How to Effectively Add PCB Date Code for Better Tracking and Quality

Introduction

In the fast-paced electronics manufacturing sector, precise control over PCB production cycles has become a key competitive advantage for companies seeking market leadership.

In PCB manufacturing, production cycle management serves as the bridge connecting customer requirements with production capabilities. Particularly in today’s market environment that demands multiple varieties, small batches, and rapid delivery, manufacturers must be capable of flexibly adding and dynamically updating production cycles to maintain their competitive edge. By optimizing production cycles, companies can significantly reduce lead time, enabling faster responsiveness to customer demands.

This article provides an in-depth analysis of PCB production cycle management strategies, helping you transition from reactive response to proactive control.

Understanding the Core Components of PCB Production Cycles

The PCB production cycle encompasses the entire timeline from order confirmation to product delivery, primarily consisting of three key phases:

Material Preparation Phase: This includes component procurement, inspection, and material preparation, typically accounting for 30%-50% of the total cycle time. Providing complete and accurate BOM lists and confirming component availability cycles are crucial. Sourcing high-quality electronic components during this phase is essential to ensure production reliability.

Production Processing Phase: This covers multiple procedures including SMT assembly, DIP plug-in, and testing. This phase offers the greatest flexibility for time optimization through management improvements.

Logistics and Transportation Phase: This varies based on customer location and shipping methods, being relatively fixed but still optimizable.

Order batch sizes primarily affect time allocation in the first two phases. Generally speaking, larger batches reduce average production time per unit but extend the overall cycle duration.

Strategies for Efficiently Adding New Production Cycles

When new orders come in, how can you efficiently incorporate production cycles without disrupting existing operations?

Advance planning is crucial. Early confirmation of order details, including verifying customer specifications to ensure production cycles align with required standards, and reserving adequate production slots can secure valuable time for subsequent manufacturing.

Establishing a multi-level production scheduling system proves to be an effective solution:

·Dedicated prototyping lines for rapid response to small-batch, urgent orders

·Parallel operation of standard and specialized production lines to enhance resource utilization

·Dynamic adjustment of production sequences based on order priorities

Supply chain coordination capabilities directly impact the efficiency of adding new cycles. Building stable partnerships with key component suppliers and maintaining reasonable inventories of common materials can significantly reduce preparation time.

Scientific Approaches to Dynamic Production Cycle Updates

Production cycles aren't static—they require dynamic adjustments based on actual conditions. A real-time monitoring system forms the foundation for dynamic updates:

·Collect production line data through digital tools (such as MES systems) to accurately track process completion rates, equipment utilization rates, and other key metrics

·Implement visual dashboards displaying daily planned completion volumes, actual progress, and delayed tasks to enhance exception response speed

·Utilize IoT technology for minute-level data updates that provide early warnings for potential issues

Flexible resource allocation mechanisms ensure smooth production cycle updates:

·Establish cross-departmental human resource pools that can deploy multi-skilled workers from other lines when backlogs occur

·One factory improved personnel allocation efficiency by 55% and peak season capacity by 30% after implementing a "skill matrix diagram"

Specialized optimization of bottleneck processes effectively shortens overall cycles:

·Apply TOC theory to focus on constraint breakthroughs—one photovoltaic component manufacturer increased capacity by 140% through optimization of lamination processes

·Prioritize automation investments in bottleneck areas—a semiconductor enterprise reduced misjudgment rates from 5% to 0.3% after installing vision positioning systems on wire bonders, significantly increasing daily output

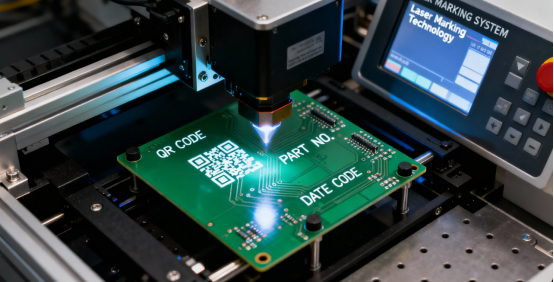

Circuit Board Marking Methods

Circuit board marking methods play a crucial role in the identification and traceability of printed circuit boards throughout the entire manufacturing process and after-sales service lifecycle. For manufacturers, the ability to uniquely identify individual boards is essential for tracking production batches, managing inventory, and ensuring efficient support long after the boards have left the production line.

One of the most widely used methods is serial numbering, where each circuit board is assigned a unique serial number during production. This allows manufacturers to trace the origin, production date, and specific process steps for every board, making it easier to manage production batches and quickly address any quality issues that may arise. Serial numbering also supports efficient after-sales service by enabling rapid identification of affected boards in the event of recalls or warranty claims.

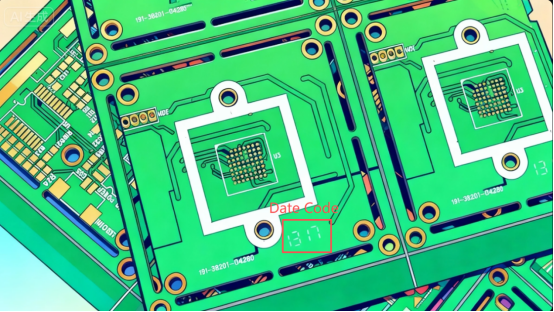

Date coding is another common marking method, indicating the exact week or date a board was produced. This information is vital for tracking the age of boards, managing warranty periods, and ensuring that inventory is rotated efficiently. Date codes help manufacturers and customers alike to identify when a board was manufactured, which is especially important for products with limited shelf life or strict quality requirements.

Barcode labeling has become increasingly popular for its ability to store more data in a compact form. By applying barcodes to circuit boards, manufacturers can encode serial numbers, batch numbers, and other production information, allowing for a single scan to retrieve all relevant data. This streamlines the identification process, supports automated inventory management systems, and enhances traceability throughout the supply chain.

Together, these marking methods ensure that every printed circuit board can be efficiently identified, tracked, and managed from production through to after-sales service, supporting high standards of quality and reliability in the electronics industry.

Application of Information Tools in Production Cycle Management

Modern PCB production cycle management relies heavily on information technology support:

Visual order progress tracking enables both customers and managers to monitor production status in real-time.

Automatic alerts for critical milestones and timely warnings for exceptional situations allow teams to prepare rather than react.

Data-driven continuous improvement utilizes OEE (Overall Equipment Effectiveness) analysis to identify loss sources, constantly enhancing on-time delivery rates through PDCA cycles. Production and process data is stored in digital systems, enabling ongoing analysis and optimization.

Best Practices: From Theory to Implementation

One major PCB manufacturer achieved over 20% improvement in production efficiency and 30% reduction in rework rates by implementing a business management system that enabled automated production processes, closed-loop exception order management, and multi-department collaborative operations. Reliable system integration played a key role in ensuring consistent data accuracy and supporting these improvements in efficiency and quality.

Another automotive components enterprise deployed IoT sensors to cut exception response time from 4 hours to 15 minutes while improving bottleneck process identification efficiency by 300%.

These cases demonstrate that scientific production cycle management not only enhances delivery efficiency but also significantly improves product quality and customer satisfaction.

Conclusion

Adding and updating PCB production cycles involves more than simple schedule adjustments—it's a systematic engineering process covering the entire workflow. Through refined process control, dynamic scheduling mechanisms, and application of information tools, manufacturers can establish flexible and efficient production systems that meet diverse customer delivery requirements while maintaining quality standards.

Remember: Excellent cycle management isn't just about meeting deadlines—it's the ability to anticipate changes and make proactive adjustments. In the increasingly competitive PCB industry, this capability will become your core advantage.

FAQs

Q. Where is the Date Code usually printed on PCB boards?

A. Mostly printed on the board edge, in blank areas of the silkscreen layer, or on non-critical pad areas to avoid affecting assembly.

Q. What information does the Date Code include?

A. The core details are the year/month/week of production. Some may also include batch numbers (e.g., 2435 = Week 35 of 2024).

Q. Is there a fixed format for Date Codes?

A. There is no unified standard. Formats can be customized to meet customer requirements (e.g., YYWW, MMYY).

Q. Can Date Codes be omitted?

A. It can be negotiated, but it is recommended to retain them for product traceability and warranty purposes.

Q. Does printing a Date Code increase cost or lead time?

A. No, it can be integrated into the silkscreen process without additional cost or time.

Q. Can Date Codes be printed on special process PCBs (e.g., ceramic, HDI)?

A. Yes, but the location and format must be specified in the GERBER files in advance.

Q. Can Date Codes be modified or erased?

A. Once the silkscreen is cured, it cannot be erased. Modifications require reproducing the board.

Author: Jack Wang