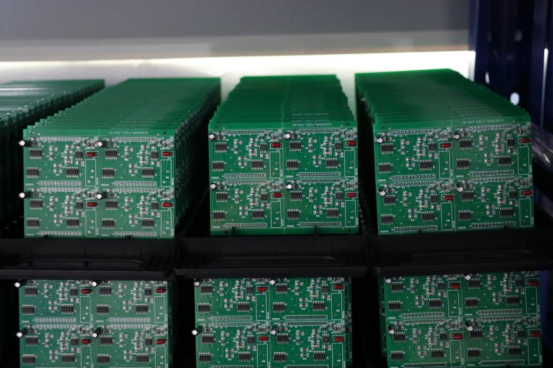

Low Volume PCB Assembly: Perfect for Custom Projects and Rapid Prototyping

In today’s fast-moving tech world, getting new products to market quickly is crucial. Low volume PCB assembly is the solution, enabling businesses to create small batches of custom circuit boards without the cost and delay of mass production.

For custom projects and rapid prototyping, this method offers flexibility and speed. It allows companies to test ideas, refine designs, and quickly adjust based on real-world feedback—without the risk of overproduction.

For businesses developing new products, low volume production enables rapid iteration, allowing companies to stay agile, reduce risks, and cut costs in the early stages of development, keeping them ahead of the competition.

What is Low Volume PCB Assembly?

Low volume PCB assembly refers to the process of manufacturing a small quantity of printed circuit boards (PCBs) and assembling them with electronic components for a specific project or prototype. Unlike large-scale manufacturing, which focuses on mass production of thousands or even millions of units, low volume PCB assembly is about producing just enough to test, refine, and verify designs without committing to large production runs.

This process is highly beneficial for companies that need to produce custom, specialized products or conduct real-world testing with a limited budget and timeframe. It allows businesses to move forward with product development without the financial risk and long lead times of mass production.

In low volume production, the quantity of PCBs typically produced is fewer than 1,000 units. This small batch production method is ideal for various stages of product development, such as:

l Prototypes: When a new product or design needs to be tested before going into mass production, low volume production lets you create a few units to test functionality, make adjustments, and gather feedback.

l Pre-production or Small Runs: After finalizing a prototype, businesses may produce a small number of units to test out manufacturing processes, or to supply small quantities to early customers.

Low volume assembly is often used in situations where producing hundreds or thousands of units would be wasteful or unnecessary. The goal is to make just enough units to test the design, gather feedback, and decide whether to proceed with mass production.

Advantages of Low Volume PCB Assembly

Low volume PCB assembly offers many benefits, especially for businesses that need flexibility, speed, and cost-effectiveness in product development. Let’s break down the main advantages:

1. Fast Prototyping

Helps Accelerate Product Design Validation: Low volume PCB assembly allows businesses to quickly create prototypes of their designs. This helps engineers and designers test their ideas in real-world conditions, identify issues early, and make improvements. Instead of waiting for mass production, they can quickly build and test small batches of PCBs to validate their designs. This speeds up the overall product development process.

Quickly Respond to Market Demands: In today’s fast-changing market, the ability to quickly respond to new trends or customer needs is crucial. With low volume production, companies can build small batches of new products or variations to meet these demands quickly. This means they can get their products into the market faster than competitors, giving them an edge.

2. Flexibility and Customization

Supports Various PCB Designs and Functional Requirements: Low volume PCB assembly offers great flexibility in terms of design. Companies can create PCBs with complex, customized layouts and specific features without worrying about the limitations of large-scale manufacturing. Whether it’s a unique shape, size, or component placement, low volume assembly can accommodate almost any requirement.

Meets Personalized Customization Needs, Especially for Small and Medium Businesses: Smaller businesses or startups often need to create highly specialized products tailored to specific customer needs. Low volume PCB assembly is perfect for this because it allows for customization without the need for large investments in mass production. This is especially beneficial for companies with niche markets or unique product requirements.

3. Cost-Effectiveness

Lower Costs Compared to Mass Production: Low volume production is much more affordable than large-scale manufacturing. When producing fewer units, businesses don’t have to invest in expensive tools, machines, or large quantities of raw materials. This significantly reduces the upfront cost, making it an ideal solution for companies that don’t want to tie up capital in mass production.

Avoids Inventory Overload and Reduces Waste: One of the challenges of mass production is the risk of producing too many units, which leads to excess inventory. Low volume PCB assembly helps avoid this problem because businesses only produce the number of units they need. This helps reduce waste and minimize the risk of unsold products piling up, saving both money and resources.

4. Risk Reduction

Lower Risk in Low Volume Production: One of the biggest risks in product development is investing too much in a product that may not work as expected. Low volume production allows businesses to test designs on a smaller scale, reducing the risk of costly mistakes. If something goes wrong or needs improvement, changes can be made quickly, without the large losses associated with mass production.

Ability to Make Quick Adjustments: With low volume production, companies can easily make changes to their designs based on test results and market feedback. If a product has a design flaw or requires new features, businesses can make those adjustments before committing to large-scale production. This quick response capability helps companies stay agile and competitive.

Applications of Low Volume PCB Assembly

Low volume PCB assembly is widely used across different industries and by various types of businesses. It provides a flexible and cost-effective solution for companies that need to develop custom products, test new ideas, or quickly bring products to market. Let’s look at some common applications:

1. Startups and Research & Development Teams

Cost-Effective Production for Startups and R&D Teams: For new companies or research teams working on new technologies, low volume PCB assembly is an affordable way to begin product development. These businesses often don’t have the budget for large-scale production but still need to test their ideas and produce small batches of products. Low volume assembly allows them to produce just the right amount of units they need for testing or market research without spending too much money upfront.

Testing New Concepts: Startups and R&D teams often work on innovative ideas that require testing and validation. Low volume PCB assembly enables them to produce prototypes and small runs of products to evaluate their design and functionality. They can make adjustments as they go, which helps avoid costly mistakes in the later stages of production.

2. Prototyping and Small Batch Production

An Ideal Choice for Prototyping During Product Development: When developing a new product, it’s important to test how the design works in the real world. Low volume PCB assembly is the perfect solution for prototyping. It allows designers to create a small number of PCBs to test their designs, experiment with different configurations, and make any necessary changes before moving forward with mass production.

Small Batch Production for Market Testing: After prototyping, businesses can use low volume assembly for small batch production. This is often done to test a product in the market or to produce limited quantities for special customers. Low volume production enables companies to test products with real users, gather feedback, and make improvements before committing to larger-scale production.

3. Custom Projects

Providing Small Batch Production Solutions for Specific Needs: Sometimes, businesses need to produce very specific or unique products that are not suitable for mass production. Low volume PCB assembly allows companies to create custom solutions in small quantities. For example, if a company is creating a specialized device or equipment for a particular application, low volume assembly enables them to produce just the right number of units to meet demand, without the need for a large investment in mass production.

Custom Design Flexibility: Many custom projects require very specific designs or components. Low volume PCB assembly is highly flexible and can be tailored to meet those specific needs. This is particularly useful for industries like medical devices, automation, or consumer electronics, where off-the-shelf solutions don’t always fit the requirements.

4. Fast Time-to-Market

Quick Response to Market Changes: In today’s competitive market, things move fast. Companies need to be able to quickly adapt to new trends, changes in customer preferences, or emerging technologies. Low volume PCB assembly helps businesses respond quickly by allowing them to produce small quantities of products on short notice. This means they can get new products into the market faster than competitors.

Launching New Products Quickly: For businesses that need to introduce new products quickly, low volume assembly is a great way to get things moving. Whether it’s testing a new electronic device or responding to changes in consumer demand, low volume PCB assembly helps companies launch products faster. This fast turnaround can be crucial in staying ahead of the competition and making sure products meet market demands on time.

Choosing the Right Low Volume PCB Assembly Provider

When selecting a provider for low volume PCB assembly, it’s important to consider several factors to ensure you are getting the best service for your needs. Here’s what to look for:

1. Provider Selection Criteria

Technical Capability: Make sure the provider can handle high-precision and complex designs. Some PCBs require very specific designs or components, and not all assembly providers have the expertise to handle these advanced requirements. A good provider should be able to create the specific PCB layout and design you need without issues, ensuring your product works as expected.

Clear Pricing: It’s important to choose a provider who offers transparent pricing. Before you begin, make sure they give you a clear breakdown of costs, including assembly, materials, and any additional charges. This way, you won’t face unexpected fees later on. Having a clear price system is essential for budgeting and planning your project effectively.

Delivery Time: The provider should be able to meet your delivery deadlines. In product development, timing is often crucial. Whether you’re working on a prototype or a small production run, you need a provider who can deliver your PCBs on time, so you can continue your work without delays. A reliable provider will have a solid track record of meeting deadlines.

2. Quality Control

Quality Monitoring and Testing During Production: A good provider will have a strong quality control system in place. They should monitor and test the PCBs throughout the assembly process to ensure that the final product meets the required standards. This includes checking for any defects, errors, or issues that could affect the functionality of the PCB.

Use of High-Quality Materials and Components: The provider should use high-quality materials and components for the assembly. Poor-quality materials can lead to faulty PCBs that don’t perform well or may fail early. It’s important to ensure that the PCB assembly provider uses trusted, reliable components to make sure the end product is durable and functions as expected.

3. After-Sales Service

Technical Support and Customer Service: A good PCB assembly provider should offer excellent technical support throughout the entire process. This includes helping you with any design questions, providing advice on how to improve your PCB, and assisting with troubleshooting if any issues arise during production.

Post-Production Support: After your PCB is assembled and delivered, it’s important that the provider offers solid after-sales service. This means they should be available to help if you need any modifications, replacements, or if something goes wrong with the order. A reliable provider will be there to assist you even after the product has been delivered.

PCBMASTER: A Great Choice

When looking for a reliable and trustworthy provider, PCBMASTER is an excellent option. PCBMASTER has a strong reputation for delivering high-quality PCBs with fast turnaround times, clear pricing, and exceptional technical support. Whether you need a prototype or small production run, PCBMASTER has the experience and expertise to meet your specific needs.

By choosing a reliable provider like PCBMASTER, you can ensure that your low volume PCB assembly project runs smoothly, on time, and within budget, with the quality you need.

Conclusion: Low Volume PCB Assembly – The Key to Future Electronics Development

Low volume PCB assembly is essential for rapid prototyping and custom projects. It allows businesses to test designs quickly, make adjustments, and move forward without the risks and costs of mass production. This flexibility is crucial for staying competitive in today’s fast-changing market.

By using low volume PCB assembly, companies can develop innovative products faster and at lower costs. It’s the key to agile development, helping businesses respond to market demands and get ahead of the competition.

For both startups and established companies, low volume PCB assembly is the path to efficient, cost-effective product development in the future of electronics.

FAQs

1. Why should businesses choose low volume PCB assembly instead of mass production?

Low volume PCB assembly is a great choice for businesses that are still testing new designs or creating custom products. Unlike mass production, which requires making thousands or even millions of units, low volume assembly allows businesses to make only the number of units they need. This is helpful because:

l It’s much cheaper to produce fewer units, saving money upfront.

l You can test your designs and make changes before committing to large production runs.

l It allows businesses to reduce risk, because if there’s a problem with the product, they don’t have to throw away a lot of unsold inventory.

For businesses looking to stay flexible, low volume PCB assembly offers the right balance between affordability and speed without taking big financial risks.

2. How does low volume PCB assembly support innovation and product development?

Low volume PCB assembly supports innovation by giving businesses the chance to experiment with new ideas and custom designs. This method allows:

Faster prototyping: You can create prototypes quickly to test your ideas and make improvements without waiting for mass production.

Flexibility: Low volume production can accommodate customized designs and meet specific needs that large-scale manufacturing can't always handle.

Quick market testing: Businesses can create limited runs of products to test customer reactions or gather feedback before scaling up production.

This flexibility helps companies stay ahead of the competition and respond quickly to changing market demands, which is essential for innovation.

3. What industries benefit the most from low volume PCB assembly?

Low volume PCB assembly is especially useful in industries where products are highly customized or require rapid development. Some of the key industries that benefit the most include:

Medical Devices: Many medical devices require custom PCBs for specific functions. Low volume assembly allows for testing designs in small batches before committing to larger production.

Consumer Electronics: Companies in this industry need to create new gadgets quickly and test them in the market. Low volume assembly allows them to produce small quantities for testing and feedback before mass production.

Automation & Robotics: These industries often need specialized PCBs for specific applications. Low volume production provides the flexibility to create customized solutions without the need for large-scale manufacturing.

In short, any industry that needs customization, speed, and testing can benefit from low volume PCB assembly.