Exploring Custom Flex PCBA Solutions for Advanced Electronic Applications

In today’s electronics landscape, devices are getting thinner, faster, and smarter — and the circuits inside them must keep up. Traditional rigid boards often limit design freedom, but flex PCBA changes the game. By combining flexibility with advanced electronic performance, custom flex PCBA solutions open new possibilities for innovation across industries — from medical wearables to aerospace systems. As technology pushes boundaries, these adaptable assemblies are becoming the silent backbone of next-generation electronics, where reliability and design agility matter most.

Understanding Flex PCBA and Its Core Advantages

What Is Flex PCBA?

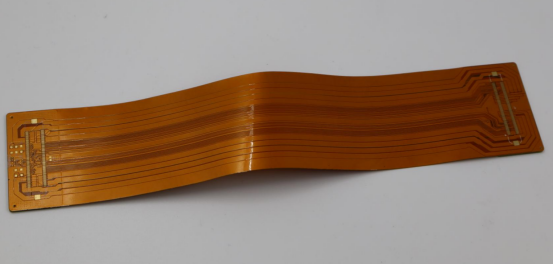

Flex PCBA (Flexible Printed Circuit Board Assembly) refers to an electronic assembly that uses a flexible base material instead of the rigid fiberglass found in standard circuit boards. This flexibility allows the board to bend, fold, or twist without damaging the conductive pathways or components. A Flex PCBA integrates both the flexible circuit and the mounted electronic components, forming a complete, ready-to-use assembly for compact or movable devices.

Difference between Flex PCB and Rigid PCB:

A Flex PCB is made from a flexible polymer substrate—typically polyimide—that can conform to tight spaces and curved shapes, while a Rigid PCB is built on stiff materials like FR-4 and cannot bend. In practice, Flex PCBA replaces rigid interconnections with continuous flexible circuits, eliminating bulky connectors and cables. For example, a smartphone camera module often uses a flex PCBA to connect the camera sensor to the motherboard through a thin, flexible ribbon instead of a rigid connector.

Basic Structure:

A typical Flex PCBA consists of:

Flexible substrate: Usually polyimide (PI) or polyethylene terephthalate (PET), providing both strength and flexibility.

Copper traces: Etched or printed to form conductive paths.

Coverlay: A protective insulating film that shields copper circuits from moisture and abrasion.

Components: Surface-mounted (SMT) or through-hole parts soldered directly onto the flex surface.

These layers are laminated together to achieve a thin, durable circuit capable of handling repeated bending cycles without failure.

Key Advantages of Flex PCBA

1. Lightweight and Space-Saving

Flex PCBA reduces overall product size and weight by replacing multiple rigid boards and connectors with a single flexible circuit. This makes it ideal for wearable electronics, drones, and medical implants, where compactness is essential.

2. Superior Flexibility and Durability

The flexible substrate allows the board to move with the device, absorbing vibration and mechanical stress. For instance, in automotive sensors exposed to constant motion, Flex PCBA maintains stable performance far longer than rigid alternatives.

3. Enhanced Signal Integrity in High-Speed Applications

With fewer connectors and shorter trace lengths, signal transmission is cleaner and faster. Flex PCBA minimizes impedance discontinuities, making it well-suited for high-frequency or high-speed communication systems such as radar modules and 5G devices.

4. Reduced Assembly Complexity

By integrating multiple interconnects into a single flexible circuit, Flex PCBA simplifies manufacturing and reduces potential failure points. This also shortens assembly time and improves long-term reliability.

Common Materials and Construction Methods

Flexible Substrates:

Most Flex PCBAs use polyimide (PI) for its excellent thermal stability and flexibility, or PET for lower-cost applications requiring moderate flexibility. Polyimide can withstand high soldering temperatures, making it suitable for aerospace and medical use.

Adhesiveless Laminates:

Modern Flex PCBAs often use adhesiveless copper-clad laminates, where the copper foil is directly bonded to the polyimide without adhesive layers. This improves dimensional stability, heat resistance, and bend reliability, while enabling finer line widths and spacing.

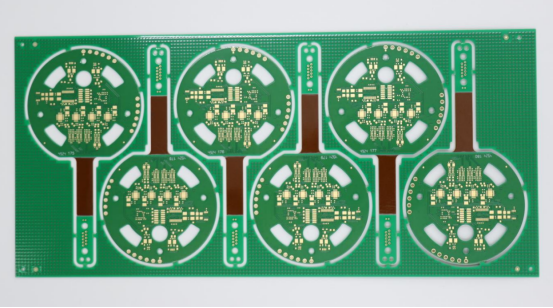

Design Variants:

Single-sided flex: Simple and cost-effective, used in printers and cameras.

Double-sided flex: Conductive layers on both sides connected by plated vias, suitable for moderate circuit density.

Multilayer flex: Combines several flex layers with interconnections, supporting complex, high-performance electronics like medical diagnostic equipment or satellite systems.

Each construction type balances flexibility, durability, and electrical performance, allowing engineers to tailor the design to their specific application requirements.

The Need for Customization in Flex PCBA

As electronic devices become more compact, high-performing, and mechanically demanding, relying on standard flex PCBs often falls short. Advanced applications require circuits that can withstand dynamic stress, extreme temperatures, and high-frequency signals while maintaining reliability. This is where custom Flex PCBA becomes essential — enabling engineers to tailor every aspect of the board to meet the unique demands of each application.

Why Standard Solutions Aren’t Enough

Standard, off-the-shelf flex PCBs are designed for general use, offering fixed material options, trace layouts, and thicknesses. While suitable for basic consumer products, they often fail to meet the electrical, mechanical, or environmental requirements of advanced or specialized industries.

For example, medical implants, aerospace sensors, and automotive control units operate under extreme conditions—high vibration, temperature shifts, or constant movement—that standard flex PCBs are not engineered to handle. In these cases, custom Flex PCBA becomes essential.

Customization allows engineers to fine-tune every element of the circuit — from signal integrity and current capacity to mechanical bend tolerance — ensuring the board performs reliably in its unique application. In short, custom Flex PCBA solutions align the circuit’s design with the specific functional and environmental demands of the end product, something standard options cannot achieve.

Key Custom Parameters in Flex PCBA Design

1. Layer Count and Thickness Optimization

Custom designs let engineers determine the optimal number of conductive and dielectric layers based on electrical load and flexibility needs. Thinner boards improve flexibility but may reduce current-carrying capacity; thicker or multilayer designs add mechanical stability for complex devices. For example, a 4-layer flex PCBA may be ideal for compact sensor arrays, while a 10-layer version suits high-density aerospace modules.

2. Controlled Impedance Design for High-Speed Circuits

In high-frequency or high-speed circuits, maintaining controlled impedance is critical for stable signal transmission. Customization allows precise control of trace width, spacing, and dielectric thickness to achieve consistent impedance values. This is especially important for 5G communication modules, radar systems, and high-speed data lines, where minor variations can cause signal loss or interference.

3. Tailored Bend Radius and Dynamic Flex Life

Different applications require different bend radii—the minimum curve a flex circuit can tolerate without damage. Engineers can customize material selection and trace routing to extend dynamic flex life, allowing the circuit to bend repeatedly during operation. For instance, robotic arms and foldable devices need circuits that can survive thousands of motion cycles without fatigue.

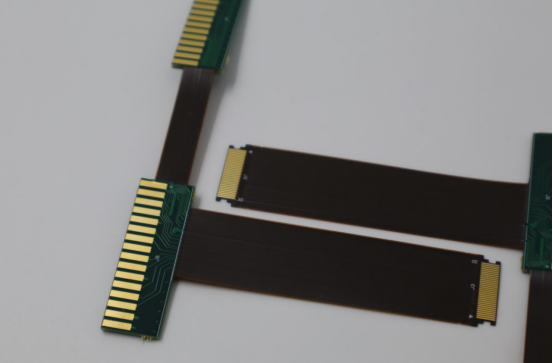

4. Integration with Rigid Sections (Rigid-Flex PCBA)

When both durability and flexibility are required, Rigid-Flex PCBA provides an optimal solution. It combines flexible layers with rigid board sections, enabling stable component mounting and flexible interconnections in one structure. This hybrid design reduces connectors, improves reliability, and saves space — a key advantage in medical imaging systems or compact defense electronics.

Example – Custom Flex PCBA in Wearable Electronics

Wearable technology demonstrates the power of customization in Flex PCBA. Devices like smartwatches, fitness trackers, and medical patches demand ultra-thin, durable circuits that operate reliably under constant motion and heat exposure.

Miniaturized Circuits for Constant Bending: Engineers design ultra-fine traces and thin copper layers that can flex repeatedly without cracking. This ensures comfort and long-term performance even during continuous wear.

Reinforcement Zones for Connector Interfaces: Critical areas, such as connectors or battery pads, are reinforced with stiffeners or thicker polyimide sections to prevent tearing and improve mechanical strength.

Shielding for Signal Integrity: To maintain stable Bluetooth, Wi-Fi, or 5G connections, designers add EMI shielding layers and optimize grounding paths, protecting signals from interference in compact enclosures.

In short, custom Flex PCBA enables wearable electronics to remain lightweight, durable, and highly functional, supporting continuous innovation in health monitoring, fitness, and personal connectivity.

Applications of Custom Flex PCBA in Advanced Industries

Custom Flex PCBA (Flexible Printed Circuit Board Assembly) has become a cornerstone of modern electronics, enabling designs that are lighter, smaller, and more durable. Its adaptability allows engineers to create circuits that perform reliably in harsh or dynamic environments — making it indispensable across automotive, medical, aerospace, defense, and industrial applications.

Automotive Electronics

In the automotive sector, custom Flex PCBA is used in systems that demand both precision and resilience, including sensors, lighting modules, infotainment systems, and driver-assistance units.

Sensors and Control Units: Flex PCBA enables compact and vibration-resistant designs for engine management sensors, brake control modules, and airbag systems, where reliability under mechanical stress is essential.

Lighting and Infotainment: Flexible circuits support LED lighting modules and dashboard displays, allowing for slim, curved designs that rigid PCBs cannot achieve.

Thermal Management and Vibration Resistance: Automotive environments expose circuits to high temperatures and constant vibration. Custom flex assemblies use polyimide substrates, reinforced stiffeners, and controlled impedance routing to manage heat dissipation and maintain signal stability.

By tailoring materials and construction, automotive Flex PCBA ensures consistent performance in demanding conditions, supporting the shift toward smarter and more energy-efficient vehicles.

Medical Devices

Medical devices rely heavily on miniaturized, biocompatible, and reliable electronic assemblies, and Flex PCBA meets these requirements perfectly.

Portable Diagnostic Devices: Handheld ECG monitors, glucose sensors, and wearable patches use ultra-thin flex assemblies that conform to body contours while maintaining electrical performance.

Implantable Electronics: In pacemakers or neurostimulators, custom Flex PCBA provides biocompatibility and long-term durability. The circuits are designed using medical-grade polyimide or PEEK materials, which can endure sterilization processes without degrading.

Sterilization and Safety: Customization allows manufacturers to select heat- or chemical-resistant coatings and ensure compliance with ISO 13485 medical standards.

Through material and design customization, Flex PCBA in medical devices enhances patient comfort, safety, and device longevity — enabling more reliable, real-time health monitoring solutions.

Aerospace and Defense

In aerospace and defense applications, reliability, lightweight construction, and electromagnetic stability are top priorities.

Avionics and Satellites: Flex PCBA is used in communication arrays, navigation systems, and satellite control units, where minimal weight and maximum durability are crucial.

Radar and Guidance Modules: High-frequency radar modules depend on controlled impedance flex circuits to maintain precise signal transmission under extreme conditions.

EMI Shielding and Structural Strength: Advanced designs integrate electromagnetic interference (EMI) shielding layers, ensuring stable operation in high-radiation or electromagnetic environments.

Custom aerospace-grade Flex PCBA offers the perfect balance of flexibility, thermal resistance, and mechanical strength—meeting stringent spaceflight standards while reducing overall system weight.

Consumer and Industrial Electronics

Flex PCBA plays a key role in the next generation of consumer and industrial products, where flexibility and miniaturization enable new design possibilities.

Foldable and Wearable Devices: Smartphones, AR/VR headsets, and smartwatches depend on flexible circuits that can fold or twist without losing functionality. For example, in foldable phones, Flex PCBA is integrated into the hinge area, allowing seamless electrical connectivity as the screen bends.

IoT Modules and Robotics: Custom flex assemblies provide compact, durable interconnections for industrial sensors, robotic arms, and smart home systems, where space and motion constraints limit the use of rigid boards.

Durability in Harsh Environments: Industrial-grade flex PCBAs are reinforced with protective coatings and stiffeners, ensuring performance in dusty, high-vibration, or temperature-variable conditions.

By enabling lightweight, space-efficient, and high-reliability electronics, custom Flex PCBA drives innovation across consumer and industrial applications — powering everything from connected homes to autonomous factories.

The Manufacturing Process of Custom Flex PCBA

Producing a custom Flex PCBA (Flexible Printed Circuit Board Assembly) requires precision, collaboration, and process control at every stage. Unlike rigid boards, flexible circuits must balance electrical performance with mechanical reliability, ensuring they can bend or move without failure. The manufacturing process involves three major stages — Design and DFM, Fabrication and Assembly, and Testing and Quality Assurance — each critical to delivering dependable, high-performance results.

Design and DFM (Design for Manufacturability)

Successful Flex PCBA production begins with a strong design foundation. Early collaboration between designers and fabrication engineers ensures that creative concepts can be efficiently manufactured without compromising quality or flexibility.

Importance of Early Collaboration:

Engaging manufacturing teams during the design phase helps identify limitations related to material selection, trace spacing, bend radius, and copper thickness. This reduces rework and production errors later in the process. For instance, specifying an overly tight bend radius early on may lead to cracked copper traces; DFM review helps adjust the layout before fabrication begins.

Simulation Tools for Bend Radius and Impedance Control:

Engineers use computer-aided simulation tools to model how the flex circuit will perform under physical stress and electrical load.

Bend radius simulation predicts how the board will behave when folded or flexed repeatedly.

Impedance control analysis ensures that high-speed signals remain stable by fine-tuning trace width, spacing, and dielectric thickness.

These simulations help balance flexibility, durability, and signal integrity — essential for applications like medical sensors or aerospace systems.

By addressing manufacturability at the design stage, companies can shorten production time, minimize scrap rates, and ensure consistent quality across batches.

Fabrication and Component Assembly

Once the design is finalized, fabrication transforms the digital layout into a physical flex circuit ready for assembly. This process combines chemical precision and mechanical accuracy to achieve a lightweight yet robust structure.

Etching, Lamination, and Via Plating:

The manufacturing sequence starts with copper etching to form circuit traces on a flexible substrate (often polyimide). Layers are then laminated using heat and pressure, bonding copper and insulating materials without distorting flexibility. Via plating electrically connects layers through tiny drilled holes, ensuring smooth signal transmission across multilayer structures.

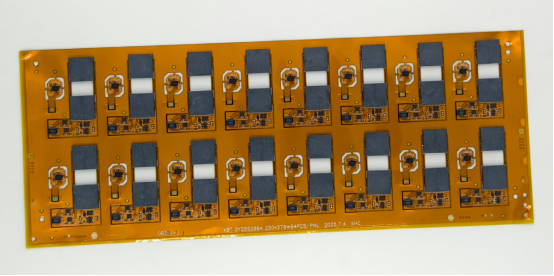

SMT and Through-Hole Assembly:

Components are mounted onto the flexible substrate using Surface Mount Technology (SMT) or through-hole soldering, depending on design requirements. Flexible boards require low-temperature solder pastes and precision alignment since excessive heat or stress can deform the substrate. Robotic pick-and-place systems ensure accuracy during component placement.

Solder Joint Reliability and Mitigation Techniques:

Because flexible materials expand and move differently than components, solder joints can experience stress or cracking over time. To enhance solder joint reliability, manufacturers use techniques like:

Controlled reflow temperature profiles.

Flexible stiffeners under component areas.

Reinforced adhesive bonding.

These measures prevent delamination and maintain consistent electrical connectivity during the product’s life cycle.

Testing and Quality Assurance

Testing verifies that every Flex PCBA meets performance, durability, and safety standards before deployment.

Electrical Testing:

Techniques such as flying probe tests, continuity checks, and impedance measurement confirm that all connections function correctly and that the circuit’s signal performance aligns with design specifications.

Environmental and Flex Life Cycle Testing:

Flex PCBAs are subjected to thermal cycling, humidity exposure, and repeated flex tests to ensure mechanical endurance. These tests simulate real-world conditions, confirming that circuits can withstand bending, vibration, and temperature fluctuations without failure.

Compliance with IPC Standards:

Leading manufacturers follow strict IPC-6013 (for flexible circuits) and IPC-A-610 (for electronic assemblies) standards. Compliance ensures that the final product meets international benchmarks for solder joint integrity, cleanliness, and mechanical strength.

Through rigorous testing and certification, custom Flex PCBA achieves the high reliability demanded by industries such as automotive, medical, and aerospace — where even a minor defect could lead to system failure.

A well-executed manufacturing process transforms a flexible design concept into a high-precision electronic assembly capable of withstanding mechanical motion, temperature extremes, and long-term operation — the hallmark of truly advanced Flex PCBA engineering.

Choosing the Right Flex PCBA Partner

Selecting the right Flex PCBA manufacturer is one of the most critical decisions in developing a high-performance electronic product. The ideal partner not only provides technical capability but also offers design collaboration, consistent quality, and scalable production capacity. A strong partnership ensures that your custom Flex PCBA meets exact functional, mechanical, and regulatory requirements — from prototype to mass production.

Key Criteria for Selecting a Manufacturer

When evaluating potential Flex PCBA suppliers, focus on proven expertise, production flexibility, and compliance with industry standards.

Experience with Multilayer and Rigid-Flex Assemblies:

Manufacturers with deep experience in multilayer flex and rigid-flex PCBA can handle complex designs that integrate both flexible and rigid sections. This capability is essential for high-density applications such as aerospace, automotive, and advanced medical electronics. A qualified partner should demonstrate proficiency in impedance control, microvia drilling, and fine-line etching for multilayer designs.

Capability for Small-Batch Prototyping and Volume Production:

The ability to transition smoothly from prototype to mass production is key. During early development, small-batch prototypes help verify performance and manufacturability. Once validated, a capable manufacturer can scale up production while maintaining consistency in quality, lead time, and cost. This flexibility supports faster product launches and continuous improvement cycles.

Material Sourcing and Certification Compliance:

Reliable suppliers use traceable, certified materials such as UL-approved polyimide films and RoHS-compliant finishes. They should also maintain compliance with industry standards like ISO 9001, ISO 13485 (medical), or AS9100 (aerospace) depending on the target market. Verified sourcing ensures long-term supply chain stability and product reliability.

Comparing Domestic vs. Offshore Production

Choosing between domestic and offshore Flex PCBA manufacturing depends on project priorities such as cost, speed, and communication.

Lead Time and Cost:

Offshore manufacturers — particularly in Asia (China, Taiwan, South Korea) — often offer lower unit costs and access to high-volume production capabilities. However, longer logistics times and customs processes may extend overall lead time. Domestic production, such as in the U.S. or Europe, typically costs more but offers shorter turnaround times and greater control over design changes.

Communication and Collaboration Efficiency:

Domestic partners provide easier communication due to time zone alignment and language compatibility, which can speed up issue resolution during prototyping. Offshore partners, on the other hand, often offer dedicated engineering liaisons or multilingual support teams to bridge communication gaps.

Example: A U.S.-based company developing medical wearables may choose an American Flex PCBA partner for early-stage prototyping to ensure close collaboration and compliance with FDA-related standards. Once the design stabilizes, large-scale production may shift to an Asia-based manufacturer to optimize cost efficiency while maintaining strict process documentation.

By understanding these trade-offs, organizations can choose a hybrid approach — local development with offshore scaling — that balances agility, quality, and cost.

Evaluating Quality and Support

A reliable Flex PCBA partner does more than deliver boards — they ensure quality, traceability, and continuous support throughout the product lifecycle.

Traceability and Inspection:

High-quality manufacturers implement end-to-end traceability systems, logging materials, lot numbers, and process data for every board. Automated optical inspection (AOI) and X-ray verification detect assembly defects such as solder voids or misalignments before shipment.

After-Sales Service and Technical Support:

Ongoing support after delivery is critical. A strong partner provides assistance with failure analysis, warranty claims, and process feedback, ensuring consistent field reliability.

Partnering for Design Co-Optimization:

The best suppliers act as engineering collaborators, not just fabricators. They work closely with your design team to optimize layout, materials, and stack-up configuration for manufacturability and performance. This co-engineering approach reduces redesign cycles, improves yield, and speeds time-to-market.

Choosing the right Flex PCBA manufacturer is ultimately about building a long-term partnership grounded in trust, technical expertise, and transparency. With the right partner, companies can confidently bring advanced electronic products from concept to global deployment — efficiently and reliably.

For businesses seeking a professional, experienced, and flexible Flex PCBA partner, PCBMASTER offers comprehensive solutions. From multilayer and rigid-flex assemblies to small-batch prototyping and large-scale production, PCBMASTER combines high-quality materials, precise fabrication, and engineering support to meet your custom requirements. Partnering with PCBMASTER ensures optimized performance, reliable delivery, and ongoing technical guidance, helping your products succeed in competitive markets.

Future Trends in Flex PCBA Technology

The world of Flex PCBA is evolving rapidly, driven by advances in materials, manufacturing processes, and digital integration. Emerging technologies are enabling smaller, lighter, smarter, and more sustainable electronic devices, opening opportunities across consumer electronics, medical devices, aerospace, and industrial applications.

Emerging Materials and Processes

Flexible Hybrid Electronics (FHE) and Printed Conductive Inks:

FHE combines rigid and flexible substrates with printed electronics, allowing circuits to be applied directly onto surfaces such as plastics, textiles, or wearable fabrics. Conductive inks, often silver or copper-based, enable printing of fine traces without traditional etching, reducing material waste and enabling ultra-thin, lightweight designs. For example, a wearable health patch can integrate sensors and interconnects directly into a flexible polymer substrate using printed conductive inks.

Ultra-Thin Copper Foils and Stretchable Substrates:

Next-generation Flex PCBA uses ultra-thin copper foils, sometimes below 9 µm, to achieve extreme flexibility while maintaining electrical performance. Stretchable substrates, made from silicone or elastomeric materials, allow circuits to stretch or bend dynamically, supporting applications like foldable smartphones, robotic skin, or wearable electronics that conform to human motion.

These innovations improve circuit density, flexibility, and durability, expanding design possibilities beyond traditional flex assemblies.

Integration with AI and IoT Systems

Smart Flex PCBA for Adaptive Sensing and Connectivity:

Flex PCBA is increasingly used in IoT devices and AI-enabled sensors, where circuits must flex, fold, or twist while maintaining connectivity. Examples include smart wearables that monitor heart rate, motion, or environmental conditions and adjust their data collection based on real-time AI algorithms.

Data-Driven Optimization in Design and Manufacturing:

AI and machine learning are being applied to analyze flex PCBA design data, predict failure points, and optimize manufacturing processes. This includes automated adjustment of trace layouts, bend radius calculations, and soldering parameters to enhance reliability and reduce defects. By integrating digital feedback loops, manufacturers can accelerate development cycles and improve first-pass yield.

Together, AI-enabled and IoT-integrated Flex PCBAs are creating responsive, connected electronics that adapt to usage conditions and environmental changes.

Sustainability and Green Manufacturing

Lead-Free and Halogen-Free Materials:

The push for environmentally responsible electronics has led to lead-free solder alloys and halogen-free substrates, reducing toxic waste and chemical hazards during production. These materials comply with global regulations such as RoHS (Restriction of Hazardous Substances) and are increasingly expected by OEMs for consumer and industrial products.

Recycling and Environmental Impact Reduction:

Flex PCBA manufacturers are adopting recycling programs for copper and polyimide waste, as well as energy-efficient lamination and etching processes to reduce environmental footprint. By designing boards for ease of disassembly and material recovery, companies can achieve a circular production model that minimizes landfill waste.

Sustainable practices not only reduce environmental impact but also meet regulatory requirements and customer expectations for eco-friendly electronics.

The future of Flex PCBA technology points to smarter, lighter, and greener electronics, enabled by advanced materials, AI-driven design, and environmentally conscious manufacturing. These trends are shaping the next generation of electronic devices, from wearable health monitors to aerospace systems, offering higher performance, adaptability, and sustainability than ever before.

Conclusion

Custom Flex PCBA delivers unmatched advantages for modern electronics. Its lightweight, space-saving design, combined with flexibility, durability, and high signal integrity, makes it ideal for applications in automotive, medical, aerospace, consumer, and industrial devices. By tailoring each board’s layer count, bend radius, and material selection, engineers can achieve reliable performance even in complex or harsh environments.

Customization plays a key role in turning standard circuits into high-performance solutions. It enables precise adaptation to mechanical stress, electrical requirements, and environmental conditions, driving innovation in advanced electronics such as wearable devices, foldable smartphones, IoT modules, and aerospace systems.

Custom Flex PCBA is not just a component — it’s a foundation for innovation, reliability, and future-ready electronics.

FAQs

What factors influence the cost of custom Flex PCBA manufacturing?

The cost of custom Flex PCBA depends on several key factors:

Layer count and board complexity: More layers and fine-line traces increase fabrication difficulty.

Material selection: Polyimide, PET, or stretchable substrates have different prices, and high-performance or biocompatible materials cost more.

Circuit size and volume: Larger boards or low-volume prototypes typically cost more per unit.

Component assembly requirements: Complex SMT, through-hole placement, or rigid-flex integration adds labor and process cost.

Testing and certification: Compliance with IPC, ISO, or medical standards adds to manufacturing overhead.

How do you design a Flex PCBA to withstand repeated bending?

To ensure durability under continuous flexing:

Optimize bend radius: Keep traces and substrate bends within safe limits to prevent cracking.

Use flexible materials: Polyimide or stretchable substrates improve mechanical resilience.

Reinforce high-stress areas: Add stiffeners near connectors or mounting points.

Control trace layout: Route traces along neutral axes and avoid sharp angles.

Test flex life cycles: Simulate repeated bending during design to confirm performance.

What’s the difference between Flex PCBA and Rigid-Flex PCBA?

Flex PCBA: Fully flexible, designed to bend or fold, ideal for compact or wearable devices.

Rigid-Flex PCBA: Combines flexible circuits with rigid sections, allowing stable mounting for components while maintaining flexibility where needed.

Use case comparison: Flex PCBA is common in wearable sensors, while rigid-flex is preferred in aerospace or medical devices requiring both flexibility and robust component placement.

Which industries benefit most from custom Flex PCBA solutions?

Custom Flex PCBA is especially valuable in industries that require compact, durable, or high-performance electronics:

Automotive: Sensors, lighting modules, infotainment systems.

Medical: Wearables, implants, portable diagnostic devices.

Aerospace and Defense: Avionics, satellites, radar modules.

Consumer and Industrial Electronics: Foldable devices, IoT modules, robotics, wearable tech.

How do manufacturers ensure the reliability of flexible circuit assemblies?

Reliability is ensured through careful design, manufacturing, and testing:

Design optimization: Proper layer count, bend radius, and trace layout prevent mechanical failure.

High-quality materials: Certified polyimide, adhesives, and coatings enhance durability.

Precise assembly: Controlled SMT, through-hole soldering, and stiffener placement reduce stress on joints.

Testing protocols: Electrical tests (continuity, impedance), flex life cycles, environmental testing, and IPC standard compliance ensure boards perform under real-world conditions.