What Does FPC Connector Mean on iPhone? Full Explanation

If you’ve ever peered inside an iPhone or noticed the tiny, flat cables connecting its components, you’ve likely come across something called an FPC connector. Though small and easy to overlook, these connectors play a crucial role in keeping your device’s screen, camera, and other features working seamlessly. Understanding what an FPC connector is and why it matters can shed light on the intricate engineering that goes into every iPhone.

Introduction to FPC Connectors in iPhone

Definition of FPC Connector

An FPC connector, or Flexible Printed Circuit connector, is a small electronic component that links a flexible circuit to a rigid printed circuit board (PCB). Flexible circuits are thin, bendable strips of conductive material that can carry signals or power within tight spaces, while rigid boards are the stable platforms that hold most of the electronics in a device. The FPC connector acts as the bridge between these two, ensuring a reliable electrical connection even when the flexible circuit is bent or folded.

FPC connectors are widely used in consumer electronics, such as smartphones, tablets, laptops, and cameras. In smartphones like the iPhone, they connect delicate components such as displays, cameras, and sensors without taking up much space. Compared to traditional wiring or ribbon cables, FPC connectors allow for more compact designs while maintaining stable signal transmission.

Importance in iPhone Design

Apple relies heavily on FPC connectors to achieve the slim, high-performance design that iPhones are known for. These connectors allow multiple internal components to communicate efficiently without increasing the device’s thickness. For example, the display connector links the OLED panel to the motherboard, while camera connectors transmit high-speed image data. Other sensors, including Face ID modules, proximity sensors, and touch panels, also depend on FPC connectors to function correctly.

Using FPC connectors offers several advantages:

Space efficiency: Flexible circuits can curve around corners and fit into tight internal layouts.

High-density connections: Multiple signals can be routed through a single connector, reducing the number of individual wires.

Durability: They withstand repeated bending and stress better than traditional ribbon cables.

In short, without FPC connectors, the iPhone’s sleek form factor and advanced features would be much harder to achieve. These tiny components are essential for connecting the many layers of technology hidden beneath the phone’s glass surface.

How FPC Connectors Work in iPhones

Structure and Components

An iPhone’s FPC connector is made up of several key parts that work together to ensure a reliable electrical connection:

Contacts: Tiny conductive points that touch the flexible circuit and transmit signals.

Terminals: Metal strips or pads that connect contacts to the motherboard.

Housing: The plastic casing that holds the connector in place and aligns the FPC.

Locking Mechanism: A small clip or slide that secures the FPC, preventing accidental disconnection.

FPC connectors come in different types. Standard FPC connectors require gentle pressure to insert the flexible cable, while ZIF (Zero Insertion Force) connectors allow the FPC to slide in easily and lock without applying force. ZIF connectors are common in iPhones because they reduce the risk of damaging delicate circuits during assembly or repair.

Step-by-Step Functionality

The process of how an FPC connector works in an iPhone can be broken down as follows:

1. Alignment: The flexible circuit is carefully positioned over the connector’s contacts.

2. Insertion: The FPC slides into the connector. For ZIF connectors, this requires minimal force.

3. Locking: The connector’s locking mechanism secures the FPC in place, ensuring stable contact.

4. Signal Transmission: Electrical signals travel from the flexible circuit through the connector to the motherboard, enabling communication between components like the display, camera, or sensors.

This system ensures that even when the iPhone is moved, dropped, or vibrated, the internal components remain connected and functional.

Types of FPC Connectors Used in iPhones

iPhones use several types of FPC connectors depending on the required density and size:

Standard FPC Connectors: Suitable for low-density signals and larger connections, such as some older iPhone models’ button circuits.

High-Density FPC Connectors: Handle multiple signals in a compact space, used in modern iPhone displays and camera modules.

Micro FPC Connectors: Extremely small connectors for miniaturized components like proximity sensors, Face ID modules, and microphone circuits.

Examples in iPhones:

Display Connector: Transfers video and touch signals from the motherboard to the screen.

Battery Connector: Carries power from the battery to the logic board.

Camera Connector: Sends high-speed image data from the camera module to the processor.

Choosing the correct type of FPC connector ensures optimal performance, durability, and compact internal design, which are all critical in Apple’s iPhone engineering.

Identifying FPC Connectors on Your iPhone

Visual Guide

FPC connectors are small but distinctive components inside an iPhone. They typically appear as flat, flexible cables with shiny gold contacts, attached to a plastic or metal housing. Many FPC connectors include a locking tab or clip that secures the cable in place.

Examples of FPC connectors in iPhones include:

Display connector: A wide flat cable linking the screen to the motherboard.

Camera connector: Smaller, often located near the top of the device, transmitting high-speed image data.

Battery connector: Usually near the logic board, carrying power signals.

Key visual features to recognize:

Thin, flexible ribbon or strip of conductive material.

Gold-plated contact pads at one end.

Locking mechanism that flips or slides to secure the cable.

These visual cues help technicians or curious users identify which component they are inspecting or replacing.

Tools Needed for Inspection

Inspecting FPC connectors requires precision tools and careful handling:

Screwdrivers: Pentalobe or Phillips depending on the iPhone model.

Magnifying glass or loupe: To see small contacts and locking tabs clearly.

Anti-static equipment: Wrist straps or mats to prevent ESD (electrostatic discharge) damage.

Safety tips:

Power off the iPhone completely before disassembly.

Work in a clean, static-free environment.

Avoid bending or forcing flexible cables, as this can damage the FPC or connector.

Using the right tools and precautions ensures that the delicate FPC connectors remain intact during inspection or minor repairs.

Common Signs of Connector Issues

FPC connector problems can affect iPhone performance in subtle or obvious ways. Common signs include:

Display flickering or touch unresponsiveness: Often caused by a loose or damaged display FPC connector.

Unresponsive buttons or sensors: Faulty connectors for volume buttons, Face ID, or proximity sensors.

Camera malfunction or image distortion: If the camera FPC connector is not properly seated.

Other potential symptoms: intermittent device freezing, failed charging, or error messages related to hardware components. Recognizing these signs early can help determine whether the issue is with the connector itself or the connected component.

Comparison with Other Connectors

FPC vs. Ribbon Cable Connectors

While FPC connectors and ribbon cable connectors may look similar at first glance, they have distinct structural and functional differences.

Structure: Ribbon cables are typically thicker and less flexible, consisting of multiple insulated wires in a flat arrangement. FPC connectors, on the other hand, use thin, flexible circuits with conductive traces embedded in a plastic substrate, allowing them to bend and fit into tight spaces.

Function: Ribbon cable connectors often rely on mechanical pressure to maintain contact, whereas FPC connectors, especially ZIF types, use a locking mechanism for a secure, low-resistance connection.

Advantages of FPC connectors in iPhones:

Allow components like the display and camera to be positioned in complex internal layouts without adding bulk.

Support high-density signal routing, enabling multiple signals to pass through a single connector.

Reduce the risk of damage during assembly or repair, thanks to ZIF mechanisms.

For example, the iPhone’s front camera uses a high-density FPC connector instead of a standard ribbon cable, which saves space and allows for precise placement of Face ID sensors.

FPC vs. Standard PCB Connectors

Standard PCB connectors are rigid, larger, and generally used for fixed, low-flexibility connections on circuit boards. FPC connectors differ in several ways:

Flexibility: FPC connectors can bend, fold, and follow the contours of the device interior. Standard PCB connectors are rigid and cannot accommodate compact or curved designs.

Size: FPC connectors are much smaller, making them ideal for modern smartphones where space is limited.

Signal Handling: FPC connectors can manage high-speed digital signals over short distances with minimal interference, which is critical for iPhone display, camera, and sensor modules.

Because of these advantages, FPC connectors are preferred for dense mobile electronics, where space efficiency, flexibility, and reliable signal transmission are essential. For instance, connecting an iPhone’s OLED display to the logic board would be challenging with a standard PCB connector due to space and flexibility limitations.

Maintenance and Replacement of iPhone FPC Connectors

Common Maintenance Practices

Maintaining FPC connectors in your iPhone helps prevent malfunctions and prolongs the life of your device. Key practices include:

Cleaning contacts: Dust, debris, or corrosion on the gold contacts can interrupt signal flow. Use a soft, lint-free cloth or isopropyl alcohol to gently clean the surfaces.

Reseating cables: Over time, slight loosening can occur. Carefully disconnect and reconnect the FPC cable to ensure a secure connection.

Avoiding bending stress: FPCs are flexible but can be damaged by excessive bending or folding. Always handle cables gently and avoid sharp angles.

Regular attention to these practices can prevent common issues like display flickering, unresponsive sensors, or camera errors.

Step-by-Step Replacement Guide

Replacing an FPC connector requires precision and the right tools:

1. Tools and materials needed:

Precision screwdrivers (Pentalobe, Phillips)

Plastic pry tools or spudgers

Anti-static wrist strap and mat

Replacement FPC connector

2. Removing the old connector safely:

Power off the iPhone completely.

Open the device using proper screwdrivers and remove the relevant internal components to access the connector.

Release the locking mechanism gently, then slide out the FPC cable without applying force.

3. Installing a new FPC connector and testing function:

Insert the new FPC cable into the connector slot carefully.

Secure the locking tab or slide to lock the cable in place.

Reassemble the device and power it on. Test the component (display, camera, or sensor) to ensure proper functionality.

Following these steps ensures a secure, functional replacement while minimizing the risk of damage.

Professional Repair vs. DIY

While some users attempt DIY FPC connector replacements, there are risks:

Accidental damage to the delicate flexible circuit or surrounding components.

Misalignment of the connector, leading to intermittent or nonfunctional signals.

Voiding Apple warranty or support eligibility.

When to seek professional repair:

If the connector is high-density or extremely small (e.g., camera or Face ID modules).

When precision tools or experience are lacking.

If multiple internal components need disassembly to access the connector safely.

Professional repair services ensure that connectors are replaced accurately and safely, reducing the risk of permanent damage to your iPhone.

Future of FPC Connectors in iPhones

Trends in iPhone Design

As iPhones continue to evolve, the design of internal connectors is also changing. One clear trend is the increasing use of high-density and smaller FPC connectors. These compact connectors allow Apple to fit more components into a thinner device without compromising performance.

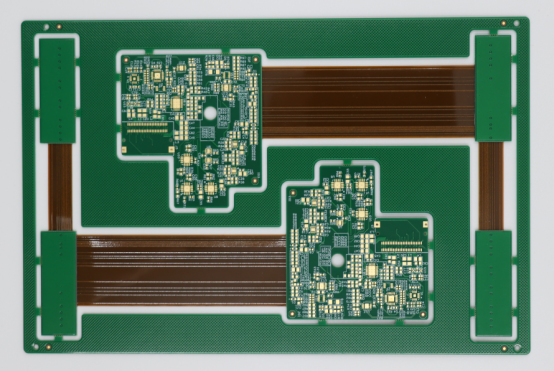

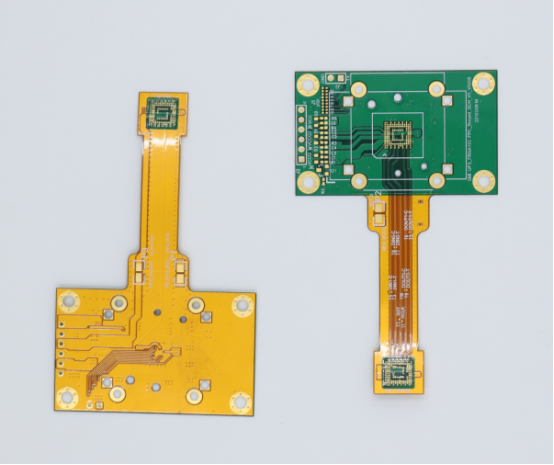

Additionally, innovations in flexible circuit technology are shaping future designs. Flexible circuits are becoming more durable and capable of handling higher-speed signals, enabling features such as advanced cameras, 120Hz displays, and Face ID systems. Engineers are also exploring multi-layer flexible circuits that can combine several signal paths into a single thin ribbon, further saving space inside the iPhone.

Potential Improvements

Future FPC connectors are likely to focus on:

Durability: More robust materials and reinforced contacts to withstand repeated bending and stress.

Signal reliability: Improved conductivity and shielding to support faster data transfer without interference

Ease of replacement: Designs that simplify repair, reducing the risk of damage during assembly or service.

Emerging alternatives may also influence future designs:

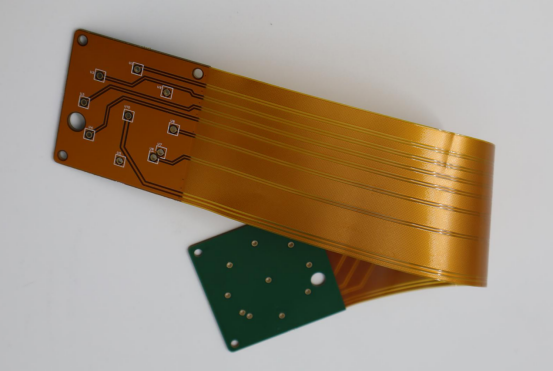

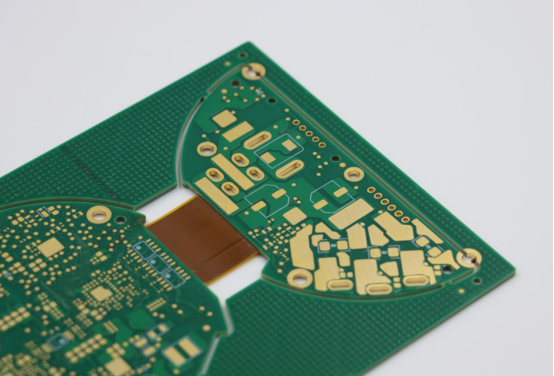

Rigid-flex PCBs: These combine rigid and flexible layers into a single board, potentially reducing the need for separate connectors.

Wireless internal connections: While still experimental, wireless transmission between certain components could minimize reliance on physical connectors, freeing up internal space.

By embracing these improvements, iPhones can maintain slimmer profiles, higher performance, and easier repairability, all while accommodating increasingly complex hardware.

Conclusion

FPC connectors are small but essential components that ensure the seamless operation of iPhone features like displays, cameras, and sensors. Understanding their structure, function, and maintenance is crucial for both users and technicians who want to keep devices performing reliably.

Careful handling of FPC connectors—avoiding excessive bending, properly cleaning contacts, and using the correct tools—can prevent common issues such as flickering screens or unresponsive components. When replacement is necessary, professional repair or high-quality components ensures safety and optimal performance.

Companies like PCBMASTER specialize in advanced PCB solutions, including high-density flexible and rigid-flex boards widely used in compact consumer electronics such as smartphones and wearable devices. For example, their standard 10-layer rigid-flex boards can be delivered in as fast as 7 days, and they support HDI rigid-flex fabrication using premium materials from brands like DuPont and Panasonic. These capabilities highlight the importance of reliable interconnects and high-quality PCBs in modern mobile devices.

By understanding FPC connectors and relying on quality PCB manufacturing, users and technicians can help ensure that iPhones remain both functional and durable, while maintaining the high standards expected in compact, high-performance electronics.

FAQs

Can I replace an iPhone FPC connector myself?

Replacing an iPhone FPC connector is possible for someone with experience and the right tools, but it is generally not recommended for most users. FPC connectors are delicate, and improper handling can damage the cable, surrounding components, or the logic board. For high-density connectors, such as those used for cameras or Face ID modules, professional repair is strongly advised. If you do attempt a DIY replacement, ensure you have precision screwdrivers, anti-static equipment, and a clear step-by-step guide.

How do I know if my iPhone’s FPC connector is damaged?

Signs of a damaged FPC connector include:

Flickering or unresponsive display

Buttons or sensors not working correctly

Camera malfunction or distorted images

Intermittent device freezes or error messages related to hardware

If you notice any of these symptoms, the issue may be a loose or damaged FPC connector. Visual inspection under good lighting can help identify visible damage, such as bent contacts or a disconnected locking tab.

Are all iPhone FPC connectors the same across models?

No, iPhone FPC connectors vary by model and component. Older models may use standard connectors, while newer models often use high-density or micro FPC connectors for displays, cameras, and sensors. Each connector is designed to fit specific components and layouts, so replacement parts must match the exact iPhone model.

What makes FPC connectors better than ribbon cables in iPhones?

FPC connectors are preferred because they are:

Smaller and more flexible, fitting compact iPhone layouts

High-density, allowing multiple signals through a single connector

Durable, especially ZIF (Zero Insertion Force) types, which reduce stress during installation

Reliable, providing stable signal transmission even when the device is moved or bent

In comparison, ribbon cables are thicker, less flexible, and generally take up more space inside the phone.

How long do FPC connectors last under normal usage?

FPC connectors are designed for long-term durability and typically last for the lifetime of the iPhone under normal usage. They can withstand repeated bending and daily operation. However, exposure to physical stress, improper repairs, or environmental factors like moisture can shorten their lifespan. Proper handling and maintenance can help ensure reliable performance over many years.