Thermoelectric Heat Dissipation PCB The Silent Solution to Overheating Gadgets

Introduction

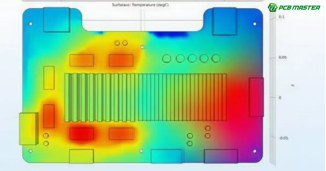

If you’ve ever felt your laptop’s bottom get hot enough to warm your hands, or noticed your phone slow down when you’re gaming, you’ve seen the enemy of modern electronics: overheating. For printed circuit boards (PCBs)—the green “brains” inside every device—too much heat is a death sentence. It can fry chips, ruin signals, and cut your gadget’s lifespan in half. High surface temperature on critical components can lead to performance drops and reliability issues, making effective thermal management essential for device longevity.

For years, engineers relied on fans, heat sinks, or even liquid cooling to keep PCBs cool. But as devices get smaller (think ultra-thin laptops, tiny wearables, or 5G modems), these old solutions stop working—fans are too bulky, heat sinks take up too much space, and liquids are a disaster waiting to happen. Conventional cooling methods like air, water, or liquid cooling often struggle to meet the high heat dissipation demands of modern compact electronics, limiting their effectiveness in maintaining optimal surface temperature and overall device performance.

Enter thermoelectric heat dissipation—a silent, compact technology that’s changing how we cool PCBs. It doesn’t have moving parts, fits in the tiniest spaces, and works in extreme conditions (like inside a car or a medical device). Thermoelectric systems improve heat dissipation efficiency compared to traditional solutions, enabling better temperature regulation and more reliable operation in advanced electronics. In this guide, we’ll break down what thermoelectric heat dissipation is, why it’s a game-changer for PCBs, how it works (no engineering degree needed!), and which gadgets are already using it. By the end, you’ll understand why this “invisible cooler” is becoming a must-have for the devices we use every day.

First: Why Do PCBs Overheat, and Why Does It Matter?

Before we dive into thermoelectric cooling, let’s answer the basics: Why do PCBs get hot in the first place?

Every component on a PCB—from the processor in your phone to the capacitors in your smartwatch—uses electricity. When electric current flows through these PCB components, it generates heat due to electrical resistance; this is called joule heat (also known as Joule heating), but you can just think of it like a light bulb getting warm when it’s on.

For small devices, this heat builds up fast. A smartphone’s PCB is smaller than a credit card, but it’s packed with parts that run nonstop: 5G modems, cameras, and processors that handle everything from social media to video editing. These components act as multiple heat sources that contribute to the overall thermal load. If that heat can’t escape, bad things happen:

·Performance drops: Your phone lags when gaming, or your laptop freezes during a video call (devices slow down to avoid overheating).

·Shorter lifespan: Heat damages components over time—an overheated PCB might last 2 years instead of 5.

·Safety risks: In rare cases, extreme heat can cause batteries to swell or PCBs to catch fire (remember those laptop recall scandals a few years back?).

The problem is only getting worse. As engineers cram more power into smaller PCBs (hello, foldable phones and AI wearables), traditional cooling methods are failing. Fans need space to spin, heat sinks need to be big to work, and both add weight—something a smartwatch or a drone can’t afford.

That’s where thermoelectric heat dissipation comes in. It’s a cooling method that’s small, silent, and precise—perfect for the tiny, powerful PCBs in today’s gadgets.

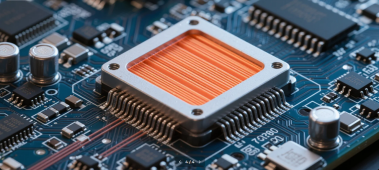

The Role of Copper Foil in PCB Heat Management

When it comes to keeping PCBs cool, copper foil is the unsung hero working behind the scenes. Thanks to its exceptional thermal conductivity, copper foil acts like a superhighway for heat, quickly moving generated heat away from high power components before it can build up and cause trouble.

Why copper? Compared to other materials used in PCBs, copper foil offers far superior heat dissipation performance. Its low thermal resistance means that heat can flow efficiently from the heat source—like a powerful processor or voltage regulator—through the copper layer and out toward the edges of the board or into an external heat sink. This rapid heat transfer is essential for managing the intense heat generation found in today’s high power electronics.

By integrating copper foil into the PCB design, engineers can dramatically improve the board’s overall thermal performance. The copper layer helps spread heat evenly, preventing hot spots and reducing the risk of overheating. This not only protects sensitive components but also ensures stable performance, even when devices are pushed to their limits.

In short, copper foil is a key player in modern PCB heat management. Its ability to lower thermal resistance and boost heat flow makes it indispensable for high power applications—helping your favorite gadgets run cooler, last longer, and perform at their best.

What Is Thermoelectric Heat Dissipation, and How Does It Differ from a Heat Sink?

Thermoelectric heat dissipation (also called “thermoelectric cooling” or TEC for short) is a way to move heat away from a PCB using electricity and special materials—no fans, no liquids, no moving parts at all. These systems rely on the thermoelectric effect, where an electric current passed through thermoelectric devices causes heat to be transferred from one side to the other, enabling efficient heat flux and improved system performance.

Here’s the simplest way to think about it: Imagine a small, flat “cooling tile” (which is a type of thermoelectric device, also known as a thermoelectric cooling module) stuck directly onto a hot component on a PCB (like a processor). When you plug this tile into power, one side gets cold (absorbing heat from the PCB) and the other side gets hot (releasing that heat somewhere else, like to a small heat sink). It’s like a tiny, invisible pump that moves heat from where it’s bad (the PCB) to where it’s harmless (the outside of the device).

This technology isn’t new—it was invented in the 1830s (thanks to scientists Seebeck and Peltier), but it’s only recently become cheap and small enough for consumer electronics. Advances in thermoelectric devices have enabled their integration into modern electronics, making today’s thermoelectric coolers thinner than a credit card, weighing just a few grams, and able to cool a PCB by 20–50°F (10–28°C) depending on the power.

How Does Thermoelectric Cooling Work? (No PhD Required)

You don’t need to be an electrical engineer to understand the science behind thermoelectric heat dissipation. Let’s break it down with a analogy and three simple steps.

First, the key ingredient: thermoelectric materials. These are special metals or semiconductors (like bismuth telluride, a common one) that can move heat when electricity flows through them. This movement of heat relies on both thermal conduction and heat conduction, which are essential for transferring thermal energy efficiently through the material. Think of them like “heat pipes” that work with electricity instead of liquid.

Imagine a sponge soaking up water and moving it from one side to the other—except here, it’s heat being moved. This process is a great example of heat mass transfer, where both heat and energy are transported to improve cooling efficiency.

Now, here’s how a thermoelectric cooler (TEC) works on a PCB: The TEC is attached to the PCB, and a thermal interface material is used between the TEC and the PCB to ensure efficient heat transfer and minimize thermal resistance.

Step 1: The TEC Is Attached to the Hot Spot

A thermoelectric cooler is a small, square module (usually 10–20mm wide) with two sides: a “cold side” and a “hot side.” Engineers glue the cold side directly onto the hottest part of the PCB—like the processor or a power management chip. To ensure efficient heat transfer and minimize thermal resistance at this interface, it is important to use suitable thermal interface materials between the TEC and the hot spot. This way, the TEC is touching the source of the heat, so it can absorb it right away.

Step 2: Electricity Flows, and Heat Moves

When the device turns on, electricity flows through the thermoelectric materials inside the TEC. This causes the materials to “push” heat from the cold side (the one touching the PCB) to the hot side (the opposite side). The temperature difference between the cold and hot sides of the TEC is what drives this heat transfer, and the efficiency of the process depends on the magnitude of this temperature difference.

It’s like if you had a sponge that soaks up water (heat) from a spill (the PCB) and squeezes it out the other end (the hot side). The more electricity you send to the TEC, the faster it moves heat—engineers can even adjust the power to match how hot the PCB gets (e.g., more power when gaming, less when just browsing). Managing temperature differences is key to achieving optimal performance in thermoelectric cooling systems, as maintaining the right temperature differences ensures efficient heat dissipation.

Step 3: The Hot Side Releases Heat

For the TEC to keep working, the hot side needs to get rid of the heat it’s collected. If the hot side stays hot, the TEC can’t absorb more heat from the PCB (it’s like a sponge that’s already full). The TEC operates based on the peltier effect, where an electric current causes active heat transfer from one side to the other, generating and moving peltier heat (QP) within the device.

So engineers pair the TEC’s hot side with a small heat sink (a metal plate with fins) or a heat spreader (a thin layer of copper that spreads heat across the device’s case). In some gadgets (like laptops), the heat sink might have a tiny fan to blow away the heat—but even then, the fan is smaller than a traditional one because the TEC is doing most of the work. A cooling fan or cooling fans can significantly enhance convective heat transfer, improving the efficiency of heat dissipation from the hot side.

That’s it! No moving parts except (sometimes) a tiny fan, no liquids, just electricity moving heat away from the PCB.

Why Thermoelectric Heat Dissipation Is Perfect for PCBs

Traditional cooling methods work for big devices (like desktop computers), but thermoelectric cooling solves the unique problems of small, modern PCBs. Unlike air cooling and passive heat dissipation strategies—which rely on conduction, natural convection, and other non-active methods—thermoelectric cooling offers more precise and efficient thermal management, overcoming the limitations of these conventional approaches. Let’s break down its biggest advantages:

Thermoelectric cooling delivers superior cooling performance and superior performance compared to traditional methods, providing improved heat dissipation efficiency, faster thermal response, and higher cooling power for demanding applications.

1. It’s Tiny and Light—Perfect for Small Gadgets

The average thermoelectric cooler for a PCB is just 1–5mm thick and weighs less than 10 grams. That’s small enough to fit inside a smartwatch, a wireless earbud case, or a 5G router—places where a fan or a big heat sink would be impossible. The heat dissipation part becomes especially important in these compact electronics, as it helps maintain device performance by efficiently managing thermal loads.

For example: A foldable phone’s PCB is folded in half, so there’s no space for a fan. A TEC can be glued to the processor inside the fold, with a small heat sink that releases heat through the phone’s metal frame. In this setup, the thermal layer and thermal layer part within the PCB structure ensure efficient heat transfer from the processor to the heat dissipation part, which is crucial for preventing overheating and maintaining smooth folding. Without the TEC, the phone would overheat and stop folding smoothly.

2. It’s Silent—Great for Quiet Devices

Fans make noise, and liquid cooling can gurgle. But thermoelectric coolers have no moving parts (unless paired with a tiny fan), so they’re completely silent. This is a big deal for:

·Wearables: You don’t want a smartwatch buzzing with a fan on your wrist.

·Medical devices: A heart monitor or insulin pump needs to be quiet for patients.

·Home electronics: A smart speaker or a security camera shouldn’t make noise while it’s working.

3. It’s Precise—Cools Exactly Where It’s Needed

PCBs don’t get hot evenly—usually, one component (like the processor) is the “hot spot,” while the rest of the board is cool. Thermoelectric coolers can be placed directly on that hot spot, cooling it down without wasting energy cooling the entire board. This approach enables localized cooling, which is especially effective for managing critical components and preventing thermal issues in specific areas.

This precision saves power (important for battery-powered devices) and prevents “over-cooling” (which can cause condensation—water damage is bad for PCBs!). For example, a drone’s PCB has a GPS chip that gets hot, but the rest of the board is cool. A TEC on the GPS chip keeps it from overheating, while the rest of the board stays at a normal temperature.

4. It Works in Extreme Conditions

Traditional fans stop working in dust, moisture, or extreme temperatures (like a car’s PCB in -40°F winter or 120°F summer). But thermoelectric coolers are sealed, so they’re resistant to dust and water. They also work in extreme temperatures—making them perfect for:

·Automotive PCBs: EVs have PCBs in their battery management systems that need to stay cool in hot weather. In these harsh environments, thermoelectric separation technology and thermoelectric separation are used in metal core PCBs to improve reliability and thermal management, ensuring stable operation under thermal stress.

·Industrial equipment: Factory machines have PCBs that get dusty—TECs keep them cool without getting clogged.

·Aerospace: Satellites have PCBs that face extreme cold in space—TECs can heat and cool (more on that later!).

5. It’s Low-Maintenance—No Repairs Needed

Fans break (their motors wear out), and liquid cooling can leak. But thermoelectric coolers have no moving parts, so they rarely fail. This is crucial for devices that are hard to repair—like a PCB inside a satellite or a medical implant. A TEC can last for years without needing to be replaced.

Which Gadgets Are Already Using Thermoelectric Cooling for PCBs?

Thermoelectric heat dissipation isn’t a “future technology”—it’s already in the devices you use every day. Performance analysis and thermal modeling are essential for optimizing thermoelectric cooling across different applications, ensuring efficient heat management and system reliability. Here are the biggest industries and products relying on it:

In high-power devices, the effectiveness of thermoelectric cooling is strongly influenced by the material properties of the components, such as thermal conductivity and interface quality, which determine how efficiently heat is transferred and dissipated.

When integrating thermoelectric cooling into complex systems, designers often incorporate a heat exchanger to further enhance heat dissipation, reduce system size and weight, and improve overall thermal management efficiency.

1. Consumer Electronics (Phones, Laptops, Wearables)

·Foldable Phones (Samsung Galaxy Z, Google Pixel Fold): These phones have PCBs folded into tight spaces. A TEC cools the processor inside the fold, preventing overheating when the phone is folded for hours.

·Gaming Laptops (Razer Blade, ASUS ROG): Gaming laptops have powerful PCBs that get very hot. Some models use TECs to cool the GPU (graphics chip), letting the laptop run games faster without a loud fan.

·Smartwatches (Apple Watch Ultra, Garmin Fenix): The Ultra models have PCBs with GPS, heart rate sensors, and cellular modems. A tiny TEC keeps the PCB cool during long hikes or workouts, so the watch doesn’t die early.

·Wireless Earbuds (Sony WH-1000XM5): Earbud cases have small PCBs that charge the earbuds. A TEC prevents the case from getting hot when fast-charging—so you don’t burn your fingers when you pick it up. Some advanced designs also use phase change material or phase change materials to absorb excess heat during fast charging, maintaining safe temperatures and improving device efficiency.

2. Automotive (EVs, Self-Driving Cars)

Electric vehicles (EVs) and self-driving cars have more PCBs than ever—battery management systems (BMS), radar, lidar, and touchscreens all rely on PCBs. Thermoelectric cooling is critical here because:

·EV batteries get hot when charging, and the BMS PCB needs to stay cool to prevent fires. A TEC cools the BMS PCB, even in hot weather.

·Self-driving cars have radar PCBs that work 24/7. A TEC keeps them cool without a fan (fans would get dusty and fail).

·Companies like Tesla, Ford, and Volkswagen all use TECs in their latest EV PCBs.

·Copper core PCBs in automotive applications often incorporate a thermoelectric separation structure, such as convexity pads or raised thermal columns, to improve heat transfer and enhance reliability under high current conditions.

3. Medical Devices (Heart Monitors, Insulin Pumps)

Medical devices need PCBs that are small, quiet, and reliable—thermoelectric cooling checks all three boxes. Electrical insulation is crucial in thermoelectric cooling systems for medical PCBs, as it ensures safety, prevents short circuits, and supports reliable device operation:

·Heart Monitors: Wearable heart monitors have PCBs that track heart rate 24/7. A TEC keeps the PCB cool on the patient’s chest, so it doesn’t irritate the skin.

·Insulin Pumps: These devices have PCBs that control the insulin dose. A TEC prevents the PCB from overheating, ensuring the pump delivers the right amount of insulin (a glitch could be deadly).

·MRI Machines: MRI machines have powerful magnets that heat up their PCBs. TECs cool the PCBs without using metal (which would interfere with the magnet).

4. Industrial & Aerospace (Factory Machines, Satellites)

·Factory Robots: Robots have PCBs that control their movements. TECs cool the PCBs in dusty factories, so the robots don’t break down. For effective thermal management, it is crucial to monitor both the ambient temperature and the heat source temperature within the factory environment. Additionally, leveraging natural heat flow can enhance passive cooling strategies for these robotic systems.

·Satellites: Space is extreme—cold at night, hot during the day. TECs can both cool and heat satellite PCBs (by reversing the electricity flow), keeping them at a safe temperature. NASA uses TECs in many of its satellites. Monitoring ambient temperature and heat source temperature is essential for maintaining optimal performance in these harsh conditions, and natural heat flow can be utilized as part of passive thermal management in satellite design.

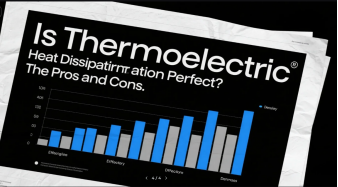

Is Thermoelectric Heat Dissipation Perfect? The Pros and Cons

No technology is perfect, and thermoelectric cooling has a few tradeoffs. Let’s be honest about its pros and cons so you can understand when it’s the right choice for a PCB:

One limitation is that high thermal resistance in certain designs can reduce the effectiveness of thermoelectric cooling, as it creates barriers to efficient heat transfer.

Additionally, if heat is not properly managed, heat accumulation can occur, leading to increased risks of overheating and reduced device reliability.

Pros of Thermoelectric Heat Dissipation for PCBs

·Tiny and light: Fits in the smallest gadgets (smartwatches, earbuds).

·Silent: No moving parts—great for quiet devices.

·Precise: Cools only the hot spots, saving power.

·Durable: Resists dust, moisture, and extreme temperatures.

·Low-maintenance: Rarely fails, so no repairs needed.

Cons of Thermoelectric Heat Dissipation for PCBs: The Role of Thermal Resistance

·Uses power: TECs need electricity to work, which can drain a device’s battery (though less than a fan). For example, a smartwatch with a TEC might lose 5% more battery per day than one without.

·Not for super-high power: TECs work best for small, medium-heat PCBs (like those in phones or wearables). They can’t cool a high-power PCB (like a desktop computer’s GPU) as well as a liquid cooler.

·Needs a heat sink: The TEC’s hot side needs a way to release heat—so you still need a small heat sink (though it’s smaller than a traditional one).

·Costs more: TECs are more expensive than fans or basic heat sinks. A TEC for a PCB costs $5–$20, while a fan costs $1–$5. But the cost is dropping as more companies use them. The use of solder paste and surface treatments like silver plating can also add to manufacturing costs, but they help improve the performance and durability of thermoelectric cooling modules.

The Future of Thermoelectric Heat Dissipation for PCBs

As devices get smaller and more powerful, thermoelectric cooling will only become more important. Here’s what engineers are working on next to make it even better:

Researchers are developing new materials, such as Bi₂Te₃-based compounds, with enhanced thermoelectric properties to improve device performance and efficiency.

Ongoing research in this field is supported by organizations like the National Natural Science Foundation, which plays a crucial role in advancing thermoelectric cooling technologies.

1. Even Smaller TECs—For Micro-Gadgets

Engineers are developing TECs smaller than a grain of rice—small enough to fit inside wireless earbuds or smart contact lenses. These micro-TECs will cool tiny PCBs that power next-gen wearables (like a contact lens that tracks glucose levels).

2. More Efficient Materials—Less Power Use

Right now, TECs use bismuth telluride, which is good but not perfect. Scientists are testing new materials (like topological insulators) that can move heat with less electricity. This would mean TECs use less battery—great for smartwatches and other portable devices.

3. Integrated TECs—Built Into the PCB

Instead of gluing a TEC onto a PCB, engineers want to build the TEC into the PCB itself. Imagine a PCB with a built-in cooling layer—no extra parts needed. This would save even more space and make manufacturing faster.

4. TECs for AI PCBs

AI devices (like chatbot servers or self-driving cars) have PCBs that run 24/7 and get very hot. Engineers are designing TECs that can cool these high-power PCBs without using too much electricity. This would make AI devices more efficient and reliable.

Final Thoughts: Why Thermoelectric Heat Dissipation Matters for You

You might never see a thermoelectric cooler, but it’s making your gadgets better every day. Without it:

·Your foldable phone would overheat and stop working.

·Your smartwatch would die halfway through a hike.

·EVs would be less safe (their battery PCBs would overheat).

Thermoelectric heat dissipation is a perfect example of “invisible innovation”—the tech you don’t notice, but can’t live without. It’s solving the biggest problem of modern electronics: how to make small, powerful PCBs that don’t overheat.

If you’re an engineer, a hobbyist building PCBs, or just someone who loves gadgets, keep an eye on thermoelectric cooling. It’s only going to get better—and it will be key to the next generation of devices (like foldable laptops, AI wearables, and even smart homes).

The next time you use your phone or laptop and it doesn’t overheat, take a second to thank the tiny thermoelectric cooler working behind the scenes. It’s the silent hero keeping your PCB—and your gadgets—running cool.

Have questions about thermoelectric cooling for PCBs? Drop a comment below—I’d love to hear from you!

FAQs

Q. How does thermoelectric cooling work?

A. Thermoelectric cooling is based on the Peltier effect. When an electric current passes through a circuit composed of two different semiconductor materials (N-type and P-type), one end absorbs heat (the cold side), while the other end releases heat (the hot side), thereby achieving directional transfer of heat. For example, in common thermoelectric coolers, direct current passes through an N-type and P-type semiconductor module. The cold side absorbs energy during electron transfer and thus becomes cold, while the hot side expels the accumulated heat.

Q. Which devices are suitable for thermoelectric cooling?

A. Devices suitable for thermoelectric cooling are those with limited space, sensitivity to noise, or needing to operate under extreme conditions. Examples in the consumer electronics field include foldable screen smartphones, gaming laptops, smartwatches, and wireless earbuds; in the automotive industry, electric vehicle battery management systems and radar for autonomous driving cars; medical equipment such as heart rate monitors, insulin pumps, and MRI machines; as well as industrial and aerospace applications like factory robots and satellites. For instance, PCBs in satellites need to cope with extreme temperatures in space, and thermoelectric cooling can achieve both cooling and heating by reversing the electric current, ensuring stable PCB temperatures.

Q. How efficient is thermoelectric cooling?

A. The efficiency of thermoelectric cooling is influenced by various factors, including the performance of thermoelectric materials and the design of the cooling structure. Currently commonly used thermoelectric materials, such as bismuth telluride compounds, can achieve certain cooling effects, but overall efficiency is still limited compared to some highly efficient traditional cooling systems (such as large liquid cooling systems). However, in miniaturized scenarios, thermoelectric cooling can effectively reduce local hotspot temperatures, for example, lowering PCB temperatures by 20–50°F (10–28°C).

Q. Does thermoelectric cooling affect device battery life?

A. Thermoelectric cooling requires electricity to operate, which increases the power consumption of the device's battery. For example, a smartwatch equipped with a thermoelectric cooler might consume about 5% more power per day compared to one without this technology. However, compared to other active cooling methods like fans, the increase in power consumption from thermoelectric cooling is relatively small.

Author: Jack Wang