5 Top Benefits of Using a Printed Circuit Board Holder in Your Workshop

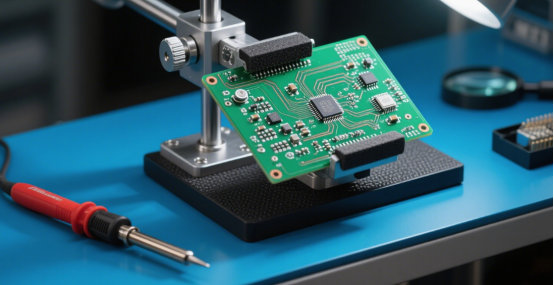

Figure 1: Using Printed Circuit Board Holder in the design and manufacturing process of circuit boards

Printed circuit boards, or PCBs, are the heart of almost every electronic device. From your smartphone to a small DIY gadget, they make the electronics work. But when you are soldering or assembling a PCB, it can be tricky. The board might move, tilt, or slip, making your work harder and less safe.

This is where a Printed Circuit Board Holder, or PCB holder, comes in. It holds the board steady, so you can work more accurately, safely, and efficiently. In this article, we will explore the main benefits of using a PCB holder on your workbench.

What is a Printed Circuit Board Holder

A Printed Circuit Board Holder, or PCB holder, is a tool used to secure a circuit board while you solder, assemble, or inspect it. Without a holder, the PCB can slide, tilt, or wobble, making it hard to work on small components and increasing the risk of mistakes or accidents. A good PCB holder keeps the board stable, allowing you to work more safely and accurately.

PCB holders come in different types and designs.

l Rotating holders let you turn the board freely to reach all sides without removing it.

l Clamp-style holders firmly grip the PCB in a fixed position, which is perfect for precise tasks like soldering tiny resistors or IC chips.

l Multi-functional holders can adjust to fit different board sizes and thicknesses, and some even hold extra tools, like magnifying lenses or soldering irons.

Thus, PCB holders are used by many people.

l DIY electronics hobbyists use them at home for small projects, making soldering easier and safer.

l Electronics engineers rely on them in labs for building prototypes and testing circuits, where precision is important.

l Repair technicians use holders when fixing or modifying devices, reducing the chance of damaging sensitive components.

Benefits of Using a PCB Holder

When working with PCBs, having a holder can make a big difference. It not only makes your work easier but also improves safety, precision, and efficiency. Here are the main benefits explained in detail:

1. Improved Work Efficiency

A PCB holder keeps your circuit board stable and secure, so you don’t need to constantly hold or adjust it with your hands. This makes soldering and assembly much faster and smoother. You can focus on precise work without interruptions. For projects with tiny components or multiple layers, a holder can save significant time and reduce frustration by keeping the board in the exact position you need.

2. Better Soldering Accuracy

When the PCB is held firmly in place, your solder joints are cleaner and more accurate. A stable board prevents components from shifting while soldering, which reduces mistakes and avoids damaging delicate parts like resistors, ICs, or connectors. This ensures your finished circuit is reliable and professional-looking, which is especially important for prototypes or boards that will be used in real devices.

3. Enhanced Safety

A holder prevents the PCB from slipping, tipping, or falling, reducing the risk of burns or injuries while soldering. It also keeps your hands away from hot soldering tips or molten solder, lowering the chance of accidents. Using a PCB holder helps maintain a safer working environment, which is crucial in labs, classrooms, or home workshops.

4. Versatility in Different Work Environments

PCB holders are flexible tools that can be used on workbenches, portable setups, or even in classrooms and labs. They support different board sizes, thicknesses, and designs, making them suitable for a wide range of tasks. Some holders can rotate or tilt, allowing you to access hard-to-reach areas of the board without removing it. This versatility makes them useful for DIY projects, professional prototyping, or educational purposes.

5. Reduced Material Waste

A stable board means less chance of damaging PCBs or components during assembly or soldering. This reduces material waste, saves money, and helps ensure your projects are completed successfully on the first try. By minimizing errors and rework, a PCB holder contributes to higher efficiency and better overall project outcomes.

Figure 2: 5 Top Benefits of Using a PCB Holder

How to Choose the Right PCB Holder

Not all PCB holders are the same, and choosing the right one can make your work easier, safer, and more precise. A good holder ensures your circuit board stays stable while you solder, assemble, or inspect it. Here are some detailed tips to help you pick the best holder for your needs:

1. Match the PCB Size and Thickness

The holder should fit the exact size and thickness of your circuit board. A board that is too big or too small may wobble or slip, making soldering or assembly more difficult and increasing the risk of mistakes. Many holders are adjustable, so check the range of sizes they can hold. For very small or very large PCBs, make sure the holder can secure the board firmly without putting stress on delicate components.

2. Choose the Right Holding Mechanism

PCB holders use different mechanisms to hold a board in place. Some rotate or tilt, which lets you work on different angles without removing the board. This is useful when you need to solder components on the top and bottom or inspect the circuit from multiple sides. Others use multi-point clamps or strong grips for maximum stability, ideal for precise or delicate tasks. Consider the type of work you will do most often and pick a mechanism that matches your workflow and precision needs.

3. Consider the Material

They are made from metal, plastic, or composite materials. Metal holders are very strong and durable, suitable for heavy boards or repeated use, but they can be heavier and less portable. Plastic holders are lightweight and easy to carry, but may not be as stable for heavy boards. Composite holders aim to balance strength and portability, giving you both stability and convenience. Think about your workspace and how you plan to use the holder when choosing the material.

4. Additional Features to Look For

Some of them come with extra features like magnifying lenses, tool trays, or adjustable arms. These can make your work more efficient and comfortable, especially if you spend a lot of time on fine soldering or detailed inspections. Features like non-slip feet or heat-resistant pads can also improve safety and stability.

Best Practices for Using a PCB Holder

Using a PCB holder correctly can greatly improve your work quality and extend the life of both your tools and your circuit boards. Here are some important tips to help you get the most out of your holder:

1. Secure the Board Properly

Always make sure the PCB is firmly and evenly positioned in the holder. The board should be level or slightly tilted depending on your working angle. A stable board prevents slipping or wobbling, which makes soldering or assembly more accurate and less frustrating. For larger boards, consider using holders with extra clamps or supports to ensure the entire board is fully stabilized.

2. Adjust the Holder Gently

When tightening or adjusting any part of the holder, do it slowly and carefully. Avoid using excessive force, as this can bend the PCB or damage delicate components like tiny resistors, ICs, or connectors. Make small incremental adjustments and double-check that the board is secure before starting your work. Gentle handling also protects the holder itself, preventing scratches, stripped screws, or worn clamps.

3. Regularly Check Screws, Clips, and Moving Parts

Over time, screws, clips, or pivot points may loosen due to repeated use. Inspect them regularly and tighten any loose parts. If your holder has rotating or tilting mechanisms, make sure they move smoothly without wobbling. Proper maintenance ensures the holder continues to perform reliably, keeps your boards safe, and prevents accidents or errors during work.

4. Keep the Holder Clean

Dust, solder residue, or small metal particles can accumulate on your holder over time. Clean the holder regularly with a soft brush or cloth to maintain smooth operation and prevent debris from scratching the PCB. Keeping your tools clean also contributes to a safer and more professional work environment.

Conclusion

A PCB holder is a simple tool, but it makes a big difference. It helps you work faster, more accurately, and safely. Whether you are soldering small components or assembling a complex board, a holder keeps your PCB stable and easy to handle.

To improve your work experience, it’s a good idea to have a PCB holder on your workbench or in your lab. If you have any questions about PCBs or need expert advice, contact PCB MASTER. They can provide guidance and solutions to help you work smarter and get better results.

FAQs

1. Can a PCB holder be used for very small or tiny boards?

Yes, many PCB holders are adjustable and can hold very small boards securely. Some multi-functional holders even have extra clamps or pads to keep tiny boards from moving, making soldering much easier.

2. Are PCB holders only useful for soldering?

No, PCB holders are also useful for inspection, testing, and repairs. They keep the board steady while you check connections, measure voltages, or replace components, which helps prevent mistakes and damage.

3. Do PCB holders work for high-temperature soldering?

Yes, most holders are made from heat-resistant materials like metal or high-quality plastics. This allows them to handle the heat from a soldering iron without melting or warping.

4. Can a PCB holder help beginners learn electronics faster?

Definitely. By keeping the board stable and easy to handle, beginners can practice soldering and assembly safely. It reduces frustration, helps them focus on learning, and builds confidence.

5. How do I maintain a PCB holder for long-term use?

You should clean it regularly, check screws and clamps for tightness, and avoid dropping it. If it has moving parts, make sure they move smoothly. Proper care keeps the holder reliable and safe for years.