High-Difficulty PCB Manufacturing: Expert Techniques for Precision & Reliability

Modern industrial systems demand unmatched speed, precision, and reliability. Every advanced machine, medical device, and smart energy system relies on PCBs that can withstand extreme conditions while ensuring flawless data transmission. High-difficulty PCBs are engineered to meet these challenges, turning complex designs into consistent, high-performance operation. Exploring their capabilities reveals how advanced manufacturing transforms intricate technology into dependable results.

Understanding High-Difficulty PCB Manufacturing

What Makes a PCB “High-Difficulty”?

High-difficulty PCBs are distinguished by the complexity of their design and the precision required in manufacturing. Several factors contribute to this classification:

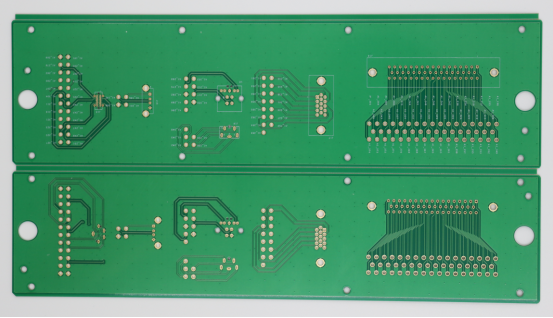

Multiple design constraints: These boards often feature ultra-fine traces, tight spacing between conductors, high layer counts, and combinations of different materials. For example, a 16-layer PCB with 3.8/3.8 mil track/space and mixed materials like polyimide and FR4 requires extreme precision to avoid signal loss or short circuits.

Specialized processes: Manufacturing high-difficulty PCBs requires advanced techniques such as controlled impedance, HDI (High-Density Interconnect) structures, microvias, and precise thermal management. Controlled impedance ensures signals travel without distortion, while microvias allow for high-density routing in limited space.

Limitations of standard methods: Conventional PCB manufacturing methods cannot reliably meet these requirements. Standard boards may fail under high temperatures, strong vibration, or electromagnetic interference, leading to signal errors, component damage, or complete system failure.

High-difficulty PCBs demand tighter tolerances, specialized materials, and advanced fabrication processes to perform reliably in conditions that would overwhelm typical boards.

Core Requirements for Mission-Critical Applications

High-difficulty PCBs are commonly used in mission-critical applications where failure is not an option. Key requirements include:

Reliability under harsh conditions: These PCBs must withstand shock, vibration, and thermal cycling. For instance, automotive electronics or industrial control systems often operate in environments ranging from -40°C to +125°C while experiencing constant mechanical stress.

Real-time communication and high-speed signaling: Systems such as robotics, automation, and medical equipment depend on boards that maintain stable, high-speed data transmission. Features like low crosstalk, controlled impedance, and high-frequency signal support are essential.

Stable performance in electrically noisy environments: Industrial or transportation settings often have significant electromagnetic interference (EMI). High-difficulty PCBs are designed to maintain signal integrity through proper grounding, shielding, and layer stack optimization.

By meeting these core requirements, high-difficulty PCBs ensure that complex systems operate reliably, safely, and efficiently in even the most challenging applications.

Key Design Characteristics of High-Difficulty PCBs

Structural Reinforcement for Extreme Conditions

High-difficulty PCBs are often exposed to harsh environments, requiring designs that can endure extreme temperatures, mechanical stress, and continuous operation.

Temperature resilience: Industrial-grade PCBs are engineered to operate reliably between -40°C and +125°C. This involves selecting materials with low thermal expansion and designing layer stacks that minimize stress under temperature cycling. For example, combining high-Tg FR4 with polyimide layers can reduce warping and maintain dimensional stability.

Vibration and impact resistance: Mechanical stresses from shocks or vibration are addressed through structural reinforcement. Techniques include adding stiffeners, copper pour reinforcement, and mechanical supports to critical areas. Automotive control units or factory automation boards often use these methods to prevent trace fractures or component detachment.

Material selection for durability: Materials are chosen for chemical resistance, thermal endurance, and mechanical strength. Polyimide and PTFE are preferred in high-temperature or high-frequency applications, while reinforced FR4 remains cost-effective for standard industrial use.

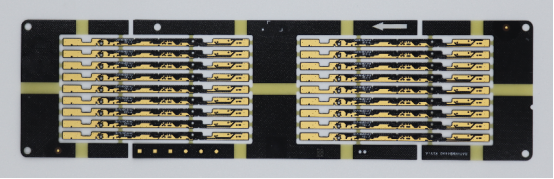

High-Speed and High-Frequency Performance

Modern industrial systems rely on fast, accurate data transmission. High-difficulty PCB design ensures signal integrity under demanding conditions.

Controlled impedance strategies: Designers implement precise impedance control, typically 50Ω single-ended, 90Ω, or 100Ω differential pairs, to maintain signal quality. This prevents reflections and ensures reliable high-speed communication.

Crosstalk mitigation: Crosstalk can disrupt sensitive signals. Methods such as guard traces, optimized layer stacking, and careful routing reduce interference. For example, placing critical differential pairs between ground planes or alternating signal layers can lower crosstalk by 30–50%.

Use cases: Applications requiring fast, stable signal integrity include industrial automation networks, transportation communication modules, and power system controllers. High-speed PCB design enables real-time monitoring and control in these environments.

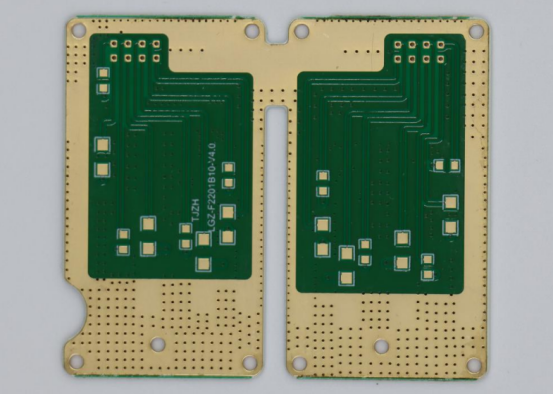

Advanced Material Integration

Material choice is a key factor in balancing performance, reliability, and cost in high-difficulty PCBs.

Polyimide vs. PTFE vs. high-Tg FR4: Polyimide offers excellent thermal stability, PTFE supports ultra-high-frequency applications, and high-Tg FR4 is cost-effective for moderate frequencies. Designers often select materials based on operating temperature, frequency requirements, and mechanical stress.

When aluminum-core PCBs are used: Aluminum-core boards are ideal for applications with high power density or heat generation, such as LED drivers, power converters, and high-current modules. The metal core efficiently dissipates heat and improves thermal management.

Trade-offs: Advanced materials improve performance but increase manufacturing complexity and cost. Engineers must balance thermal, mechanical, and electrical needs against budget and producibility, selecting the optimal combination for each project.

Essential Components and Manufacturing Techniques

Precision Components for Industrial-Grade Systems

High-difficulty PCBs rely on precision components to handle complex tasks and ensure reliable operation in industrial applications.

Microcontrollers and processors: These components serve as the brain of the PCB, managing high-speed serial data, executing real-time instructions, and controlling system functions. In industrial automation, microcontrollers often handle RS-485 or CAN bus communications while maintaining low latency.

Interface support: Different serial communication standards are used depending on the application. For example:

Interface | Typical Use | Advantages |

|---|---|---|

RS-232 | Legacy industrial equipment | Simple, reliable for short distances |

RS-485 | Factory automation, long-distance networks | Differential signaling reduces noise |

CAN | Automotive, robotics | Multi-node communication, robust error handling |

Selecting the appropriate interface ensures accurate and reliable data transfer, even in electrically noisy environments.

Embedded displays: Many high-difficulty PCBs integrate small screens to provide real-time monitoring of system parameters, allowing operators to make quick decisions. Examples include temperature displays in power converters or status screens in automated production machines.

Advanced Thermal Management Strategies

Thermal management is critical for high-difficulty PCBs, as overheating can degrade performance or cause failure.

Heat dissipation techniques: Common methods include metal-core PCBs, thermal vias, and copper coins. Metal-core boards improve heat conduction, thermal vias transfer heat from hot components to internal layers, and copper coins distribute heat across critical areas.

IPC-2221 guidelines: These standards define temperature rise limits, copper thickness, and via placement rules. Following IPC-2221 helps designers prevent hotspots and ensures thermal reliability in industrial-grade systems.

Example of thermal simulation: Designers often perform thermal simulations during PCB development. Steps include defining heat sources (like microcontrollers), modeling heat transfer through copper layers and vias, and adjusting component placement or adding thermal reliefs to maintain safe operating temperatures.

Protective Layers and Reliability Enhancements

Protective coatings and reliability-focused design techniques extend the lifespan of high-difficulty PCBs in harsh environments.

Conformal coatings: Materials like acrylic, silicone, and parylene protect against moisture, dust, and chemical exposure. Acrylic is easy to apply but less heat-resistant, silicone offers flexibility under thermal cycling, and parylene provides superior barrier performance but at higher cost.

Moisture and chemical protection: Boards exposed to industrial chemicals or high humidity require coatings, encapsulation, or sealed housings to prevent corrosion and insulation failure.

Long-term reliability testing: Manufacturers test PCBs for durability using methods such as salt spray, humidity cycling, and insulation resistance measurements. These tests simulate years of real-world operation, ensuring the PCB maintains electrical and mechanical integrity over time.

Applications Across High-Demand Industries

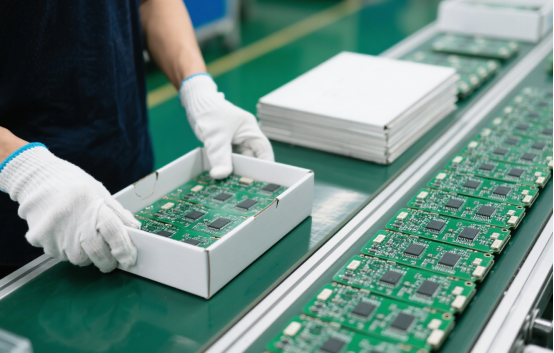

Factory Automation and Intelligent Manufacturing

High-difficulty PCBs are integral to modern factory automation systems, where reliability and precision are essential.

Real-world use cases: These PCBs are commonly used in robotic controls, motor drivers, and programmable logic controller (PLC) systems. For example, a robotic assembly line may rely on high-density PCBs to process sensor inputs and coordinate multiple actuators in real time.

Low-latency communication: Maintaining minimal delay in data transmission is critical for production uptime. High-speed serial interfaces and controlled impedance traces ensure signals travel without disruption, preventing machine errors and downtime in automated production environments.

Automotive and Transportation Systems

The automotive and transportation sectors demand PCBs that can endure vibration, temperature extremes, and electromagnetic interference.

Key applications: High-difficulty PCBs are used in advanced driver-assistance systems (ADAS), engine control units (ECUs), and infotainment systems. For example, ADAS modules require rapid signal processing from multiple sensors to provide real-time driver assistance.

Vibration and EMC considerations: Automotive PCBs must maintain electrical performance despite continuous vibration and EMI from motors, alternators, and wireless systems. Reinforced structures, proper grounding, and shielding are standard practices to ensure reliability.

Healthcare and High-Precision Equipment

In medical applications, failure is not an option. High-difficulty PCBs support life-critical systems where precision and safety are paramount.

Life-critical use cases: Medical imaging systems, diagnostic tools, and wearable medical devices rely on these PCBs for consistent operation. For instance, MRI scanners use PCBs to control high-frequency signals while managing heat and maintaining signal integrity.

Zero-failure tolerance: These applications demand extremely low failure rates. High-quality materials, advanced manufacturing processes, and rigorous testing protocols ensure that PCBs function reliably under continuous operation.

Energy, Utilities, and Smart Infrastructure

High-difficulty PCBs are essential in energy management and smart infrastructure systems, supporting both monitoring and control functions.

Applications: Grid monitoring units, energy converters, and renewable energy controllers often integrate high-performance PCBs. For example, solar inverters use PCBs to handle high power density and maintain thermal stability while regulating energy flow.

Screen-integrated monitoring: Embedded displays allow operators to visualize critical data in real time, enhancing system management and decision-making. This feature is particularly useful in smart grids and industrial IoT systems, where fast response and accurate monitoring are required.

Why Partner with a Specialist in High-Difficulty PCB Manufacturing

Expertise with Complex Structures

High-difficulty PCBs often involve multilayer stacks, HDI (High-Density Interconnect) designs, and hybrid-material constructions. Working with a specialist ensures that these complex structures are handled with precision.

Experience matters: Experts have extensive knowledge of multilayer routing, microvias, blind and buried vias, and hybrid materials such as polyimide combined with high-Tg FR4.

Solving common challenges: Typical manufacturing issues include misalignment of microvias, layer warping during lamination, or signal degradation in high-speed traces. Specialists apply advanced techniques like precision lamination, controlled impedance tuning, and automated inspection to address these problems efficiently.

Advanced Equipment and Process Control

Specialized equipment and tightly controlled processes are critical for consistent high-difficulty PCB production.

Key technologies: Laser drilling enables microvia creation with micron-level accuracy, automated optical inspection (AOI) detects trace and pad defects early, and controlled-depth routing allows precise layer cuts without damaging adjacent layers.

Workflow control: Maintaining strict process sequences, from lamination to solder mask application, ensures uniformity and minimizes defects. Specialists implement process monitoring and automated checks to achieve high yield rates.

Quality Assurance and Certifications

Reliable high-difficulty PCBs require rigorous quality control and adherence to recognized industry standards.

Standards: IPC-6012 defines performance and qualification requirements for rigid PCBs. IATF 16949 ensures quality in automotive-related electronics, and UL certifications verify safety compliance.

Quality checkpoints: From initial design verification to raw material inspection, in-process testing, and final electrical and mechanical validation, specialists follow structured protocols. This step-by-step approach prevents defects and guarantees that PCBs meet both functional and regulatory requirements.

Project Support and Delivery Reliability

Partnering with a specialist provides more than manufacturing—it includes proactive engineering support and reliable delivery.

DFM/DFX collaboration: Design-for-Manufacturing (DFM) and Design-for-Excellence (DFX) reviews early in the project identify potential production challenges, optimize layouts, and reduce rework.

Reducing risk and lead time: Case examples show that involving engineers during prototype stages can prevent costly redesigns. For instance, early review of high-density interconnect layouts can ensure proper via alignment, prevent signal loss, and shorten overall production cycles.

Choosing the Right Partner for High-Difficulty PCB Projects

Key Evaluation Criteria

Selecting the right manufacturer is critical for successful high-difficulty PCB projects. Key factors include:

Technical capability and equipment level: The supplier must have experience with multilayer, HDI, and hybrid-material PCBs. Advanced equipment like laser drills, automated optical inspection (AOI), and controlled-depth routing machines ensures precision in complex fabrication processes.

Material suppliers and sourcing: Reliable material sourcing is essential for consistent performance. High-Tg FR4, polyimide, PTFE, and aluminum-core substrates must meet stringent quality standards to ensure durability in extreme environments.

Ability to handle complex stackups and multi-stage fabrication: Experienced manufacturers can manage high-layer-count boards, blind/buried vias, microvias, and sequential lamination processes. Their expertise reduces errors and improves yield rates.

Track record in industrial-grade and harsh-environment products: Proven experience with automotive, aerospace, medical, or industrial automation applications indicates the manufacturer can meet the demands of mission-critical systems.

Questions to Ask Before Selecting a Manufacturer

Before committing to a partner, it is important to clarify their capabilities and processes. Key questions include:

Can the supplier maintain impedance tolerance of ±10%? Controlled impedance is crucial for high-speed signal integrity. Ask for examples or test reports demonstrating consistent results.

What testing methods are used for vibration and thermal reliability? Reliable manufacturers perform thermal cycling, vibration tests, and humidity or insulation resistance tests to validate performance under harsh conditions.

How does the team support long product lifecycles? Enquire about DFM/DFX collaboration, spare part availability, and ongoing support to ensure boards remain reliable throughout the product’s operational life.

Why Choose PCBMASTER for High-Difficulty PCB Projects

When selecting a partner for complex PCB manufacturing, PCBMASTER stands out for its proven expertise and advanced capabilities. Our team has extensive experience with multilayer, HDI, and hybrid-material boards, using state-of-the-art equipment like laser drills, automated optical inspection (AOI), and controlled-depth routing machines.

We ensure consistent quality through reliable material sourcing, rigorous testing, and adherence to industry standards. From design-for-manufacturing (DFM) collaboration to full lifecycle support, PCBMASTER delivers high-difficulty PCBs that meet the demands of industrial, automotive, healthcare, and energy applications.

Partner with PCBMASTER to achieve precision, reliability, and performance in your most challenging PCB projects.

Conclusion

High-difficulty PCB manufacturing demands more than advanced materials—it requires precise process control, experienced engineering, and rigorous quality management. Manufacturers with deep expertise can reliably handle multilayer HDI boards, controlled-impedance designs, and hybrid-material constructions while maintaining performance under extreme temperatures, vibration, and electrical noise.

By combining material selection, precision fabrication, and thorough testing, high-difficulty PCBs deliver unmatched precision, speed, and reliability for industries such as automotive, healthcare, industrial automation, and energy systems. For example, a well-engineered PCB in an ADAS module or industrial motor controller can maintain signal integrity and thermal stability even under continuous, high-stress operation.

Partnering with an experienced manufacturer ensures your complex PCB projects are executed efficiently, meet stringent performance standards, and remain reliable over their entire lifecycle. Contact PCBMASTER today to discuss your high-difficulty PCB needs and achieve superior results in demanding applications.

FAQs

What qualifies as a high-difficulty PCB?

A high-difficulty PCB is defined by its complex design, precise manufacturing requirements, and ability to operate under extreme conditions. Characteristics include:

Multiple constraints such as fine traces, tight spacing, and high layer counts.

Use of mixed or advanced materials like polyimide, PTFE, or high-Tg FR4.

Specialized manufacturing processes including controlled impedance, microvias, HDI structures, and advanced thermal management.

The capability to maintain performance under high temperatures, vibration, or electromagnetic interference.

Which industries rely most on complex, high-reliability PCBs?

High-difficulty PCBs are critical in sectors where reliability, speed, and precision are essential:

Industrial automation: Robotic controls, motor drivers, and PLC systems.

Automotive and transportation: ADAS modules, engine control units, and infotainment systems.

Healthcare and medical devices: Imaging systems, diagnostic equipment, and wearable devices.

Energy and utilities: Smart grids, renewable energy controllers, and power converters.

How do thermal management techniques improve PCB performance?

Thermal management prevents overheating, which can reduce signal integrity or damage components. Techniques include:

Metal-core PCBs: Efficiently dissipate heat from high-power components.

Thermal vias and copper coins: Transfer heat from hotspots to other layers.

Simulation and design compliance: Following IPC-2221 standards and performing thermal simulations ensures temperature distribution remains within safe limits.

These methods maintain performance, extend lifespan, and prevent failure in high-stress applications.

What materials are best for high-speed or high-temperature PCB designs?

Material choice depends on thermal, mechanical, and electrical requirements:

Polyimide: Excellent thermal stability for high-temperature operation.

PTFE: Supports ultra-high-frequency signals, ideal for RF and high-speed applications.

High-Tg FR4: Cost-effective and reliable for moderate-speed, industrial-grade applications.

Aluminum-core substrates: Used in high-power or heat-intensive circuits to improve thermal dissipation.

How do manufacturers ensure signal integrity in harsh industrial environments?

Maintaining signal integrity requires both design and process strategies:

Controlled impedance: Ensures signals travel without reflections or distortion.

Crosstalk mitigation: Guard traces, optimized layer stacking, and proper routing reduce interference.

Shielding and grounding: Protect sensitive signals from electromagnetic interference (EMI).

Testing: Boards are validated under vibration, thermal cycling, and electrically noisy conditions to confirm reliable performance.