Flexible Printed Circuit Boards: Types, Uses, and Design Guide

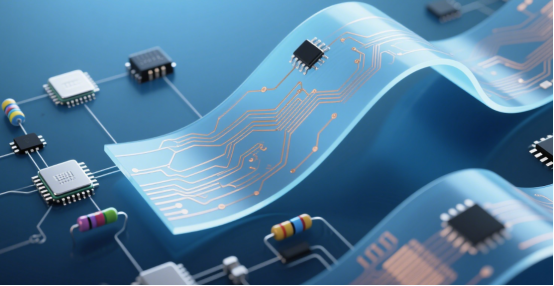

Have you ever wondered how your phone, smartwatch, or even your car can be so small yet so powerful? One of the secrets is something called a Flexible Printed Circuit Board (FPC).

Unlike the old, hard circuit boards, these flexible boards are thin, light, and can bend. This makes them perfect for today’s electronics, where space is small and devices need to be lighter but still very strong.

In this guide, we will talk about the different types of flexible circuit boards, where they are used, and some simple design rules that make them work so well.

What is a Flexible Printed Circuit Board?

A Flexible Printed Circuit Board, or FPC, is a special kind of circuit board. It does the same job as a normal hard board (rigid PCB), but the big difference is this: it can bend and fold without breaking.

Inside a smartphone or smartwatch, space is very limited and the parts are packed tightly together. A rigid board cannot always fit in these small spaces, but a flexible board can bend around corners, fit in thin layers, and still connect all the electronic parts.

Basic Structure

A flexible PCB is made of three main parts:

Base material – This is the soft and bendable film, often made of a plastic called polyimide.

Conductor layer – This is usually thin copper that carries electricity, just like wires.

Protective layer – This covers the board to keep it safe from heat, dust, or damage.

Like a sandwich: the soft film is the bread, the copper is the filling, and the protective cover is the wrap that keeps everything safe.

Key Advantages

Thin and light – Saves space and reduces weight, which is perfect for portable devices.

Flexible – Can bend, fold, and twist to fit inside small or unusual shapes.

Durable – Even though it is thin, it is strong and can handle many bends without breaking.

In short, flexible PCBs allow modern devices to be smaller, lighter, and smarter.

Types of Flexible Printed Circuit Boards

Flexible PCBs come in several types. Each type has its own structure, cost, and purpose. Let’s go through them one by one, slowly and clearly.

Single-Layer Flexible PCB

This is the most basic type of flexible circuit board.

Features and Cost:

It has only one layer of copper that carries the electrical signals. Because it is so simple, the manufacturing process is easy, the cost is low, and production time is short. But, it cannot handle very complex circuits since there is only one path for electricity.

Common Applications:

You can see single-layer FPCs in many everyday products that don’t need advanced functions. For example:

Printers and scanners

Simple cameras

Keyboards and calculators

LED lights and toys

It is like a single sheet of paper with one drawing—easy to make, but limited in what it can show.

Double-Layer Flexible PCB

This one adds more power by using two copper layers — one on the top and one on the bottom of the flexible film.

Structure Advantage:

With two layers, you can place circuits on both sides. Vias (tiny holes) connect the top and bottom, allowing electricity to move between them. This gives more design flexibility, supports more components, and still keeps the board bendable.

Suitable Products:

Double-layer FPCs are used when devices need more complex circuits but still must remain thin and light. For example:

Smartphones and tablets

Automotive dashboards and touch displays

Portable medical monitors

Digital cameras

It’s like having a notebook with two pages instead of just one. You can write more information and connect the ideas between both pages.

Multi-Layer Flexible PCB

This type is made by stacking three or more copper layers with insulation films between them.

High-Density Design:

With multiple layers, engineers can design very complex circuits in a small space. It allows high-speed signals, controlled impedance (important for stable communication), and strong electrical performance.

High-Performance Applications:

These boards are used in industries where performance, reliability, and compact size are critical:

Aerospace and satellites (lightweight but high-function systems)

Medical devices like pacemakers or imaging equipment

High-speed computers and networking equipment

You can imagine this like a multi-level highway. Each level handles its own traffic, but together they move a huge number of cars without jams.

Rigid-Flex PCB

This is a combination of rigid PCB sections and flexible PCB sections built into a single board.

Mixed Design Advantage:

The rigid parts hold and support heavy components (like chips and connectors), while the flexible parts connect these rigid sections together. This saves space, reduces the need for extra connectors, and increases durability since there are fewer weak points.

Typical High-End Applications:

Because of its reliability and space-saving design, Rigid-Flex PCBs are often found in advanced products:

Aerospace systems (satellites, aircraft control)

High-end smartphones and foldable devices

Laptops and cameras where space is very tight

It like a bridge with both solid pillars and flexible joints. The solid parts give strength, while the flexible parts allow movement and connection.

Applications of Flexible Printed Circuit Boards

Flexible PCBs are used everywhere around us. They make our electronics smaller, lighter, and smarter. Let’s look at the main areas where they are used.

Consumer Electronics

Flexible PCBs are very common in smartphones, tablets, and wearable devices.

Why: These devices are small, thin, and have limited space. Flexible boards can bend and fit into corners where rigid boards cannot.

Examples:

Smartphones: Flexible PCBs connect cameras, screens, and buttons inside tiny spaces.

Smartwatches and fitness trackers: They bend around the wrist, so the board must be flexible.

Tablets and cameras: Help reduce weight and make devices slimmer.

It like a soft ribbon inside your phone, connecting parts without taking up much space.

Automotive Electronics

Cars today are full of electronics, and many of them use flexible PCBs.

Why: Cars need compact, durable, and reliable connections that can handle vibration and heat.

Examples:

ADAS (Advanced Driver Assistance Systems): Helps with parking, lane keeping, and safety alerts.

Lighting systems: Headlights and dashboard lights need small, flexible boards.

Navigation systems: GPS screens and touch panels use flexible PCBs for their slim design.

The flexible PCB acts like a tiny bendable highway inside the car, safely carrying signals to every part.

Medical Devices

Flexible PCBs are essential in modern medical equipment.

Why: Medical devices must be small, lightweight, and reliable. Some devices go inside the body, so the board must be safe and flexible.

Examples:

Pacemakers: Tiny flexible boards help control the heart safely.

Portable monitoring devices: Blood pressure monitors or glucose meters use FPCs to save space.

It is soft yet strong, allowing medical devices to fit and function inside tiny spaces.

Aerospace

High-end technology like satellites, and airplanes also uses FPCs.

Why: These devices need lightweight, durable, and high-performance electronics.

Examples:

Satellites: Flexible boards save space and reduce weight for launch.

Aircraft electronics: Control systems use FPCs to connect instruments in tight spaces.

FPCs here are like tiny flexible bridges, carrying signals in tough conditions where space is very limited.

Industrial Automation

Factories and robots also need flexible PCBs.

Why: Machines need precise control, sensors, and quick responses, often in small, moving spaces.

Examples:

Sensors: Detect temperature, pressure, or movement.

Robot control systems: FPCs allow wiring inside moving robot arms.

Automated machines: Help connect complex electronics in a small area.

FPCs are like bendy highways inside robots and machines, carrying signals quickly and safely.

Design Guide for Flexible Printed Circuit Boards

Designing a flexible PCB is a careful process. Engineers must think about materials, bending, heat, and cost. Let’s go through the main points step by step.

Material Selection

Choosing the right material is very important because it affects strength, flexibility, and heat resistance.

PI (Polyimide): It is very strong and heat resistant, able to handle high temperatures without melting or shrinking, and is often used in smartphones, medical devices, and aerospace applications.

PET (Polyethylene Terephthalate): It is cheaper and lighter than PI, works well for low-cost electronics and simple devices, but is not as heat resistant, so it is not suitable for high-power applications.

Rule of thumb: Use PI for tough, high-temperature devices and PET for simple, low-cost products.

Routing and Bend Radius Design

How you lay out the copper traces and how sharply the board bends is very important.

Avoiding stress and breakage: Copper traces should never bend too sharply, because a tight bend can crack the copper and break the circuit. It is better to use round corners and keep important signals away from areas that will bend whenever possible.

Practical tip: Always leave a small “loop” or curve in the trace when the board needs to bend. It acts like a spring, reducing stress.

Like a garden hose, bending it too sharply will kink it and block the water, but bending it gently lets the water flow smoothly.

Thermal Management and Heat Dissipation

High-power circuits produce heat. Flexible boards are thin, so heat can be a problem.

Design considerations: Use wider copper traces in areas that carry more current, add thermal vias (small holes that carry heat away) when the board connects to other layers, and keep sensitive components away from hot areas.

This helps prevent overheating, which can damage the board or make the device fail.

Cost Optimization

Design choices also affect cost. Engineers must balance performance and price.

Layer count: More layers allow complex circuits but increase cost.

Manufacturing process: Simple single-layer boards are cheaper; multi-layer or rigid-flex boards are more expensive.

Material choice: PI is stronger but costs more than PET.

Tip: Only use high-end materials or extra layers where absolutely necessary. This keeps the board reliable but avoids unnecessary cost.

Comparison with Rigid PCBs

Flexible PCBs and rigid PCBs are both used to connect electronic components, but they are very different in structure, performance, cost, and usage. Let’s look at the main differences.

Structure and Performance Differences

Rigid PCBs are made from hard, solid materials. They cannot bend and are usually thicker. Flexible PCBs, on the other hand, are thin and bendable, so they can fit into small or unusual spaces.

Performance: Flexible PCBs are lighter, can handle vibrations better, and are good for devices that move or fold, like smartphones and wearable devices. Rigid PCBs are more stable for heavy components and high-power circuits, but they take up more space.

A rigid PCB is like a wooden board—strong but stiff. A flexible PCB is like a thin sheet of plastic—light, bendable, and easier to shape.

Cost and Manufacturing Differences

Rigid PCBs are usually cheaper and easier to manufacture for simple designs because they don’t need special materials or bending considerations. Flexible PCBs require special materials (like polyimide), careful design, and precise manufacturing, so they are often more expensive.

Rigid PCB → Low cost, simple to produce, ideal for desktop electronics and large devices.

Flexible PCB → Higher cost, more complex production, necessary for compact and high-tech electronics.

Complementary Usage Scenarios

FPCs and rigid PCBs often work together in the same device. For example, a smartphone might have:

Rigid sections to hold heavy chips and connectors

Flexible sections to connect the screen, camera, or buttons in tight spaces

This combination is called a rigid-flex PCB. By mixing both types, engineers get the strength of rigid boards and the flexibility of FPCs, making devices smaller, lighter, and more reliable.

Conclusion

Flexible PCBs are an essential part of modern electronics. We have seen the different types — from single-layer to multi-layer and rigid-flex boards — and how each type is used in consumer electronics, automotive systems, medical devices, aerospace, and industrial machines. We also covered some simple design tips, including choosing the right materials, careful routing, managing heat, and balancing cost.

Flexible PCBs are becoming more important as devices get smaller, lighter, and more advanced. In the future, we can expect even more innovation, with flexible PCBs helping new electronics designs reach higher performance and reliability.

If you have any questions or want to learn more about manufacturing and custom flexible PCBs, you can contact PCB MASTER, a professional and trusted PCB supplier. They can help you find the right solution for your project.

FAQs

Can flexible PCBs be used in devices that fold or bend?

Yes! Flexible PCBs are made to bend, twist, and fold without breaking. This makes them ideal for devices where space is tight or the board needs to move. For example, foldable smartphones use FPCs to connect the screen to the main board while allowing the phone to open and close. Wearable devices like smartwatches rely on FPCs to fit the circuit around a small wrist. Even medical devices, like portable heart monitors, use flexible boards to fit inside compact cases.

Why are flexible PCBs more expensive than rigid PCBs?

Flexible PCBs cost more because of the materials and careful manufacturing they require. They use special films like polyimide, which can bend and withstand heat. The design must avoid sharp bends and stress points to prevent the copper from cracking. Manufacturing also needs precise control to make thin, flexible layers without defects. In contrast, rigid PCBs use regular materials and simpler production, which is cheaper. So, the extra cost of FPCs comes from better materials, precise design, and more careful manufacturing.

Can flexible PCBs replace all rigid PCBs in a device?

Not always. Flexible PCBs are excellent for saving space and allowing movement, but rigid PCBs are stronger for holding heavy components and carrying high power. For example, a laptop might use rigid sections to support the CPU and memory chips, while flexible sections connect the screen, keyboard, and touchpad. Engineers often combine them into a rigid-flex PCB, which gives the strength of rigid boards where needed and the flexibility of FPCs in tight spaces. This combination is common in smartphones, tablets, and medical equipment.