Aluminum Printed Circuit Boards: Tips for High-Performance Electronics

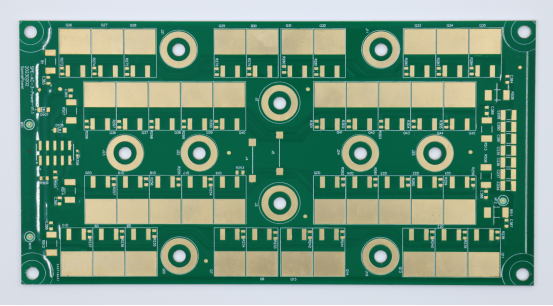

Aluminum printed circuit boards (PCBs) have become a cornerstone of high-performance electronics, offering superior thermal management, mechanical strength, and reliability compared to traditional FR-4 boards. Widely used in LED lighting, power electronics, automotive systems, and industrial applications, aluminum PCBs help engineers manage heat effectively while maintaining compact, durable designs. In this guide, we provide practical tips on design, manufacturing, and optimization strategies to help you maximize the performance and lifespan of your aluminum PCB projects.

Introduction to Aluminum Printed Circuit Boards

What Are Aluminum PCBs?

Aluminum PCBs are printed circuit boards that use an aluminum or metal substrate instead of standard FR-4. This design allows for efficient heat dissipation, making them ideal for high-power or high-temperature applications.

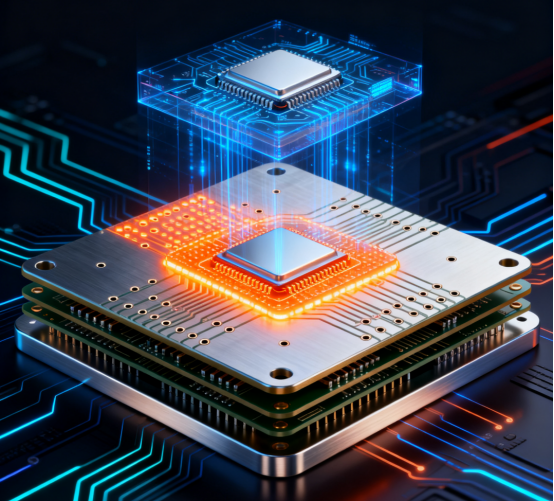

Key components of aluminum PCBs include:

l Aluminum core: Provides mechanical support and spreads heat efficiently.

l Dielectric layer: Electrically isolates copper traces from the metal substrate while transferring heat.

l Copper traces: Conduct electrical signals between components, similar to standard PCBs.

Example: Aluminum PCBs are widely used in LED lighting, power electronics, and automotive control boards because they maintain stable temperatures and prevent component overheating.

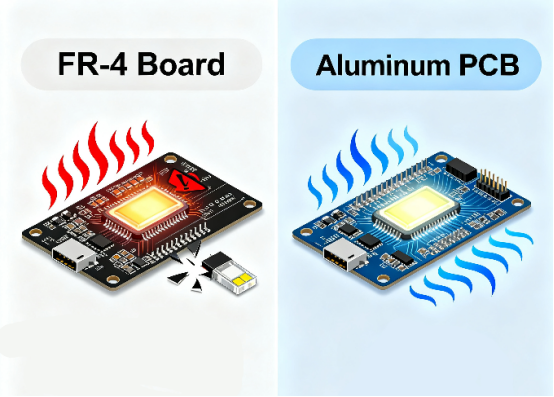

Advantages Over Standard FR-4 PCBs

Aluminum PCBs offer several benefits over traditional FR-4 boards, especially in high-performance applications:

l Superior thermal management: The aluminum core efficiently spreads and dissipates heat from high-power components, reducing the risk of overheating.

l Increased mechanical stability: Aluminum provides a rigid, durable substrate that can withstand vibrations and thermal cycling better than FR-4.

l Longer lifespan: Components mounted on aluminum PCBs typically experience lower thermal stress, improving reliability.

Comparison example: A high-power LED module using a standard FR-4 PCB may suffer from hotspots and reduced lifespan. Replacing it with an aluminum PCB allows the module to operate at higher brightness without overheating, while maintaining stable performance over time.

Key Applications of Aluminum PCBs

LED Lighting and Displays

Aluminum PCBs are widely used in LED lighting and display applications because effective heat dissipation is critical for maintaining long lifespan and consistent brightness. High-power LEDs generate significant heat, and traditional FR-4 boards often cannot manage thermal stress effectively.

Examples:

l Streetlights: Aluminum PCBs prevent overheating, ensuring LEDs maintain brightness over years of operation.

l High-power spotlights and panel lights: Aluminum substrates enable compact designs without thermal hotspots.

By transferring heat away from LED chips efficiently, aluminum PCBs reduce the risk of premature failure and color shifting in lighting devices.

Power Electronics

In power electronics, aluminum PCBs help maintain reliability under high current and temperature conditions. They are used in:

l Motor controllers for industrial and consumer applications

l Power supplies for computers, servers, and appliances

l Inverters for renewable energy systems like solar panels

Why aluminum PCBs excel here:

l High thermal conductivity spreads heat from power components quickly.

l Reduced thermal stress increases component reliability and overall device lifespan.

Example: A server power supply with an aluminum PCB can handle higher currents without overheating compared to an FR-4 board, reducing downtime and maintenance costs.

Automotive and Industrial Applications

Automotive and industrial environments demand PCBs that withstand vibration, temperature fluctuations, and mechanical stress. Aluminum PCBs provide the necessary mechanical strength and thermal stability.

Examples:

l Electric vehicle motor drivers: Aluminum PCBs manage heat from high-current power transistors while enduring vibrations.

l Industrial sensor boards: Maintain performance in high-temperature, high-vibration factory environments.

By combining thermal management and rigidity, aluminum PCBs ensure reliable operation in demanding automotive and industrial applications.

Design Considerations for High-Performance Aluminum PCBs

Thermal Management

Effective thermal management is the most critical aspect of designing high-performance aluminum PCBs. Proper heat dissipation prevents component failure and ensures long-term reliability.

Key practices:

l Layer stack-up and thermal vias: Plan multiple layers to optimize heat flow from components to the aluminum core.

l Step-by-step approach:

1. Copper thickness: Thicker copper improves heat conduction.

2. Dielectric selection: Choose a dielectric material with high thermal conductivity.

3. Aluminum core: Acts as the primary heat sink for the entire PCB.

Example: High-power LED modules use thermal vias connecting the LED pads directly to the aluminum substrate, efficiently removing heat.

Component Placement

Strategic component placement reduces thermal hotspots and improves electrical performance.

Guidelines:

l Place heat-generating components near thermal vias or directly above aluminum areas.

l Separate high-power and sensitive low-power components to avoid thermal interference.

l Avoid clustering components that create localized heat buildup.

Example: In power supply boards, MOSFETs are placed above aluminum areas with sufficient vias, ensuring stable temperature during high-current operation.

Trace Routing and Impedance Control

Consistent trace design is essential for high-speed and high-power aluminum PCBs.

Best practices:

l Maintain consistent trace width and spacing to handle current loads and minimize resistance.

l Implement controlled impedance where high-speed signals are present, ensuring signal integrity.

l Minimize long parallel traces that can cause crosstalk or EMI issues.

Example: Communication modules on aluminum PCBs may route high-speed signals with microstrip layers above the aluminum core, carefully controlling impedance.

Mechanical and Electrical Reliability

Aluminum PCBs must endure thermal cycling, vibrations, and mechanical stress in demanding applications.

Key practices:

l Use proper mounting techniques and board supports to reduce mechanical strain.

l Reinforce solder pads for high-power components.

l Add stiffeners or additional support for large or heavy components.

Example: Electric vehicle motor driver boards often incorporate reinforced pads and aluminum stiffeners to prevent solder fatigue under constant vibration and heat.

Manufacturing Tips for Aluminum PCBs

Material Selection

Choosing the right materials is critical to balance thermal performance, mechanical strength, and board flexibility.

Key considerations:

l Dielectric thickness: Thinner dielectrics improve heat transfer but may reduce insulation.

l Copper weight: Heavier copper increases current capacity and thermal conductivity but adds cost.

l Aluminum alloy type: Different alloys offer varying thermal and mechanical properties.

Trade-offs:

l High thermal conductivity may reduce board flexibility.

l Selecting the optimal combination depends on application requirements, such as LED lighting, power electronics, or automotive modules.

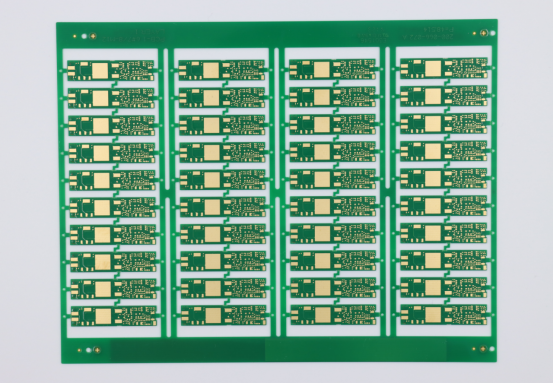

Assembly Considerations

Aluminum PCBs require careful assembly due to the metal substrate.

Best practices:

l SMT and through-hole compatibility: Ensure both technologies are supported for mixed-component boards.

l Fine-pitch components: Special attention is needed for BGA, QFN, and 01005 packages to avoid soldering defects.

l Heat management during assembly: Avoid excessive heat that could warp or delaminate the aluminum substrate.

Example: High-power LED boards often combine SMT LEDs with through-hole connectors, requiring precise reflow and soldering control.

Testing and Quality Assurance

Rigorous testing ensures reliability and performance in high-power applications.

Key steps:

l Prototype testing: Verify thermal performance, electrical functionality, and solder integrity.

l Burn-in tests: Stress boards under elevated temperature and load to identify early failures.

l Batch production QA: Use AOI (Automated Optical Inspection) and X-ray inspection to detect hidden defects.

Example: A server power supply PCB may undergo prototype thermal testing, followed by a burn-in at 85°C and full AOI/X-ray inspection before full-scale production.

Cost and Efficiency Considerations

Comparing Aluminum vs FR-4 Boards

When evaluating aluminum PCBs, it’s important to consider both upfront costs and long-term benefits.

Key points:

l Upfront material cost: Aluminum PCBs are generally more expensive than standard FR-4 due to metal substrates and specialized manufacturing.

l Lifecycle benefits: Improved thermal management and reliability reduce failures, maintenance, and replacements, which can offset the initial cost.

Example: A high-power LED board using FR-4 may fail prematurely due to overheating, requiring replacement or rework. The same board using an aluminum PCB maintains performance for years, saving overall lifecycle cost despite higher initial investment.

Manufacturing Best Practices to Reduce Cost

Optimizing the manufacturing process can lower costs while maintaining performance.

Best practices:

l Standardize component packages: Using commonly available sizes reduces sourcing costs and assembly errors.

l Optimize layout: Minimize copper and board area where possible without compromising performance to save material.

l Early DFM review: Conduct a Design for Manufacturability review to identify spacing, placement, and routing issues before production, reducing rework and scrap.

Example: By standardizing components and performing early DFM checks, a power electronics PCB manufacturer reduced rework rates by 30%, saving both time and cost.

Future Trends in Aluminum PCB Technology

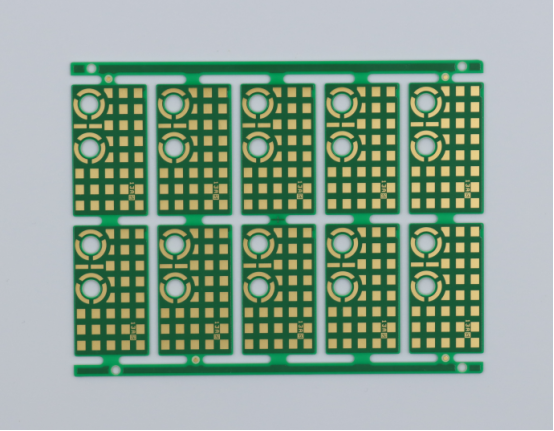

Thinner and Flexible Aluminum PCBs

As electronic devices become more compact and versatile, thinner and flexible aluminum PCBs are gaining popularity. These boards maintain the thermal efficiency and mechanical stability of standard aluminum PCBs while enabling new form factors.

Applications:

l Compact LED modules: Smaller size without compromising heat dissipation.

l Foldable or wearable electronics: Boards can bend or flex to fit non-traditional shapes.

Example: Flexible LED panels or wearable sensors use thin aluminum substrates to achieve both durability and lightweight design.

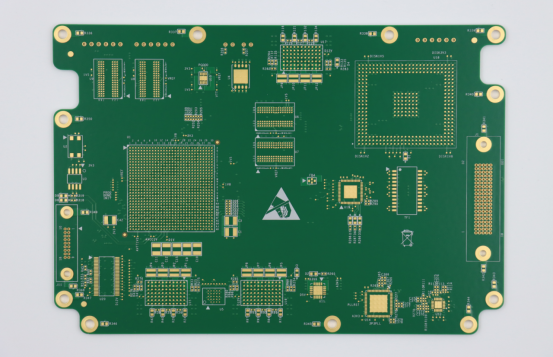

Integration with High-Speed Electronics

The rise of high-speed circuits demands that aluminum PCBs support fine-pitch components and HDI (High-Density Interconnect) technology.

Key points:

l HDI layers and microvias allow more interconnections in smaller areas.

l Fine-pitch ICs can be mounted on aluminum substrates with precise thermal and mechanical design.

Example: High-speed communication modules or compact motor controllers combine aluminum cores with HDI layouts to maintain signal integrity and heat dissipation simultaneously.

Sustainable and Lead-Free Manufacturing

Environmental and regulatory pressures are driving the adoption of sustainable aluminum PCB manufacturing practices.

Best practices:

l Lead-free soldering: Compliant with RoHS standards, reducing environmental impact.

l Recyclable materials: Aluminum cores and copper layers can be recycled efficiently.

l Energy-efficient processes: Optimized reflow and soldering techniques reduce energy consumption.

Example: Modern LED manufacturers adopt lead-free solder and recyclable aluminum cores to produce boards that meet both performance and environmental standards.

Conclusion

Aluminum PCBs offer high thermal efficiency, robust mechanical stability, and long-term reliability, making them ideal for demanding electronics applications. By focusing on thermal management, component placement, trace routing, and thorough testing, designers can achieve boards that perform consistently under high power and high-temperature conditions. Choosing the right materials, following best manufacturing practices, and collaborating with experienced PCB partners ensures your projects meet performance goals while minimizing rework and cost.

For reliable, high-performance aluminum PCB solutions, contact PCBMASTER today. Our expert engineering support, precision manufacturing, and turnkey services help turn your designs into durable, efficient, and high-performing electronic boards.

FAQs

Can aluminum PCBs be used for flexible or bendable electronics?

Yes, aluminum PCBs can be designed for flexibility, though traditional aluminum PCBs are rigid. Manufacturers achieve bendable designs by:

l Using thinner aluminum substrates to reduce stiffness.

l Incorporating flexible dielectric layers that allow slight bending without damaging copper traces.

l Designing rigid-flex hybrid boards, where certain sections remain rigid for components, and others can bend.

Applications: Wearable devices, foldable LED modules, and compact sensors where space constraints require a slightly flexible PCB while maintaining thermal efficiency.

How do thermal vias in aluminum PCBs improve performance?

Thermal vias are vertical copper-filled holes that transfer heat from surface-mounted components directly to the aluminum core.

Benefits:

l Enhanced heat dissipation: Reduces localized hotspots under high-power components.

l Improved component reliability: Lower junction temperatures prevent premature failure.

l Optimized board performance: Supports higher current and power densities without thermal degradation.

Example: High-power LEDs use thermal vias beneath the diode pads to transfer heat efficiently to the aluminum substrate, maintaining brightness and extending lifespan.

What are common mistakes when designing high-power aluminum PCBs?

Designing high-power aluminum PCBs requires careful attention. Common mistakes include:

l Insufficient thermal vias or poor via placement, leading to hotspots and component failure.

l Incorrect copper thickness, which can reduce heat spreading or limit current capacity.

l Clustering high-power components without thermal separation, causing thermal interference.

l Ignoring mechanical stress, resulting in solder joint cracks under vibration or thermal cycling.

l Neglecting controlled impedance in high-speed traces, causing signal integrity issues.

Tip: Early DFM (Design for Manufacturability) reviews and thermal simulations can prevent these issues.

How does aluminum PCB thickness affect thermal dissipation?

Aluminum PCB thickness directly impacts heat conduction and mechanical stability:

l Thicker aluminum layers: Better thermal spreading and mechanical rigidity, ideal for high-power or high-vibration applications.

l Thinner aluminum layers: Allow compact or flexible designs but reduce heat dissipation capacity.

Example: A 1.5 mm thick aluminum PCB dissipates heat more effectively than a 0.8 mm board in the same LED application, allowing higher power operation without overheating.

Are aluminum PCBs recyclable or environmentally friendly?

Yes, aluminum PCBs are more environmentally friendly than many traditional PCBs:

l Aluminum cores can be recycled multiple times, reducing material waste.

l Copper and dielectric layers can also be recovered with proper PCB recycling processes.

l Lead-free soldering and RoHS-compliant materials further reduce environmental impact.

Example: Modern LED manufacturers use lead-free aluminum PCBs with recyclable aluminum cores to meet sustainability and regulatory standards while maintaining high thermal performance.