ensuring your projects achieve reliable performance and superior signal integrity.

High-Frequency & High-Speed PCB Material References

For readers looking to dive deeper into PCB materials, PCBMASTER provides two comprehensive selection guides:

l High-Frequency PCB Material Selection Guide – Detailed reference for choosing the right high-frequency substrates.

l High-Speed PCB Material Selection Guide – Practical guide for selecting high-speed PCB materials.

Download these guides to support your design decisions and ensure optimal PCB performance.