Automotive PCB Assembly: Ensuring Reliability in Modern Vehicles

The world of cars is changing fast. Modern vehicles are no longer just machines—they are smart devices on wheels. From advanced driver assistance systems (ADAS) to infotainment screens and electric powertrains, cars now rely heavily on electronics to work safely and efficiently.

At the heart of these electronics is the printed circuit board (PCB). A car’s PCB connects all the important parts, allowing signals and power to flow smoothly. Without reliable PCB assembly, even the most advanced car systems can fail, putting safety and performance at risk.

As a result, the automotive electronics market is growing quickly. According to industry data, in 2024, its global value reached $295.42 billion and is expected to rise to $437.84 billion by 2029, growing at a steady 8.5% annually. This rapid growth shows how much cars depend on advanced electronics—and why high-quality PCB assembly is so important.

In this article, we will explore the key technologies, assembly processes, and quality control measures that ensure automotive PCBs are reliable. By understanding these steps, we can see why a well-made PCB is the backbone of modern vehicles.

Why Automotive PCBs Matter

Modern cars are no longer just machines—they are complex electronic systems on wheels. Every advanced feature, from driver assistance to entertainment, depends on electronic circuits. At the heart of these circuits is the automotive PCB, which ensures that signals and power flow correctly between components. Let’s explore in detail why automotive PCBs are so important.

1. Complexity of Automotive Electronics

Modern vehicles are packed with advanced systems. For example:

l Smart driving features like lane-keeping assist, adaptive cruise control, and automatic emergency braking rely on sensors, cameras, and processors. Each of these components needs a well-designed PCB to communicate accurately.

l Infotainment systems and navigation units require PCBs that can handle multiple signals simultaneously without interference.

Because of this complexity, automotive PCBs must manage a high volume of electrical signals in a very small space. Poorly designed or assembled PCBs can cause system errors, malfunctions, or complete failure of key vehicle functions.

2. Reliability and Safety Requirements

Safety is the most important concern in modern vehicles, and automotive PCBs play a direct role in protecting passengers. Critical systems like braking, airbags, and engine control units all rely on well-assembled circuits. A failure in these components can have serious consequences.

PCBs in cars must operate continuously under changing conditions, from stop-and-go city traffic to long highway drives. High-quality assembly ensures strong electrical connections, reduces the risk of short circuits or signal loss, and keeps the vehicle’s systems functioning reliably.

3. High Performance and Durability Needs

Vehicles experience harsh environmental conditions that PCBs must withstand:

l Temperature extremes: From freezing winters to hot engine compartments, PCBs must function without warping or degrading.

l Mechanical stress: Vibrations, bumps, and shocks from the road can damage poorly made circuits.

l Humidity and corrosion: Moisture and chemicals can cause PCB damage over time.

To meet these challenges, automotive PCBs are made with durable materials, advanced coatings, and precise assembly methods. This ensures that even under long-term stress, the electronics remain functional and reliable.

Key Processes in Automotive PCB Assembly

Automotive PCBs are carefully assembled using multiple processes to ensure they are reliable, durable, and capable of handling complex electronic functions. Each step plays a critical role in making sure the vehicle’s systems work correctly.

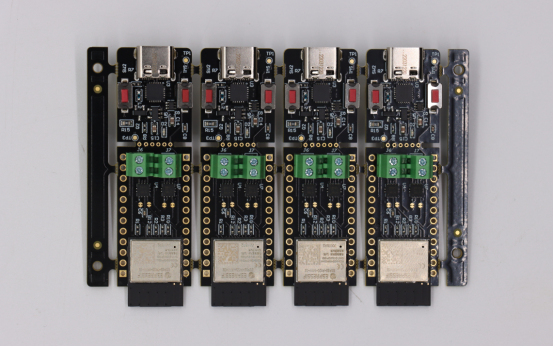

1. Surface Mount Technology (SMT)

Surface Mount Technology, or SMT, is the process of placing electronic components directly onto the surface of a PCB. This method is essential for high-density boards, where many small components need to fit into limited space. SMT allows for precise placement, which is critical for signal accuracy and overall board reliability.

High-density SMT assembly ensures that all components are connected properly, reducing the risk of electrical faults. It also helps maintain signal integrity, which means the electronic signals travel accurately from one component to another without interference. This process is especially important in modern automotive electronics, where speed and accuracy of signal transmission are crucial.

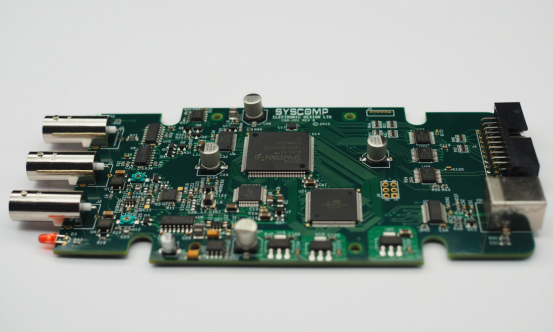

2. Through-Hole Technology (THT)

Through-Hole Technology involves inserting component leads into pre-drilled holes on the PCB and then soldering them. This method is particularly useful for parts that experience mechanical stress or carry higher power, such as connectors, power modules, and certain sensors.

Through-hole assembly provides stronger mechanical support compared to surface-mounted components. It ensures that heavy or high-stress parts remain securely attached even under vibration or shock, which is common in automotive environments.

3. Soldering Processes

Soldering is the process that permanently connects components to the PCB. Two main soldering techniques are used in automotive assembly: reflow soldering for SMT components and wave soldering for through-hole components.

Controlling the soldering process is vital. Proper temperature profiles and timing ensure that each joint is strong and reliable. High-quality soldering reduces the risk of cracks or cold joints, which can lead to failure over time. Well-executed soldering ensures that the PCB can perform reliably for many years under harsh automotive conditions.

4. Rigid-Flex PCB Assembly

Rigid-Flex PCBs combine rigid and flexible sections in a single board. This design allows PCBs to fit into tight spaces or areas that move during vehicle operation. Rigid-Flex assembly requires careful handling and precise placement to prevent damage.

These boards are ideal for modern vehicles, where space is limited and electronic systems need to bend or twist without breaking connections. Proper assembly of Rigid-Flex PCBs is critical to maintain performance and durability in dynamic environments.

5. Testing and Inspection

Testing and inspection are the final, but equally important, steps in automotive PCB assembly. Various methods are used to ensure every board works correctly. Automated Optical Inspection (AOI) checks for misaligned or missing components. In-Circuit Testing (ICT) measures electrical performance at specific points. Functional testing verifies that the PCB operates as intended in a simulated automotive environment.

Thorough testing helps detect and fix any issues before the PCB is installed in a vehicle. This step is crucial for maintaining safety, reliability, and long-term performance of automotive electronics.

Measures to Ensure Reliability

Ensuring the reliability of automotive PCBs is essential because cars operate in challenging environments and electronics must function flawlessly for years. Manufacturers use a combination of material selection, strict standards, adaptive design, quality control, and rigorous testing to achieve this goal.

1. Material Selection

The choice of materials has a direct impact on PCB performance. Automotive PCBs are exposed to high temperatures inside engine compartments, continuous vibrations from road conditions, and frequent temperature changes from day to night or across seasons. Using low-quality materials can result in warping, cracking, or loss of electrical connectivity over time.

Manufacturers select materials with high heat resistance, strong mechanical durability, and low thermal expansion. Heat-resistant substrates prevent boards from deforming, while materials with low thermal expansion ensure that components remain securely attached during temperature fluctuations. Strong mechanical durability allows the PCB to withstand vibrations and shocks, keeping critical automotive systems operational.

2. Process Standards and Certification

Automotive PCBs must be produced following strict industrial standards. Standards like IPC guidelines, ISO 9001, and IATF 16949 set rules for every stage of design, production, and quality management.

Adhering to these standards ensures consistent product quality and reduces the risk of failures. For example, IPC standards define how traces and solder joints should be designed to handle current loads safely. ISO 9001 ensures that quality management processes are followed, and IATF 16949 focuses specifically on automotive industry requirements. Together, these certifications guarantee that PCBs meet the high expectations of modern vehicles.

3. Environmentally Adaptive Design

Automotive PCBs must perform reliably in moist, hot, or electrically noisy environments. Designers take steps to protect boards from moisture, corrosion, and electromagnetic interference (EMI).

Protective coatings can prevent water or chemicals from causing short circuits. Shielding and careful layout help minimize EMI, which can disrupt signals in sensitive automotive electronics. Additionally, designers plan the PCB layout to reduce thermal hotspots, ensuring that heat does not damage components. By adapting the design to environmental challenges, PCBs remain stable and functional under real-world conditions.

4. Quality Control

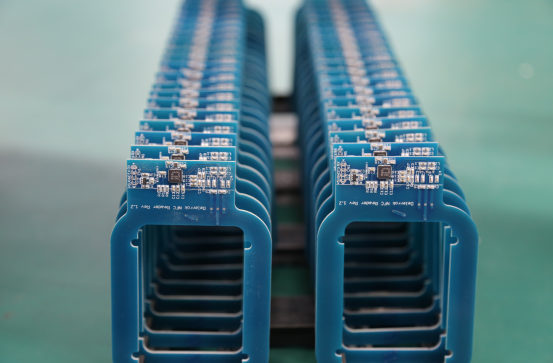

Quality control is applied at every stage of PCB production. From selecting components to assembling boards and final testing, manufacturers monitor each step carefully.

During production, automated inspections detect misaligned or missing components. Soldering is monitored to ensure strong, consistent connections. After assembly, PCBs undergo functional tests to verify that all circuits work correctly. By controlling quality throughout the entire process, manufacturers reduce the risk of defects and ensure that each PCB meets reliability standards before installation in vehicles.

5. Lifetime and Reliability Testing

Before automotive PCBs are installed, they undergo rigorous reliability tests to simulate real-world conditions. Accelerated aging tests replicate years of use in a short time, exposing the board to high heat, humidity, and electrical load. Thermal cycling tests subject the PCB to repeated heating and cooling to identify potential failure points. Mechanical shock tests simulate vibrations and impacts from driving on rough roads.

These tests confirm that the PCB can withstand harsh conditions over the vehicle’s lifetime. Only boards that pass all reliability tests are approved for use, ensuring the electronics remain safe and functional for years.

Conclusion

Automotive PCB assembly plays a critical role in the reliability of modern vehicles. Every electronic system, from safety features to infotainment, depends on well-assembled PCBs to function correctly. Without careful design, high-quality materials, precise assembly, and thorough testing, vehicles could face failures that affect both performance and safety.

High-quality assembly, strict process control, and comprehensive testing ensure that automotive PCBs can withstand harsh conditions, deliver consistent performance, and support the advanced electronics that drivers rely on every day.

If you want to learn more about automotive PCBs or have any questions about PCB design and assembly, feel free to contact PCB MASTER, a professional PCB supplier dedicated to providing reliable solutions for modern automotive electronics.

FAQs

1. What is the difference between automotive PCBs and regular PCBs?

Automotive PCBs are designed to handle tough conditions that regular PCBs might not face. Cars experience extreme temperatures, vibrations, humidity, and electrical interference. Automotive PCBs use special materials and coatings to survive these challenges. They are also tested more thoroughly to ensure long-term reliability. Regular PCBs, like those in home electronics, don’t need this level of durability.

2. Why do cars need both SMT and through-hole components?

Cars use both because each type has its advantages. SMT (Surface Mount Technology) allows for compact, high-density circuits, which is perfect for modern electronics like sensors and control boards. Through-hole components are stronger and more durable, making them ideal for heavy or high-stress parts like connectors or power modules. Using both ensures the PCB is both precise and mechanically strong.

3. How do automotive PCBs handle electrical interference?

Electrical interference, or EMI, can disrupt signals in a car’s electronics. To prevent this, automotive PCBs use shielding, proper layout design, and protective coatings. Components are placed carefully to reduce crosstalk between circuits, and sensitive parts may be surrounded by metal shields. These measures help ensure that signals stay clean, so features like braking systems and sensors work reliably.

4. Can automotive PCBs be repaired if they fail?

Minor issues, like a broken solder joint or damaged trace, can sometimes be repaired in a lab using special tools and soldering techniques. However, many modern automotive PCBs are complex and compact, making repairs difficult or risky. Often, replacing the entire PCB is safer and ensures long-term reliability and safety. That’s why high-quality assembly and testing are so important before a PCB is installed.

5. How do manufacturers test automotive PCBs for safety and performance?

Manufacturers perform several tests to make sure a PCB will last for years under tough conditions. They use thermal cycling to simulate extreme temperature changes, mechanical stress tests to simulate road vibrations, and functional tests to check all circuits. Accelerated aging tests can mimic years of use in just a few weeks. These tests ensure the PCB is safe, reliable, and ready for real-world driving.