Buy Custom Automotive Printed Circuit Boards from Trusted Suppliers

In today’s vehicles, electronics drive the core functions of safety, performance, and connectivity. From advanced driver-assistance systems to electric power management, every critical system depends on precisely engineered circuit boards. Selecting the right automotive PCB can directly impact the reliability and lifespan of a vehicle.

Introduction to Automotive Printed Circuit Boards (PCBs)

What Are Automotive PCBs?

Automotive printed circuit boards (PCBs) are specialized electronic boards designed to connect and support electronic components in vehicles. They provide a stable platform for circuits while ensuring reliable electrical connections. Unlike standard PCBs used in consumer electronics, automotive PCBs are built to withstand extreme conditions such as high temperatures, vibrations, and exposure to moisture or chemicals.

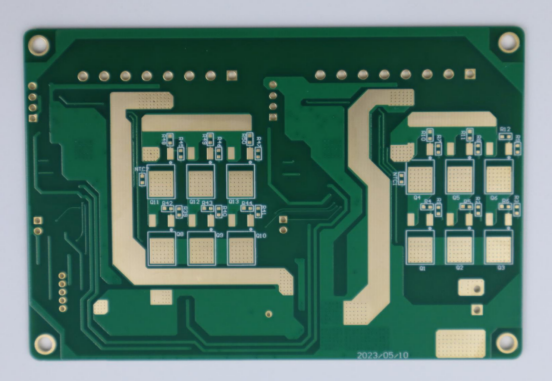

The basic structure of an automotive PCB includes multiple layers of conductive copper traces, insulating substrates, solder masks, and protective coatings. Depending on the application, they can range from simple two-layer boards to complex multi-layer designs with advanced materials for high-speed signal transmission.

A key difference between automotive PCBs and general-purpose PCBs lies in durability and performance. Automotive PCBs must meet strict industry standards for safety and longevity, while general PCBs focus more on cost efficiency and standard functionality. For example, a PCB in a vehicle’s infotainment system primarily handles audio, display, and connectivity functions, whereas a PCB in an engine control unit (ECU) manages critical engine operations, requiring higher reliability and heat tolerance.

Importance of PCBs in Modern Vehicles

PCBs play a central role in modern vehicles, influencing safety, performance, and connectivity. They serve as the foundation for systems that drivers rely on every day. For instance, anti-lock braking systems (ABS) use PCBs to process sensor data and control braking pressure, enhancing vehicle safety. Advanced driver-assistance systems (ADAS), such as lane departure warnings and adaptive cruise control, depend on PCBs to process complex sensor and camera inputs in real time.

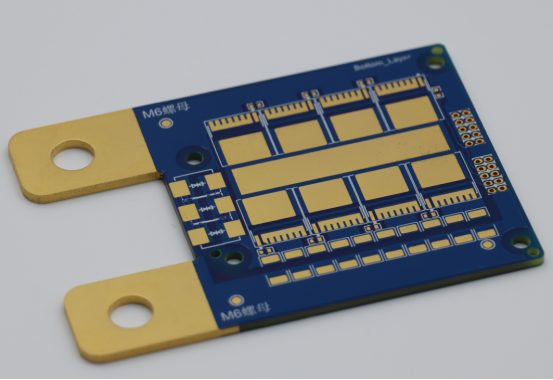

Electric vehicles (EVs) also rely heavily on automotive PCBs. Battery management systems use them to monitor cell voltage, temperature, and overall performance, ensuring efficient energy use and long-term battery health. Without reliable PCBs, these critical systems could fail, affecting both safety and vehicle performance.

By linking and supporting essential electronic components, automotive PCBs go beyond basic hardware—they form the foundation of modern vehicle systems, enabling innovations that enhance driving safety, efficiency, and overall performance.

Benefits of Custom Automotive PCBs

Tailored Design for Vehicle Requirements

Custom automotive PCBs are designed to meet the specific needs of a vehicle’s electronic system. Designers can adjust the size, shape, and layer count to fit unique components or tight spaces, ensuring seamless integration with other systems. For example, a PCB for an electric vehicle battery management system may require multiple layers to handle high-current circuits, while a PCB for a sensor module may prioritize compactness and high-speed signal routing.

Step-by-step design process for a car-specific PCB:

1. Requirement Analysis – Identify the vehicle system, operating conditions, and performance needs.

2. Material Selection – Choose substrates and copper thickness based on temperature, vibration, and electrical requirements.

3. Layer Stackup Design – Determine the number of layers needed for signal routing, power distribution, and thermal management.

4. Circuit Layout – Place components and route traces to minimize interference and ensure reliability.

5. Simulation and Validation – Test thermal performance, signal integrity, and mechanical stress before production.

Enhanced Performance and Reliability

Custom automotive PCBs provide higher performance and durability compared with standard PCBs. They are engineered to resist high temperatures, mechanical vibrations, and electromagnetic interference (EMI)—common challenges in automotive environments.

Comparison example:

Standard PCB: Suitable for consumer electronics, may fail under continuous vibration or high heat.

Automotive-grade PCB: Uses reinforced materials, thicker copper layers, and specialized coatings to withstand harsh conditions, ensuring long-term reliability and system stability.

Compliance with Industry Standards

Automotive PCBs must comply with strict industry standards to guarantee safety and quality. Key standards include:

ISO 26262 – Functional safety for electrical and electronic systems.

IPC Class 3 – High-reliability PCBs for mission-critical applications.

RoHS/REACH – Environmental compliance for hazardous substances.

Example: A manufacturer seeking ISO 26262 certification for a PCB must document design processes, material selection, testing procedures, and traceability. This certification ensures the PCB performs reliably under all specified automotive conditions.

Custom PCBs not only meet vehicle-specific requirements but also deliver performance, durability, and regulatory compliance, making them essential for modern automotive electronics.

Choosing a Trusted Automotive PCB Supplier

Key Criteria to Evaluate Suppliers

Selecting a reliable automotive PCB supplier is crucial to ensure quality, performance, and compliance. Key factors to evaluate include:

Certifications: Look for ISO 9001, ISO 26262, IPC Class 3, and RoHS/REACH compliance to guarantee quality and safety standards.

Track Record: Assess the supplier’s experience in automotive electronics and long-term projects.

Customer Reviews: Check testimonials and case studies to verify reliability and service quality.

Quality Control Processes: Ensure the supplier follows rigorous testing, inspection, and documentation procedures.

Example: Top 3 qualities of a reliable automotive PCB manufacturer

1. Consistent delivery of high-reliability PCBs for automotive applications.

2. Transparent quality assurance and traceability processes.

3. Proven ability to handle complex designs with advanced materials and technologies.

PCBMASTER exemplifies these qualities, offering years of experience in automotive PCB manufacturing, strict adherence to industry standards, and a strong reputation among global clients.

Supplier Capabilities to Consider

When choosing a supplier, it’s important to match their capabilities with your project requirements. Key aspects include:

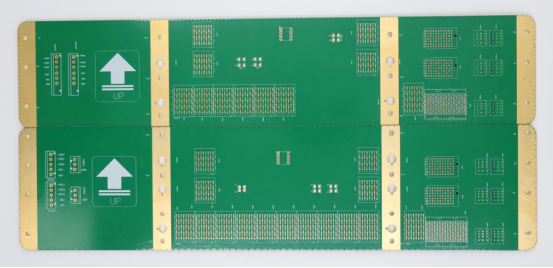

Layer Count: Ability to produce multi-layer PCBs, from simple 2-layer boards to complex 16+ layer designs.

Material Options: Substrates suitable for high-temperature, high-speed, or high-reliability applications, such as FR-4, Rogers, and PTFE.

Surface Finishes: Immersion gold (ENIG), HASL, or other finishes to support soldering and long-term reliability.

Advanced Technologies: High-speed routing, HDI, via-in-pad, and controlled impedance for modern automotive systems.

Step-by-step: Matching supplier capabilities to your project

1. Define your vehicle system’s electrical and environmental requirements.

2. Identify necessary PCB layers, materials, and finishes.

3. Compare these requirements with the supplier’s manufacturing capabilities and technology portfolio.

4. Confirm they can provide prototyping and full-scale production to meet project timelines.

PCBMASTER offers a wide range of capabilities, including advanced multi-layer designs, diverse material options, and specialized surface finishes tailored for automotive applications.

Communication and Support

Effective communication and technical support are essential when working with a PCB supplier. Important aspects include:

Design Consultation: Assistance with layout optimization, materials selection, and manufacturability.

Prototyping Support: Rapid prototyping to validate designs before full-scale production.

After-Sales Service: Ongoing support for troubleshooting, modifications, and quality issues.

Example: PCBMASTER provides design-for-manufacturing (DFM) checks to ensure every custom automotive PCB is optimized for reliability and cost-efficiency before production begins. Their team works closely with clients to review layouts, suggest improvements, and verify compliance with automotive standards.

By carefully evaluating suppliers and choosing a partner like PCBMASTER, automotive manufacturers can ensure high-quality, reliable, and compliant PCBs that support critical vehicle functions.

Manufacturing Process of Custom Automotive PCBs

Material Selection

The first step in manufacturing custom automotive PCBs is selecting the right materials. Common substrates include:

FR-4: Standard epoxy-based material, widely used for general automotive applications.

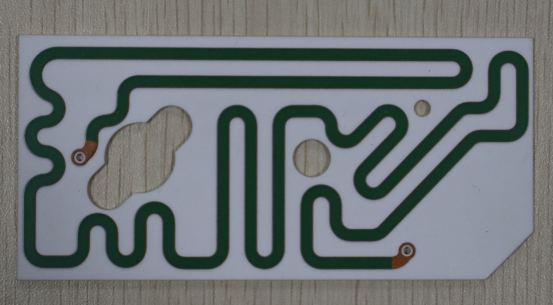

Rogers: High-frequency laminate suitable for high-speed signal transmission.

PTFE (Teflon): Low-loss material for RF and high-frequency circuits, offering excellent thermal stability.

Comparison of key material properties:

Material | Thermal Conductivity | Dielectric Constant | Cost |

|---|---|---|---|

FR-4 | Moderate | 4.2 | Low |

Rogers | High | 3.0–3.7 | Medium |

PTFE | Very High | 2.1–2.5 | High |

Choosing the right substrate depends on the application, required signal integrity, heat resistance, and budget. For example, an ECU PCB may use FR-4 for cost-effective durability, while a high-speed radar PCB may require PTFE or Rogers.

PCB Fabrication Steps

After material selection, the PCB goes through multiple fabrication steps to become a finished board. These steps include:

1. Layer Stacking: Assemble multiple layers of copper and substrate according to the design.

2. Etching: Remove excess copper to create circuit patterns.

3. Drilling: Make vias and holes for component mounting.

4. Plating: Deposit conductive material in vias to ensure electrical connectivity.

5. Solder Mask Application: Apply protective coating to prevent short circuits and oxidation.

Step-by-step process from CAD file to finished PCB:

1. Convert CAD layout into manufacturing files (Gerber, NC drill).

2. Select appropriate substrate and layer stackup.

3. Fabricate inner layers, etch traces, and perform inspections.

4. Laminate layers together under heat and pressure.

5. Drill, plate, and apply solder mask and surface finishes.

6. Conduct final inspections and electrical testing before shipment.

Quality Control and Testing

Quality control is critical for automotive PCBs to ensure reliability under harsh conditions. Common tests include:

Electrical Testing: Automated Optical Inspection (AOI) and flying probe tests check for short circuits, opens, and connectivity issues.

Thermal Cycling: Boards are subjected to high and low temperatures to simulate real-world conditions.

Vibration Testing: Ensures PCBs can withstand shocks and vibrations in vehicles.

Example: High-speed automotive PCBs, such as those used in ADAS sensors, undergo a testing protocol that combines AOI inspection, thermal cycling between -40°C and 125°C, and vibration testing to guarantee performance and durability.

By carefully selecting materials, following precise fabrication steps, and implementing rigorous quality control, manufacturers produce custom automotive PCBs that meet the high demands of modern vehicles.

Cost and Lead Time Considerations

Factors Affecting Cost

The cost of custom automotive PCBs depends on several factors:

Complexity: More intricate circuit designs with fine traces or high-density interconnects increase manufacturing difficulty and cost.

Materials: High-performance substrates like Rogers or PTFE are more expensive than standard FR-4.

Layer Count: Multi-layer PCBs require more materials and additional fabrication steps, raising the price.

Volume: Large production runs reduce the unit cost, while small batches are typically more expensive per board.

Special Finishes: Surface treatments such as ENIG (immersion gold), HASL, or solder mask variations can impact cost.

Example: A simple 2-layer automotive PCB might cost $10–$20 per unit in low-volume production, while a 16-layer high-speed PCB with advanced materials and ENIG finish could cost $80–$150 per unit. This demonstrates how complexity, materials, and layer count directly influence pricing.

Lead Time Optimization

Lead time is another crucial consideration, particularly for automotive projects with tight schedules.

Rapid Prototyping vs. Full Production: Prototypes are designed and manufactured quickly to validate designs, typically taking 1–3 weeks. Full production runs, especially for complex multi-layer PCBs, may require 4–12 weeks depending on volume and supplier capacity.

Tips for Planning:

1. Begin with a clear specification and design review to minimize revisions.

2. Select suppliers with proven prototyping and high-volume production capabilities.

3. Factor in additional time for testing, certification, and quality inspections.

4. Consider using pre-qualified materials and standard finishes to reduce manufacturing delays.

Careful planning and supplier coordination can reduce delays and unexpected costs, ensuring that automotive PCB projects are delivered on time and within budget.

Case Studies and Practical Examples

Automotive Infotainment Systems

Custom PCBs play a crucial role in modern vehicle infotainment systems. They support high-speed data processing, touchscreens, audio modules, and connectivity features such as Bluetooth and Wi-Fi. By using tailored layer designs, precise trace routing, and high-quality materials, automotive PCBs enhance both display quality and system responsiveness.

Example: In a luxury vehicle infotainment system, a multi-layer PCB enables high-definition video output and low-latency audio processing, ensuring a smooth and immersive user experience.

Electric Vehicle Battery Management

In electric vehicles (EVs), PCBs are central to battery management systems (BMS). They monitor voltage, current, and temperature for each battery cell, ensuring safe operation and maximizing battery life. High-quality automotive PCBs provide thermal stability and electrical reliability, which are essential for preventing overheating or short circuits.

Example: A custom PCB in an EV BMS uses multiple layers and high-temperature-resistant substrates to safely manage hundreds of battery cells, supporting efficient charging, discharging, and energy balancing.

Advanced Driver-Assistance Systems (ADAS)

ADAS relies on precise electronic control and real-time data processing, which demands specialized automotive PCBs. These boards support sensors, radar modules, and camera systems, providing reliable signal transmission and noise immunity. High-density interconnects and controlled impedance designs ensure accurate data processing for safety-critical functions.

Example: A radar-based collision avoidance system requires PCBs with multi-layer designs, embedded ground planes, and EMI shielding to process sensor inputs accurately at high speed, reducing latency and improving vehicle safety.

Custom automotive PCBs are therefore integral to multiple high-tech vehicle systems, from entertainment and energy management to advanced safety features, providing the performance and reliability needed in modern automotive applications.

Conclusion

Custom automotive PCBs provide tailored designs, high reliability under extreme conditions, and compliance with automotive standards. They ensure vehicle electronics perform safely and efficiently, supporting critical systems from infotainment to battery management and ADAS.

To work with a trusted supplier, provide clear project specifications, including size, layer count, materials, and application. Early communication about volume and timelines helps align expectations and avoid delays.

For successful procurement, validate designs through prototyping, choose suppliers offering design consultation and DFM checks, plan lead times carefully, and monitor quality control. Partnering with experienced manufacturers like PCBMASTER ensures high-quality, reliable, and compliant PCBs for modern vehicles.

FAQs

What materials are best for high-temperature automotive PCBs?

High-temperature automotive PCBs require substrates that can withstand heat, vibration, and harsh environmental conditions. Common options include FR-4 for standard applications, Rogers for high-speed signals, and PTFE (Teflon) for extreme thermal stability and low-loss high-frequency performance. These materials maintain structural integrity and electrical reliability even under prolonged exposure to elevated temperatures.

How do I verify if a supplier is truly automotive-grade certified?

To verify a supplier’s automotive-grade certification, check for ISO 26262 functional safety certification, IPC Class 3 quality compliance, and RoHS/REACH environmental compliance. Additionally, review their quality control processes, customer references, and documented experience in producing automotive PCBs. Certified suppliers usually provide documentation of audits, testing procedures, and traceability for their products.

Can custom PCBs reduce maintenance issues in vehicles?

Yes, custom PCBs can reduce maintenance issues by being specifically designed for the vehicle’s operating conditions. They use materials and layouts optimized for heat resistance, vibration tolerance, and EMI shielding, which minimizes failures in critical systems such as engine control units, ADAS sensors, and battery management systems. This leads to longer component lifespans and fewer system malfunctions.

What is the typical lifespan of an automotive PCB?

The lifespan of an automotive PCB depends on the materials, design, and operating environment. High-quality automotive PCBs generally last 10–15 years or the lifetime of the vehicle, provided they meet industry standards for temperature, vibration, and electrical performance. Using certified materials and rigorous quality control extends reliability in real-world conditions.

How does the PCB design affect vehicle safety systems?

PCB design directly impacts the performance of safety-critical systems. Factors such as trace layout, layer stackup, impedance control, and EMI protection ensure that signals are transmitted accurately and without interference. Poor design can lead to delayed or incorrect sensor readings in systems like ABS, ADAS, and collision avoidance, potentially compromising vehicle safety. Well-designed automotive PCBs enhance system reliability and driver protection.