Essential Guide to PCB UL Marking Importance and Compliance Explained

Introduction

In every aspect of electronics manufacturing, safety is always the primary consideration, and that small UL mark serves as a bridge of trust connecting products to the market.

In the field of electronic product manufacturing, every detail impacts the performance and safety of the final product. As the carrier of electronic components, the quality of a PCB directly determines the reliability of the entire product. UL, with expertise innovating safety solutions, plays a leading role in setting industry standards and ensuring product safety.

Among the numerous standards measuring PCB quality, UL certification is undoubtedly the most crucial international passport. With more than a century of experience, UL has established itself as a global leader in safety science. Whether in smartphones, medical devices, or automotive electronics, you can almost always find a small UL mark on the PCB. UL's mission centers on developing and advancing safety solutions for the electronics industry, helping manufacturers ensure their products meet rigorous safety requirements.

What does this seemingly simple symbol truly represent? Let’s uncover the mystery behind the UL mark on PCBs together.

What is UL Certification?

UL stands for Underwriters Laboratories Inc., often translated as “Underwriters Laboratories“ in Chinese.

Established in 1894, UL has grown into one of the world’s largest, oldest, and most authoritative safety testing organizations.

When a product passes UL’s rigorous testing, proving it meets specific safety standards, it can obtain UL certification and be authorized to use the UL mark. The UL mark is widely recognized globally as a authoritative symbol of product quality and safety. The UL mark can appear in different forms, such as 'UL Listed' or 'UL Recognized.' 'UL Listed' indicates that the entire product, such as a finished electronic device, has been tested and meets comprehensive safety standards, while 'UL Recognized' typically applies to components that are part of a larger system.

For PCB products, the UL mark is not just a “passport” for market access—it’s a declaration of the manufacturer’s commitment to quality. UL certification is important for circuit board manufacturers because it demonstrates compliance with critical safety and performance standards, such as UL 796 and UL 94, and ensures the use of UL recognized components. Particularly in the U.S. market, UL certification is almost an indispensable “ID card” for electronic products. The ul certification important aspect cannot be overstated, as it is essential for safety, regulatory compliance, and market acceptance.

Decoding the UL Mark

A typical ul mark on a PCB includes essential information such as the manufacturer’s identifier, UL file number, product type, country code, and flame resistance rating. If you look closely at the UL mark on a PCB, you’ll notice it’s more than just a simple logo. The UL logo serves as a key visual indicator of certification and compliance with UL safety standards. Taking one PCB manufacturer’s mark as an example, it contains several key elements:

·Company Identifier: A unique logo representing the manufacturer, registered with UL.

·UL File Number: A unique identifier—like an ID number—pointing to the manufacturer’s detailed records in UL’s database.

·Product Type Designation: For instance, “SL-D” indicates a single-layer board (including single-sided and double-sided FR-4 boards), while “SL-M” denotes multilayer circuit boards.

·Country Code: The “C, US” in the mark shows the product meets UL standards for both Canada and the United States.

·Flame Resistance Rating: Such as “94V-0,” indicating the printed circuit board’s flame resistance level, representing the highest level.

·Placement: The UL mark is commonly found on printed wiring boards, ensuring that these components meet safety and regulatory requirements.

Together, this information forms a complete safety traceability system, allowing every PCB to be traced back to its safety certification source.

UL's Rigorous Testing Standards

UL has specifically developed the UL 796 standard for the safety of printed circuit boards, which has been approved by the American National Standards Institute. In addition to UL 796, several UL standards, such as UL 94, are also relevant for circuit boards to ensure comprehensive safety and compliance. The UL 796 standard specifies the standard test patterns PCB manufacturers must produce to obtain UL certification, primarily including three types of test samples:

The first sample type must undergo thermal shock, bond strength, plating adhesion, and insulation material evaluation tests.

The second sample type is subjected to delamination and microsection testing.

The third sample type must pass flame and thermal shock tests. UL 94 is a key flammability standard for plastic materials used in PCBs, classifying materials based on their fire resistance to ensure fire safety and regulatory compliance.

Only after all these samples pass UL’s stringent tests can the PCB manufacturer receive UL certification. The testing process is crucial for fire safety, as it ensures that PCB materials and plastic materials meet UL standards for flammability and reliability.

During testing, samples undergo a series of preconditioning steps, including at least 48 hours at 23±2°C and 50±10% relative humidity, followed by 168±2 hours at 70±2°C, and then cooling in a desiccator for at least 4 hours. For advanced electronic devices, more comprehensive testing is often required to enhance electromagnetic compatibility and signal integrity, ensuring reliable performance and regulatory compliance.

Selecting PCB materials and plastic materials that meet UL standards is essential for product safety, regulatory approval, and market trust.

UL Recognized Components

UL recognized components are a cornerstone of safety and reliability in the electronics industry, especially when it comes to printed circuit boards (PCBs). These components have been subjected to rigorous testing and evaluation by Underwriters Laboratories (UL) to ensure they meet strict safety standards. When a component carries the UL recognized component mark, it signifies that it complies with UL standards and is suitable for use in certified products.

For PCB manufacturers, incorporating UL recognized components into their designs streamlines the UL certification process. Since these components have already been vetted for safety and performance, manufacturers can more efficiently demonstrate compliance with industry standards and reduce the risk of safety concerns during certification. This not only accelerates the certification process but also helps in maintaining UL certification over the product’s lifecycle.

The use of UL recognized components is essential for ensuring that circuit boards meet the highest safety standards. By selecting recognized components, manufacturers can build PCBs that are not only reliable but also compliant with regulatory requirements, giving both manufacturers and end-users confidence in the safety and quality of the final product. In a competitive market, leveraging UL recognized components is a proactive step toward achieving and maintaining UL certification, supporting long-term success in the electronics industry.

Polymeric Materials in PCBs

Polymeric materials are fundamental to the construction and performance of printed circuit boards (PCBs). These materials, which include industrial laminates and filament wound tubing, serve as the backbone of circuit boards, providing essential properties such as electrical insulation, mechanical strength, and resistance to environmental factors. To ensure these materials are safe and effective, they must comply with UL standards like UL 746E, which governs the safety and performance of polymeric materials used in electrical equipment.

The UL certification process for PCBs involves comprehensive testing of polymeric materials to assess their suitability for use in demanding electronic applications. Key properties evaluated include the comparative tracking index (CTI), which measures resistance to electrical tracking, and voltage difference, which assesses the material’s ability to withstand electrical stress. Flammability ratings and other performance tests are also conducted to ensure the materials can handle the operational demands of modern electronic devices.

By using UL certified polymeric materials, PCB manufacturers can significantly reduce the risk of electrical fires, shocks, and other hazards. This not only helps in meeting safety standards but also enhances the long-term reliability of the final product. As technology evolves and the electronics industry continues to innovate, the role of high-quality, UL certified polymeric materials in PCBs becomes even more critical for ensuring product safety and regulatory compliance.

The Core Value of UL Certification

The significance of UL certification extends far beyond a piece of paper. It represents a comprehensive assessment of product safety, helping prevent fires and loss of life caused by faulty products.

For manufacturers, obtaining UL certification means directly benefiting from UL’s philosophy of “safety throughout the product life cycle.” Using UL certified components is essential for ensuring product safety, regulatory compliance, and building customer trust.

During the product development phase, product safety is treated as a core element, driving the pursuit of safer, higher-quality products that gain recognition in domestic and international markets.

Continuous monitoring is another key feature of UL certification. Obtaining UL certification isn’t a one-time event—UL regularly conducts market surveillance and sampling of certified products to ensure ongoing compliance with safety standards.

This long-term mechanism guarantees the consistency of certified products throughout their manufacturing lifecycle.

In conclusion, UL certification is vital for PCB manufacturers and the electronics industry as a whole. The conclusion UL certification is that it ensures safety, reliability, regulatory compliance, and greater market acceptance, making it an essential part of responsible manufacturing.

Ongoing Compliance and Follow-up Inspections

Achieving UL certification is only the beginning—maintaining UL certification requires a steadfast commitment to ongoing compliance with UL standards. For PCB manufacturers, this means implementing robust quality control measures and keeping detailed records of every step in the manufacturing process. These records are essential for demonstrating that each batch of printed circuit boards continues to meet UL requirements and safety standards.

UL conducts regular follow-up inspections as part of the certification process to verify ongoing compliance. During these inspections, UL representatives may review manufacturing processes, examine material properties, and conduct additional testing on finished products. The goal is to identify any potential safety concerns before they reach the market and to ensure that the manufacturer’s processes remain aligned with UL standards.

By participating in follow-up inspections and maintaining strict quality control, PCB manufacturers can ensure ongoing compliance and uphold the integrity of their UL certification. This proactive approach not only helps prevent safety issues but also reinforces the manufacturer’s reputation for producing safe, reliable, and UL certified products. In a rapidly evolving industry, ongoing compliance is essential for meeting regulatory requirements and maintaining market acceptance.

UL Certification and International Markets

For electronic product manufacturers targeting international markets, choosing PCB suppliers with UL certification is crucial. Relevant U.S. authorities have issued e-commerce specific regulations requiring overseas sellers on these platforms to provide relevant safety standard reports.

Before submitting test reports compliant with UL standards, e-commerce platforms must order sellers to cease sales.

This regulation has turned UL certification from a “nice-to-have” into a “must-have” for entering the U.S. market. Furthermore, the required test reports must be compliant reports issued by ISO 17025 accredited laboratories.

With the rapid development of industries like 5G, big data, cloud computing, artificial intelligence, and the Internet of Things, requirements for PCBs are becoming increasingly stringent. UL standards are also evolving to address new technologies such as flexible and 3D-printed PCBs, ensuring safety and compliance as these innovations become more common in electronic products.

The new FR-15.0/FR-15.1 certification, compared to the well-known FR-4.0/FR-4.1, raises the temperature requirement from 130°C (electrical properties)/140°C (mechanical properties) to 150°C, meeting the needs of high-power products and high-temperature operating environments.

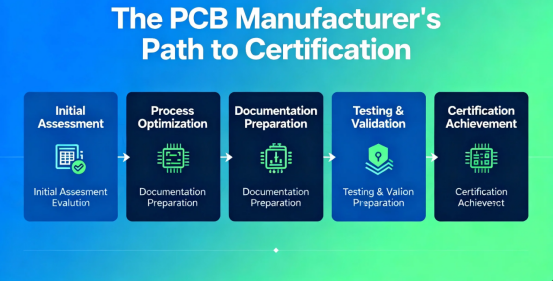

The PCB Manufacturer's Path to Certification

For PCB manufacturers, obtaining UL certification is a systematic and rigorous process, typically involving several key steps:

During the application stage, applicants must complete application forms and provide product documentation and technical files, including company information, product description, component lists, and product performance and specifications.

In the testing phase, UL determines test items based on relevant standards and arranges product testing. If testing fails, the applicant is notified and allowed to improve the product until it passes.

Certification maintenance requires manufacturers to undergo UL’s periodic follow-up inspections to ensure continued compliance with standards.

The entire certification process typically takes 5-7 working days, though this extends if retesting with improved samples is needed. However, the actual duration can vary significantly depending on factors such as product complexity, manufacturer preparedness, and any procedural delays.

Provided the U.S. UL test standard used remains unchanged, the UL test report remains valid long-term.

Identifying Genuine UL Marks

Since misuse or counterfeiting of UL marks occasionally occurs in the market, knowing how to identify genuine UL marks is essential. Legitimate UL marks should be clear, durable, and contain complete identification information.

As required, the company identifier and registered model must be added to the printed wiring board (either etched or silkscreened onto the PCB), while other items are added based on customer requirements.

Consumers and procurement specialists can verify a product's UL certification status through UL's online certification directory—UL Product iQ. This database provides access to UL certification data for products, components, and systems.

Conclusion

As emerging technologies like 5G, IoT, and automotive electronics rapidly develop, PCBs are operating in increasingly complex environments with ever-growing demands for safety and reliability.

The UL mark is no longer just a market access threshold—it has become a cornerstone of technological innovation and safety assurance.

Whether you're a product designer, procurement specialist, or quality manager, that small mark etched onto the PCB deserves more than a passing glance.

FAQs

Q.What is UL certification?

A. UL stands for Underwriters Laboratories. UL certification is a testing and certification process conducted by the American safety science company, designed to ensure PCBs and their materials meet strict safety standards—such as fire resistance and electrical safety criteria.

Q.Why is UL certification important for PCBs?

A. UL certification verifies that PCB manufacturers adhere to rigorous safety protocols, reducing the risk of component failure or non-compliance. It facilitates global market access for products and avoids costly recalls or redesigns.

Q.What key tests are involved in UL certification?

A. Key tests include flame retardancy, thermal stability, and electrical insulation assessments. Examples include evaluating the temperature resistance rating of PCB materials and verifying that electrical clearance and creepage distances meet standards.

Q.What are common reasons for UL certification failure?

A. Common failure causes include insufficient electrical clearance and creepage distances, defective overcurrent protection design, inadequate grounding continuity, failed abnormal temperature rise tests, and issues with marking or documentation.

Q.How to select suitable PCB materials for UL certification?

A. Choose UL-certified V-0 flame-retardant materials with a performance margin of over 10%. Additionally, consider whether the material’s temperature resistance and electrical insulation properties comply with UL standards.

Q.What is the typical lead time for PCB UL certification?

A. The certification cycle varies based on product complexity and the number of test items, generally ranging from several weeks to several months.

Q.Does UL certification have an expiration date?

A. UL certification itself has no fixed expiration date, but manufacturers must maintain compliance with UL requirements. UL may conduct unannounced surveillance audits periodically.

Author: Jack Wang