How to Choose the Right Standard Printed Circuit Board Thickness for Your Project

When designing electronic products, PCB thickness might seem like a small detail, but it plays a big role in how your device works. It like the foundation of a house—if the foundation is too weak or too strong, the whole house might not perform well. Similarly, the thickness of your Printed Circuit Board (PCB) directly affects its performance, reliability, and durability.

Choosing the right PCB thickness is crucial because it can impact everything from how well the components function to how much heat the board can handle. If the thickness is too thin or too thick for your design, it can lead to problems like overheating, poor signal quality, or even failure in the long run. So, understanding and selecting the correct PCB thickness ensures your electronic product works reliably, lasts longer, and performs as expected.

What is Standard PCB Thickness?

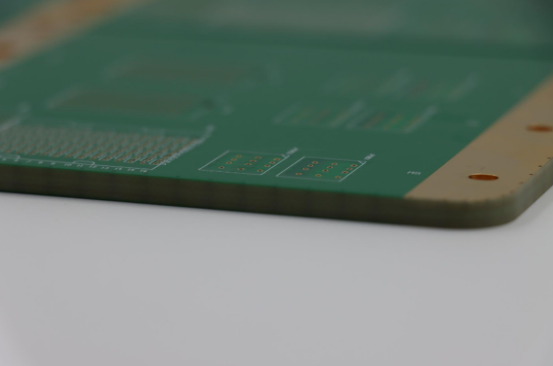

PCB thickness refers to the measurement of how thick the printed circuit board (PCB) is. The standard PCB thickness used in most electronics is 1.6mm. This thickness is widely accepted because it strikes a balance between strength, performance, and cost. However, sometimes a custom thickness is required based on the specific needs of the project.

1. Common PCB Thickness Range

Thin PCBs: These range from 0.2mm to 0.5mm and are used for small, compact devices like mobile phones or wearables.

Standard PCBs: The most common thickness is 1.6mm, which works for most consumer electronics, like computers, televisions, and other everyday devices.

Thicker PCBs: These can range from 2.0mm to 3.2mm and are used in industries that need extra strength, like automotive or industrial equipment, where the board needs to withstand tough environments.

2. Standardization in the Industry

The reason 1.6mm is the most commonly used thickness is because it has become the industry standard. This means that manufacturers and designers can easily find materials, components, and manufacturing processes that work well with this thickness. It also ensures that products are compatible with existing technology, tools, and machines, which helps save time and costs in production.

Factors to Consider When Choosing the Right PCB Thickness

When selecting the right PCB thickness, several important factors need to be considered. These factors can affect how the board performs, how durable it is, and how well it fits into the final product.

1. Circuit Design Requirements

Different circuit designs have different needs when it comes to PCB thickness. For example:

l High-Frequency Signals: If your PCB needs to carry high-frequency signals (like in wireless communication or radio devices), the thickness can affect how the signals travel. Thinner PCBs can sometimes work better for high-frequency designs, as they allow for quicker signal transmission with less interference.

l Power Distribution: For circuits that need to distribute a lot of power (such as in power supplies or LED lighting), a thicker PCB might be necessary. A thicker board can handle larger currents and provide better power distribution without overheating.

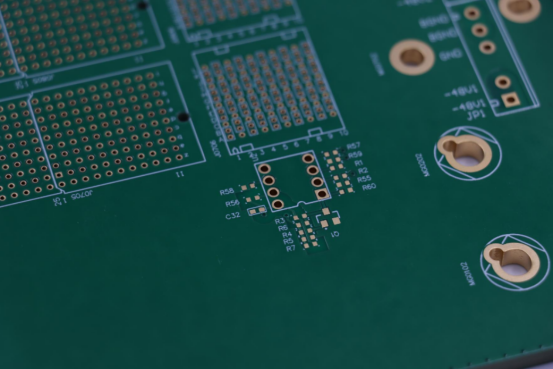

2. Component Size and Layout

The thickness of the PCB can also impact how you place and fit your components on the board. A thicker PCB:

l Allows for more space between the layers, which is important when placing large components or designing more complex circuits.

l Affects the layout by influencing the distance between traces (the electrical paths on the board). Thicker boards can sometimes allow for better spacing, which helps avoid short circuits or electrical interference.

3. Heat Dissipation

In electronic devices that generate a lot of heat, PCB thickness plays a big role in heat dissipation:

l Thicker PCBs help spread heat more effectively across the board. This is especially important in high-power applications, such as power supplies, motors, or devices that run on high currents.

l A thicker PCB has better thermal management properties, helping to prevent overheating, which can cause damage to components or shorten the device's lifespan.

4. Mechanical Strength and Durability

The thickness of a PCB is also closely related to its mechanical strength. Thicker PCBs are:

l Stronger and better able to withstand physical stress, such as pressure or vibration.

l More durable, which is especially important in harsh environments like in the automotive industry, industrial machines, or outdoor electronics where the board may be exposed to constant movement or heavy conditions.

Common Applications of PCB Thickness

The thickness of a PCB depends largely on the specific needs of the device or system in which it is used. Different applications require different thicknesses to meet performance and durability requirements. Here are some common examples:

1. Thin PCB Designs

Thin PCBs are often used in devices where space is limited or the device needs to be lightweight. Some common needs for thin PCBs include:

l Mobile Devices: Smartphones, tablets, and wearables need thin PCBs to keep the device compact and lightweight, without sacrificing performance.

l Consumer Electronics: Gadgets like headphones, cameras, and portable devices benefit from thin PCBs to save space and reduce the overall size of the product.

l Flexible Circuits: Thin PCBs are also used in flexible circuits, such as in flexible displays or devices that need to bend or twist.

These thin PCBs help manufacturers create small, portable devices while maintaining good electrical performance.

2. Thicker PCBs for High-Strength and High-Frequency Applications

Thicker PCBs are necessary for certain high-performance applications, including:

l High-Frequency Electronics: Devices like radios, GPS systems, and wireless communication equipment often require thicker PCBs to handle high-frequency signals effectively. Thicker boards can help manage signal integrity and reduce interference.

l Power Electronics: For devices like power supplies, electric vehicles, and solar inverters, thicker PCBs are used to handle high power and manage the increased heat generated during operation. These thicker boards can prevent overheating and support higher current loads.

These types of applications require thicker PCBs to ensure that the device works safely and efficiently, especially when dealing with high speeds or high power.

3. Specific PCB Thickness for Stability and Precision

In some applications, the thickness of the PCB is carefully chosen to ensure stability and precision:

l Medical Devices: In products like heart monitors, pacemakers, and diagnostic equipment, precise and stable PCBs are crucial. The thickness of the PCB can help ensure reliable signal processing and prevent failures in critical environments.

l Aerospace and Defense: Equipment used in these fields often requires thick PCBs to handle the extreme conditions of temperature, pressure, and vibration. A stable PCB ensures that sensitive systems, like navigation or communication equipment, function without interference.

In these high-precision applications, the PCB’s thickness plays a key role in maintaining the accuracy and reliability of the device, ensuring it operates correctly under demanding conditions.

How to Choose the Right PCB Thickness

Choosing the correct PCB thickness is essential for your project’s success. Several factors need to be considered to ensure you get the right thickness for your circuit. Let’s go through the steps:

1. Analyze the Project Requirements

Before deciding on the PCB thickness, you need to carefully analyze your project’s needs. This involves looking at a few key elements:

l Circuit Design: Understand the type of circuit you're designing. For example, if your design involves high-frequency signals, you might need a thinner PCB to reduce signal loss. On the other hand, if you’re dealing with high-power electronics, you will need a thicker PCB to manage heat and carry more current.

l Component Sizes: Larger or heavier components may require thicker PCBs to provide more space and support. If you are using many components that generate heat, a thicker PCB can also help with heat dissipation.

l Durability Needs: If your project needs to withstand physical stress (like in automotive or industrial applications), you might choose a thicker PCB to make it more mechanically strong.

By analyzing these factors, you can determine what thickness will best suit your project.

2. Communicate with Your PCB Manufacturer

It’s important to talk to your PCB manufacturer before making a final decision on thickness. Here’s why:

l Manufacturing Constraints: Different PCB manufacturers may have specific limitations on how thick or thin they can make a board. Talking to them ensures that your design is within their capabilities.

l Production Process: Thicker or thinner boards may require different production techniques, which can affect the production time and cost. For instance, thinner boards are often more difficult to handle during assembly, while thicker boards may require more materials and take longer to produce. Knowing these details can help you plan your project better.

l Cost Implications: Thicker PCBs can cost more to produce, so discussing the cost impact with your manufacturer helps you stay within your budget.

3. Testing and Validation

Once you’ve selected a PCB thickness, it’s always a good idea to test and validate it before moving into full production. Here’s why this step is crucial:

l Prototyping: By creating a prototype with the selected thickness, you can test the board in real-world conditions. This helps you see if the design works as expected, especially when it comes to signal integrity, power handling, and heat dissipation.

l Making Adjustments: If you find that the PCB isn’t performing as needed, you can make adjustments to the thickness before committing to a larger run. For example, if the board is overheating, a slightly thicker PCB might help solve the problem. Or, if the signals are being distorted, a thinner PCB might improve performance.

l Minimize Risks: Testing helps you avoid costly mistakes later in the project. If the board fails during testing, you can quickly make changes to get it right.

Conclusion

Choosing the right PCB thickness is a critical decision for the success of your project. To make the best choice, consider the specific needs of your design, such as power requirements, component size, heat dissipation, and mechanical strength. By carefully analyzing these factors, communicating with your manufacturer, and testing prototypes, you can ensure your PCB performs reliably and efficiently.

Remember, the thickness of your PCB can have a lasting impact on your product’s quality and performance. A well-chosen PCB thickness will not only improve functionality but also save you time and costs in the long run. On the other hand, choosing the wrong thickness might lead to issues like overheating, signal loss, or even failure of the product.

If you have any questions or would like to learn more about PCBs, feel free to reach out to PCBMASTER, a trusted PCB supplier. We’re here to help guide you through the process and ensure your project’s success!

FAQs

1. Why is PCB thickness so important in electronic devices?

PCB thickness affects the overall performance, durability, and safety of electronic devices. Here’s why it matters:

l Signal Quality: If your PCB is too thin or too thick, it can impact how well the signals travel through the circuit. A thicker board might cause delays in high-frequency signals, while a thinner board could cause issues in handling high current.

l Heat Dissipation: Devices that produce a lot of heat (like power supplies) need thicker PCBs to help spread out the heat and keep the components cool. If the board is too thin, it may overheat and cause the device to fail.

l Strength and Durability: A thicker PCB is more durable and can handle physical stress better. It’s ideal for devices that will be exposed to vibration, pressure, or harsh environments, like in automotive or industrial applications.

Choosing the right thickness ensures your product works properly and lasts longer.

2. How does PCB thickness affect the cost of production?

The thickness of a PCB can affect the production cost in several ways:

l Material Costs: Thicker PCBs require more materials to produce, which generally makes them more expensive. The type of materials used can also impact the cost. For example, special materials for high-frequency or high-power applications can cost more.

l Manufacturing Process: Thicker boards may require more time and effort during the manufacturing process. They may need special machines or more careful handling, which can increase labor costs. On the other hand, thinner boards might be easier to produce, but they can be more prone to damage during assembly, requiring extra care.

l Testing and Prototyping: If you’re testing different PCB thicknesses, you may need to create several prototypes, which can add extra costs. However, it’s worth the investment because it ensures you choose the right thickness for your product.

Overall, while thicker PCBs can be more expensive, they may be necessary for the product’s performance and reliability.

3. What are the risks of choosing the wrong PCB thickness?

Choosing the wrong PCB thickness can lead to several issues that may affect your product’s performance and durability:

l Overheating: If your PCB is too thin for a high-power device, it won’t be able to spread the heat properly. This can lead to overheating, which can damage the components or cause the device to fail.

l Poor Signal Quality: For high-frequency applications like communication systems, a too-thick PCB can cause delays in signal transmission. On the other hand, a too-thin PCB may not be able to handle the electrical load, causing signal distortion or loss.

l Physical Damage: Thin PCBs are less durable and can be easily damaged by physical stress, like pressure or vibrations. This can be a problem in devices that are used in rough environments, like in cars or industrial machines.

To avoid these risks, it’s important to carefully choose the right PCB thickness based on your project’s specific needs.