Why Some Components Need Electronic Device Baking Before PCB Assembly

Introduction

We all know you need to bake raw dough in an oven to get delicious cookies. But you might not know that in the world of high-precision electronics manufacturing, we also need to place some electronic components into a special “oven” for “baking” before they can be mounted onto circuit boards (also known as printed circuit boards).

This might sound surprising, even a bit like a “dark art” of manufacturing. But trust me, this step, known as component baking, is an essential and critical process in modern PCB assembly. It directly determines whether expensive chips survive the process and whether the entire board will function reliably for years to come.

So, why do these delicate components need such special treatment? Certain components can absorb moisture from the environment, which can cause issues like delamination or damage during soldering, so baking is necessary before assembly. Let’s find out.

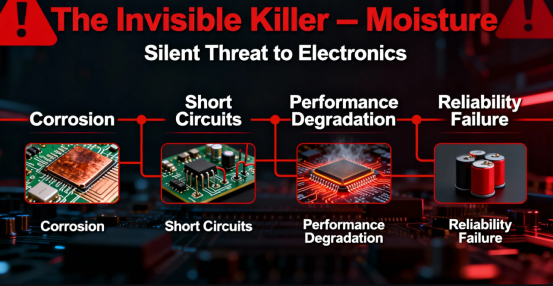

The Invisible Killer — Moisture

The core of the answer lies with a familiar yet often overlooked enemy: moisture, or water vapor in the air.

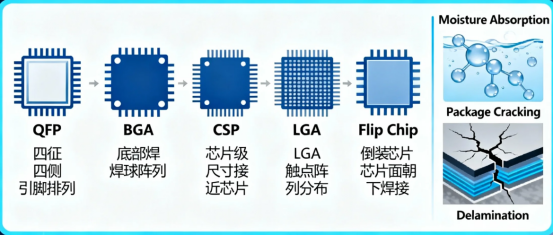

Most electronic components are inherently moisture-proof. However, a significant category of special components, called Moisture-Sensitive Devices (MSDs), are not. These components (typically integrated circuit chips like BGAs, QFPs, CSPs) have packages with microscopic pores, acting like miniature sponges. The packaging materials and internal substrates used in these components can allow moisture to penetrate and accumulate. During prolonged storage or exposure to humid environments, moisture can silently seep through these pores into the component’s interior.

This invading moisture accumulates in two critical areas:

·The interface between the silicon die and the leadframe.

·Around the internal wire bond connections.

At room temperature, this moisture is harmless. The problem arises during the next manufacturing stage — Reflow Soldering.

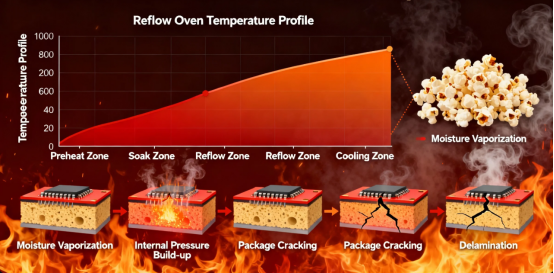

Reflow's "Heat" and the Disastrous "Popcorn Effect"

Reflow soldering is the core process in SMT assembly. It uses a precisely controlled high-temperature oven to melt the solder paste, permanently attaching components to the PCB. Temperatures inside the oven rapidly climb to 200°C and beyond, far exceeding the boiling point of water (100°C). This means any absorbed moisture inside components will turn into steam. Rapid heating in the oven can cause this transformation to happen almost instantly, increasing the risk of the popcorn effect.

For a moisture-laden MSD, this heating process is a recipe for disaster. Think of dropping a water droplet into hot oil – it instantly vaporizes violently and splatters.

Inside the sealed component, a similar drama unfolds:

·Rapid Vaporization: The high heat causes the absorbed moisture to expand almost instantly into high-pressure steam.

·Pressure Build-up: This high-pressure steam has nowhere to escape, creating immense stress at the weakest points inside the component (often the interface between the plastic package and the die/leadframe).

·Internal Cracking: When the stress exceeds the strength of the packaging material, it causes micro-cracks or delamination. This damage is often invisible to the naked eye from the outside.

·Permanent Damage: The cracks can sever the hair-thin internal gold wires or damage the fragile silicon die itself, and in some cases, cracks can also sever internal leads within the component.

Because this process sometimes involves an audible faint “pop” sound from the pressure release, it’s vividly named the “Popcorn Effect” in the industry.

For example, a typical scenario involves a memory IC that passes initial inspection but fails in the field due to internal cracks caused by the popcorn effect, resulting in device malfunction.

A “popped” chip might manifest as:

·Instant Failure: Found to be non-functional or completely dead during testing.

·Intermittent Faults: Works sporadically, creating debugging nightmares.

·Latent Defect: Micro-cracks form but don’t immediately cause failure. During subsequent use, under stress from vibration or thermal cycling, these cracks can propagate, leading to premature product failure in the field. This is the most dangerous scenario, severely damaging brand reputation.

How to Identify These "Water-Shy" Components? — Understanding MSDs and Moisture Sensitivity Levels

Not all components need baking. To manage MSDs scientifically, the industry has established standards like J-STD-020, formally classifying them.

Every MSD package carries a very clear label indicating its Moisture Sensitivity Level (MSL) and its “Floor Life.” Components are typically packaged in moisture-proof bags to protect them before assembly, and a humidity indicator card is included in the packaging to monitor moisture exposure. It is critical not to exceed the allowed floor life of these components, as doing so can lead to moisture absorption and compromise reliability.

Moisture Sensitivity Levels (MSL)

MSDs are categorized into levels (e.g., 1, 2, 2a, 3, 4, 5, 5a, 6) based on their susceptibility to moisture absorption. A lower number indicates a more robust device; a higher number indicates greater sensitivity. Packaging for these components typically includes a desiccant and a moisture indicator card to help keep components dry during storage and handling.

·Level 1: Nearly impervious. Can be stored indefinitely at < 30°C/85%RH.

·Level 2: Floor life of 1 year at < 30°C/60%RH.

·Level 2a: Floor life of 4 weeks.

·Level 3: Floor life of 168 hours (7 days).

·Level 4: Floor life of 72 hours.

·Level 5, 5a, 6: Even shorter floor life (48, 24 hours), often requiring baking before use due to their high moisture sensitivity.

The Critical Point: Once the original sealed bag is opened, if the components are exposed to ambient air for longer than the specified “Floor Life” on the label, they must be baked before being sent through the reflow process. These processes, including baking, are essential to prepare components for assembly and to ensure reliability.

Why Bake? — The Benefits of the Baking Process

The baking process is a vital safeguard in the assembly of printed circuit boards and electronic components, especially when working with moisture sensitive components. In the fast-paced world of electronics manufacturing, even a thin layer of excessive moisture inside a component or on a PCB can spell disaster during the reflow process. That’s why electronics manufacturers rely on baking to remove absorbed moisture before components ever see the inside of a reflow oven.

Moisture sensitive devices, such as integrated circuits and other advanced chips, are particularly prone to absorbing moisture from the environment. When these components are exposed to ambient air—even for a short period—trapped moisture can accumulate within the component body or on the surface of the PCB. If not removed, this moisture can rapidly turn to steam during the high temperatures of the soldering process, leading to soldering defects, unreliable solder joints, and even catastrophic component failure.

By using a controlled environment and heating components and PCBs to a specific temperature in a lab oven or reflow oven, the baking process effectively removes absorbed moisture. This step is crucial for preventing thermal stress and corrosion on PCB pads and component leads, both of which can compromise the reliability of the finished device. Corrosion, in particular, can weaken solder joints and create pathways for electrical failure, while thermal stress can cause micro-cracks and delamination within the component itself.

Beyond preventing immediate soldering defects, the baking process also plays a key role in ensuring the long-term reliability and quality of the assembly process. By thoroughly drying moisture sensitive components and circuit boards, manufacturers can form strong, reliable solder joints that stand up to the rigors of daily use. This is especially important in consumer electronics, where devices like smartphones and laptops demand flawless performance and durability. Baking also helps prevent the growth of dendrites—tiny metallic filaments that can form on component leads in the presence of moisture and cause short circuits or intermittent failures.

For electronics manufacturers, incorporating the baking process into their assembly procedures offers significant benefits. It reduces the risk of costly rework, minimizes the chance of product recalls due to moisture-related defects, and ultimately leads to higher customer satisfaction. By ensuring that every component and PCB is properly dried before assembly, manufacturers can deliver products that meet the highest standards of reliability and performance.

In summary, the baking process is not just an extra step—it’s a critical part of modern electronics manufacturing. By removing excessive moisture, preventing thermal stress and corrosion, and ensuring robust solder joints, baking helps guarantee the quality and reliability of every device that leaves the production line. For any manufacturer committed to excellence, prioritizing the baking process is essential for producing high-quality, dependable electronic devices.

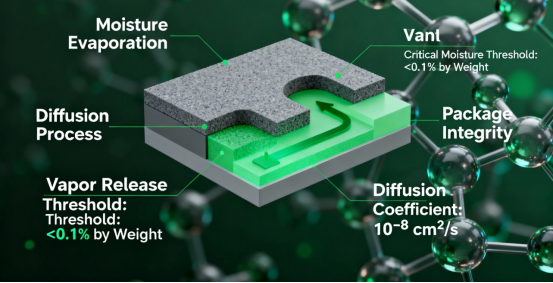

The Rescue Operation — The "Right Way" to Bake Components

The essence of baking is to use a controlled, gentle heating process to “drive out” the internal moisture, restoring the component to a dry and safe state by reaching the desired level of dryness or temperature. Prototype boards, as well as production circuit boards, may require baking to ensure reliability. Properly baked components are less likely to fail when soldered onto the board.

1.Baking Parameters: The Art of Temperature and Time

Baking is not about higher temperatures or longer times being better. It must strictly follow standards (like J-STD-033) based on the component’s MSL and package thickness. Proper heat distribution within the oven is critical to ensure all components are evenly baked and moisture is removed uniformly.

·Temperature: Two main options are commonly used:

·125°C ±5°C: This is standard high-temperature baking. It’s efficient and faster (typically 4-28 hours).

·40°C ±5°C, < 5% RH: This is low-temperature baking, performed in a very low-humidity dry cabinet. It takes longer (typically 5-10 days) but imposes less thermal stress on components, suitable for those more sensitive to high heat.

·Special Note: The baking temperature must never exceed the component’s maximum rated temperature, or it will be damaged.

2.Baking Equipment

Common types of baking ovens used in electronics manufacturing include convection ovens, vacuum ovens, and nitrogen ovens, each offering specific features for effective moisture removal and process control.

Professional baking requires industrial ovens. These ovens provide precise control over temperature uniformity and stability, ensuring every tray of components is heated evenly. Using a kitchen oven or a heat gun is strictly forbidden due to their significant temperature fluctuations and uneven heating, which can easily oxidize or thermally damage components.

3. The Baking Process

A standardized baking process looks roughly like this:

·Identification & Sorting: Identify all MSDs that have exceeded their floor life based on the BOM and package labels. Components with multiple layers or complex structures may be more susceptible to moisture and require careful handling.

·Removing Old Packaging: Take components from their exposed packaging and place them neatly on high-temperature-resistant trays. Components must not be stacked to ensure proper airflow.

·Loading & Baking: Place the trays into a preheated oven, set the correct temperature and time.

·Cooling & Use: After baking, remove the components and let them cool down to room temperature in a dry environment. Crucially, baked components must be used within their specified (new) floor life (e.g., 168 hours for Level 3), or they must be re-baked! Applying flux before soldering can help ensure reliable connections after baking.

Conclusion

In the intricate world of electronics manufacturing, component baking is far from an optional step. It is a simple, cost-effective, and highly reliable "insurance policy" against the invisible threat of moisture, preventing costly "popcorn" failures.

It embodies the attention to detail and respect for quality that defines modern manufacturing. Ignoring it might save a little time or electricity in the short term, but it plants a time bomb that could detonate in your product's future.

So, the next time you see components heading into an oven on the production line, understand that this isn't a redundant step. It's a meticulous and careful practice by engineers to ensure the long-term reliability of the device in your hands. Just like baking the perfect pastry, the right amount of "heat" at the right time is crucial for a flawless outcome.

Author: Jack Wang