Decoding Customer-Specified Part Numbers, Material Codes and Order IDs Key Information in PCB Procurement

Introduction

In PCB (Printed Circuit Board) procurement, accurately understanding customer-specified part numbers, material codes, and order IDs forms the foundation for a successful project. Behind these seemingly simple codes lies a sophisticated system of critical information.

In the field of electronic product design and manufacturing, PCB procurement is a complex yet crucial stage. When a client provides specific part numbers, material codes, and order IDs, these codes create an information bridge from design to production, ensuring everyone is on the same page.

For engineers, procurement specialists, and newcomers alike, understanding the meaning and management of these identifiers can significantly reduce errors, improve efficiency, and lower costs.

The Core Value of the Three Key Identifiers

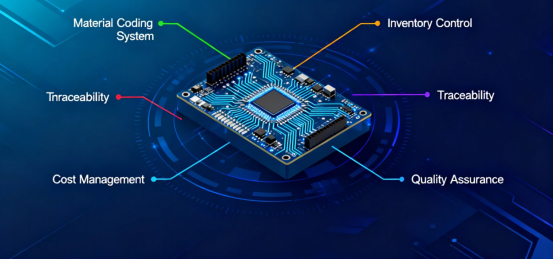

In the PCB procurement and execution process, the part number, material code, and order ID form a crucial information triangle, each carrying distinct and vital information.

·A Part Number typically refers to a category of products sharing the same functional performance—it represents a group of products sharing key electrical and mechanical characteristics.

For instance, a specific part number for a PCB might dictate a particular circuit layout, number of layers, and material composition.

·A Material Code goes a step further. It is a unique identifier assigned by a company within its internal management system to each distinct item. Following common practice in the electronics industry, each material receives a unique code, adhering to the principle "same item, same code; different item, different code."

Even if produced by different companies, identical physical components should ideally receive one standardized code, disregarding the manufacturer during the coding process.

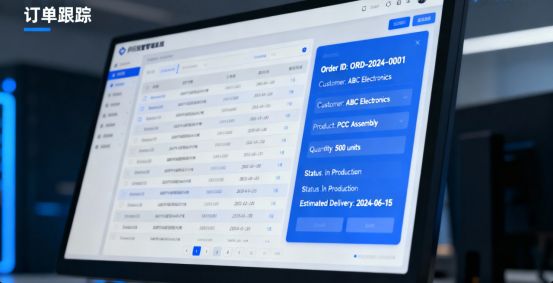

·An Order ID is the transaction credential in the supply chain, linking the customer and the supplier. It records all transaction details for a specific production batch, including price, quantity, delivery date, and specification requirements.

When quality issues arise, the Order ID is the key to tracing the entire production history.

Deep Dive into Material Coding Systems

A material code is far from a simple serial number; it is a carefully designed classification system. Within the management frameworks of large corporations, material codes adhere to strict rules and organization.

A typical material code might consist of 8 digits or uppercase letters, combined according to specific rules.

The first two characters often represent the major category—for example, '07' might indicate resistors, while '08' could denote capacitors.

The third and fourth characters usually indicate the sub-category. For instance, '0706' might represent wire-wound resistors, and '0709' could stand for thick-film chip resistors. The final four characters are typically sequential numbers used to distinguish different items within the same sub-category.

This structured, hierarchical system allows the coding framework to maintain excellent organization and flexibility, capable of adapting even as the variety and number of materials grow.

While a component can be uniquely identified by "Manufacturer + Manufacturer Part Number," these manufacturer part numbers vary in length, change frequently, and are difficult to manage consistently.

Therefore, companies establish their own material coding systems, assigning unified codes to both purchased components and in-house produced parts for standardized management.

The Critical Role of Customer-Specified Part Numbers

When a customer specifies a part number, they are essentially defining the functional and performance boundaries of the product. This specification ensures consistency and replaceability throughout the product's lifecycle.

In the electronics sector, a single part number can represent a set of rigorous technical standards—encompassing material requirements, electrical characteristics, dimensional tolerances, and environmental compliance.

The act of specifying a part number is based on trust in the supplier's technical capability and consistent quality.

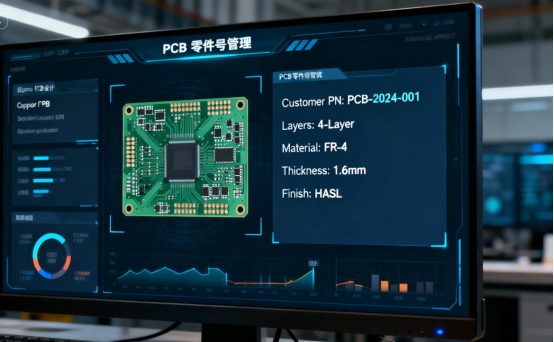

For PCBs, the part number might define key parameters such as the number of layers, substrate material type, thickness, copper weight, surface finish, and trace width/spacing. These parameters collectively determine the PCB's performance within the final product.

As a supplier, accepting a customer-specified part number entails the responsibility of maintaining product consistency and traceability. Even if manufacturing processes or material sources change, the core performance must remain within the boundaries defined by the part number.

Management and Practice of Material Codes

In practice, material coding systems are typically integrated into the company's ERP (Enterprise Resource Planning) system, enabling precise management from procurement and inventory to production.

Small companies lacking a formal material system often face issues like excess inventory, obsolete stock, incorrect purchases, missed purchases, and usage of wrong materials. While problems might be manageable at low production volumes, they can lead to significant losses at scale.

A comprehensive material database contains not only the codes but also a complete set of attributes for each item: supplier information (manufacturer, manufacturer part number), internal management data (substitute component relationships), hardware details (specification sheet, electrical performance, schematic symbol, PCB footprint), and procurement information (price, minimum order quantity, lead time).

Substitute (Alternate) Component Management is a particularly critical aspect of the material coding system. It defines the relationship where one component can be used interchangeably with another.

For example, 10KΩ ±5% resistors from different manufacturers are typically interchangeable and considered substitutes. Procurement might select from a list of substitutes based on best price and availability.

It is important to note that substitutability is generally higher for digital circuits than for analog circuits, where substitutions must be approached cautiously to avoid impacting performance.

The Tracking and Traceability Function of Order IDs

The Order ID plays a vital role in quality management. It enables batch tracking and issue traceability. When a product quality issue arises, the Order ID allows for rapid identification of the production batch, review of original parameters, and implementation of targeted corrective actions.

In modern manufacturing, Order IDs are often integrated with barcode systems. Labels applied by suppliers upon shipment include the barcode, material code, description, supplier part number, order ID, quantity, and shipment date.

The warehouse can use these barcodes for scanning goods receipt, forming the basis for subsequent digital management.

The Order ID is also closely linked to the concept of the Minimum Package Unit. According to labeling management standards, labels must be affixed to the smallest saleable unit of the product and are generally not permitted solely on the outer shipping carton.

This practice ensures precise product identification and prevents material mixing or errors.

Strategies for Managing Identification Challenges

Facing complex coding systems, companies need to establish rigorous management procedures. The first priority is ensuring consistency in coding—materials of a similar nature should follow consistent numbering logic.

The introduction of a new material should undergo a strict review process, including theoretical analysis, lab testing, small-batch trials, and high-volume production testing. Only after passing all stages without issues can the material be approved for relatively confident use.

Each stage should have a clear Material Status designation, providing reference for engineer selection and procurement ordering.

For obsolete materials or those identified with problems during validation, the material status should be clearly marked—for example, "Not For New Design" or "Obsolete"—to prevent their continued use in new designs.

Document Management is equally indispensable. Each component should have an associated datasheet (specification sheet) containing its description, electrical characteristics, key parameters, pinout, timing diagrams, package information, and manufacturing data.

A simple datasheet might be just a few pages, while a complex one can run into hundreds of pages.

Summary

In an increasingly complex electronics industry, customer-specified part numbers, material codes, and order IDs are no longer merely codes on paper. They constitute the common language of the modern supply chain. Mastering this language means maintaining product competitiveness and market responsiveness under the dual pressures of speed and precision.

When each identifier is correctly understood and applied, the path from design to production becomes clear and efficient. This embodies the manufacturing ethos of continuous refinement and pursuit of excellence.

Author: Jack Wang