PCB Assembly Express – Rapid Prototyping Made Simple & Reliable

If you want to bring your idea to life fast, PCB Assembly Express is your best friend.

Think of it like a shortcut — instead of waiting weeks to see if your design works, you can get a working PCB in just a few days. This means you can test, fix, and improve your product much faster. PCB Assembly Express helps you build your first prototype quickly, so you can get your product ready for market without wasting time.

What is PCB Assembly Express?

PCB Assembly Express means fast PCB assembly service.

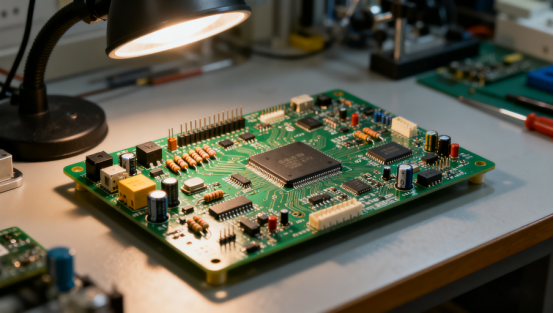

Let’s make it simple: a PCB is the “base” where all electronic parts are connected. Assembly is when we put all those tiny parts on the board. Normally, this takes a long time, but PCB Assembly Express is made to do it much faster.

1. The Main Goal: Shorter Delivery Time

The key idea is speed.

With normal PCB assembly, you might wait 7–14 days to get your boards. That can slow you down if you are testing a new product or trying to fix a problem.

With PCB Assembly Express, the boards can be ready in just 24–72 hours. Some services even offer same-day shipping if you send your files early in the morning.

Think of it like delivery services:

l Standard shipping → wait more than a week

l Express shipping → get it in 1–3 days

This is why many engineers choose express assembly when they are in a hurry.

2. The Difference from Traditional PCB Assembly

Feature Traditional PCB Assembly PCB Assembly Express Delivery Time 7–14 days 1–3 days (sometimes same day) Use Case Large production runs Prototypes, small batches Flexibility Less flexible, fixed schedule Very flexible, supports quick changes Cost Usually cheaper for big orders A little higher (you pay for speed)

| Feature | Traditional PCB Assembly | PCB Assembly Express |

|---|---|---|

| Delivery Time | 7–14 days | 1–3 days (sometimes same day) |

| Use Case | Large production runs | Prototypes, small batches |

| Flexibility | Less flexible, fixed schedule | Very flexible, supports quick changes |

| Cost | Usually cheaper for big orders | A little higher (you pay for speed) |

So, PCB Assembly Express is not just faster — it is also more flexible, perfect for people who need quick results.

3. Common Use Cases

People use PCB Assembly Express in many situations:

l New Product Prototyping

When you have a fresh idea, you want to see if it works as soon as possible. Express assembly lets you get a working board in days, so you can test your design and fix mistakes quickly.

l Small Batch Testing

Before you spend money on making thousands of boards, you can first make 5, 10, or 50 boards to see if everything works well. This helps you find problems early.

l Product Updates and Changes

If your customer wants a new feature, or you find a bug in your circuit, you can quickly make a new version of the board and keep your project moving forward.

Why Rapid Prototyping Needs PCB Assembly Express

When you are making a new product, time is very important. You want to go from an idea in your head to something you can touch and test — as fast as possible. This is called rapid prototyping. And here is why PCB Assembly Express is so helpful.

1. Faster Time to Market

Every day you wait is a day your product is not selling.

With normal PCB assembly, waiting 1–2 weeks for every version of your board can slow you down.

But with PCB Assembly Express, you can get your boards in just 1–3 days. This means you can build, test, and fix your design many times in one month. The faster you do this, the sooner your product is ready for customers.

Think about it like cooking: if you can taste your food every few minutes, you can make it perfect quickly. But if you can only taste once a week, it takes forever to get it right.

2. Lower Cost of Mistakes

Making mistakes is normal when you design something new.

The problem is, if you make thousands of boards before you find the mistake, you lose a lot of money.

With PCB Assembly Express, you make only a few boards first. You test them, see what works, and fix what doesn’t. This way, you find problems early, when they are cheap to fix.

It’s like drawing a plan on paper before building a house — fixing the plan is much cheaper than fixing a real building.

3. Stay Flexible and Respond to Changes

The market changes quickly. Customers may ask for a new feature, or your competitor may launch a similar product.

Because PCB Assembly Express is fast, you can make a new version of your board right away and stay ahead. This helps you keep your project on track and respond to changes without losing weeks of time.

The Key Advantages of PCB Assembly Express

PCB Assembly Express is not just fast — it has many benefits that make building prototypes much easier and safer. Let’s look at the key advantages.

1. Fast Delivery: 24–72 Hours

The biggest advantage is speed. With PCB Assembly Express, you can get your boards in 1 to 3 days. Some services even offer same-day delivery.

This is very important when you are testing new ideas. You don’t have to wait a long time to see if your design works. You can build, test, fix, and rebuild quickly. The faster you get your boards, the faster your product can reach the market.

2. One-Stop Service

PCB Assembly Express usually includes everything you need:

l Component sourcing: They buy all the tiny parts for you.

l SMT assembly: Surface-mount technology puts the parts on the board precisely.

l Testing: The board is checked to make sure it works correctly.

This means you don’t have to worry about buying parts from many places or learning how to assemble them yourself. Everything is done for you, saving time and effort.

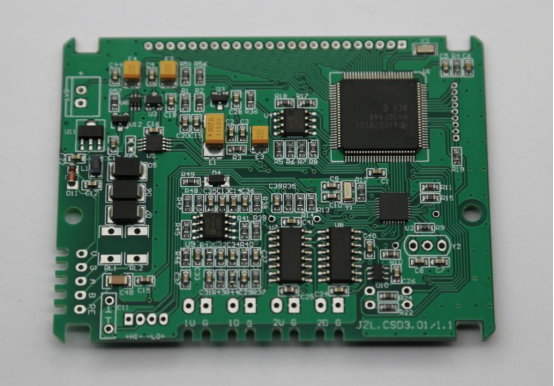

3. High Reliability

Even though the service is fast, quality is not sacrificed.

PCB Assembly Express uses modern machines and strict quality control. Every board is carefully checked to make sure it works perfectly.

You don’t have to worry that “fast” means “bad quality.” The goal is fast AND reliable.

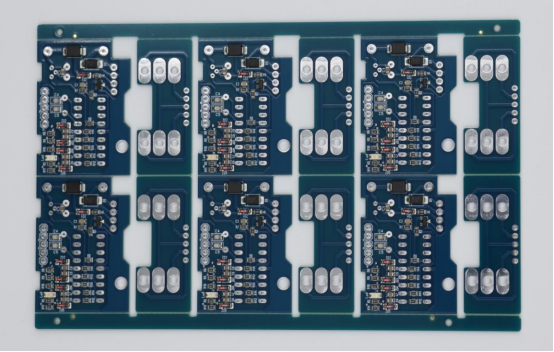

4. Perfect for Small Batches

This service is ideal for prototypes and small production runs.

If you only need 5, 10, or 50 boards, PCB Assembly Express is the best choice. You save money by not making thousands of boards before you know the design works.

It gives engineers and makers the flexibility to test ideas, make changes, and improve designs without wasting resources.

How to Choose a PCB Assembly Express Service

Choosing the right PCB Assembly Express service is very important. The right service can save you time, reduce mistakes, and help your product succeed. Let’s look at the key things you should check carefully.

1. Delivery Speed

The main reason to use PCB Assembly Express is speed.

l Check if the service can finish your boards in 24–72 hours.

l Ask if they offer same-day or next-day options for urgent projects.

l Some companies can even start your assembly the same day you send the files.

Fast delivery helps you test your ideas quickly. Imagine you design a board today — with express service, you could have it in your hands in just a couple of days. This allows you to find and fix problems fast, instead of waiting weeks.

2. Quality Assurance

Fast boards are only useful if they work correctly. Quality assurance is critical. Ask about:

l Testing process: Do they check every board before sending it to you? Some companies test voltage, current, and signal connections to make sure nothing is broken.

l Certifications and standards: Do they follow recognized rules like ISO 9001 or IPC? Certified processes are more reliable.

l Inspection methods: Do they use machines or visual checks to ensure all parts are soldered correctly?

High-quality boards reduce mistakes, wasted money, and frustration. You don’t want to get your boards and find out they don’t work.

3. Supply Chain Ability

A PCB is only useful if all the parts are available. Good supply chain ability means:

l Quick sourcing of hard-to-find components ensures your project keeps moving.

l Sufficient inventory prevents delays in your order.

l Alternative parts can be provided if a supplier runs out, keeping your schedule on track.

Strong supply chain support is especially important for small or unusual orders. Without it, your project can get stuck waiting for parts, which defeats the purpose of express service.

4. Cost Transparency

Clear and honest pricing is very important. You should know:

l How much you pay for each board

l If extra fees exist, like setup fees or testing charges

l If express options cost more and how much

Transparent costs help you plan your budget, avoid surprises, and decide whether express service is worth it for your project.

5. Customer Support

Good support makes the process much easier. Look for:

l Professional engineers available to answer questions

l Help with design issues or BOM (bill of materials) problems

l Quick response if something goes wrong

A strong support team can save you days of confusion, especially if you are new to PCB assembly.

PCBMASTER is an example of a reliable PCB Assembly Express provider. They offer fast delivery, high quality, and strong support, making it easy to get your prototypes quickly and safely.

How to Start a PCB Assembly Express Project

Starting a PCB Assembly Express project is easier than it sounds. If you follow a few simple steps, you can get your prototype quickly and safely.

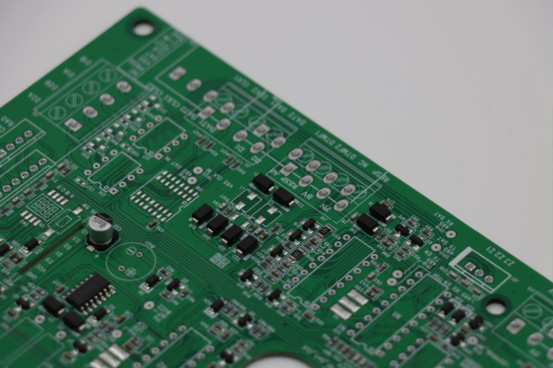

1. Prepare Your Files

Before anything else, you need to get your design ready. This usually includes:

l Gerber files: These are the instructions that tell the machine how to make your PCB.

l BOM (Bill of Materials): A list of all the parts you need, like resistors, chips, and connectors.

l Assembly instructions: Notes about how the parts should be placed on the board.

Having these ready saves time and helps avoid mistakes.

2. Confirm Delivery Time and Cost

Next, check with the service:

l How fast they can finish your boards — usually 24–72 hours for express service.

l The total cost — make sure you understand all fees, including setup or testing charges.

This step makes sure there are no surprises and you can plan your project properly.

3. Submit Your Order

Once your files are ready and the cost and delivery are confirmed, you send the order to the service.

l They will start the fast assembly process.

l Your boards will go through component sourcing, placement, soldering, and testing.

This is where the express service really helps — everything is done quickly and efficiently.

4. Testing and Delivery

After assembly, the boards are carefully tested to make sure they work.

l Some tests check if the electricity flows correctly.

l Others check if components are placed and soldered correctly.

Once testing is complete, your boards are shipped to you. You can now test your prototype, make improvements, or start small production.

Conclusion

To sum up, PCB Assembly Express is all about speed, simplicity, and reliability. It helps you take your ideas from paper to working boards faster and easier than traditional methods.

This service is perfect for rapid prototyping and small production runs. Whether you are testing a new product or making a few boards for a project, PCB Assembly Express saves you time and reduces mistakes.

If you want to shorten your product development cycle and get your boards quickly, it’s a great idea to try this service or talk to an expert.

For more questions or to learn more about PCB assembly, you are always welcome to contact PCBMASTER. Their team can guide you through every step and help make your project a success.

FAQs

1. Can PCB Assembly Express handle very small or unusual PCB designs?

Yes! PCB Assembly Express can work with small, unusual, or custom PCB designs. These services often have advanced machines that can place tiny components very accurately, even parts that are hard to handle by hand. They can also adjust their process to match special layouts, unusual shapes, or double-sided boards. This means your unique design can be built quickly and reliably, without changing your original idea.

2. How do I know if my PCB design is ready for express assembly?

Before using PCB Assembly Express, your design should be complete and correct. This includes:

l Gerber files with all layers of your board

l BOM (Bill of Materials) listing all the parts

l Assembly instructions, if any special placement is needed

You should also check your design for errors using simple software tools. If your files are complete and clear, the assembly service can start immediately, which keeps the process fast and avoids mistakes.

3. Is PCB Assembly Express more expensive than normal PCB assembly?

Usually, yes, PCB Assembly Express can cost a little more than standard assembly. The reason is speed and priority handling. You pay for:

l Faster delivery times

l Quick component sourcing

l Extra labor or machine time for urgent orders

Even though it costs more, it often saves money overall because you can test your ideas faster, avoid mistakes, and get your product to market sooner. Many companies find this extra cost worth it for prototypes and small production runs.