Colorless Polyimide (CPI): Key Material for PCB & Flexible Electronics

As a technology service provider deeply involved in the PCB and flexible electronics industry, PCBMASTER knows how important innovative materials are for advancing technology. One material that has been gaining attention is Colorless Polyimide (CPI). With its unique mix of transparency, high heat resistance, and flexibility, CPI is becoming a key material in areas like foldable displays, high-end sensors, and advanced electronics.

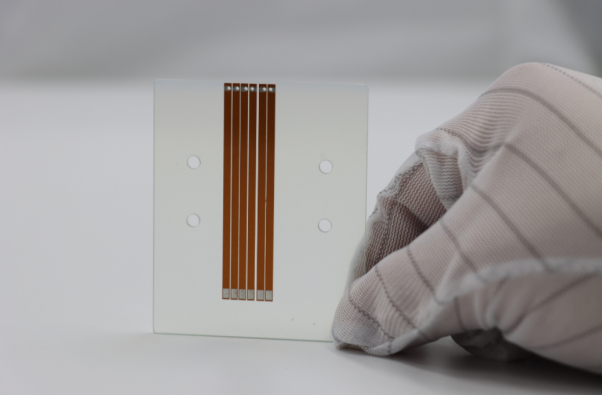

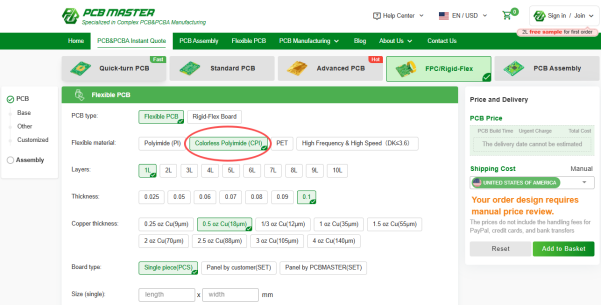

To meet the growing demand, PCBMASTER now offers CPI options in its FPC and Rigid-Flex sections on the official website. But what exactly is CPI, and why is it so special? In this article, we will break down the technical features and real-world applications of CPI, and explain the key differences between CPI, Transparent Polyimide, and conventional Polyimide.

What is CPI? — Definition and Key Terminology Explained

In the PCB and flexible electronics industry, CPI (Colorless Polyimide) is a high-performance polyimide material made “colorless and transparent” through molecular structure modification. This description is much more accurate than simply calling it “Transparent Polyimide.” The core differences between CPI, Transparent Polyimide, and conventional PI can be compared across the following dimensions:

1. Essential Differences in Technical Definitions CPI (Colorless Polyimide)

CPI is a high-performance polyimide material that is engineered to be both colorless and highly transparent. It must reach a visible light transmittance of ≥ 88% (400–700 nm) and maintain a Yellowness Index (YI) below 2.0.

To achieve this, chemists modify the molecular structure by adding fluorine groups (like –CF₃), alicyclic structures, or non-coplanar groups. These changes break the strong conjugate system found in conventional PI, which is what normally causes yellowing in the 400–500 nm wavelength range.

For example, the alicyclic CPI used by PCBMASTER reaches 90% transmittance at 550 nm with a YI of only 1.2, meeting the needs of high-end optical applications like foldable displays.

Transparent Polyimide

Transparent PI focuses only on transmittance (typically ≥ 80%) and does not control color strictly. This means some materials still appear slightly yellow, with YI values up to 3.5. The yellowing comes from residual Charge Transfer Complexes (CTCs) in the polymer chain.

This level of performance is not enough for high-end optical devices like OLED displays, where even a slight yellow tint can cause color distortion. PCBMASTER’s laboratory testing found that one transparent PI sample had only 78% transmittance in the 450 nm blue light range, leading to visible display discoloration.

Conventional Polyimide

Traditional PI has a deep yellow to brown color because its molecular chains have a strong aromatic conjugate system. Its light transmittance is usually below 60% (400–700 nm), and its YI is typically greater than 15.

Although it offers excellent heat resistance (Tg ≥ 250℃) and high mechanical strength, its poor optical performance makes it unsuitable for transparent or colorless applications. In fact, conventional PI is mainly used for insulation layers in rigid PCBs, where optical clarity is not required.

2. Industry Standards and Practical Consensus

Major global manufacturers such as DuPont, Kolon, and PCBMASTER’s partner suppliers, as well as end-brand leaders like Samsung and Huawei, all use the standardized term Colorless Polyimide (CPI). This shows that CPI has become the accepted industry name rather than “Transparent Polyimide.”

l For example, the flexible PCB cover of Samsung’s Galaxy Z Fold series specifically requires CPI material with a Yellowness Index (YI) below 1.0, based on the ASTM E313 standard.

l In PCBMASTER’s high-frequency 5G flexible PCB solutions, the CPI substrate must pass the ASTM D1003-13 transmittance test (≥88%) and be clearly labeled as Colorless Polyimide.

This consistent adoption across global supply chains confirms that CPI is not just a marketing term but an industry-standard material name, recognized for its optical clarity and high performance in flexible electronics.

Key Technical Properties of CPI for PCB Applications

Through precise molecular design, CPI achieves a balanced combination of transparency, heat resistance, and flexibility that meets the strict performance requirements of PCBs and flexible electronics. Below are the key technical parameters, based on PCBMASTER’s laboratory test results:

| Performance Indicator | Industry Standard Requirement | Typical CPI Value | Transparent PI | Conventional PI |

|---|---|---|---|---|

| Visible Light Transmittance | ≥88% (400-700nm) | 89%-91% | ≥80% | <60% |

| Yellowness Index (YI) | <2.0 | 0.6-1.5 | ≤3.5 | >15 |

| Glass Transition Temp (Tg) Dielectric Constant (Dk, 10GHz) | ≥200℃ (UL 746B) | 280℃-380℃ | ≥220℃ | ≥250℃ |

Dielectric Constant (Dk, 10GHz) | ≤3.0 | 2.53 | ≈2.8 | ≈3.2 |

| Flex Life | 200,000 cycles without damage | ≤4% performance drop after 200,000 cycles | ≈150,000 cycles | Not suitable for flexible scenarios |

Key Technical Breakthroughs

l Molecular Structure Innovation – CPI is designed at the molecular level using advanced monomers such as 6FDA (fluorine-containing dianhydride) or CBDA (alicyclic dianhydride). These structures prevent the formation of charge transfer complexes (CTC), which are the main cause of yellowing in conventional PI. For instance, PCBMASTER’s fluorine-free CPI achieves both environmental friendliness and true colorlessness through the use of alicyclic structures.

l Performance Synergy Design – By applying biaxial stretching technology, the Coefficient of Thermal Expansion (CTE) is reduced to ≤ 15 ppm/K, which means the material expands very little when heated. This thermal stability allows the CPI to perfectly match the copper and metal plating layers in PCBs, preventing warping or cracking during high-temperature processes.

l Surface Modification Optimization – The surface of CPI is treated with plasma technology to improve flatness to Ra ≤ 10 nm (nanometer-level smoothness). A smoother surface enhances the bonding strength with conductive materials such as silver nanowires and ITO (Indium Tin Oxide), which is crucial for touch panels and flexible displays.

Core Applications of CPI in PCB and Electronics Industry

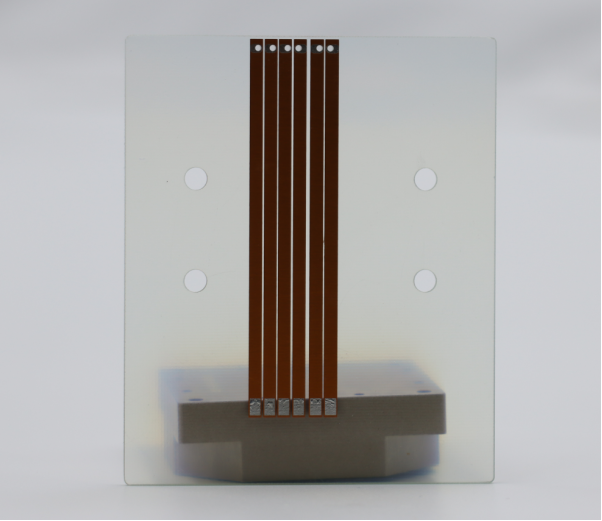

PCBMASTER has developed multiple industry solutions based on Colorless Polyimide (CPI) materials, covering core sectors such as consumer electronics, automotive, and aerospace.

1. Flexible PCB (FPCB) and High-Density Interconnect (HDI)

CPI plays a critical role as a flexible substrate material in advanced PCB applications:

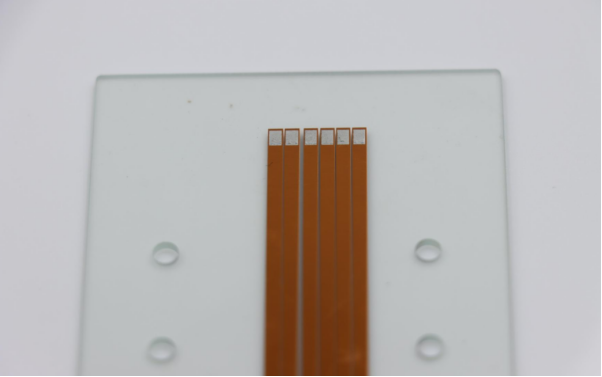

l Foldable Phones: CPI serves as the hinge-area substrate (25μm–50μm) to support complex 3D wiring. In PCBMASTER’s foldable FPCB solution for a leading brand, the CPI substrate maintained a 99.9% conduction rate even after 200,000 bending cycles.

l 5G High-Frequency Communication: Its low dielectric constant (Dk = 2.53) and low dissipation factor (Df ≤ 0.0088) minimize signal loss, making it ideal for base station antenna FPCBs.

l Wearable Devices: Ultra-thin CPI (≤12μm) enables lighter, thinner FPCBs that easily fit curved layouts used in smartwatches and other compact devices.

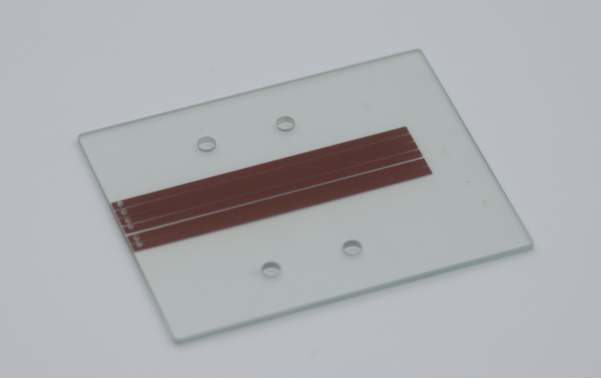

2. Flexible Displays and Optical Components

CPI is widely adopted as a glass substitute in next-generation displays and optical devices:

l OLED Encapsulation: CPI is 10× thinner than glass yet provides excellent barrier performance (WVTR ≤ 10⁻⁶ g/m²·day). PCBMASTER supports mass production of this solution for display makers.

l Transparent Electrode Substrates: Indium Tin Oxide (ITO) can be vapor-deposited on CPI to produce flexible touch films with ≥90% light transmittance, enabling automotive HUDs and transparent displays.

l AR/VR Waveguides: CPI’s low optical distortion makes it perfect for virtual display light paths. PCBMASTER, in collaboration with leading universities, has developed CPI waveguide substrates that are currently under testing.

3. Extreme Environment Applications

CPI is also a reliable choice for electronics that must endure harsh operating conditions:

l Automotive Electronics: CPI substrates with a high glass transition temperature (Tg = 320℃) are used in FPCBs for engine compartment sensors that must withstand ≥150℃.

l Aerospace Applications: PCBMASTER’s CPI solutions have passed 100krad total-dose radiation tests, making them suitable for satellite flexible solar cell substrates.

CPI Industry Trends and PCBMASTER’s Technology Strategy

1. Global CPI Industry and Technology Trends

Report data shows, the Colorless Polyimide (CPI) films market is expected to expand from USD 202.55 million in 2024 to over USD 9.28 billion by 2032, with a CAGR of 61.3%. Key drivers include the increasing adoption of flexible PCBs and OLED technology.

In terms of technology, fluorine-free CPI (environmentally friendly), self-healing CPI (enhanced durability), and conductive CPI (for multi-functional integration) have become key R&D hotspots in the industry.

2. PCBMASTER’s Core Advantages in CPI Applications

l Supply Chain Integration: PCBMASTER works closely with leading CPI manufacturers such as Sinochem Wanrun and Kolon, ensuring a stable supply of high-end substrates.

l Customization Capability: CPI thickness (12μm–125μm), dielectric properties, and surface treatments can be tailored to meet specific PCB requirements.

l Cost Optimization: Through integrated manufacturing processes (combining CPI and FPCB production), PCBMASTER can reduce customers’ overall costs by over 30%.

3. Existing Challenges and Solutions

l Cost Bottleneck: Fluorine-containing CPI raw materials are 3–5 times more expensive than conventional PI. PCBMASTER addresses this by offering a fluorine-free CPI alternative with Tg ≥ 280℃ and 90% transmittance.

l Processing Difficulty: High-temperature imidization and plating adhesion are challenging. PCBMASTER solves this with an independently developed primer technology, improving adhesion by 40%.

CPI: Ushering in a New Era of Flexible Electronics with PCBMASTER

As a technology pioneer in the PCB industry, PCBMASTER believes that Colorless Polyimide (CPI) is more than a simple material upgrade. It is a core driver propelling electronic devices toward flexibility, transparency, and high-frequency performance.

From foldable phones to aerospace sensors, CPI is reshaping product forms and expanding application boundaries in flexible PCB solutions.

If you need CPI-based flexible PCB design, material selection consultation, or sample testing, reach out to PCBMASTER's technical team. We are ready to provide tailored, high-performance solutions for your projects.

FAQs

1. Can CPI be used in high-temperature flexible electronics beyond consumer devices?

Yes, CPI is suitable for flexible electronics that operate under high-temperature conditions. Its high glass transition temperature (Tg), often exceeding 280–320℃, allows it to maintain mechanical stability and dimensional integrity even under extreme heat. This makes CPI ideal for automotive sensors in engine compartments, industrial control electronics, and aerospace applications such as satellite flexible solar panels. Unlike conventional polyimide, which may degrade or yellow under high heat, CPI ensures long-term reliability while keeping the substrate flexible.

2. How does CPI improve the durability and lifecycle of flexible PCBs?

CPI enhances durability through its unique molecular design, which resists yellowing, cracking, and degradation over repeated mechanical stress. For example, ultra-thin CPI substrates (≤12μm) can withstand hundreds of thousands of bending cycles without performance loss. The material also maintains excellent adhesion with copper and conductive coatings, preventing delamination during thermal cycling. As a result, flexible PCBs made with CPI can endure repeated folding, bending, or vibration in wearable devices, foldable phones, and industrial sensors, significantly extending product lifespan compared to traditional polyimide substrates.

3. What factors should engineers consider when selecting CPI for a new flexible PCB project?

When choosing CPI, engineers should evaluate several key factors:

l Thickness Requirements: CPI is available in a wide range (12μm–125μm) to meet bending radius, weight, and flexibility constraints.

l Optical Performance: Ensure the Yellowness Index (YI) and transmittance meet display or optical sensor requirements. High-transparency CPI (YI <2.0, transmittance ≥88%) is preferred for foldable screens and transparent electrodes.

l Thermal and Mechanical Stability: Consider the glass transition temperature (Tg) and coefficient of thermal expansion (CTE) to prevent warping or cracks during soldering, high-frequency operation, or harsh environments.

l Surface Compatibility: Surface treatments or plasma modification can improve adhesion with conductive layers like copper, silver nanowires, or ITO, which is critical for touch panels and flexible displays.

l Cost and Supply Chain: Evaluate the availability of high-quality CPI and potential alternatives (like fluorine-free CPI) to optimize project budget without compromising performance.