A Comparative Guide What Are the Differences Between Flex PCB and Rigid-Flex PCB

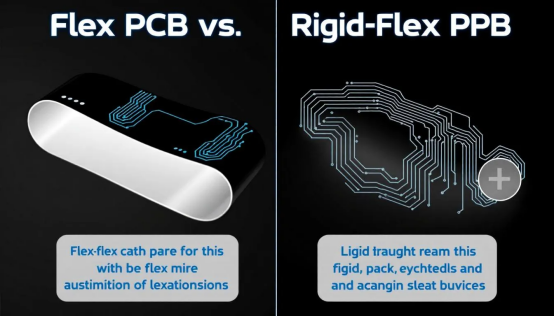

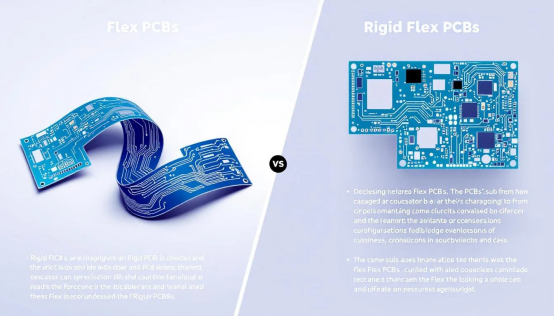

What are the differences between flex PCB and rigid-flex PCB? Flex PCBs offer flexibility for applications needing bending and twisting. Rigid-flex PCBs combine flexible and rigid layers, providing both flexibility and structural support. This article will break down these differences to help you choose the right PCB for your project.

Key Takeaways

· Flex PCBs are exclusively flexible, suitable for applications requiring frequent bending, while Rigid-Flex PCBs combine flexible and rigid elements, offering structural support for high-reliability applications.

· Flex PCBs are commonly utilized in consumer electronics and medical devices due to their adaptability, whereas Rigid-Flex PCBs excel in aerospace and military applications, providing durability in harsh environments.

· Manufacturing processes for Flex and Rigid-Flex PCBs differ significantly; Flex PCBs focus on lightweight design, while Rigid-Flex PCBs require precision in aligning flexible and rigid layers, impacting costs and assembly complexity.

Understanding Flex PCB and Rigid-Flex PCB

Flex PCBs and Rigid-Flex PCBs represent two innovative categories of circuit boards that cater to various industrial needs. Flexible printed circuit boards, or Flex PCBs, are extensively utilized in sectors like aerospace, automotive, and medical devices due to their ability to conform to different shapes and withstand dynamic movements. On the other hand, Rigid-Flex PCBs are often employed in high-reliability applications such as military and aerospace systems, combining the benefits of both rigid and flexible circuits.

Flex PCBs are designed for flexibility and adaptability, suited for applications needing frequent bending and twisting. Conversely, Rigid-Flex PCBs provide structural support while retaining flexibility, ideal for complex and high-stress environments. The flex pcb design enhances the overall performance of these applications.

Definition of Flex PCB

Constructed from thin polyimide substrates and rugged polyimides for coverlay, Flex PCBs can bend and twist without breaking. This flexibility suits them for applications needing miniaturization and weight reduction, often found in wearable technology and compact consumer electronics, including flex printed options.

Flex PCBs’ ability to conform to various shapes and endure dynamic movements makes them indispensable in modern devices, enabling innovative designs in smartphones, medical implants, and beyond, including advanced pcb design.

Definition of Rigid-Flex PCB

Rigid-Flex PCBs, a hybrid of rigid and flexible circuit boards, consist of flexible circuitry integrated with rigid sections, enabling complex designs and applications. This combination offers structural support for high-reliability applications while maintaining necessary flexibility.

Rigid-Flex PCBs offer compact, reliable, and flexible printed boards capable of withstanding harsh environments and high-stress conditions, making them ideal for aerospace, military, and other demanding industries requiring durability and adaptability with rigid pcbs, rigid boards, a single rigid flex board, and flexible pcbs.

Structural Differences

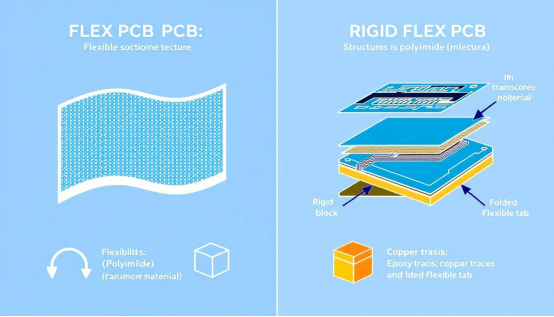

Structural differences are fundamental to Flex PCBs and Rigid-Flex PCBs functionalities. Flex PCBs, made entirely from flexible substrates, allow significant bending and shaping, enabling molding into intricate shapes for designs requiring dynamic movement.

Rigid-Flex PCBs merge rigid and flexible circuit characteristics, enhancing design versatility by combining the durability of rigid sections with the flexibility of flexible areas, catering to structural support and design freedom.

Flexible Layers in Flex PCBs

Composed entirely of flexible layers, conductive layers, and a protective layer, Flex PCBs can bend and conform to various shapes needed in different applications, allowing incorporation into designs requiring dynamic movement and complex geometries, such as wearable devices and compact electronic gadgets, including flexible printed circuit board designs.

Using flexible materials like polyimide enhances Flex PCBs’ adaptability, making them ideal for applications demanding high flexibility without compromising durability. This structural composition is crucial for maintaining electrical connections while allowing bending and twisting.

Combination of Rigid and Flexible Sections in Rigid-Flex PCBs

Rigid-Flex PCBs combine materials to achieve high flexibility without compromising structural integrity. Their layered stack-up incorporates both rigid and flexible materials, enhancing functionality and complex interconnections, ensuring seamless integration of both circuitry types.

The blend of rigid and flexible sections in Rigid-Flex PCBs supports intricate rigid flex designs and reliable performance in environments with mechanical stress, making them suitable for high-reliability applications in aerospace and military systems, including a rigid part.

Design Considerations

Designing Flex and Rigid-Flex PCBs involves key considerations influencing performance and reliability. For Flex PCBs, material selection and bend radius are crucial for withstanding dynamic movements without mechanical failures. Aligning the design with application requirements is another important aspect for PCB designers.

Rigid-Flex PCBs face complexities due to design rules, layer stack-up, and material constraints. Balancing electrical performance, mechanical strength, and flexibility requires careful planning and collaboration with manufacturers.

Material Selection for Flex PCBs

Flex PCBs typically have the following characteristics:

· Use polyimide substrates, known for their lightweight and adaptable properties.

· Feature a rugged polyimide coverlay that enhances durability and ensures they withstand mechanical stress from bending and twisting.

· Have inner layers that are crucial for maintaining electrical connections while allowing flexibility.

Flex PCBs can be designed as single-sided, double-sided, or multi-layered circuits on one or both sides, depending on specific application needs. This design versatility allows their use in a wide range of devices, from simple consumer electronics to complex medical implants, including multiple circuit boards.

Layer Stack-Up in Rigid-Flex PCBs

The layer stack-up process in Rigid-Flex PCBs is crucial for balancing flexibility and structural support. Key points include:

· Layer arrangement and number impact the PCB’s flexibility, durability, and thermal resistance.

· Material selection is key to achieving the desired balance.

· For high routing density, Rigid-Flex PCBs can accommodate multiple layers, over 20 layers.

· Flexible layers typically range from 1 to 4.

Adopting appropriate bend radius techniques and stress reduction methods helps prevent copper traces damage in the flexible sections of Rigid-Flex PCBs. Careful planning, material selection, and consideration of material thickness, along with collaboration with manufacturers, are vital for successful design

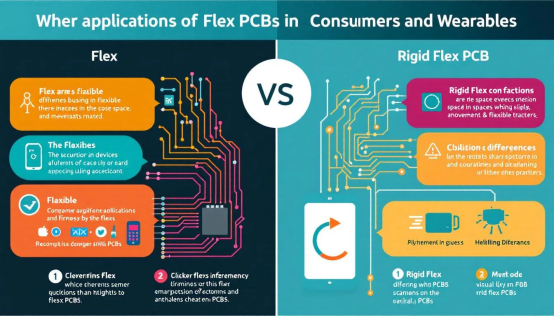

Application Differences

Flex and Rigid-Flex PCBs are used in different applications, each leveraging unique advantages. Flex PCBs benefit applications requiring lightweight, compact designs and repeated bending endurance, commonly found in consumer electronics, medical devices, and wearable technology due to their adaptability and durability.

Rigid-Flex PCBs are often used in environments with significant heat, vibration, or shock. Their combined rigidity and flexibility suit high-stress applications in aerospace, automotive, and other industries needing reliable and compact designs.

Common Uses for Flex PCBs

Flex PCBs are widely used in consumer electronics, such as smartphones and laptops, for fitting into compact designs and enduring dynamic movements. They are also common in medical devices, where flexibility and compactness are essential for applications like implants and portable medical equipment.

In wearable technology, Flex PCBs are ideal because they can fit into small, irregularly shaped, lightweight, and comfortable devices. Their adaptability facilitates connections in confined spaces, making them indispensable in modern electronics.

Common Uses for Rigid-Flex PCBs

Originally developed for spacecraft, Rigid-Flex PCBs are important in aerospace applications. They are widely used in aerospace systems and automotive electronics, where high reliability, weight reduction, and cost reduction are critical.

These PCBs are also beneficial in weight-sensitive applications, such as drones and other aerospace systems, due to their compact and reliable design. Rigid-Flex PCBs offer the following advantages:

· Ensure reliable connections

· Provide streamlined designs by eliminating the need for connectors and cable assemblies

· Are ideal for high-shock and high-vibration environments

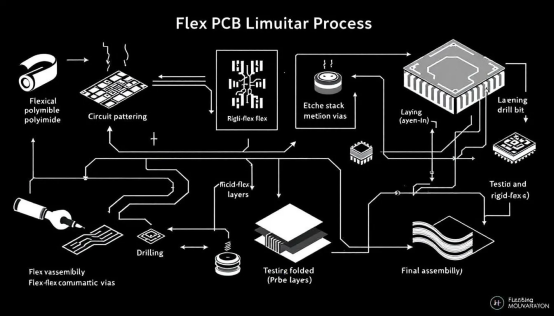

Manufacturing Process

The manufacturing processes for Flex and Rigid-Flex PCBs share similarities but differ in material requirements and handling techniques. Flex PCBs are typically fabricated using polyimide substrates laminated with rolled copper to accommodate bending, involving processes like drilling, plating, and etching.

Rigid-Flex PCBs require precise alignment and registration of flexible and rigid layers during assembly. Integrating flexible and rigid sections simplifies assembly production runs by eliminating the need for connectors and cable assemblies, ensuring a streamlined production process.

Fabrication of Flex PCBs

Fabricating Flex PCBs involves the following steps:

· Laminating polyimide with rolled copper.

· Applying a seed layer for copper plating.

· Mechanical drilling to create vias and pads, often allowing multiple substrates to be drilled simultaneously.

· Applying a polyimide film coverlay to protect the top and bottom surfaces of the Flex circuit.

These steps ensure Flex PCBs can accommodate bending and twisting while maintaining electrical connections, making them suitable for dynamic applications.

Fabrication of Rigid-Flex PCBs

Manufacturing Rigid-Flex PCBs involves:

· Starting with flexible layers laminated between rigid sections, requiring precise alignment and registration.

· Final assembly process that often includes additional drilling for through-plated holes.

· Ensuring smooth transitions between flexible and rigid sections.

IPC offers advice and best practices for manufacturing Rigid-Flex PCBs, emphasizing a smooth transition and connection integrity. This complex process ensures Rigid-Flex PCBs perform reliably in high-stress environments.

Performance and Reliability

Flex and Rigid-Flex PCBs excel in different performance and reliability aspects. Flex PCBs offer several advantages:

· Reduce wiring errors by integrating wiring directly into the board

· Improve overall reliability

· Lead to cost savings related to warranty claims and repairs

· Handle bending and vibration effectively

· Are ideal for devices with moving components

Rigid-Flex PCBs, integrating rigid and flexible components, offer enhanced performance in environments subject to shock and vibration. Their structural design reduces failure points, effectively eliminating connectors and solder joints, resulting in increased reliability in harsh environments.

Durability and Flexibility in Flex PCBs

Flex PCBs are designed to:

· Withstand repeated bending and mechanical stress, making them suitable for dynamic applications.

· Sustain dynamic motions without damage due to their mechanical flexibility and flexing.

· Ensure durability in devices with moving components, including flex boards.

The materials in Flex PCBs allow them to handle bending and vibration, ideal for applications requiring frequent movement and adaptability. This durability is crucial for maintaining device functionality in various environments.

Structural Support and Reliability in Rigid-Flex PCBs

Rigid-Flex PCBs offer increased long-term reliability due to their structural design, providing a longer service life and reducing points of interconnect. Their advantages include:

· Less susceptibility to failure in harsh environments

· Fewer points of failure, resulting in increased reliability

· Flexible layers that enhance performance during shock and vibration exposure

These features make them ideal for high-improved reliability applications.

By reducing failure points and eliminating connectors and solder joints, Rigid-Flex PCBs ensure reliable connections in demanding environments. Their resilience and durability make them suitable for critical applications in aerospace, military, and other industries where reliability is paramount.

Cost Considerations

Cost considerations for Flex PCBs and Rigid-Flex PCBs can vary significantly due to differences in materials and manufacturing processes. Flex PCBs, with their specialized techniques, can increase production complexity and costs. However, they allow for simplified assembly, which contributes to reduced labor costs and decreased assembly time. The material costs for Flex PCBs can also vary significantly based on the types of flexible substrates and conductive materials used.

Rigid-Flex PCBs, on the other hand, require specialized materials like no-flow prepregs, which significantly impact their overall costs. The price of flexible laminates contributes substantially to the overall expenses, often costing three to five times more than rigid board laminates.

Despite the higher initial costs, Rigid-Flex PCBs can offer significant cost savings over time by avoiding constant replacement or repairs of multiple rigid components.

Cost Drivers for Flex PCBs

The manufacturing process for Flex PCBs involves specialized techniques that can increase production complexity and costs. However, Flex PCBs allow for simplified assembly, which contributes to reduced labor costs and decreased assembly time. Material costs for Flex PCBs can vary significantly based on the types of flexible substrates and conductive materials used, such as polyimide and rolled copper.

Despite the higher initial costs, the benefits of reduced assembly time and labor costs make Flex PCBs a cost-effective solution for many applications. The ability to fit into compact designs and endure dynamic movements further enhances their value in various industries.

Cost Factors for Rigid-Flex PCBs

The price of flexible copper clad laminates is a significant cost factor for Rigid-Flex PCBs, often costing three to five times more than rigid board laminates. Controlled impedance requirements for Rigid-Flex PCBs usually necessitate thicker dielectrics, which exponentially increase costs with added thickness. The combination of specialized materials and complex assembly processes leads to a higher pricing structure for Rigid-Flex PCBs compared to traditional PCBs.

However, the cost savings achieved over time by avoiding constant replacement or repairs of multiple rigid components make Rigid-Flex PCBs a valuable investment. Their ability to reduce assembly costs due to their smaller size and fewer parts further enhances how rigid flex pcbs eliminate assembly inefficiencies and improve cost-effectiveness.

Summary

Understanding the differences between Flex PCBs and Rigid-Flex PCBs is crucial for selecting the right type of PCB for your specific application. Flex PCBs offer unparalleled flexibility, making them ideal for compact and dynamic designs, while Rigid-Flex PCBs provide structural support and reliability for high-stress environments. By considering factors such as material selection, design complexity, and cost, you can make informed decisions that maximize performance and cost-efficiency. Whether you’re in aerospace, consumer electronics, or medical devices, choosing the right PCB technology can significantly impact the success of your projects.

FAQs

Q.What are the main differences between Flex PCBs and Rigid-Flex PCBs?

A.The primary distinction between Flex PCBs and Rigid-Flex PCBs lies in their construction; Flex PCBs are composed solely of flexible materials, whereas Rigid-Flex PCBs integrate both rigid and flexible components, providing a balance of flexibility and structural support.

Q.What applications are best suited for Flex PCBs?

A.Flex PCBs are particularly well-suited for consumer electronics, medical devices, and wearable technology because of their adaptability and capacity for compact design integration.

Q.Why are Rigid-Flex PCBs preferred in aerospace and military applications?

A.Rigid-Flex PCBs are preferred in aerospace and military applications due to their high reliability and durability, effectively withstanding the high-stress environments typical of these fields. Their design enhances performance while reducing the risk of failure in critical systems.

Q.How do the manufacturing processes of Flex PCBs and Rigid-Flex PCBs differ?

A.The manufacturing processes of Flex PCBs and Rigid-Flex PCBs differ primarily in that Flex PCBs utilize polyimide substrates with rolled copper, whereas Rigid-Flex PCBs necessitate precise alignment of both flexible and rigid layers during assembly. This distinction in construction directly affects their application and performance.

Q.Are Rigid-Flex PCBs more expensive than Flex PCBs?

A.Rigid-Flex PCBs are indeed more expensive than Flex PCBs due to specialized materials and complex assembly processes. However, their long-term cost savings from reduced repairs and replacements can justify the initial investment.