PCB Assembly First Article Verification A Complete Guide to Photo, Sample, and No Verification

Introduction

In electronics manufacturing, a single small error can lead to massive product recalls. First article verification serves as the first line of defense against such disasters.

In PCB assembly (PCBA), First Article Inspection (FAI) represents a critical phase of quality control. The “first article” refers to the initial units produced at the start of each shift or following any process change, typically involving inspection of at least 3-5 samples. These verification processes are built to ensure quality and reliability in PCB assembly.

This inspection aims to prevent mass production defects by identifying issues early, thus avoiding large-scale rework or complete scrap. In high-stakes industries like automotive electronics, first article inspection is considered absolutely essential. A key point of first article verification is its role in reducing risk and ensuring compliance with industry standards.

Currently, a range of three primary verification methods exist: photo verification, physical sample verification, and no verification. For example, in one case, physical sample verification proved especially effective in catching a critical soldering defect before mass production. These methods address different manufacturing needs, each with its own advantages and disadvantages. What are the respective advantages and disadvantages of each approach?

The Critical Importance of First Article Verification

First article inspection functions as an active, preventative quality control measure, addressing changes in any elements of the 5M1E framework (Man, Machine, Material, Method, Measurement, and Environment).

When production lines experience equipment adjustments, personnel changes, material substitutions, or process modifications, first article inspection helps manufacturers understand whether these changes adversely affect product quality.

The GB/T19001-2016 “Quality Management System Requirements” standard emphasizes that organizations must conduct production and service provision under controlled conditions—first article inspection serves as a key method to fulfill this requirement.

By inspecting the initial units from each production batch, manufacturers can promptly detect systematic issues such as severe tooling wear, degraded measurement instrument accuracy, drawing misinterpretations, or incorrect material usage, thereby preventing batch-level nonconformities.

Photo Verification Method

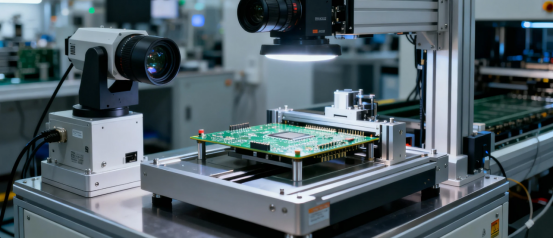

Photo verification involves digital image transmission for first article validation. Operators can use mobile devices to capture and send verification images, making the process more flexible. Photo verification can also be conducted over the web, allowing for remote collaboration. Operators send photographs of initial production units to relevant personnel or clients for confirmation.

Advantages

Convenience and real-time capability represent the most significant benefits of photo verification. Operators can simply send images for verification, making the process straightforward. Compared to traditional physical sample shipping, digital images can reach any global destination almost instantly, dramatically shortening the confirmation cycle. Once the images are received, the recipient is ready to review and confirm the first article.

This approach also significantly reduces confirmation costs by eliminating logistics expenses and minimizing production interruptions—particularly advantageous for international collaborations.

Modern technology further enhances the reliability of photo verification. When integrated with AI-powered visual inspection systems, users can train the system to automatically examine received components and circuit boards, determining whether products meet specified requirements.

Limitations and Drawbacks

Authenticity concerns present the primary risk with photo verification. Images may not comprehensively or accurately represent product conditions due to factors like camera angles, lighting conditions, or potential digital manipulation. It can also be challenging to find subtle defects that may not be visible in the provided images.

Additionally, this method lacks physical verification capability, making functional testing—such as evaluating solder joint strength or electrical performance—impossible through images alone. Photo verification cannot remove all uncertainties regarding product functionality.

Furthermore, photo verification heavily depends on photographic quality. Missing details may lead to misinterpretations, necessitating strict shooting standards and verification protocols.

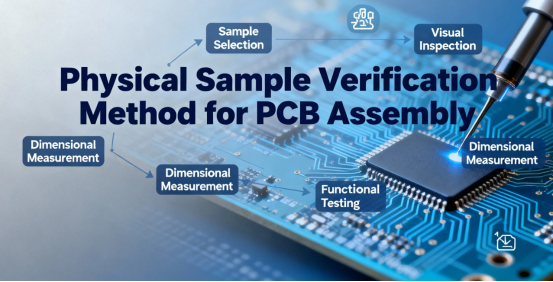

Physical Sample Verification Method

Physical sample verification represents the traditional approach, where actual first articles are shipped to customers or quality departments for hands-on examination. It is important that the physical sample is representative of the entire production batch to ensure accurate assessment. Additionally, you should set clear criteria for sample verification to maintain consistency and reliability in the evaluation process.

Key Benefits

Sample verification provides unmatched authenticity, allowing decision-makers to directly observe, handle, and even test physical samples, which serve as the source of truth for verifying product quality and obtaining comprehensive and accurate product information.

This method lowers communication barriers, as parties don’t require specialized skills to interpret technical drawings or photographs, instead making assessments based on direct physical examination.

For complex assemblies or products requiring functional validation, sample verification often remains the only reliable approach. For instance, verifying BGA soldering quality typically requires X-ray inspection of internal solder balls—a procedure demanding physical samples.

Cost and Practical Challenges

Substantial time investment constitutes the main drawback of sample verification. International shipping may require days or even weeks, during which production lines often sit idle, resulting in capacity losses.

Equally important are the logistics and sample production costs, particularly for large or high-value products where multiple shipping cycles generate considerable expenses.

Additionally, the process carries inherent risks of sample damage or loss during transit, potentially causing production delays and impacting delivery schedules. It is also essential to securely store physical samples for future reference or quality audits.

No Verification Approach

Some manufacturers opt to skip first article verification entirely, prioritizing production efficiency or cost reduction. However, skipping verification can convert immediate production gains into potential long-term risks, such as increased defects or compliance issues.

Potential Risks and Fraud Detection

Skipping verification essentially forfeits the opportunity to prevent batch-quality issues. When problems surface in subsequent processes or reach end customers, correction costs increase exponentially.

Documented cases illustrate this risk: one factory neglected measurement steps in first article inspection, leading to incorrect installation of 18mm sleeves and resulting in mass nonconformity. Such preventable errors, when multiplied by skipping verification, can cause devastating losses.

More seriously, quality failures may inflict long-term brand reputation damage, as customer doubts about supplier capabilities can jeopardize future business opportunities.

Appropriate Applications

Despite the inherent risks, skipping verification may be justifiable in specific circumstances: mature and stable manufacturing processes, simple product structures with extensive production history, or low-value, fast-moving consumer goods with minimal quality requirements.

For extremely time-sensitive small batch production, companies might choose to bypass verification after careful risk assessment—though this decision should be grounded in substantial experience and process confidence.

Verification Using Search Images

Verification using search images has become an essential solution for businesses seeking to enhance security, prevent fraud, and verify identity in an increasingly digital world. By leveraging image search technology, companies can quickly search images online to confirm the authenticity of users, products, or documents—without always relying on traditional phone verification or phone numbers. This process is especially valuable for fraud detection, as it allows businesses to detect suspicious activity and protect both their brand and their customers from potential threats.

For example, in online onboarding or customer registration, businesses can request users to upload an image for verification. The system then conducts an image search to compare the uploaded image against trusted databases, helping to verify identity and detect fraudulent attempts. This not only streamlines the verification process but also ensures compliance with regulatory requirements, safeguarding sensitive data and maintaining customer trust.

By integrating image search into their verification processes, businesses can create a more secure online environment, reduce the risk of errors, and protect themselves and their customers from fraud. Ultimately, search images technology empowers companies to comply with industry standards while delivering a seamless and secure experience for users.

Label Scanning in Verification

Label scanning plays a pivotal role in modern verification processes, particularly in industries where product authenticity and traceability are paramount, such as wine production and pharmaceuticals. By utilizing advanced label scanning technology, businesses can upload images of product labels, which are then verified against a database of authenticated labels. This process enables companies to quickly identify genuine products, detect counterfeit items, and ensure that only verified goods reach customers.

The use of images in label scanning not only enhances security but also streamlines the inspection and verification process. Automated comparison tools reduce the need for manual inspection, minimizing human error and accelerating the verification workflow. For customers, this means greater confidence in the products they purchase, knowing that businesses are actively working to protect them from counterfeit goods.

Moreover, label scanning helps businesses comply with regulatory requirements by providing a reliable method for product verification and traceability. In the wine industry, for example, label scanning ensures that only authentic bottles are distributed, protecting both the brand and the consumer. By integrating label scanning into their verification processes, businesses can strengthen their security measures, improve customer trust, and maintain compliance with industry standards.

Consulting Services for PCB Assembly Verification

Consulting services for PCB assembly verification offer businesses a comprehensive approach to ensuring the quality and reliability of their electronic products. These services typically involve a detailed inspection and verification process, where experts use image search technology to analyze images of PCB assemblies. By searching and comparing these images, consultants can quickly identify defects, errors, or counterfeit components that might otherwise go undetected.

Through this process, consulting services help businesses detect issues early, recommend corrective actions, and enhance their overall PCB assembly processes. This not only improves product quality but also helps companies maintain compliance with industry regulations and standards. By leveraging image search and inspection tools, businesses can protect their reputation, reduce the risk of costly errors, and build stronger relationships with their customers.

Additionally, consulting services provide valuable insights that enable businesses to continuously improve their verification processes, ensuring that each PCB assembly meets the highest standards of quality and reliability. By partnering with trusted consultants, companies can enhance their verification capabilities, safeguard their brand, and build lasting customer trust.

Streamlining the Production Process

Streamlining the production process is vital for businesses aiming to stay competitive and responsive in today’s global market. By incorporating image search technology into their operations, companies can automate key aspects of production, such as inspection, verification, and quality control. This automation allows businesses to search and analyze images in real time, quickly identifying errors and ensuring that only high-quality products reach customers.

The ability to rapidly detect and correct issues not only reduces production time but also minimizes costly mistakes, leading to higher conversion rates and improved customer satisfaction. As businesses enhance their processes, they can expand into new territories, strengthen their brand reputation, and build long-term relationships with their customers.

Furthermore, streamlining production with image search technology enables companies to focus on innovation and customer engagement, rather than being bogged down by manual inspection tasks. This shift not only drives operational efficiency but also positions businesses for growth, helping them to reach new markets and deliver exceptional value to their customers. By embracing these advanced tools, companies can build a more agile, efficient, and customer-centric production process.

Comparative Analysis

To better illustrate the differences among these verification methods, here’s a table that helps group the verification methods for easier comparison:

| Verification Method | Cost Investment | Time Efficiency | Risk Control | Suitable Scenarios |

|---|---|---|---|---|

| Photo Verification | Medium | High | Medium | Design changes, remote collaboration, short-cycle projects |

| Sample Verification | High | Low | High | Complex components, new suppliers, high-reliability products |

| No Verification | Low | Highest | Low | Mature processes, simple products, low quality requirements |

This table can help fill knowledge gaps regarding the strengths and weaknesses of each method.

From a quality assurance perspective, sample verification provides the most comprehensive validation. Regarding efficiency, no verification offers the fastest approach. Photo verification strikes a balance between quality assurance and operational efficiency.

Implementation Recommendations and Best Practices

Based on the characteristics of each verification method, companies can develop appropriate first article verification strategies tailored to their specific situations. It is important to keep verification records private to protect sensitive company information. Additionally, companies should consider privacy when handling and storing verification data to ensure data protection and security.

Key Selection Factors

Product complexity represents the primary consideration. Simple products might only require photo verification, while high-density boards, BGA components, and other complex designs strongly warrant physical sample confirmation.

Production batch size similarly influences decision-making. Large-volume production demands rigorous first article verification, as batch errors can lead to catastrophic losses.

Geographical distance from customers presents practical considerations. Local clients facilitate easier physical verification, while remote collaborations may rely more heavily on digital photo transmission.

Recommended Hybrid Approach

For most manufacturers, implementing hybrid verification strategies often yields optimal results. For example, initial production runs might utilize sample verification to establish trust and technical benchmarks, with subsequent changes managed through photo verification.

Implementing a three-stage inspection system—combining self-check, mutual check, and specialized inspection—proves effective for enhancing first article inspection reliability. Operators conduct initial self-checks, followed by mutual checks by team leaders or colleagues, concluding with specialized inspections by quality personnel. This triple-layered approach ensures first article quality.

Technology-Enhanced Solutions

Introducing dedicated first article inspection instruments or specialized detection systems can improve verification accuracy and efficiency. Certain systems can scan circuit boards and overlay them with CAD designs, making any discrepancies immediately visible and enabling operators to easily identify defects.

AI-based visual inspection systems also serve as powerful tools in modern electronics manufacturing. These systems compare stored "golden" reference images against first articles, automatically flagging any differences to enhance quality control standards.

Conclusion

In practical manufacturing environments, no single method suits all scenarios. Effective quality control strategies should remain flexible and multi-layered. For high-reliability products like automotive electronics, even when using sample or photo verification, subsequent production should incorporate Automated Optical Inspection (AOI) and functional testing to establish multiple quality protection layers.

The ultimate goal of first article verification extends beyond product inspection to assessing the stability and reliability of the production system itself. Regardless of the chosen verification method, strict implementation of first article inspection protocols remains fundamental to ensuring PCB assembly quality and reducing overall risk.

Sometimes, the true cost isn't implementing quality control measures, but rather the price paid for their absence.

FAQs

Q. What is PCB Assembly First Article Confirmation?

A. A quality control process conducted after the initial batch of PCB assemblies is produced, using specific methods to verify that the craftsmanship, components, soldering, etc., comply with design requirements.

Q. What is the core process of photo confirmation?

A. Take clear photos of key areas of the first article (pads, components, polarity), send them to the customer / quality inspector for review, and proceed with mass production only after approval.

Q. What are the advantages of photo confirmation?

A. Low cost, high efficiency (completed in 1-2 hours), easy archiving. Suitable for urgent orders or simple board types.

Q. What are the main limitations of photo confirmation?

A. Cannot test solder joint strength or electrical performance; prone to missing subtle issues due to photo angle or clarity.

Q. How long does sample shipping confirmation take?

A. Including transportation and inspection, it typically takes 3-7 days, depending on logistics lead time.

Q. What scenarios is sample shipping confirmation suitable for?

A. High-precision PCBs (e.g., with BGAs, fine-pitch components), complex process orders, or clients with extremely high-quality requirements.

Q. What are the additional costs for sample shipping confirmation?

A. Sample production cost, packaging cost, logistics cost, and the time cost incurred during the waiting period.

Q. Under what circumstances might one skip first article confirmation?

A. Small-batch trial production, mature and stable orders (no process changes), or emergency repair scenarios where risks are controllable.

Q. What is the biggest risk of skipping first article confirmation?

A. Batch occurrences of issues like incorrect component placement, poor soldering, or reversed polarity, leading to rework/scrap and increased production costs.

Q. How to reduce the risk of skipping first article confirmation?

A. Implement strict incoming component inspection, optimize SOPs, and increase the frequency of in-process sampling inspections.

Q. Photo confirmation vs. sample shipping confirmation, how to choose?

A. Choose photo confirmation for prioritizing speed/cost control; choose sample shipping confirmation for prioritizing accuracy/risk reduction.

Q. What if issues are found after first article confirmation?

A. Halt mass production, rework the process/replace components, then produce and confirm a new first article before resuming production.

Q. How long should first article confirmation records be kept?

A. It is recommended to keep them for at least 1 year after order delivery to facilitate quality tracing.

Q. Does sample shipping confirmation include electrical performance testing?

A. It can be arranged as needed. Typically, it includes only visual inspection. Electrical testing must be specified in advance if required.

Q. Are there requirements for the camera equipment used in photo confirmation?

A. Yes, a high-definition camera (≥10 megapixels) is required. Key areas must be photographed close-up to ensure component model numbers and polarity are clearly visible.

Author: Jack Wang