Double-Sided IMS PCBs: Superior Thermal Management for High-Power Electronics

As the performance of electronic devices continues to improve, heat dissipation and space optimization have become more challenging. Traditional PCBs often struggle to effectively dissipate the heat generated by high-performance components, leading to overheating and reduced reliability. At the same time, the demand for more compact designs makes it difficult to integrate high-performance components without compromising performance.

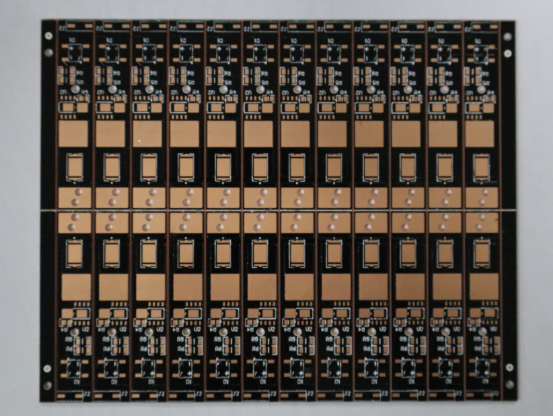

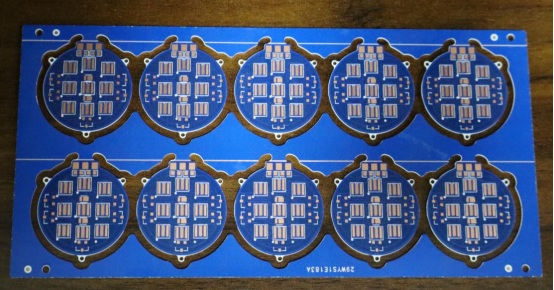

Double-Sided IMS (Insulated Metal Substrate) PCBs are engineered to tackle these issues. These advanced circuit boards are designed for efficient heat management in high-power applications. By incorporating a metal core—typically aluminum or copper—sandwiched between two conductive copper layers and an insulating dielectric, they provide superior heat dissipation. Additionally, the ability to mount components on both sides of the board enables a compact and reliable solution for demanding electronic systems.

Key Features of Double-Sided IMS PCBs

Thermal Management Superiority

Enhanced Heat Dissipation: IMS PCBs are designed to efficiently manage heat. With a metal substrate that conducts heat up to 400 W/m·K and a dielectric layer with 1–8 W/m·K thermal conductivity, they outperform traditional FR-4 PCBs (0.2–0.4 W/m·K). This ensures that heat generated by power-hungry components is quickly and evenly spread across the board.

Lower Operating Temperatures: The improved thermal conductivity means that components like LEDs and power transistors operate at temperatures 20–30°C lower than those mounted on traditional FR-4 PCBs. This temperature reduction enhances the lifespan and reliability of sensitive components.

Design Flexibility and Space Efficiency

Dual-Side Component Placement: One of the key advantages of Double-Sided IMS PCBs is their ability to mount components on both sides of the board. This allows for a 30–50% reduction in overall board size, which is particularly valuable in space-constrained designs like automotive electronics, LED lighting, and mobile devices.

Integrated Thermal Management: The metal core not only dissipates heat but also eliminates the need for external heat sinks in many applications. This integration reduces the complexity and size of the final device, making it slimmer and more efficient.

Durability and Reliability

Vibration Resistance: The metal core of IMS PCBs provides significant resistance to vibration and mechanical shock (up to 20G). This is crucial for automotive, industrial, and outdoor applications, where environmental stress is common.

Temperature Range: IMS PCBs can withstand extreme temperatures, with aluminum-core designs operating effectively between -40°C to 125°C and copper-core designs reaching up to 150°C, making them suitable for industrial and automotive environments.

Mechanical Strength: IMS PCBs are structurally rigid, resisting bending and warping, which improves the overall durability and reliability of the board in high-stress environments.

Environmental and Cost Considerations

Recyclable Materials: The use of aluminum and copper substrates makes IMS PCBs environmentally friendly, as these materials are fully recyclable. This aligns with global sustainability goals and regulations such as RoHS and REACH.

Long-Term Savings: Although IMS PCBs have a higher initial cost compared to FR-4, their long-term advantages—such as eliminating the need for external heat sinks and reducing failure rates due to better thermal management—make them a more cost-effective choice over time.

Advantages Over Other PCB Types

Double-Sided IMS vs. FR-4

Thermal Performance: IMS PCBs offer significantly better thermal dissipation compared to traditional FR-4 boards, making them essential for high-power applications where heat management is critical.

Compactness: The ability to place components on both sides of the board allows for a more compact design, reducing overall device size and weight.

Double-Sided IMS vs. Single-Sided IMS

Greater Flexibility: Double-sided designs provide more flexibility for component placement, allowing for more complex circuits and better utilization of space. This is particularly useful in designs that require higher component density.

Double-Sided IMS vs. Ceramic PCBs

Cost-Effectiveness: Ceramic PCBs offer superior thermal performance but are significantly more expensive and heavier than IMS PCBs. For most high-power applications, Double-Sided IMS PCBs provide a comparable thermal solution at a much lower cost.

Comparison Table

| Feature | Double-Sided IMS PCB | Traditional FR-4 PCB | Single-Sided IMS PCB | Ceramic PCB |

| Thermal Conductivity | 1–8 W/m·K (dielectric), up to 400 W/m·K (metal core) | 0.2–0.4 W/m·K | 1–8 W/m·K (dielectric), up to 400 W/m·K (metal core) | 200–300 W/m·K |

| Component Placement | Both sides of the board | One side only | One side only | Both sides of the board |

| Weight | 30g (aluminum core, 100mm × 100mm) | 20g (100mm × 100mm) | 25g (aluminum core, 100mm × 100mm) | 45g (100mm × 100mm) |

| Cost (per 10k units) | $12–$18/unit | $5–$10/unit | $10–$15/unit | $30–$50/unit |

| Vibration Resistance | 20G | 10G | 20G | 15G (brittle) |

| Temperature Range | -40°C to 125°C (Aluminum core), up to 150°C (Copper core) | -40°C to 85°C | -40°C to 125°C (Aluminum core), up to 150°C (Copper core) | -50°C to 150°C |

| Best For | High-power, compact designs | Low-power consumer electronics | Simple high-power designs | Extreme-temperature applications |

| Durability | High resistance to vibration and temperature fluctuations | Moderate durability | High resistance to vibration and temperature fluctuations | Moderate durability |

Key Applications of Double-Sided IMS PCBs

LED Lighting

High-Brightness LEDs: IMS PCBs are widely used in high-power LED applications, such as streetlights and horticultural lamps. The metal core efficiently transfers heat away from the LED junction, preventing overheating and ensuring consistent brightness and color over time.

Automotive Lighting: In automotive applications, IMS PCBs enable compact designs for headlights and taillights, where thermal management and space are critical. These PCBs can integrate complex circuits while keeping the components cool, ensuring reliable performance under harsh conditions.

Automotive Electronics

Electric Vehicle (EV) Systems: IMS PCBs are ideal for electric vehicle systems, where components such as battery management systems (BMS), inverters, and power modules need to handle high currents (200–500A). The thermal efficiency of IMS PCBs ensures these components stay within safe operating temperatures, even during fast charging.

Advanced Driver Assistance Systems (ADAS): In ADAS applications, such as radar and LiDAR sensors, IMS PCBs offer vibration resistance and excellent thermal management, which is critical for maintaining the accuracy and reliability of sensors in real-world driving conditions.

Power Electronics

Industrial Inverters: IMS PCBs are used in industrial inverters that convert AC to DC or DC to AC, handling power levels ranging from 100W to 1kW. The enhanced thermal management ensures stable operation of components such as rectifiers and transformers, preventing overheating.

Renewable Energy: In solar microinverters and wind turbine controllers, IMS PCBs provide the necessary thermal stability to convert energy efficiently while withstanding outdoor temperatures and environmental stresses.

Other Applications

5G Power Modules: The compact size and thermal efficiency of IMS PCBs make them ideal for use in 5G infrastructure, where power modules need to be both thermally efficient and space-saving. These PCBs help manage heat in densely packed circuits while ensuring stable performance.

Consumer Electronics: IMS PCBs are also used in power supplies for devices like routers, amplifiers, and chargers. They enable smaller, more efficient power supplies that maintain thermal stability, leading to better performance and longer product life.

Conclusion

Double-Sided IMS PCBs offer a unique combination of thermal efficiency, space-saving design, and durability that makes them ideal for high-power applications across various industries. With superior heat dissipation, the ability to integrate complex circuits, and the advantage of being eco-friendly and cost-effective in the long run, IMS PCBs are the go-to solution for modern electronics. As the demand for more compact, reliable, and thermally efficient devices continues to grow, Double-Sided IMS PCBs will play a crucial role in the development of next-generation technologies.

For those looking to leverage the full potential of Double-Sided IMS PCBs in their designs, PCBMASTER stands out as a leading manufacturer and supplier. With years of expertise in advanced PCB solutions, PCBMASTER provides high-quality, custom IMS PCBs that meet the unique needs of industries such as automotive, LED lighting, and renewable energy. Their commitment to quality, precision manufacturing, and customer-centric approach ensures that each project receives the highest level of performance, reliability, and sustainability. Whether you're developing high-power modules or designing compact electronic systems, PCBMASTER is a trusted partner for all your IMS PCB needs.

FAQs

How Do Double-Sided IMS PCBs Improve LED Lifespan?

IMS PCBs significantly enhance LED lifespan by effectively managing heat. LEDs are sensitive to temperature, and excessive heat can cause thermal degradation, leading to reduced light output and premature failure. Double-Sided IMS PCBs help mitigate this issue by lowering the operating temperature of the LED junction by 20–30°C compared to traditional FR-4 PCBs. This reduction in temperature prevents overheating and ensures more stable performance over time, extending the lifespan of LEDs by up to 50%. This makes IMS PCBs particularly ideal for high-brightness LEDs used in applications such as streetlights, stadium lighting, and horticultural lighting, where long-term reliability is crucial.

Can Double-Sided IMS PCBs Be Used in EV Applications?

Yes, Double-Sided IMS PCBs are highly suitable for Electric Vehicle (EV) applications. These PCBs excel in systems that handle high power and require efficient thermal management, such as inverters and battery management systems (BMS). Inverters, which control the flow of electricity between the battery and motor, and BMS, which monitor and manage the battery's health, both generate significant heat during operation. Double-Sided IMS PCBs, with their superior heat dissipation capabilities, ensure that these components remain within safe temperature ranges even under high loads (200–500A), reducing the risk of thermal failure and enhancing the overall reliability and lifespan of EV systems. Additionally, their compact design helps in optimizing space in EV power electronics.

Are Double-Sided IMS PCBs More Expensive Than FR-4?

Double-Sided IMS PCBs generally have a higher upfront cost than traditional FR-4 PCBs due to the more specialized materials and manufacturing processes involved, especially the metal core (typically aluminum or copper). However, this initial investment is offset by long-term cost savings. IMS PCBs improve thermal management, which reduces the need for bulky, expensive external heat sinks, cuts down on system failures caused by heat-related issues, and extends the lifespan of components. This leads to lower maintenance and replacement costs over time. In many high-power applications, such as LED lighting or automotive power modules, the total cost of ownership for IMS PCBs can be lower than FR-4, especially considering the reduced likelihood of failure and enhanced system efficiency.

What is the Maximum Operating Temperature for Double-Sided IMS PCBs?

Double-Sided IMS PCBs are designed to operate in a wide range of temperatures, making them suitable for demanding environments. IMS PCBs with aluminum cores typically perform reliably in temperatures ranging from -40°C to 125°C. Aluminum, being an excellent conductor of heat, helps in maintaining stable temperatures in high-power applications. For even more demanding industrial applications, IMS PCBs with copper cores can withstand temperatures up to 150°C, providing additional reliability in environments subject to extreme heat fluctuations. These high temperature tolerances make IMS PCBs ideal for use in automotive systems, outdoor lighting, power supplies, and renewable energy applications.

Are Double-Sided IMS PCBs Eco-Friendly?

Yes, Double-Sided IMS PCBs are eco-friendly and align with global sustainability standards. The metal cores used in IMS PCBs—typically aluminum or copper—are 100% recyclable, making them a more environmentally responsible choice compared to traditional PCBs that often rely on materials that are harder to recycle. Additionally, IMS PCBs are manufactured using lead-free soldering materials, complying with regulations like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals). This makes IMS PCBs an excellent option for companies looking to meet sustainability goals and reduce their environmental impact while still maintaining the performance needed for high-power applications.