The Importance of Aluminum PCBs in Automotive Electronics

As vehicles become smarter and more efficient, the electronics that power them are evolving too. In this shift, aluminum PCBs are stepping into the spotlight, offering solutions that traditional circuit boards simply can't match. With their superior heat dissipation, durability, and lightweight design, aluminum PCBs are playing a crucial role in everything from electric vehicle power systems to safety technologies. As the automotive industry embraces electric and autonomous vehicles, these advanced circuit boards are proving essential for the performance and reliability of the next generation of cars.

What Are Aluminum PCBs and Why Are They Important in Automotive Applications?

Aluminum PCBs are advanced circuit boards that use aluminum as their base material, offering superior heat dissipation, durability, and lightweight design compared to traditional FR4 PCBs. In automotive applications, these unique properties make aluminum PCBs essential for managing high-power systems, ensuring safety, and enhancing the overall performance and reliability of vehicles, especially as they become more electric and autonomous.

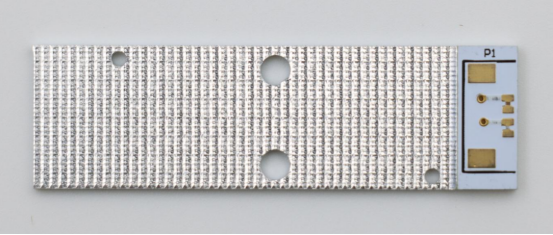

Overview of Aluminum PCBs: Structure and Unique Properties Compared to Traditional FR4 PCBs

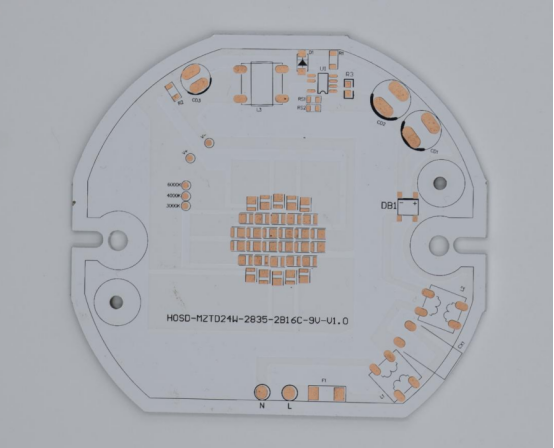

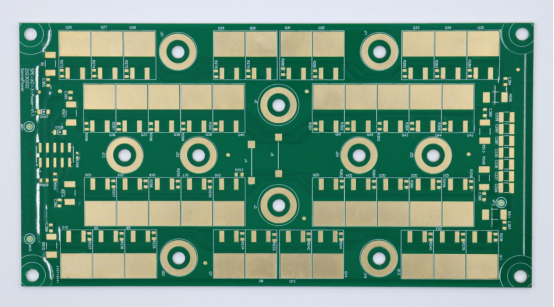

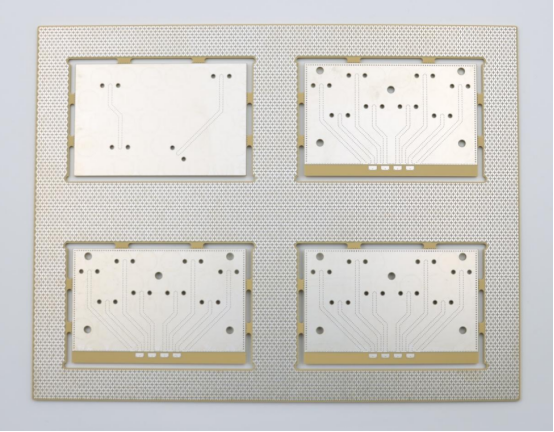

Aluminum PCBs, also known as metal-core PCBs (MCPCBs), are a type of circuit board that use aluminum as their base material, replacing the traditional fiberglass (FR4) commonly used in most electronics. This unique structure allows aluminum PCBs to offer better thermal management, strength, and durability, making them especially suited for automotive applications where high temperatures, vibrations, and moisture are common.

The key feature of aluminum PCBs is their ability to quickly dissipate heat. Unlike FR4 PCBs, which tend to trap heat, aluminum PCBs use the metal base to act as a heat sink, spreading heat away from critical components. This ensures that sensitive electronics stay cool, even in harsh conditions.

In automotive applications, aluminum PCBs are used in power systems, lighting, safety devices, and control modules. Their enhanced thermal conductivity helps manage the heat generated by high-power components like electric motors, EV inverters, and LED headlights, making them indispensable in modern vehicles.

Core Components of Aluminum PCBs: Base Plate, Dielectric Layer, and Copper Circuit Layer

An aluminum PCB is made up of three main layers, each designed for specific functions that cater to the demanding needs of automotive electronics:

Base Plate (Aluminum Layer)

The aluminum base is the backbone of the PCB. Made from high-purity aluminum (often 6061 alloy), this layer acts as both the structural support and the primary heat sink. Its role is to dissipate heat from electronic components, keeping the PCB cool and preventing overheating. The base is also resistant to rust and vibration, which is critical for automotive applications where reliability is a must.

Dielectric Layer

The dielectric layer is made from thermally conductive epoxy, often combined with ceramic fillers like alumina. This layer helps transfer heat from the copper circuit layer to the aluminum base, preventing heat build-up. Additionally, it blocks electrical leakage between layers, ensuring the safe operation of the PCB in high-voltage environments, such as in EV battery management systems or power control modules.

Copper Circuit Layer

The copper layer is where the electrical signals and power are routed. This thin copper foil (typically 1–3 ounces per square foot) carries the electrical current and acts as the path for communication or power distribution. In automotive electronics, it is crucial that the copper traces are thick enough to handle high currents, like those found in electric vehicle inverters or lighting systems, without overheating.

These three components work together to provide thermal efficiency, structural strength, and electrical conductivity, all of which are vital for automotive electronics.

Aluminum PCBs vs. FR4 PCBs: Thermal Conductivity, Durability, Weight, and Power Handling Comparison

Aluminum PCBs outperform traditional FR4 PCBs in several key areas crucial for automotive applications. Here's a quick comparison:

| Feature | Aluminum PCBs | FR4 PCBs |

| Thermal Conductivity | 237 W/mK (better heat dissipation) | 0.3 W/mK (poor heat management) |

| Durability | Excellent vibration, moisture, and heat resistance | Limited durability under extreme conditions |

| Weight | 30-50% lighter, reducing vehicle weight | Heavier due to fiberglass core |

| Power Handling | Handles 50W+ without overheating | Limited to 10W-20W, prone to thermal failure |

Thermal Conductivity

Aluminum PCBs have a thermal conductivity of 237 W/mK, far surpassing the 0.3 W/mK of FR4. This means aluminum PCBs are much more efficient at dissipating heat, essential for high-power automotive applications like EV inverters and LED headlights.

Durability

Aluminum PCBs are highly durable, able to withstand extreme temperatures (from -40°C to 150°C), vibration (up to 20G), and moisture. In contrast, FR4 PCBs are less reliable under these conditions, making aluminum the better choice for safety-critical systems like airbag controllers and ADAS sensors.

Weight

Aluminum PCBs are 30-50% lighter than FR4, which helps reduce the overall weight of the vehicle. This weight reduction improves fuel efficiency in ICE vehicles and extends the range of EVs.

Power Handling

Aluminum PCBs can safely handle high power loads (50W+), making them ideal for power-intensive applications. FR4 PCBs, however, can only manage 10-20W and are prone to overheating in high-power environments, limiting their use in automotive electronics.

In summary, aluminum PCBs offer superior performance in heat management, durability, weight reduction, and power handling, making them the ideal choice for automotive applications.

How Do Aluminum PCBs Improve Heat Management in Automotive Electronics?

Aluminum PCBs significantly improve heat management in automotive electronics by efficiently dissipating heat, preventing overheating, and ensuring reliable performance in harsh conditions. With their high thermal conductivity, they help manage heat in critical systems like EV inverters, battery management, LED lighting, and safety sensors, making them essential for the longevity and efficiency of modern vehicles.

Thermal Conductivity and Its Role: Why Aluminum's 237 W/mK Thermal Conductivity Is Essential for Heat Dissipation

Aluminum PCBs are designed to handle heat better than traditional circuit boards due to the metal’s high thermal conductivity—237 W/mK. This is about 700 times more efficient at transferring heat compared to FR4 PCBs, which have only 0.3 W/mK. The ability to move heat so efficiently is crucial for automotive electronics, where components like EV inverters, LED lights, and battery management systems generate significant amounts of heat. With aluminum's high thermal conductivity, it prevents these components from overheating, ensuring they operate safely and last longer.

In simple terms, aluminum PCBs work like heat sinks, pulling heat away from sensitive electronics and distributing it evenly, preventing hot spots that could damage or shorten the lifespan of the components. This is especially important in automotive applications, where heat can quickly build up due to high-power demands and challenging environments.

Preventing Overheating in EV Power Modules: How Aluminum PCBs Help Manage Heat in EV Inverters, Battery Management Systems, and DC-DC Converters

Electric vehicles (EVs) rely heavily on high-performance power modules, such as inverters, battery management systems (BMS), and DC-DC converters, which handle and distribute power to the motor, batteries, and other systems. These components generate a lot of heat, especially when operating at full capacity during acceleration, charging, or heavy driving conditions. Aluminum PCBs play a crucial role in managing this heat, keeping the system cool and preventing thermal damage.

For instance, in EV inverters, which convert DC power from the battery into AC power for the motor, aluminum PCBs act as efficient heat sinks. The aluminum base layer draws heat away from the inverters' high-power transistors (IGBTs), ensuring they stay within safe temperature limits. Similarly, in Battery Management Systems, aluminum PCBs help maintain the temperature of the battery cells, preventing overheating or thermal runaway, which could lead to fires or failures. In DC-DC converters, which lower high-voltage power to the 12V level needed for lights and infotainment, aluminum PCBs keep the components cool, ensuring stable performance over time.

Without aluminum PCBs, these systems would require bulky external cooling solutions, adding weight and complexity to the vehicle. Aluminum PCBs provide an integrated, compact solution, reducing the need for additional parts while maintaining optimal heat control.

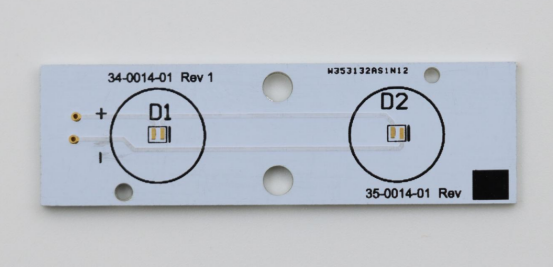

Benefits for LED Lighting Systems: Heat Management in Automotive LED Headlights, Taillights, and Interior Lighting

Aluminum PCBs are particularly valuable in automotive LED lighting systems, including headlights, taillights, and interior lights. LEDs generate a significant amount of heat, especially in high-power applications like headlights, and this heat can reduce their brightness and lifespan if not properly managed.

In automotive headlights, where LEDs produce 30W–50W of heat, aluminum PCBs act as a built-in heat sink, pulling heat away from the LED chips. By maintaining an optimal temperature range (usually between 60°C–80°C), aluminum PCBs ensure that the LEDs remain bright and have a long operational life—up to 50,000 hours in many cases, compared to only 20,000 hours for LEDs without proper heat management.

The benefits extend to taillights and interior lighting, where aluminum PCBs prevent heat buildup in confined spaces. For example, in modern cars with compact cabin lighting strips or high-intensity taillights, aluminum PCBs allow for efficient heat dissipation, ensuring consistent performance throughout long drives or high-usage conditions.

This heat management also results in better energy efficiency. When LEDs operate at the correct temperature, they convert more energy into light, rather than wasted heat, contributing to the overall energy efficiency of the vehicle.

Long-Term Heat Resistance: How Aluminum PCBs Handle Extreme Temperature Fluctuations from -40°C to 150°C

Aluminum PCBs are designed to handle extreme temperature fluctuations, making them well-suited for automotive environments where temperatures can vary widely. They can function reliably in temperatures as low as -40°C and as high as 150°C, ensuring that they perform in both freezing winters and scorching summers, as well as in the intense heat found under the hood of a vehicle.

This temperature resistance is particularly important for systems like Engine Control Units (ECUs) and safety devices such as airbag controllers and ADAS sensors, which are exposed to extreme conditions during operation. Aluminum PCBs maintain their structural integrity and thermal performance even under these stress conditions. FR4 PCBs, in contrast, may crack or fail when exposed to such temperature extremes, leading to system failures or reduced lifespan.

For example, in cold climates, aluminum PCBs continue to function at their peak, preventing the failure of crucial components such as sensors or power modules, which are critical for the vehicle’s safety and functionality. In hot environments, aluminum PCBs effectively dissipate the excess heat, preventing overheating that could cause damage to sensitive components or lead to reduced efficiency in power systems.

What Makes Aluminum PCBs Ideal for Harsh Automotive Environments?

Aluminum PCBs are perfectly suited for harsh automotive environments due to their strength, corrosion resistance, lightweight design, and ability to block electromagnetic interference (EMI). These features allow them to withstand vibration, moisture, and extreme temperatures, ensuring reliable performance in critical automotive systems like power management, lighting, and safety technologies.

Mechanical Strength for Vibration and Impact Resistance: How Aluminum PCBs Withstand High Levels of Vibration and Physical Stress

Aluminum PCBs are highly durable and designed to withstand the rough conditions that automotive electronics face, particularly vibration and impact. Cars experience constant vibrations, especially from the engine, road, and driving over rough terrains. For traditional PCBs like FR4, these vibrations can lead to cracks, broken connections, and failure over time. Aluminum PCBs, however, have superior mechanical strength, allowing them to absorb and resist these physical stresses without breaking down.

The aluminum base plate in these PCBs provides excellent structural support, making them resistant to the shaking and impacts commonly encountered in automotive environments. Whether it’s the constant vibration under the hood or the bumps from driving on uneven roads, aluminum PCBs maintain the integrity of the connections, ensuring long-term reliability in safety-critical systems like airbag controllers, engine control units (ECUs), and power modules. This durability is crucial for systems that need to function flawlessly throughout the car’s lifespan.

Corrosion Resistance: Role of Anodization in Preventing Damage from Moisture, Salt, and Other Environmental Factors

Corrosion is one of the biggest threats to electronics exposed to moisture, road salt, and other environmental factors. Automotive electronics, particularly those located under the vehicle or in engine compartments, are constantly exposed to these harsh conditions. Aluminum PCBs are protected against corrosion through a process called anodization, which creates a durable oxide layer on the aluminum surface. This protective layer prevents moisture, salt, and other environmental contaminants from reaching the metal base, thus ensuring that the PCB remains intact and operational for years.

In regions with harsh winters, where roads are salted to prevent ice buildup, anodized aluminum PCBs prevent rusting and degradation that could otherwise compromise the electronics. The anodization also protects against the typical automotive environmental stressors, including extreme humidity, high temperatures, and oil exposure. This corrosion resistance is essential for ensuring that automotive systems, such as power management units or safety sensors, remain reliable and functional in all weather conditions.

Lightweight Advantage: How Reducing Weight with Aluminum PCBs Contributes to Fuel Efficiency and Battery Range

In the automotive world, reducing weight is a key goal for improving both fuel efficiency in internal combustion engine (ICE) vehicles and increasing battery range in electric vehicles (EVs). Aluminum PCBs are 30-50% lighter than traditional FR4 PCBs, making them an ideal choice for lightweight automotive designs. By using aluminum PCBs, manufacturers can reduce the overall weight of a vehicle without compromising the performance or durability of its electronics.

For EVs, every kilogram saved in weight translates directly into an increase in battery range. Reducing the weight of power management systems, lighting, and safety components using aluminum PCBs can lead to an increase in the number of kilometers a vehicle can travel on a single charge. For ICE vehicles, lighter cars are more fuel-efficient, as less energy is required to move them. Aluminum PCBs contribute to these efficiency improvements by allowing for smaller, lighter, and more compact electronic systems that don't add unnecessary weight to the vehicle.

EMI Shielding: The Ability of Aluminum PCBs to Block Electromagnetic Interference, Ensuring Safe Operation of Critical Systems like ADAS

Electromagnetic interference (EMI) is a serious issue in modern cars, especially with the increasing number of electronic systems working simultaneously. Components like advanced driver assistance systems (ADAS), airbags, and engine control units (ECUs) rely on accurate signals to function safely. EMI can distort these signals, leading to errors and system failures, which is why preventing interference is critical.

Aluminum PCBs provide built-in EMI shielding thanks to their metal core. This layer of metal helps block unwanted electromagnetic signals, ensuring that sensitive systems like radar, cameras, and sensors continue to operate correctly. In ADAS systems, for instance, accurate data from cameras and radar sensors is crucial for features like lane-keeping assist, automatic emergency braking, and adaptive cruise control. If these signals are interrupted or distorted by EMI, the system could malfunction, leading to safety hazards. By using aluminum PCBs, automakers can reduce the risk of such interference, ensuring that safety features operate as intended.

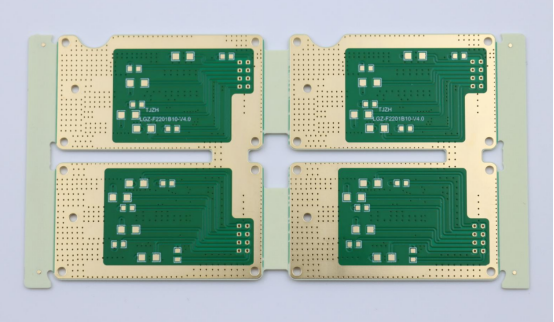

How Are Aluminum PCBs Used in Power Management Systems for EVs and ICE Cars?

Aluminum PCBs play a crucial role in power management systems for both electric vehicles (EVs) and internal combustion engine (ICE) cars. By efficiently managing heat dissipation, handling high currents, and ensuring reliability under vibration, they help optimize the performance and safety of critical components like EV inverters, battery management systems, and DC-DC converters. These features make aluminum PCBs essential for powering modern automotive systems while preventing overheating and system failure.

Key Applications in Power Systems

Aluminum PCBs play a crucial role in power management systems, particularly in electric vehicles (EVs) and internal combustion engine (ICE) cars. Their superior heat dissipation, strength, and reliability make them ideal for handling the demanding electronics in these vehicles. Let’s break down their specific applications in power systems.

EV Inverters: How Aluminum PCBs Handle Heat Dissipation in High-Power Applications

In electric vehicles, inverters are responsible for converting direct current (DC) from the battery into alternating current (AC) to power the motor. In high-power applications like EV inverters, heat buildup is inevitable due to the high currents being processed. Aluminum PCBs are specifically designed to manage this heat.

The metal base of aluminum PCBs acts as an efficient heat sink, drawing heat away from the critical components of the inverter, such as Insulated Gate Bipolar Transistors (IGBTs). With a thermal conductivity of 237 W/mK, aluminum PCBs dissipate heat far more effectively than traditional FR4 boards, preventing overheating that could damage the inverter or cause thermal runaway. This ensures smooth and safe operation even in demanding driving conditions.

Battery Management Systems: Role in Temperature Monitoring to Prevent Battery Fires

Battery Management Systems (BMS) in electric vehicles are responsible for monitoring the voltage, temperature, and health of individual battery cells. Temperature monitoring is crucial because overheating can lead to thermal runaway, which may cause a battery fire. Aluminum PCBs help manage the temperature by dispersing the heat generated by sensors and other BMS components.

The high thermal conductivity of aluminum PCBs ensures that the BMS stays within a safe operating range. The aluminum base plate efficiently pulls heat away from the sensors, preventing overheating. Additionally, this helps maintain accurate readings, allowing the BMS to respond quickly to any issues, such as abnormal temperature rises, before they lead to battery damage or failure. This makes aluminum PCBs an essential part of a BMS in preventing safety hazards and extending the life of EV batteries.

DC-DC Converters: Power Distribution Without Overheating

DC-DC converters in EVs and ICE vehicles step down high-voltage DC from the battery to lower voltages, such as 12V, for other components like lights, infotainment, and power steering. These converters must handle significant power loads, often up to 100W or more. Aluminum PCBs help manage the heat generated during this power conversion process.

In DC-DC converters, the copper layer of the aluminum PCB carries the high current, while the aluminum base effectively dissipates the heat produced. This ensures the converter operates without the risk of overheating, which can damage delicate components and cause system failures. By preventing excessive heat buildup, aluminum PCBs ensure that power distribution remains stable and efficient, improving the reliability and longevity of the vehicle's electrical systems.

Current Handling and Thermal Management: How Aluminum PCBs Manage High Currents and Avoid Thermal Runaway

One of the key advantages of aluminum PCBs is their ability to handle high currents without overheating. In automotive power systems, components like EV inverters and DC-DC converters need to manage substantial electrical loads—often exceeding 100A in some cases. Aluminum PCBs are equipped with thicker copper traces (2–3 oz) and thermal vias that allow them to carry high currents while simultaneously dissipating the heat generated by these high-power components.

The metal core of the PCB efficiently transfers the heat from the copper traces to the aluminum base, preventing the PCB from reaching dangerous temperatures. This thermal management prevents thermal runaway, which is when the temperature of a component increases uncontrollably, potentially leading to system failures, fires, or component damage. Aluminum PCBs offer a safer and more reliable solution for managing high currents in automotive power systems.

Reliability in Power Management: Vibration Resistance Ensuring Long Service Life in EV Motor Compartments

Automotive power systems, particularly in EV motor compartments, are subject to constant vibration and physical stress. Whether driving over rough roads or through high-speed turns, components like inverters, DC-DC converters, and battery management systems face constant shocks and vibrations.

Aluminum PCBs are highly resistant to vibration due to the strength of the aluminum base, which supports the PCB structure. This resistance is crucial for ensuring the longevity and reliability of the vehicle’s power management systems. Traditional FR4 PCBs, in comparison, are more prone to damage from vibration, leading to failed connections or broken circuits over time. The robust mechanical strength of aluminum PCBs ensures that critical components, such as power modules, continue to function properly for 10+ years without being compromised by vibration.

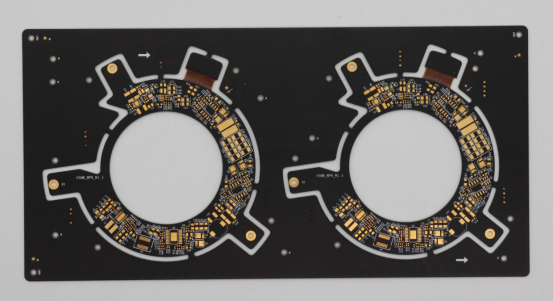

How Do Aluminum PCBs Enhance Automotive Lighting Systems?

Aluminum PCBs are crucial for enhancing automotive lighting systems by efficiently managing heat, improving LED brightness, and increasing the durability of lighting components. Whether for headlights, taillights, or interior lighting, aluminum PCBs ensure optimal performance and longevity by preventing overheating, enabling compact designs, and offering custom solutions like reflective copper layers and anodized aluminum for added strength and efficiency.

LED Headlights and Taillights: The Importance of Heat Management in LED Lighting Performance and Lifespan

LED headlights and taillights are widely used in modern vehicles due to their energy efficiency, brightness, and long lifespan. However, like all electronics, LEDs generate heat, which can reduce their performance and lifespan if not properly managed.

Aluminum PCBs are essential in addressing this issue by efficiently dissipating the heat produced by LED components. The aluminum base plate in these PCBs acts as a heat sink, drawing heat away from the LED light sources. This prevents the LEDs from overheating, which can lead to reduced brightness, color shifts, or even failure of the LED units. By maintaining a stable operating temperature, aluminum PCBs ensure that automotive lighting systems, such as headlights and taillights, continue to perform at optimal levels for many years. This heat management feature is particularly crucial for high-intensity LEDs that can generate significant amounts of heat, ensuring both performance and safety.

Interior Lighting Efficiency: How Aluminum PCBs Are Used in Compact Spaces for Ambient and Cabin Lighting

Automotive interior lighting, including ambient lighting, reading lights, and cabin lights, is becoming more sophisticated, using LEDs to create a modern and appealing atmosphere. However, interior lighting components are often placed in tight or constrained spaces where heat buildup can be a challenge.

Aluminum PCBs are ideal for this application because of their ability to handle heat efficiently in small, confined areas. The metal core of the PCB helps to dissipate heat away from the LED components, even when space is limited. This heat dissipation prevents the LEDs from overheating, ensuring they operate efficiently while enhancing the longevity of the lighting system. Additionally, aluminum PCBs allow for compact designs, enabling automotive manufacturers to integrate LED lighting into tight spaces, such as door panels, dashboards, and under-seat areas, without compromising performance or safety.

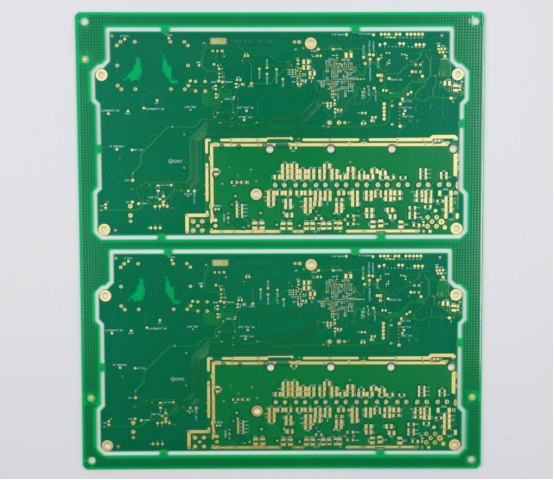

Why Are Aluminum PCBs Essential for Control Modules in Cars?

Aluminum PCBs are vital for control modules in cars due to their ability to manage heat, resist vibration, and provide electromagnetic shielding. Whether it's in engine control units (ECUs), transmission controllers, or body control modules (BCMs), aluminum PCBs ensure these critical systems operate reliably under extreme temperatures and harsh conditions, maintaining vehicle performance and safety over the long term.

Role in Engine Control Units (ECUs): Keeping Microchips Cool for Long-Term Reliability Under Extreme Conditions

Engine Control Units (ECUs) are the "brains" of a vehicle, managing critical systems like fuel injection, ignition timing, and emissions control. These microchips in the ECUs operate in a high-temperature environment under the vehicle's hood, where temperatures can soar above 100°C. To ensure the ECUs remain reliable over the long term, their components need to be kept cool to avoid failure or malfunction.

Aluminum PCBs are essential for this task. Their superior thermal conductivity (237 W/mK) allows heat to dissipate effectively from the microchips, keeping the ECUs within safe operating temperatures. By providing a built-in heat sink, aluminum PCBs prevent overheating, ensuring that the microchips continue to function optimally, even in extreme conditions. This ability to manage heat is key to maintaining the reliability and performance of ECUs, which are critical for engine operation and overall vehicle safety.

Transmission Controllers and Body Control Modules (BCMs): Ensuring Smooth Performance of Automatic Transmissions and In-Cabin Systems

In modern vehicles, transmission controllers and Body Control Modules (BCMs) manage critical systems like automatic gear shifting, power windows, locks, and lighting. These modules are vital for ensuring smooth performance, safety, and comfort inside the car.

Aluminum PCBs are particularly effective in these applications due to their ability to handle high currents and dissipate heat efficiently. Transmission controllers rely on high-power semiconductors that generate significant heat, and aluminum PCBs help to regulate the temperature, preventing overheating that could cause system failure. Similarly, in BCMs, aluminum PCBs ensure that components like power windows and door locks continue to function reliably by keeping the temperature in check, even when the vehicle is exposed to extreme heat or cold.

The mechanical strength and thermal management properties of aluminum PCBs also allow them to withstand the constant vibrations and shocks that occur while driving, ensuring that these control systems continue to operate smoothly over the long term.

Durability Under Hood Conditions: Temperature Stability and EMI Shielding to Prevent Failure in Critical Systems

One of the most demanding environments in a vehicle is under the hood, where components are exposed to extreme temperature fluctuations, moisture, vibration, and electromagnetic interference (EMI). Critical automotive systems, such as ECUs, transmission controllers, and BCMs, need to operate reliably despite these harsh conditions.

Aluminum PCBs are uniquely suited for this environment due to their durability and temperature stability. The aluminum base plate ensures that the PCB can withstand high heat (up to 150°C) without warping or degrading. In addition, aluminum PCBs have built-in EMI shielding, which prevents interference from other electronic systems in the vehicle. This is especially important for systems like ECUs and ADAS (Advanced Driver Assistance Systems), where signal clarity is essential for safe operation.

The ability to resist moisture and corrosion is another significant advantage. Aluminum PCBs are treated with anodization, which creates a protective layer that guards against the damage caused by exposure to water, road salt, and other environmental elements under the hood. This ensures that critical systems remain fully operational, even in the most challenging conditions.

How Do Aluminum PCBs Contribute to Safety and ADAS Systems?

Aluminum PCBs are crucial for the reliability of safety systems like ADAS, airbags, and ABS. They effectively manage heat in heat-sensitive components like cameras and radar sensors, prevent failures in critical systems by dissipating heat and resisting vibration, and undergo rigorous testing to meet automotive standards, ensuring long-term safety and performance under extreme conditions.

Ensuring Reliability of ADAS Cameras and Radar Sensors: Thermal Management for Heat-Sensitive Components in Autonomous Driving Systems

Autonomous driving and Advanced Driver Assistance Systems (ADAS) rely on high-tech cameras, radar sensors, and other critical components to ensure the safety of passengers. These systems are responsible for functions such as automatic braking, lane-keeping, adaptive cruise control, and collision avoidance. However, these sensors and cameras are highly sensitive to heat, and any temperature fluctuation can affect their performance and reliability.

Aluminum PCBs play a crucial role in keeping these heat-sensitive components cool. With their excellent thermal conductivity (237 W/mK), aluminum PCBs can effectively dissipate heat away from sensitive components, ensuring that ADAS cameras and radar sensors continue to work optimally even in hot or demanding environments. For example, aluminum PCBs are used to manage the heat generated by radar sensors in high-performance driving conditions, preventing overheating and ensuring that the sensors remain accurate and reliable for long-term use. This thermal management ensures that ADAS systems maintain their functionality and deliver consistent performance, contributing to the overall safety of the vehicle.

Airbag and ABS Modules: The Role of Aluminum PCBs in Preventing Failures in Safety-Critical Systems

Airbags and Anti-lock Braking Systems (ABS) are safety-critical components that protect passengers in the event of an accident. Their functionality must be guaranteed, even in extreme conditions. For example, airbag controllers need to deploy airbags in a fraction of a second during a crash, and ABS systems must prevent wheel lockup during sudden braking to maintain vehicle control.

Aluminum PCBs are essential in ensuring the reliability of these systems by preventing overheating and mechanical failures. The aluminum base layer of these PCBs helps to dissipate heat generated by the electronic components within the airbag and ABS modules, ensuring that the systems operate smoothly. Additionally, aluminum PCBs are resistant to vibration, a key factor in maintaining stability under sudden vehicle movements such as sharp turns or abrupt stops. By keeping the airbag and ABS system's microchips cool and stable, aluminum PCBs reduce the risk of system failure, ensuring that these critical safety mechanisms function properly when needed the most.

Testing for Automotive Durability: How Aluminum PCBs Undergo Rigorous Thermal and Vibration Testing to Meet Automotive Standards (ISO 26262, IATF 16949)

For components used in safety-critical systems like ADAS, airbags, and ABS, durability is paramount. Aluminum PCBs are subjected to rigorous testing to ensure they meet the tough standards required for automotive applications. These tests simulate real-world conditions to verify that the PCBs will perform reliably over the vehicle's lifespan, even under extreme conditions.

Aluminum PCBs undergo thermal cycling tests, where they are subjected to temperatures ranging from -40°C to 125°C for thousands of cycles. This tests the PCB's ability to withstand extreme temperature fluctuations, ensuring they do not crack, warp, or lose functionality. Additionally, vibration testing (up to 20G) simulates the constant shocks and movements experienced in a vehicle. This ensures that the aluminum PCBs can resist physical stress and maintain reliable performance, even in the most challenging driving conditions. These tests help aluminum PCBs meet international automotive standards, such as ISO 26262 for functional safety and IATF 16949 for quality management, ensuring that they are fit for use in the automotive industry.

What Are the Benefits of Aluminum PCBs for the Automotive Industry?

Aluminum PCBs offer significant benefits to the automotive industry by improving fuel efficiency, extending vehicle range, and reducing maintenance costs. Their lightweight design enhances energy efficiency, while their durability leads to fewer repairs and longer component lifespans. Additionally, aluminum PCBs support sustainability goals by reducing vehicle weight and improving overall energy consumption, making them a smart investment for both automakers and consumers.

Fuel Efficiency and EV Range Improvement: How Lighter Aluminum PCBs Contribute to Overall Vehicle Weight Reduction

One of the most important benefits of aluminum PCBs for the automotive industry is their contribution to reducing vehicle weight. In traditional vehicles, heavier components like FR4 PCBs add significant weight, negatively impacting fuel efficiency and driving range, especially in electric vehicles (EVs). Aluminum PCBs are significantly lighter—by 30–50%—which helps reduce the overall weight of the vehicle.

This reduction in weight leads to immediate improvements in fuel efficiency for internal combustion engine (ICE) vehicles and increased range for electric vehicles. For example, a mid-size EV can increase its battery range by 10–15 km (6–9 miles) per charge simply by replacing traditional PCBs with aluminum PCBs in systems like inverters, battery management systems (BMS), and lighting. In addition to improved fuel efficiency and range, this weight reduction can also enhance overall vehicle handling and performance, making aluminum PCBs a key enabler of advanced automotive designs.

Longer Lifespan and Lower Maintenance: Reduced Failure Rates and Extended Component Life

Aluminum PCBs contribute to a longer lifespan of automotive components due to their superior durability and thermal management properties. Traditional FR4 PCBs are more prone to failure under heat and stress, leading to breakdowns and increased maintenance costs. In contrast, aluminum PCBs handle higher temperatures and vibrations much better, resulting in fewer failures over the vehicle's lifetime.

For example, LED headlights with aluminum PCBs have a lifespan of up to 50,000 hours, compared to only 20,000 hours with traditional PCBs. This means fewer replacements and lower maintenance costs for car owners and manufacturers. In addition to LEDs, other critical components like EV inverters and control modules benefit from aluminum PCBs' heat dissipation and mechanical strength, ensuring these systems continue to perform reliably over the long term. This reduction in failures and the need for repairs makes aluminum PCBs a smart choice for manufacturers aiming to enhance the reliability and longevity of their vehicles.

Environmental Benefits: How Reducing Vehicle Weight and Improving Energy Efficiency Supports Sustainability Goals

The environmental impact of the automotive industry is a growing concern, particularly with the shift towards more eco-friendly transportation. Aluminum PCBs support sustainability goals in several ways. Firstly, by reducing the overall weight of the vehicle, aluminum PCBs help lower the energy consumption of both ICE vehicles and EVs. For ICE vehicles, a lighter car consumes less fuel, leading to fewer carbon emissions and a smaller environmental footprint.

In the case of electric vehicles, lighter vehicles consume less battery power, which directly improves their range and reduces the frequency of charging. This can lead to a reduction in the carbon emissions associated with electricity generation, particularly in regions where power plants are coal- or gas-fired. Additionally, the increased durability of aluminum PCBs means that fewer components need to be replaced over the life of the vehicle, reducing waste and the environmental impact of manufacturing and disposal.

Cost Efficiency Over Time: The Total Cost Savings from Reduced Repair Rates and Fewer Warranty Claims

Although aluminum PCBs may cost more upfront compared to traditional FR4 PCBs, they offer significant cost savings over the long term due to their reliability and durability. The ability of aluminum PCBs to withstand high temperatures, vibrations, and mechanical stress results in a lower failure rate for automotive components. This, in turn, translates into fewer repairs and less frequent replacements.

Manufacturers who use aluminum PCBs in their vehicles experience reduced warranty claims and repair costs. For instance, a vehicle with aluminum PCBs in critical components may experience up to 70% fewer failures compared to vehicles using traditional PCBs. This reduction in failures leads to lower maintenance costs, improved customer satisfaction, and less expense for automakers, ultimately offsetting the initial higher cost of aluminum PCBs. Over time, the savings in repair and replacement costs make aluminum PCBs a more cost-effective choice for automakers focused on both quality and profitability.

What Does the Future Hold for Aluminum PCBs in the Automotive Sector?

The future of aluminum PCBs in the automotive sector is promising, with their role becoming even more crucial as electric and autonomous vehicles gain momentum. As demand for advanced power management and heat dissipation systems grows, aluminum PCBs will be key to supporting the next generation of automotive technologies. With market growth projections highlighting the increasing adoption of electric vehicles and autonomous systems, aluminum PCBs are poised to shape the future of the industry.

Growth of Electric and Autonomous Vehicles: The Increasing Importance of Aluminum PCBs in Future Automotive Technologies

As the automotive industry continues to evolve, electric vehicles (EVs) and autonomous vehicles (AVs) are at the forefront of technological innovation. Aluminum PCBs will play a crucial role in this future transformation. With the rise of EVs, there is a significant increase in demand for efficient power management systems, advanced sensors, and reliable electronics. These systems require components that can handle high currents, manage heat effectively, and operate in challenging conditions—properties that aluminum PCBs excel in.

For instance, EVs rely heavily on inverters, battery management systems (BMS), and electric motor controllers, all of which generate substantial heat. Aluminum PCBs, with their excellent thermal conductivity, ensure that these systems stay cool and functional, supporting the overall efficiency and safety of EVs. In autonomous vehicles, the reliance on cameras, radar, and LiDAR systems for navigation and safety further boosts the demand for aluminum PCBs, which provide superior heat dissipation and mechanical strength, essential for keeping these critical systems operating smoothly in harsh environments.

As the automotive industry embraces electric and autonomous technologies, aluminum PCBs will become even more indispensable, driving innovations in power management, lighting, and safety systems.

Market Trends and Projections: How the Global Automotive Aluminum PCB Market is Expected to Grow

The global automotive aluminum PCB market is poised for significant growth in the coming years. According to market projections, the automotive PCB market size is expected to grow from USD 12.22 billion in 2025 to USD 16.08 billion by 2030, with a compound annual growth rate (CAGR) of 5.64%. This growth is largely driven by the increasing adoption of electric vehicles (EVs) and advancements in autonomous driving technologies.

The shift toward EVs, in particular, will fuel demand for aluminum PCBs. As automakers move away from internal combustion engines (ICE) to electric powertrains, the need for efficient, reliable, and heat-resistant components will rise. Aluminum PCBs are ideal for applications in EV inverters, battery management systems, and power modules, all of which require high power handling and efficient thermal management.

Moreover, the development of autonomous vehicles will also increase demand for aluminum PCBs in sensors and control systems. Advanced Driver Assistance Systems (ADAS), which rely on cameras, radar, and other sensors, will continue to expand, and aluminum PCBs’ ability to block electromagnetic interference (EMI) and manage heat will make them critical to the success of these technologies.

Conclusion

Aluminum PCBs are essential for the next generation of automotive electronics, offering unparalleled benefits in thermal management, durability, weight reduction, and overall system reliability. From enhancing power management in EVs to enabling high-performance lighting and safety systems, aluminum PCBs are a cornerstone of modern automotive design. As the automotive industry shifts towards electric and autonomous vehicles, aluminum PCBs will play a pivotal role in shaping safer, more efficient, and greener vehicles for the future.

PCBMASTER, a trusted and experienced PCB supplier, is well-equipped to provide high-quality aluminum PCBs tailored to the specific needs of the automotive industry. With deep expertise in automotive electronics, PCBMASTER delivers custom solutions for electric vehicles (EVs), autonomous systems, and advanced lighting technologies. Our focus on precision design, reliable performance, and thorough testing ensures that their aluminum PCBs meet the demanding requirements of modern automotive applications. As the industry continues to evolve, PCBMASTER remains a valuable partner in supporting the development of safer, more efficient vehicles.

FAQs

Why can’t FR4 PCBs be used in EV power systems?

FR4 PCBs, commonly used in consumer electronics, are not suitable for high-power applications like EV inverters due to their poor thermal conductivity and limited heat-handling capacity. FR4 typically has a thermal conductivity of around 0.3 W/mK, which is significantly lower than that of aluminum PCBs, which can reach up to 237 W/mK. This makes FR4 inefficient at dissipating the heat generated by high-power components such as inverters and battery management systems in electric vehicles (EVs). Overheating in these systems can lead to performance degradation or even catastrophic failures. Therefore, aluminum PCBs, with their superior heat dissipation properties, are essential for handling the heat generated in EV power systems.

Are aluminum PCBs more expensive than FR4?

Yes, aluminum PCBs are typically more expensive than FR4 PCBs upfront, often costing 20-30% more. However, the higher initial cost is offset by the long-term benefits they offer. Aluminum PCBs are more durable, resistant to thermal cycling, and have a significantly lower failure rate compared to FR4, which leads to fewer repairs and replacements. Their superior thermal management also enhances the overall efficiency and lifespan of automotive electronics, resulting in cost savings over time. When considering reduced maintenance costs, fewer warranty claims, and extended component life, aluminum PCBs become a more cost-effective choice for automotive applications in the long run.

Can aluminum PCBs withstand cold climates?

Yes, aluminum PCBs are designed to operate in extreme temperature conditions, including cold climates. They can withstand temperatures as low as -40°C without cracking or losing performance. This is especially important in vehicles operating in colder regions where components must remain reliable even in freezing temperatures. The robust design of aluminum PCBs, which features a metal core and excellent heat conductivity, helps maintain performance in both hot and cold environments, making them ideal for automotive applications in regions with extreme weather conditions.

How do aluminum PCBs improve EV battery safety?

Aluminum PCBs play a critical role in enhancing EV battery safety, particularly in Battery Management Systems (BMS). The BMS is responsible for monitoring the temperature, voltage, and state of charge of each individual battery cell in the pack. Aluminum PCBs ensure the sensors in the BMS remain cool, preventing overheating, which can lead to thermal runaway—a common cause of battery fires. By effectively dissipating the heat generated during charging and discharging cycles, aluminum PCBs contribute to maintaining the safety and stability of EV batteries, ensuring that they operate within safe thermal limits.

What’s the future of aluminum PCBs in cars?

The future of aluminum PCBs in the automotive sector looks promising, especially as electric and autonomous vehicles (EVs and ADAS) become more prevalent. As car manufacturers continue to innovate, aluminum PCBs will play an increasingly vital role in managing heat, power, and signal integrity in complex electronic systems. With the rise of electric motors, advanced driver-assistance systems (ADAS), and high-power battery systems, aluminum PCBs will be integral in managing the extreme demands of these technologies. Moreover, as vehicles become smarter and more connected, the need for reliable, durable, and efficient PCBs will grow, making aluminum PCBs essential in driving the future of automotive electronics.

Author Bio

Hi, I'm Carol, the Overseas Marketing Manager at PCBMASTER, where I focus on expanding international markets and researching PCB and PCBA solutions. Since 2020, I've been deeply involved in helping our company collaborate with global clients, addressing their technical and production needs in the PCB and PCBA sectors. Over these years, I've gained extensive experience and developed a deeper understanding of industry trends, challenges, and technological innovations.

Outside of work, I'm passionate about writing and enjoy sharing industry insights, market developments, and practical tips through my blog. I hope my posts can help you better understand the PCB and PCBA industries and maybe even offer some valuable takeaways. Of course, if you have any thoughts or questions, feel free to leave a comment below—I'd love to hear from you and discuss further!