Benefits of Conformal Coating Printed Circuit Boards Explained

Conformal coating is like giving your printed circuit board a shield. This thin, clear layer covers every corner of the board, keeping out water, dust, and chemicals that can cause damage. By protecting the board, it helps your electronics stay reliable, last longer, and keep working even in tough environments. If you want your devices to run smoothly for years, conformal coating is a simple but powerful solution.

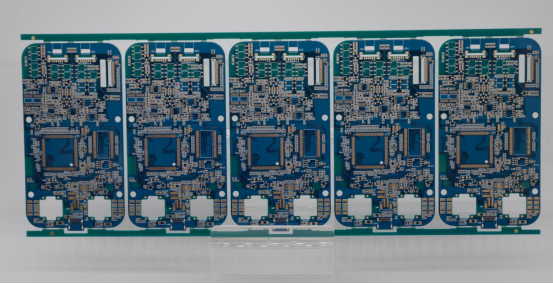

What Is Conformal Coating Printed Circuit Boards

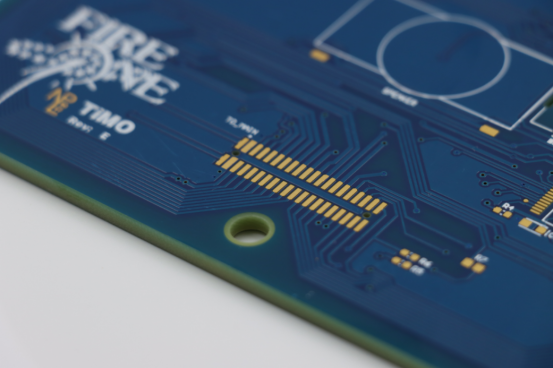

Conformal coating is a thin protective layer that covers the entire printed circuit board (PCB). It starts as a liquid and then dries into a clear, strong film. This film follows the shape of every part on the board — the lines, the chips, and even the tiny spaces between them — so we say it “conforms” to the board.

Common Coating Materials

There are several popular materials used for conformal coating:

l Acrylic: Easy to apply and remove, great for general protection.

l Polyurethane: Very strong against chemicals and scratches.

l Silicone: Works well in very hot or very cold environments.

l Parylene: Super thin but very powerful protection, used when the highest reliability is needed.

Each material has its own advantages, so engineers choose the right one depending on where the PCB will be used.

How It Protects the Board

When the coating dries, it forms a smooth shield that blocks water, dust, dirt, and even salt from touching the board. It also stops small electric leaks between parts, which keeps the board working safely. This extra layer is almost invisible, but it makes a big difference in how long and how well the electronics work.

Key Benefits of Conformal Coating

1. Protection from Moisture, Dust, and Corrosion

Moisture, dust, and chemicals are some of the biggest enemies of a printed circuit board. Water can create tiny paths that let electricity flow where it should not, causing the board to stop working. Dust and dirt can build up and block connections or make heat stay in the wrong places. Chemicals, like cleaning sprays or salty air near the ocean, can slowly eat away the metal parts of the board.

Conformal coating stops all of these problems by making a thin, clear wall over the whole board. This wall keeps out water and dust, and it stops air from reaching the metal, so corrosion cannot start. It is like giving the board a waterproof case that never comes off, keeping it safe for a very long time.

2. Better Electrical Performance and Reliability

When a PCB is not coated, electricity can sometimes jump between parts that are close together, especially when the air is humid. This can cause short circuits, sparks, or even complete failure. Conformal coating works like insulation — it makes sure the electricity stays on the right path. The coating also keeps the board’s surface clean, so no dirt or moisture can cause leaks of electricity.

This is very important for modern electronics, which have many small parts packed closely together. With conformal coating, the board stays stable and reliable, even if it is used for many hours every day. This means fewer sudden failures and fewer repairs.

3. Longer Life for PCB and Components

Every PCB has small metal joints called solder points, which connect the components to the board. Over time, these joints can rust or break if they are exposed to air, moisture, or chemicals. Once a joint breaks, the whole board might stop working.

Conformal coating covers every joint and component with a protective layer, keeping out the things that cause damage. This slows down aging and keeps the board strong for years. For companies, this means fewer broken devices coming back for repair. For users, it means their devices work longer and save them money.

4. Works Well in Harsh Environments

Some electronics must work in places that are very hot, very cold, or very dirty — like in a factory, a farm, or outdoors. These places can damage a normal PCB quickly. Conformal coating helps the board survive by protecting it from temperature swings, dust, and chemicals in the air.

Some coating materials, like silicone, can handle very high heat or freezing cold without cracking. Others, like polyurethane or parylene, are strong enough to block harmful gases and chemicals. With the right coating, a PCB can work well even in extreme conditions, which makes it perfect for heavy-duty or outdoor use.

Common Applications of Conformal Coating Printed Circuit Boards

1. Consumer Electronics

Many everyday devices like smartphones, tablets, and home appliances use printed circuit boards. These devices can be exposed to spills, dust, or humid rooms. Conformal coating protects the boards inside these gadgets, making sure they keep working even if water or dust gets nearby. For example, a phone with a coated PCB is less likely to fail if it gets wet accidentally.

2. Industrial Control Equipment

Factories and machines rely on electronics to run smoothly. The environment in factories is often harsh — full of dust, chemicals, and sudden temperature changes. Conformal coating shields the PCBs in this equipment, preventing damage from dust, sprays, or moisture. This helps machines run reliably for years, reducing downtime and maintenance costs.

3. Medical Devices

Medical electronics, like monitors and diagnostic tools, must work reliably all the time. Some of these devices are used in environments that need frequent cleaning or come into contact with liquids and disinfectants. Conformal coating protects sensitive circuit boards, keeping the devices safe and precise.

4. Harsh Environments

Some PCBs are used outdoors, in vehicles, or in chemical plants where moisture, dust, or corrosive substances are common. Conformal coating acts like a protective shield, making sure the electronics survive tough conditions. It prevents corrosion, short circuits, and other failures, keeping devices reliable even in extreme conditions.

Common Coating Methods of Conformal Coating

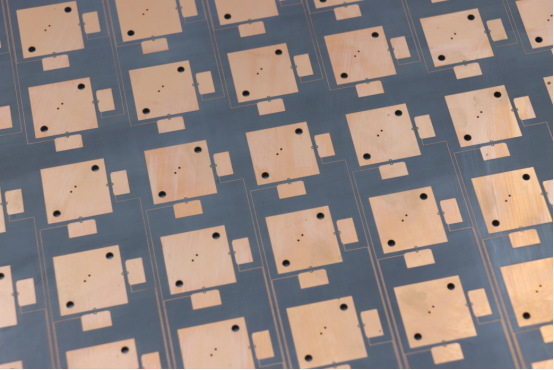

1. Spray Coating

Spray coating is like using a small paint spray to cover the entire PCB. The liquid coating is sprayed evenly over the board so it reaches all the tiny spaces between components. This method works well for boards with complex shapes or many small parts. After spraying, the coating dries quickly to form a thin protective layer. Spray coating is fast and can cover large numbers of boards at the same time, making it popular in factories. It also allows engineers to control how thick or thin the layer should be for different boards.

2. Brush Coating

Brush coating is done by using a small brush to carefully apply the coating to specific areas of the board. This method is simple and does not require expensive machines, so it is often used for small batches or prototypes. Brush coating gives engineers precise control, making sure the coating only goes where it is needed. However, it is slower than spray coating and can be harder to keep the layer perfectly even. Despite this, it is very useful when only a few boards need coating or when testing new designs.

3. Dip Coating

Dip coating is like giving the PCB a quick bath in the coating liquid. The whole board is dipped into the liquid so every part is completely covered. This method ensures complete protection because even the tiniest corners get coated. After dipping, the board is dried or cured to make the coating hard and protective. Dip coating is simple and very effective, but it uses more material than other methods and can be harder to control for very precise thicknesses.

4. Selective Coating

Selective coating uses machines to apply the coating only to certain parts of the PCB that need protection. It is very precise and saves coating material because it does not cover areas that do not need protection. This method is ideal for complex boards with many exposed connectors or components that should not be coated. Automated selective coating is fast, consistent, and perfect for high-volume production, ensuring every board is protected exactly the same way.

Conclusion

In conclusion, conformal coating gives printed circuit boards strong protection, keeps them reliable, and helps them last longer. By adding this thin layer, your electronics are safer from water, dust, chemicals, and other damage. If you are designing a new device or want your electronics to work better for years, using conformal coating is a smart choice.

If you have any questions or want to learn more about PCBs, feel free to contact PCBMASTER, a professional PCB supplier. We are happy to help you find the best solution for your electronics.

FAQs

1. Can conformal coating be removed from a PCB if needed?

Yes, many types of conformal coating can be removed if you need to repair or change the board. For example, acrylic coatings are easy to peel or wash off using special solvents. Polyurethane and silicone coatings are harder to remove, but with the right chemicals and tools, it is still possible. Removing the coating must be done carefully to avoid damaging the components or solder joints underneath.

2. Does conformal coating affect heat dissipation on a PCB?

Conformal coating is very thin, so it usually does not stop heat from leaving the board. Some coatings, like silicone or parylene, are even good at handling heat. They protect the board without causing it to overheat. However, if a coating is applied too thickly in certain areas, it might trap heat, so engineers pay attention to thickness when applying it.

3. How is quality checked after applying conformal coating?

After coating a PCB, manufacturers check it in several ways. They may use a microscope to make sure all parts are covered evenly. Sometimes, they use a UV light if the coating glows under it, which helps see any missed spots. Electrical tests are also done to make sure the board still works correctly. These steps ensure the coating is effective and the board is safe to use.

4. Can conformal coating protect against mechanical shocks or drops?

Conformal coating mainly protects against water, dust, chemicals, and small electrical leaks. It gives only a little protection against mechanical shocks or drops. It is not a strong “armor” layer. For boards that need shock protection, engineers usually combine conformal coating with other protective methods, like cases, foam padding, or vibration-resistant mounting.

5. Is conformal coating suitable for flexible PCBs?

Yes, some conformal coatings work well on flexible PCBs. Silicone and parylene coatings are soft and bendable, so they move with the board without cracking. However, hard coatings like polyurethane or thick acrylic may crack when the board bends too much. Engineers select the coating based on how much the flexible PCB will bend or stretch in its application.