Why Black Core PCBs Are Essential for Thermal Management

Effective thermal management is a critical challenge in high-power electronics. Devices like power supplies, motor drives, and LED lighting systems generate significant heat that, if not properly managed, can degrade performance, shorten component lifespans, and even cause catastrophic failures. Heat accumulation in these systems can destabilize components, leading to signal degradation, efficiency losses, and ultimately device malfunction.

For high-power electronics, controlling temperature is essential to maintain operational stability. Excessive heat can lead to component failure, reduced efficiency, and even the complete breakdown of the system. Managing this heat not only ensures better performance but also extends the life of the device, making it more reliable and cost-effective over time.

The key to solving this problem lies in selecting the right materials and designs for heat dissipation. Black core PCBs, specifically designed for high-power applications, offer superior thermal conductivity compared to traditional materials, making them an ideal solution for managing thermal challenges in high-power electronics.

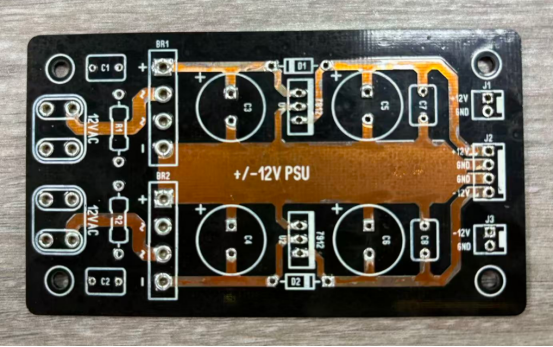

What is Black Core PCB?

Definition and Basic Composition

A Black Core PCB is a type of printed circuit board (PCB) made from a unique composite material that incorporates ceramic-filled epoxy resin. The board gets its characteristic dark color from the addition of carbon-based additives, which help enhance the PCB's thermal conductivity, electrical insulation, and mechanical strength. This specialized construction allows black core PCBs to handle demanding applications, particularly those with high thermal and electrical loads.

Main Materials:

Ceramic Fillers: These are the key component that boosts the thermal conductivity of the board, allowing it to dissipate heat more efficiently than traditional materials.

Epoxy Resin: This provides the structural integrity and adhesive properties needed for the PCB.

Reinforcing Fibers: Typically fiberglass, these fibers strengthen the overall PCB and improve its resistance to physical stress, such as bending or vibration.

In summary, the combination of ceramic fillers, epoxy resin, and reinforcing fibers gives the black core PCB a unique balance of thermal, electrical, and mechanical properties, making it highly suitable for high-power applications.

Comparison with Traditional FR-4 PCB

Traditional FR-4 PCBs are made from glass-reinforced epoxy resin (similar to black core PCB but without the ceramic fillers), which is an industry-standard material used for a wide range of electronic devices. However, FR-4 PCBs have limitations when it comes to heat management.

Thermal Conductivity: FR-4 has a thermal conductivity of 0.2-0.4 W/m·K, which is far lower than black core PCBs, which can achieve 1.0-1.5 W/m·K. This means that black core PCBs are much better at dissipating heat, which is critical in high-power electronics like LED lighting or power supplies.

Heat Management: Due to their low thermal conductivity, FR-4 PCBs struggle to manage the heat generated by high-power devices. This can lead to overheating and performance degradation, especially in power-hungry applications like industrial motor drives or electric vehicle (EV) charging stations.

In contrast, black core PCBs’ superior heat dissipation allows them to handle higher power densities and maintain stable operation over a longer period, making them the preferred choice for demanding applications.

Core Advantages of Black Core PCBs

Black core PCBs have several key advantages that make them stand out in high-performance and high-power applications:

1. High Thermal Conductivity:

The thermal conductivity of black core PCBs (1.0-1.5 W/m·K) is several times higher than that of FR-4 (0.2-0.4 W/m·K). This increased thermal conductivity helps in efficiently spreading heat across the PCB, preventing localized hot spots that could damage sensitive components.

Real-World Example: In a high-brightness LED module, using a black core PCB can help reduce the junction temperature by 15°C compared to a traditional FR-4 design, thus extending the lifespan of the LED by 50%.

2. Exceptional Thermal Stability:

Black core PCBs are designed to operate in high-temperature environments, thanks to their high glass transition temperature (Tg), which ranges from 180-220°C. This makes them ideal for use in electronics that operate in harsh environments, such as industrial motor drives, automotive applications, and solar inverters.

Benefit: The high Tg ensures that the PCB does not deform or soften under high-temperature conditions, maintaining structural integrity and preventing failure even during prolonged thermal stress.

3. Durability Under Extreme Conditions:

With the addition of ceramic fillers and carbon-based additives, black core PCBs not only manage heat efficiently but also provide high mechanical strength. This ensures the PCB remains durable and resistant to thermal cycling, vibration, and physical stress — all of which are common in aerospace, automotive, and industrial settings.

Example: Black core PCBs are often used in electric vehicle (EV) battery management systems (BMS) and charging stations, where they must withstand frequent thermal cycling and high electrical loads without degradation.

Why Can Black Core PCBs Achieve Excellent Thermal Management?

Ceramic-Filled Substrate

One of the key reasons why black core PCBs excel in thermal management is their ceramic-filled substrate. This special material greatly enhances the PCB's ability to manage heat compared to traditional materials like FR-4.

High Thermal Conductivity: The ceramic fillers within black core PCBs provide much higher thermal conductivity than standard FR-4, which helps in quickly transferring heat away from high-heat generating components such as power transistors or LEDs. The improved thermal conductivity allows heat to be spread efficiently across the PCB surface or redirected to external heat sinks or cooling systems.

Efficient Heat Distribution: Ceramic materials are highly effective at diffusing heat, which minimizes the risk of thermal hotspots on the PCB. In high-power applications, such as electric vehicle charging stations or high-wattage power supplies, efficient heat distribution is essential to avoid component failure or performance degradation.

Real-World Example: In an LED lighting system, black core PCBs can transfer heat away from the LED junction more efficiently, reducing the operating temperature and prolonging the lifespan of the LEDs by 50% compared to traditional FR-4 PCBs.

Role of Carbon-Based Additives

The black core of these PCBs owes its color and enhanced performance to carbon-based additives, which are another critical factor in their superior thermal management.

Enhanced Thermal Conductivity: These additives improve the overall thermal conductivity of the PCB, further aiding in heat dissipation. Carbon is a well-known conductor of heat, and its inclusion in the material composition of black core PCBs ensures that heat does not accumulate in one area but is evenly distributed.

Reducing Thermal Accumulation: The carbon-based components also help in reducing thermal accumulation, which prevents temperature spikes that could damage sensitive components. By preventing heat from building up in one spot, the PCB ensures that the entire device operates more efficiently and remains within safe operating temperatures.

Example: In industrial motor drives, where high currents lead to significant heat generation, black core PCBs with carbon-based additives effectively reduce temperature gradients, enhancing the overall thermal performance of the system.

Exceptional Thermal Stability

Another standout feature of black core PCBs is their high glass transition temperature (Tg), which ranges from 180-220°C. This makes them ideal for use in high-temperature environments where traditional materials like FR-4 would fail.

High Tg: The high Tg ensures that the PCB remains structurally stable under high temperatures. It prevents the material from softening, warping, or delaminating, even in extreme conditions. This is particularly important in automotive electronics, LED lighting systems, and industrial applications that require continuous operation in high-temperature environments.

Reliability in Harsh Environments: The high thermal stability makes black core PCBs suitable for applications that involve frequent temperature fluctuations or high thermal stress. For example, solar inverters and electric vehicle systems benefit from the durability and heat resistance provided by the high Tg of black core PCBs.

Case Study: In automotive electronics, such as electric vehicle battery management systems (BMS), black core PCBs endure harsh under-the-hood temperatures (up to 150°C) without deforming, ensuring reliable operation even under continuous thermal stress.

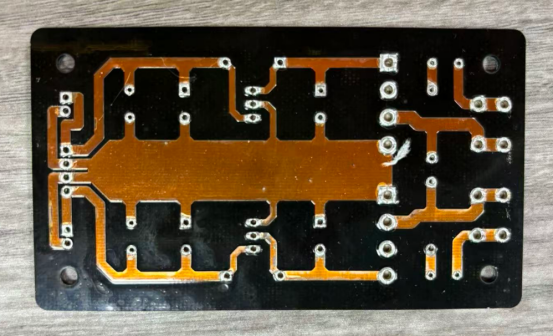

Integration with Thermal Vias and Heat Sink Designs

Black core PCBs are also designed to support thermal vias and heat sink integration, further enhancing their ability to manage heat. These design elements are crucial for maintaining optimal operating temperatures in high-power devices.

Thermal Vias: Thermal vias are small, drilled holes that allow heat to flow from one layer of the PCB to another or to an external heat sink. Black core PCBs can be easily drilled to include these vias, providing direct paths for heat to escape from hot components to cooling planes within the board or to attached heat sinks.

Heat Sink Compatibility: Black core PCBs can be used with metal-based heat sinks to create a more comprehensive cooling solution. The ability to integrate with heat sinks ensures that heat generated by high-power components like power transistors or LED drivers is quickly dissipated, preventing overheating.

Real-World Example: In a high-power LED array, integrating thermal vias into the black core PCB allows heat to be efficiently directed away from the LED components, preventing the overheating that could otherwise cause premature failure. The combination of a ceramic-filled substrate and heat sink design extends the system's lifespan and improves its performance.

Benefits of Excellent Thermal Management with Black Core PCBs

Lower Component Temperatures and Extended Lifespan

One of the most significant benefits of black core PCBs is their ability to maintain stable temperatures, which helps in reducing the thermal stress on sensitive components. By efficiently managing heat, black core PCBs reduce issues like component aging, thermal degradation, and frequency throttling that typically arise in high-temperature environments.

Reduced Heat-Induced Failures: With improved heat dissipation, components are less likely to experience the detrimental effects of overheating, such as performance drops or early failures. This is especially crucial in electronics like LEDs, where high operating temperatures can significantly shorten lifespan.

Example: In high-brightness LED applications, using black core PCBs can keep the operating temperature 15-20°C lower compared to standard FR-4 designs. This temperature reduction extends the LED lifespan by up to 50%, reducing the frequency of replacements and improving overall system reliability.

By keeping the temperature under control, black core PCBs help preserve the integrity of components, allowing systems to perform at optimal levels for longer.

Improved System Efficiency and Reliability

Effective thermal management significantly impacts the overall efficiency and reliability of high-power systems. Black core PCBs help reduce the reliance on external cooling mechanisms such as fans or heat sinks, improving the system's overall energy efficiency.

Reduced Cooling Needs: With better heat dissipation directly at the PCB level, the need for external cooling systems is minimized, reducing system power consumption and enhancing operational efficiency.

Increased Stability and Reliability: In inverters and power modules, the high heat resistance and efficient thermal management provided by black core PCBs lead to a more stable system. Consistent temperatures prevent thermal stress that could otherwise cause component failure or system shutdowns.

Example: In a power inverter system, the use of black core PCBs can enhance efficiency by up to 5% by minimizing heat-related losses, leading to better performance and lower operational costs.

With enhanced thermal management, black core PCBs contribute to both short-term efficiency and long-term reliability, reducing the risk of overheating and improving the stability of the entire system.

Increased Power Density

As devices become more compact, there is a growing need to manage higher power densities without sacrificing reliability or performance. Black core PCBs are designed to handle higher power densities, enabling devices to operate at full power without the risk of overheating.

Handling More Power: By dissipating heat more efficiently, black core PCBs allow for more power to be packed into the same physical space without exceeding thermal limits. This capability is especially important in devices like electric vehicle (EV) charging stations or high-power power supplies, where higher power requirements need to be managed in compact designs.

Example: In electric vehicle (EV) charging systems, black core PCBs can support higher current loads without the need for oversized components. This allows for higher power density within the system while maintaining efficient thermal management.

By increasing power density, black core PCBs help manufacturers meet the demand for compact yet powerful devices without compromising heat control or safety.

Reduced Maintenance and Replacement Costs

Black core PCBs contribute to lower overall maintenance and replacement costs due to their enhanced thermal management capabilities, which reduce the likelihood of failures caused by overheating.

Lower Failure Rates: The efficient heat dissipation provided by black core PCBs reduces the occurrence of heat-induced component failures, which are a common cause of device downtime and expensive repairs or replacements.

Longer Lifespan: With reduced thermal stress and consistent operational temperatures, devices using black core PCBs tend to last longer, leading to lower maintenance and replacement costs over the long term.

Example: In industrial applications, where reliability is critical, black core PCBs can reduce failure rates by 50-70%, helping companies avoid costly downtime and repair cycles. In the automotive sector, using black core PCBs in battery management systems (BMS) ensures that high-performance systems remain operational under extreme conditions, reducing repair or replacement needs.

With fewer failures and extended lifespans, black core PCBs contribute to lower operating costs, particularly in industrial, automotive, and renewable energy applications where reliability is paramount.

Conclusion

Black core PCBs offer exceptional thermal management advantages, making them the ideal choice for high-power and heat-sensitive applications. With superior thermal conductivity, excellent thermal stability, and unique design features, these PCBs efficiently dissipate heat, ensuring the longevity and reliability of components in demanding environments. They play a crucial role in key industries such as LED lighting, industrial power systems, and automotive electronics, providing consistent performance and enhanced system stability.

Looking ahead, as power densities continue to rise and the demand for effective heat dissipation in electronic devices increases, the role of black core PCBs will become even more significant. Engineers and designers will find that selecting black core PCBs is a key step in ensuring efficient thermal management and the long-term stability of high-power devices.

For those seeking high-quality black core PCBs, PCBMASTER offers top-tier solutions designed to meet the rigorous demands of modern electronics, providing reliable, high-performance boards for any high-power or heat-sensitive application.

FAQs

How does the thermal performance of black core PCBs compare to traditional FR-4 PCBs?

Black core PCBs have a thermal conductivity that is 5 times higher than that of FR-4, enabling them to dissipate heat more effectively. This helps prevent overheating and performance degradation, ensuring better thermal management in high-power applications.

How does black core PCB help extend the lifespan of LEDs?

Black core PCBs provide a much lower operating temperature compared to standard materials. This allows LEDs to run at cooler temperatures, reducing thermal stress and thereby extending their lifespan by up to 50% compared to traditional FR-4 PCBs.

What high-power devices are black core PCBs suitable for?

Black core PCBs are ideal for devices that require efficient heat management, such as LED lighting, high-power power supplies, industrial inverters, and electric vehicle charging systems. They ensure optimal thermal performance in these high-power, heat-sensitive applications.

Can black core PCBs handle extreme temperature fluctuations?

Yes, black core PCBs are designed with a high glass transition temperature (Tg) of 180-220°C, allowing them to function stably within a wide temperature range of -40°C to 125°C. This makes them highly reliable in environments with significant temperature variations.

Is the cost of black core PCBs justified?

While black core PCBs have a higher upfront cost compared to FR-4, their exceptional thermal management and longer lifespan lead to long-term savings. The reduction in maintenance, fewer failures, and improved system efficiency make black core PCBs a cost-effective choice for high-power devices in the long run.