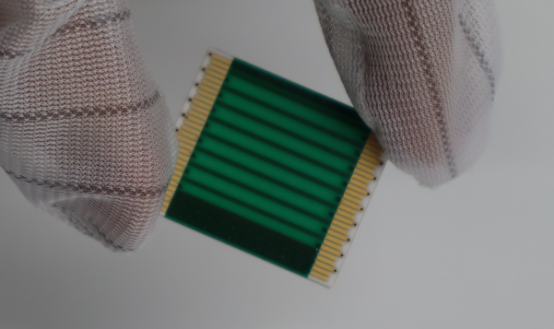

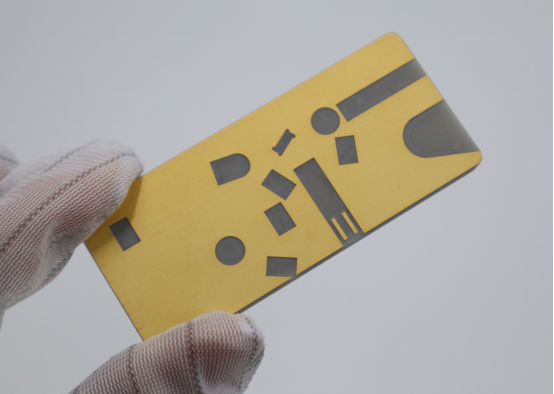

Ceramic PCBs: Key Features and Applications

Ceramic PCBs are transforming the electronics industry by delivering exceptional performance in extreme conditions. Unlike traditional FR4 PCBs, which use organic materials, ceramic PCBs are crafted from advanced ceramics like alumina, aluminum nitride, and silicon carbide. These materials offer superior heat dissipation, high-temperature resistance, and excellent electrical insulation, making ceramic PCBs the ideal choice for high-power applications in electric vehicles, LED lighting, aerospace sensors, and more.

As electronics continue to grow more powerful and operate in increasingly harsh environments, the demand for ceramic PCBs is skyrocketing. The global market is projected to expand from USD 1.73 billion in 2025 to USD 3.49 billion by 2035, driven by industries that require reliable, high-performance components capable of withstanding tough conditions.

Key Features of Ceramic PCBs

Exceptional Thermal Conductivity

Ceramic PCBs are known for their outstanding ability to manage heat, which is crucial for ensuring the longevity and reliability of electronic components. Unlike traditional FR4 PCBs, ceramic materials like alumina (Al2O3) and aluminum nitride (AlN) have much higher thermal conductivity. Here’s how this benefits various applications:

Efficient Heat Transfer: Ceramic PCBs can conduct heat up to 50 times better than FR4, reducing the risk of overheating.

Prolonged Lifespan: By managing heat effectively, ceramic PCBs help extend the lifespan of components such as LEDs and power modules.

Ideal for Heat-Intensive Applications: These PCBs are perfect for use in LED lighting, power modules, and other high-power devices where heat management is critical.

High-Temperature Resistance

Another key advantage of ceramic PCBs is their ability to withstand extreme temperatures. Unlike FR4, which is limited to around 130°C, ceramic materials can handle much higher temperatures, ensuring stable performance even in harsh environments:

Alumina (Al2O3): Can operate at temperatures up to 250°C.

Aluminum Nitride (AlN): Can handle temperatures as high as 300°C.

Perfect for Hot Environments: This makes ceramic PCBs ideal for use in industries like automotive (e.g., EV inverters) and industrial equipment, where high heat is often generated.

Outstanding Electrical Properties

Ceramic PCBs are also known for their excellent electrical properties, which make them highly suitable for high-frequency and high-voltage applications:

High Dielectric Strength: Ceramic PCBs can withstand high voltages without failure, which is critical for high-power systems.

Low Signal Loss: Materials like AlN help minimize signal loss, making these PCBs ideal for applications such as 5G networks and radar systems.

Strong Electrical Insulation: They ensure stable, efficient operation by preventing current leakage, which is crucial for the safety and performance of sensitive electronic systems.

Mechanical Stability and Environmental Adaptability

Ceramic PCBs offer exceptional durability in extreme environmental conditions, making them a perfect choice for industries that operate in challenging environments:

Low Coefficient of Thermal Expansion (CTE): The low CTE minimizes warping or cracking during temperature cycles, ensuring long-term reliability in temperature-sensitive applications like automotive and aerospace electronics.

Resistance to Moisture, Chemicals, and Radiation: Ceramic PCBs can resist moisture absorption, corrosion from chemicals, and radiation, making them ideal for use in harsh industrial and military environments.

Perfect for Harsh Conditions: They are used in aerospace and defense, where their ability to withstand radiation and extreme temperatures ensures reliability.

The superior features of ceramic PCBs—high thermal conductivity, exceptional high-temperature resistance, excellent electrical properties, and mechanical stability—make them invaluable for high-performance, high-reliability electronic applications. These qualities allow ceramic PCBs to outperform traditional FR4 PCBs in environments where heat, high voltage, and harsh conditions are common.

Main Applications of Ceramic PCBs

Electric Vehicles (EVs) and Hybrid EVs

Inverters

In electric vehicles (EVs), inverters play a crucial role in converting DC power from the battery into AC power for the motor. Ceramic PCBs, particularly those made with aluminum nitride (AlN), are essential in managing the heat generated during this process.

Thermal Management: AlN ceramic PCBs can handle high temperatures, ensuring that inverters operate efficiently even under extreme conditions.

Improved Performance: By conducting heat away from sensitive components, ceramic PCBs help prevent overheating, improving the overall reliability and lifespan of the inverter.

Battery Management Systems (BMS)

Battery management systems (BMS) are responsible for monitoring the health and performance of a vehicle’s battery pack. Ceramic PCBs are highly beneficial in BMS applications due to their high-temperature tolerance and electrical insulation properties.

High-Temperature Resistance: Ceramic PCBs, such as those made from alumina (Al2O3) or aluminum nitride (AlN), can withstand the high temperatures generated during charging and discharging, ensuring the safety and reliability of the BMS.

Electrical Insulation: The strong electrical insulation properties of ceramic PCBs prevent short circuits and ensure that the BMS functions safely, even under high voltage conditions.

Industrial and Power Electronics

Motor Drives and Solar Inverters

Ceramic PCBs are widely used in industrial and power electronics, especially in motor drives and solar inverters. These applications require reliable, high-performance components that can operate under extreme conditions.

High Temperature and Reliability: Ceramic PCBs’ ability to operate at temperatures up to 300°C makes them ideal for motor drives and solar inverters, where high currents and heat are common.

Enhanced Durability: In industrial equipment, ceramic PCBs help prevent overheating, which is essential for maintaining the reliability of power electronics, ensuring continuous operation even in harsh environments.

Welding Equipment

In welding equipment, where high currents and intense heat are common, ceramic PCBs are used to ensure safe and efficient operation.

Thermal Management in High-Power Systems: Ceramic PCBs help dissipate heat generated during welding, protecting the system from damage and extending its lifespan.

Resilience in Harsh Conditions: The high-temperature and chemical resistance of ceramic PCBs make them perfect for industrial welding applications, where exposure to high temperatures and corrosive materials is common.

LED Lighting and Display Technology

High-Power LEDs

Ceramic PCBs are extensively used in high-power LED lighting systems to ensure efficient heat dissipation, which is critical for maintaining performance and longevity.

Heat Management in LED Fixtures: High-power LEDs generate significant heat during operation, and ceramic PCBs help manage this heat, keeping the LEDs cool and improving their lifespan.

Improved Performance: By efficiently conducting heat away from the LED components, ceramic PCBs prevent overheating, ensuring that the LED lights perform at optimal levels for a longer time.

UV LEDs

Ultraviolet (UV) LEDs are used in various applications, including sterilization, curing, and medical devices. Ceramic PCBs are particularly valuable in these applications due to their durability.

Resistance to Degradation: Ceramic PCBs are highly resistant to UV radiation, ensuring that the PCB material does not degrade over time, which is a common issue with organic-based materials like FR4.

Long-Term Reliability: The ability of ceramic PCBs to withstand UV exposure makes them ideal for UV LED applications, where reliability and longevity are essential.

Aerospace

Aircraft Electronics

In the aerospace industry, ceramic PCBs are used in aircraft electronics where reliability under extreme conditions is critical.

Thermal Resistance and Durability: Ceramic PCBs can withstand the extreme temperature fluctuations experienced during flight, ensuring that electronic systems perform reliably even in the harsh conditions of high altitudes.

Radiation Resistance: Ceramic PCBs are also resistant to radiation, making them perfect for avionics systems that must perform reliably in space or during high-altitude flight.

Radar Systems

In radar systems, especially in aerospace and defense, ceramic PCBs made from materials like silicon carbide (SiC) are used to ensure that the system can function under high heat and radiation.

High-Temperature Performance: SiC ceramic PCBs can operate in temperatures that would damage conventional PCBs, making them ideal for aerospace radar systems.

Radiation Hardness: The radiation resistance of ceramic PCBs ensures that they can withstand the harsh conditions of space or military environments without degradation.

Medical Equipment

Medical Imaging Devices

Medical imaging devices, such as X-ray machines and MRI scanners, rely on ceramic PCBs for their durability and thermal stability.

Thermal Stability: Ceramic PCBs help manage the heat generated in high-performance imaging systems, preventing overheating and maintaining the accuracy of imaging systems.

Radiation Resistance: Ceramic PCBs also offer radiation resistance, which is particularly important in medical imaging applications where exposure to radiation is a concern.

Laser Therapy Equipment

In medical laser therapy devices, ceramic PCBs are used to manage the heat generated by high-power laser diodes.

Heat Management in Laser Diodes: Ceramic PCBs help dissipate heat efficiently, ensuring that the laser diodes maintain their performance without overheating.

Temperature Control: The ability of ceramic PCBs to maintain stable operating temperatures ensures precise control over the laser therapy process, which is essential for effective treatments.

Ceramic PCBs are transforming industries ranging from automotive to aerospace to healthcare by providing superior performance in extreme conditions. Their ability to manage heat, withstand high temperatures, offer electrical insulation, and resist environmental stress makes them indispensable in high-power, high-reliability applications. With the increasing demand for robust and durable electronics, ceramic PCBs are becoming essential components in the next generation of technology.

Conclusion

Ceramic PCBs are transforming industries that demand cutting-edge, high-performance electronics. With their superior heat dissipation, exceptional temperature tolerance, and robust electrical properties, ceramic PCBs are becoming essential for high-power applications in sectors like electric vehicles, renewable energy, and aerospace.

Looking ahead, ceramic PCBs are poised to play an even more pivotal role in shaping the future of high-tech industries. Their unmatched performance in high-temperature, high-power environments makes them indispensable for the next generation of electronic devices.

At PCBMASTER, we specialize in high-quality ceramic PCBs, leveraging over a decade of expertise to deliver customized solutions for industries that require exceptional reliability and performance. Whether in automotive, medical, or energy applications, we help power the most advanced technologies.

FAQs

1. Can Ceramic PCBs be used for Flexible Designs?

Yes, ceramic PCBs can be used in flexible designs, though it's important to note that ceramic materials are generally more rigid compared to traditional flexible substrates like polyimide (PI) or polyethylene terephthalate (PET). However, certain ceramic materials, such as Zirconium Dioxide (ZrO₂), are more suitable for flexible applications due to their higher toughness and crack resistance. ZrO₂-based ceramic PCBs can be used in applications like wearable devices where flexibility and durability are critical. Though flexibility is somewhat limited, these ceramics offer significant advantages in terms of thermal and electrical performance.

2. What is the Minimum Line Width for Ceramic PCBs?

The minimum line width for ceramic PCBs depends on the specific manufacturing process used. Generally, with advanced processes such as Direct Bonded Copper (DBC) and LTCC (Low-Temperature Co-fired Ceramics), ceramic PCBs can achieve minimum line widths down to 0.05 mm (50 microns). This high precision is essential for meeting the stringent requirements of high-frequency and miniaturized designs, like those used in 5G devices or medical electronics. The actual minimum width may vary depending on the material, design complexity, and production technology.

3. What High-Frequency Applications are Suitable for Ceramic PCBs?

Ceramic PCBs are highly effective in high-frequency applications such as 5G communications, radar systems, and high-speed data transmission. The key advantage of ceramic PCBs in these applications is their low dielectric loss and high thermal conductivity, which allow for efficient signal transmission without interference. In 5G networks, for example, ceramic PCBs can handle the increased data rates and high frequencies (e.g., mmWave) while maintaining signal integrity. Their electrical properties make them ideal for high-speed, high-frequency circuits where traditional PCB materials would struggle to perform.

4. How Do Ceramic PCBs Handle Vibration and Temperature Variations?

Ceramic PCBs excel in environments where vibration and temperature fluctuations are a concern. Thanks to their low coefficient of thermal expansion (CTE), ceramic PCBs maintain their mechanical stability even during rapid temperature changes. This property helps minimize stress at the solder joints, reducing the risk of cracking or failure. Moreover, ceramic PCBs are inherently more resistant to vibration-induced damage, making them ideal for use in automotive, aerospace, and industrial applications that experience extreme environmental conditions. Their durability and reliability in thermal cycling and shock resistance ensure long-term performance in high-reliability sectors.

5. How Environmentally Friendly Are Ceramic PCBs?

Ceramic PCBs are highly environmentally friendly compared to traditional PCBs. The materials used in ceramic PCBs, such as alumina (Al₂O₃) and aluminum nitride (AlN), are naturally non-toxic and recyclable. These materials have low chemical reactivity, which means they don't release harmful substances during disposal or incineration. Additionally, since ceramic PCBs can last longer and provide better thermal management, they contribute to reducing the overall energy consumption of electronic systems. In industries that emphasize sustainability and eco-friendly practices, ceramic PCBs offer a green alternative to conventional PCB materials.