FPC Certification Guide: Everything You Need to Know in 2025

In today’s fast-paced electronics industry, staying ahead means mastering not only design but also the standards that prove your technical excellence. Flexible Printed Circuits (FPC) have become a foundation of modern devices—from wearables and smartphones to medical and communication systems—driving demand for professionals with certified expertise. As the global FPC market continues its rapid rise, growing from USD 23.89 billion in 2024 to an expected USD 50.90 billion by 2030 at a CAGR of 13.7%, certification has become more than just a credential. It represents proven skill, reliability, and readiness to take on the complex challenges shaping the next generation of electronic innovation.

Introduction to FPC Certification

1. What is FPC Certification?

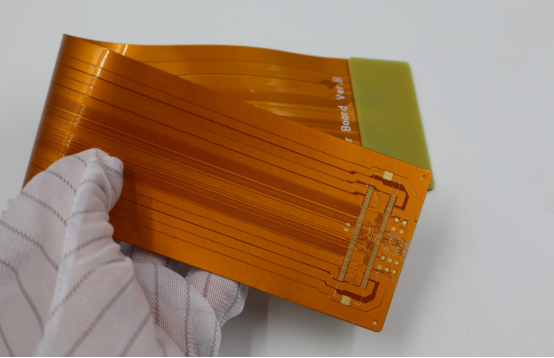

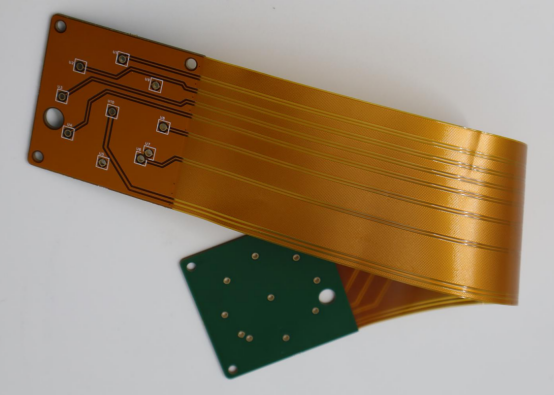

FPC Certification, short for Flexible Printed Circuit Certification, is an official recognition that an individual or company possesses the technical knowledge and practical skills to design, manufacture, and handle flexible printed circuits (FPCs) according to industry standards. Flexible circuits are used in devices where space is limited or bending is required, such as smartphones, wearable electronics, medical equipment, and automotive systems.

The importance of FPC Certification extends beyond individual competence. It ensures that products meet quality, safety, and reliability standards critical in modern electronics manufacturing. For example, a certified FPC designer can guarantee that a foldable display or flexible sensor will function under repeated bending without electrical failure.

FPC Certification is aligned with industry and regulatory standards, including IPC (Institute for Printed Circuits) guidelines, ISO quality management systems, and national electronics regulations. These standards ensure that certified professionals and manufacturers adhere to best practices, reducing defects and improving product lifespan.

2. Who Needs FPC Certification?

FPC Certification is valuable for a range of professionals in the electronics sector:

Engineers and designers who create flexible circuits or integrate them into larger systems.

Manufacturers responsible for producing high-quality FPCs that meet global standards.

Quality assurance specialists who need to verify the reliability and safety of flexible circuits.

Certain scenarios make certification especially important:

New projects involving advanced flexible electronics that demand proven expertise.

Client requirements, where companies expect suppliers or engineers to be certified.

Export compliance, particularly for international markets that mandate industry-standard certifications.

For instance, a wearable device manufacturer may only work with suppliers who have FPC-certified engineers to ensure safety and durability under repeated use.

3. Overview of the Certification Process

The FPC Certification process generally follows a clear sequence of steps:

1. Application and registration: Candidates submit their personal and professional information, including education and work experience in electronics or PCB/FPC design.

2. Training and preparation: Individuals may attend courses, workshops, or use self-study materials to gain technical knowledge of flexible circuit materials, fabrication techniques, and testing procedures.

3. Assessment or examination: Candidates are tested through written exams, practical demonstrations, or project-based evaluations. Scoring criteria vary by certification body, but passing demonstrates proficiency in both theory and application.

4. Certification issuance: Successful candidates receive a certificate, often with a unique ID or verification code, confirming their competency in FPC design and manufacturing.

The typical duration of the certification process ranges from a few weeks for focused courses to several months for comprehensive programs. Certificates usually remain valid for 2–5 years, after which renewal or continuing education may be required to maintain recognized status.

Benefits of FPC Certification

1. Professional Advantages

Obtaining FPC Certification provides significant career benefits for engineers and designers. Certified professionals are often considered more qualified for advanced roles in electronics design, R&D, and quality assurance, which can lead to promotions or higher-paying positions. For example, a certified FPC engineer may be eligible to lead projects involving flexible circuit integration in high-tech devices such as foldable smartphones or wearable medical equipment.

Beyond career advancement, certification enhances professional credibility. Being FPC-certified signals to employers, clients, and colleagues that an individual possesses verified knowledge in flexible circuit materials, design techniques, and testing standards. This recognition can distinguish professionals in a competitive job market and increase trust when collaborating on critical projects.

2. Business and Manufacturing Benefits

For companies, FPC Certification translates into tangible business advantages:

Increased client trust and marketability: Clients are more likely to partner with certified suppliers because it demonstrates adherence to high-quality manufacturing standards. For instance, electronics manufacturers sourcing FPCs for aerospace or medical devices often require certified suppliers to ensure reliability and safety.

Compliance with global manufacturing standards: Certification ensures that a company’s processes align with IPC standards, ISO quality management systems, and other regulatory requirements, reducing the risk of product failures and recalls.

Comparison: Certified vs Non-Certified FPC Suppliers: Certified suppliers consistently show higher quality yields, lower defect rates, and better process control. Non-certified suppliers may save costs initially but can incur losses due to returns, rework, or rejected shipments. This makes certification a strategic advantage in competitive markets.

Eligibility Requirements

1. Educational and Professional Background

To pursue FPC Certification, candidates typically need a combination of formal education and relevant professional experience. Recommended degrees include electrical engineering, electronics engineering, materials science, or related technical fields. Additionally, holding other certifications in PCB design or electronics manufacturing can strengthen eligibility.

Prior experience in PCB or FPC design and manufacturing is often required. For example, candidates with hands-on experience in flexible circuit layout, fabrication, or quality control are better prepared to understand the standards and practical applications tested in the certification process. This ensures that certified professionals can handle real-world challenges in electronics projects.

2. Technical Knowledge Needed

FPC Certification demands proficiency in several core technical areas:

Flexible circuit materials: Understanding polyimide, PET substrates, adhesives, and copper foils used in FPCs.

Fabrication processes: Knowledge of etching, lamination, drilling, and surface finishing techniques specific to flexible circuits.

Testing standards: Familiarity with bend testing, thermal cycling, and electrical continuity checks to ensure product reliability.

When compared with rigid PCB certifications, FPC certification requires additional focus on mechanical flexibility, bend radius limitations, and material fatigue. While both certifications cover circuit design and electrical performance, FPC certification emphasizes durability under repeated flexing and the handling of thin, flexible materials.

3. Documentation and Pre-requisites

Candidates must provide several documents to verify eligibility:

Application forms with personal and professional details.

Resume or portfolio showcasing relevant experience in electronics, PCB/FPC design, or manufacturing.

Proof of prior training or professional experience, such as letters from employers, project summaries, or course completion certificates.

For example, an engineer applying for certification may include project documentation of a wearable device circuit layout they designed and fabricated, along with training certificates in flexible circuit testing. Proper documentation helps certification bodies confirm both knowledge and practical skills, ensuring candidates meet the required standards.

Step-by-Step FPC Certification Process

1. Registration and Application

The first step in obtaining FPC Certification is registration and application. Candidates can apply online through the official certification body’s website or submit forms via authorized institutions. The application typically requires personal information, educational background, professional experience, and proof of prior training.

Fees and timelines vary by institution. For example, some certification programs charge between $300–$800, with processing times ranging from 2–4 weeks for initial verification. Online applications often allow faster confirmation, while paper submissions may take longer. Completing the application accurately helps prevent delays in the certification process.

2. Training and Study Resources

Preparation is critical for passing FPC Certification. Recommended courses and study materials include:

Online or in-person FPC design workshops

Textbooks and manuals covering flexible circuit materials, fabrication processes, and testing standards

Simulation software for circuit layout and performance testing

Candidates can choose between self-study and professional training programs. Self-study is cost-effective and flexible, while professional courses provide structured learning, hands-on labs, and mentorship from certified instructors.

A step-by-step learning roadmap may include:

1. Understanding flexible circuit materials and properties

2. Studying FPC fabrication techniques (etching, lamination, drilling, surface finishing)

3. Practicing electrical and mechanical testing procedures

4. Reviewing case studies and sample projects

Following a structured roadmap ensures comprehensive preparation and improves the likelihood of passing the exam on the first attempt.

3. Examination/Assessment

The FPC Certification exam evaluates both theoretical knowledge and practical skills.

Exam formats may include:

Multiple-choice questions covering FPC fundamentals, materials, and fabrication processes

Practical exercises such as designing a simple flexible circuit layout

Project-based tasks demonstrating assembly, testing, or troubleshooting of FPCs

Scoring criteria vary, but most programs require a minimum score of 70–75% to pass. Passing demonstrates that the candidate can apply knowledge effectively in real-world scenarios.

Example practice tasks:

Calculating the correct bend radius for a flexible circuit in a wearable device

Identifying defects in a laminated FPC sample

Designing a simple single-layer flexible circuit meeting specific voltage and spacing requirements

These exercises help candidates gain hands-on experience while preparing for official assessments.

4. Certification Issuance and Maintenance

Upon successfully passing the exam, candidates receive their FPC Certification, usually within 2–6 weeks depending on the certification body. Certificates often include a unique ID for verification purposes.

Renewal and continuing education are required to maintain active certification. Typically, FPC Certification is valid for 2–5 years. Renewal may involve:

Completing continuing education courses

Submitting evidence of ongoing professional practice

Passing a refresher or updated exam

Example: An engineer certified in 2023 may take a short online update course in 2026 and submit project documentation to renew the certificate, ensuring their skills remain current with evolving flexible circuit standards.

Common Challenges and How to Overcome Them

1. Technical Difficulties

Many candidates face challenges in understanding complex FPC designs and materials. Flexible circuits often involve multi-layer layouts, varying bend radii, and delicate substrates such as polyimide or PET. Misinterpreting these design requirements can lead to errors in fabrication or testing.

Solutions include:

Tutorials and online courses that explain material properties, fabrication steps, and common pitfalls in FPC design.

Mentorship programs where experienced engineers guide candidates through real-world flexible circuit projects.

Simulation tools that allow virtual testing of designs, including bend tests, thermal analysis, and electrical continuity checks.

For example, using a simulation tool to check the bend radius of a wearable device’s flexible circuit can prevent failures before actual production, helping candidates gain hands-on understanding without wasting materials.

2. Administrative and Documentation Issues

Administrative errors are a common source of delays in the FPC Certification process. Candidates may submit incomplete applications, forget supporting documents, or mislabel training certificates.

Step-by-step tips to avoid delays:

1. Prepare documents in advance: Include resumes, portfolios, proof of prior experience, and training certificates.

2. Double-check application forms: Ensure personal details, education, and work experience are accurately recorded.

3. Follow submission guidelines: Adhere to format requirements, deadlines, and verification procedures.

4. Keep copies of all submissions: Useful in case of inquiries or corrections.

By systematically organizing application materials, candidates reduce the risk of rejection or processing delays, ensuring a smoother certification experience.

3. Exam Preparation Challenges

The FPC Certification exam can be intensive, requiring both theoretical knowledge and practical skills. Time management is critical, as candidates often balance preparation with work or other commitments.

Strategies and resources for success:

Structured study schedule: Break preparation into daily or weekly goals, covering materials, fabrication processes, and testing standards.

Hands-on practice: Use lab exercises, sample projects, or virtual simulation tools to reinforce learning.

Mock exams: Practice under timed conditions to improve speed and accuracy.

For instance, dedicating one hour daily to simulate flexible circuit layouts while reviewing theory can significantly improve performance and confidence before the official exam.

FPC Certification vs. Other Industry Certifications

1. Comparison with Rigid PCB Certification

FPC Certification differs from rigid PCB certification in several key areas:

Knowledge and materials: FPC focuses on flexible substrates such as polyimide or PET, while rigid PCB certification emphasizes materials like FR-4 and standard laminates. Understanding bending limits, material fatigue, and adhesion is critical in FPC but less relevant for rigid boards.

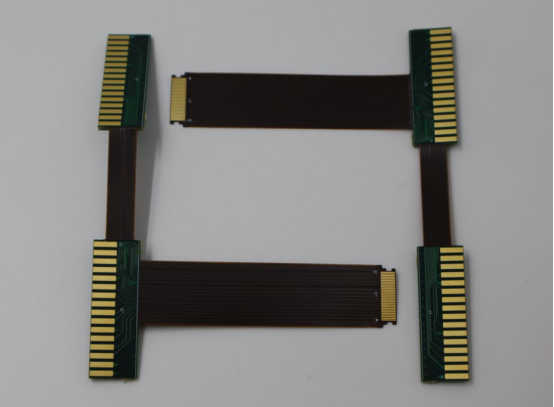

Fabrication and testing: FPC requires additional techniques like lamination under flexible conditions, controlled bend testing, and thermal cycling for durability. Rigid PCB certification mainly covers etching, drilling, solder mask application, and electrical testing under static conditions.

Advantages and limitations:

- FPC Certification provides expertise in flexible electronics applications, ideal for wearables, foldable devices, and compact assemblies.

- Rigid PCB certification focuses on high-volume, stable board manufacturing, suitable for standard consumer electronics and industrial equipment.

For example, an engineer certified in FPC can design a flexible antenna circuit for a wearable device, while a rigid PCB-certified engineer is better suited for a motherboard in a desktop computer.

2. Comparison with IPC Standards Certification

IPC certification is widely recognized for general electronics assembly and quality standards, but it differs from FPC Certification in both scope and use cases:

Scope and recognition: IPC standards cover PCB design, assembly, and inspection processes broadly, applicable to both rigid and flexible boards. FPC Certification specifically validates knowledge in flexible circuit design, fabrication, and testing, making it more specialized.

Use cases:

- FPC Certification is essential when working on products that involve bending, folding, or space-constrained designs, such as wearables, medical sensors, and aerospace electronics.

- IPC certification is often required for mass production quality assurance, compliance with global manufacturing standards, and general PCB assembly proficiency.

For instance, a company producing flexible smartwatches may require engineers with FPC Certification to handle bending and durability challenges, while IPC-certified engineers ensure assembly quality and solder joint reliability.

Future Trends in FPC Certification

1. Evolving Industry Standards

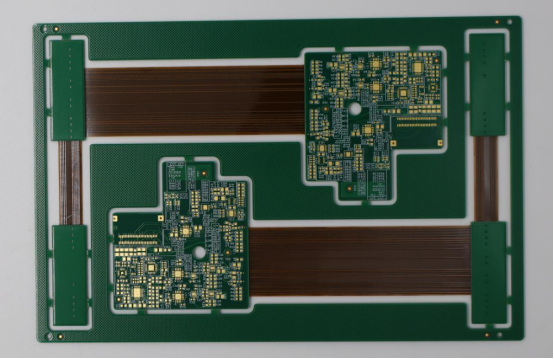

As the electronics industry continues to evolve, FPC certification standards after 2025 are expected to emphasize greater precision, reliability, and sustainability. New guidelines will likely cover ultra-thin flexible substrates, high-density interconnect (HDI) FPCs, and advanced bonding techniques. Certification bodies are aligning with global standards such as IPC-6013E to ensure consistent quality and compatibility across international markets.

Environmental considerations are also shaping the next generation of certification requirements. Expect to see mandatory training on eco-friendly materials, low-halogen laminates, and processes that reduce chemical waste. Sustainability metrics—such as recyclability, energy efficiency, and carbon footprint—are increasingly being integrated into FPC qualification frameworks.

2. Digital and Online Certifications

FPC certification is entering the digital era, where engineers and manufacturers can complete the entire process online. This includes virtual training modules, remote examinations, and digital certificate issuance. Many organizations are adopting blockchain-based verification systems, allowing employers and clients to instantly validate a professional’s credentials.

Advantages include global accessibility, lower travel costs, and faster processing times. Engineers in remote regions can now gain certification without attending in-person sessions. However, challenges remain—such as ensuring exam security, maintaining standardized proctoring, and validating hands-on skill assessments in a virtual environment.

For example, an engineer in India could complete their FPC certification remotely through an accredited online program, while a manufacturer in Germany can verify the authenticity of that certification using a blockchain database.

3. Skills in High Demand

The next decade will bring a surge in demand for engineers skilled in high-density flexible circuits, multilayer FPCs, and advanced material systems such as liquid crystal polymer (LCP) and flexible copper-clad laminates (FCCL). These technologies enable finer pitch interconnections and improved thermal stability, critical for applications in 5G devices, medical implants, and aerospace electronics.

Professionals aiming to stay competitive should pursue continuing professional development (CPD) in areas like FPC design simulation, signal integrity optimization, and reliability testing. Many certification programs are introducing modular learning paths, allowing engineers to upgrade their credentials as new technologies emerge.

Conclusion

FPC certification opens the door to greater reliability, innovation, and global recognition in the flexible electronics industry. By meeting the core requirements, completing the certification process, and keeping up with new materials and standards, engineers and manufacturers can strengthen both their skills and market competitiveness.

For professionals preparing to get certified, the best path forward is to start with official training, organize documentation that demonstrates real project experience, and choose an accredited certification provider. Continuous learning in areas such as advanced materials and HDI design will ensure long-term relevance in this fast-evolving field.

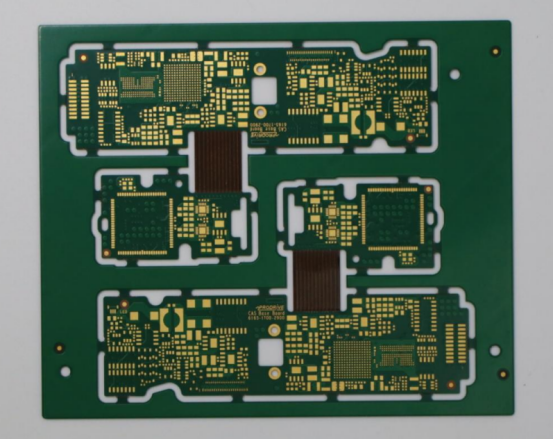

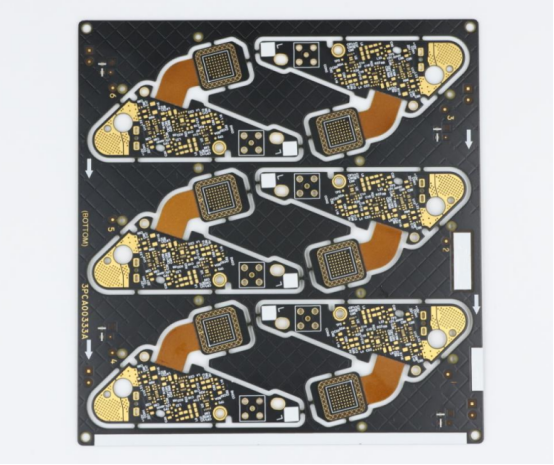

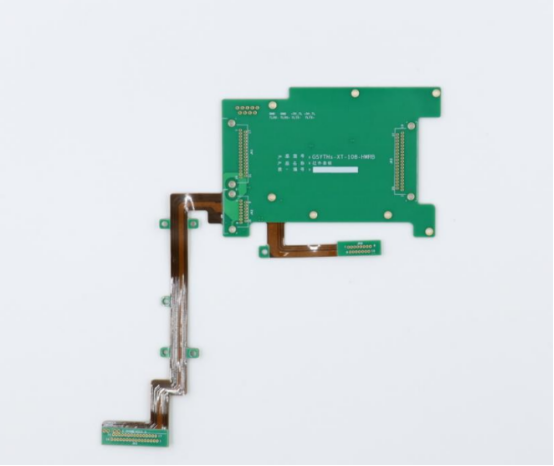

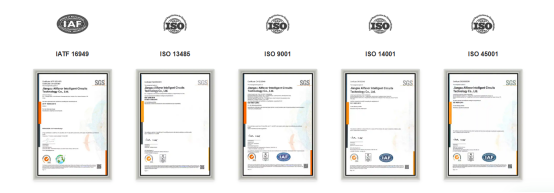

In the industry, manufacturers like PCBMASTER exemplify how certified expertise translates into real-world performance. With multiple global certifications—IATF 16949, ISO 13485, ISO 9001, ISO 14001, and ISO 45001—PCBMASTER demonstrates its commitment to quality and precision in FPC and rigid-flex PCB manufacturing. The company’s ability to deliver 10-layer rigid-flex boards within 7 days, support HDI structures from 1 to any build-up layer, and achieve flexible section lengths as short as 0.8 mm shows how certified processes directly enable faster, more reliable production.

Pursuing FPC certification and collaborating with trusted, high-standard manufacturers like PCBMASTER is the most effective way to ensure excellence—from design to final product.

FAQs

1. How long does it take to get FPC Certification?

The time required for FPC certification typically ranges from 4 to 12 weeks, depending on the certification body, training program, and applicant experience. Candidates who already have hands-on PCB or FPC experience usually complete the process faster, while newcomers may need additional study time to cover design, materials, and testing fundamentals.

2. Can FPC Certification be renewed online?

Yes. Most certification bodies now allow online renewal through virtual assessments or continuing education modules. Professionals can complete refresher courses, submit updated project documentation, or pass short online exams to extend their certification validity—often every 2 to 3 years.

3. What is the cost range for FPC Certification in 2025?

In 2025, the total cost of FPC certification generally falls between USD 500 and USD 1,200, depending on factors such as program level, region, and included training materials. Some advanced or organization-based programs may cost more if they include hands-on workshops or specialized testing modules.

4. Is prior PCB experience mandatory for FPC Certification?

While not strictly required, having prior PCB or flexible circuit design experience offers a major advantage. Candidates familiar with circuit layout, stack-up design, and manufacturing processes tend to progress more efficiently through both the coursework and the exam. Beginners are encouraged to take introductory PCB design courses before applying.

5. Which industries value FPC Certification the most?

FPC certification is highly valued in sectors that depend on lightweight, space-efficient, and high-reliability electronics. These include automotive electronics, medical devices, aerospace, consumer electronics, and telecommunications. Employers in these industries often prefer certified professionals to ensure product quality, compliance, and long-term performance in complex applications.