The Essential Guide to Confirm PCB Work File for Successful Production

Introduction

In electronic product development, a small file error can lead to losses amounting to tens of thousands of dollars, and proper file confirmation is the critical line of defense against this risk.

Having a dedicated pcb designer review and confirm files before production is essential to catch errors, ensure compliance with design rules, and prevent costly mistakes in manufacturing.

During PCB prototyping or mass production, many engineers and procurement specialists have encountered this confusion: Why do some PCB manufacturers insist on repeatedly confirming production files? Can’t they just start production directly with the design files?

What seems like an unnecessary step actually contains profound industry experience and lessons. As a professional in the electronics industry, I’ve witnessed numerous project failures caused by file issues—ranging from simple impedance mismatches to complete batch product scrapping.

What are PCB Production Files?

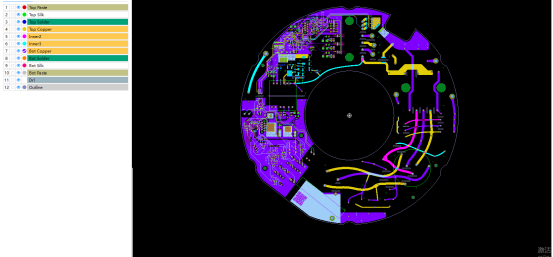

PCB production files serve as the bridge between design and manufacturing, typically including essential documents for manufacturing such as Gerber files, drill files, assembly drawings, Bill of Materials (BOM), etc. These documents serve as a reference for manufacturers to ensure accurate and consistent production.

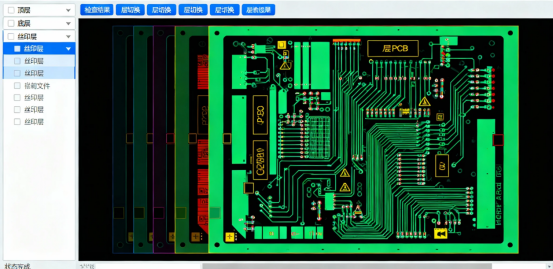

Gerber files are the standard format in the PCB industry, used to describe various elements and components of printed circuit boards, including circuit layers, solder mask layers, silkscreen layers, and more. Simply put, they’re like the “blueprint” for the PCB, telling the manufacturer what each layer should look like.

Why Must Production Files Be Confirmed for PCB Orders?

Avoiding the Hidden Danger of "Software Incompatibility"

Many designers prefer sending original design files directly (such as .brd, .pcbdoc), but this carries significant risks. Different versions of PCB design software may be incompatible, causing errors when the manufacturer opens the file. Popular tools like Altium Designer, for example, may have compatibility issues with certain manufacturers' systems.

Some PCB manufacturers explicitly state: “Preferably send Gerber files for original files. If software incompatibility issues occur with PCB original files, both parties bear 50% responsibility for the PCB boards.”

This means if production fails due to software compatibility issues, you’ll bear half the loss!

Preventing Disconnection Between "Design Intent" and "Manufacturing Reality"

What appears in design software doesn’t always match what the manufacturer sees in production files. By confirming production files, you ensure what the manufacturer receives is completely consistent with your design.

Common issues include:

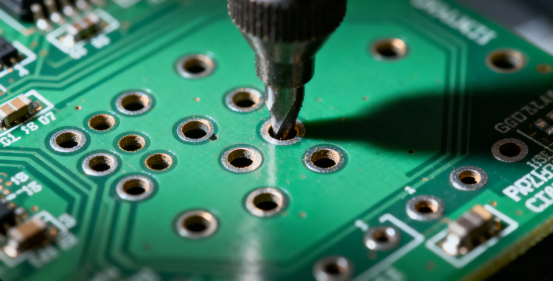

·Missing Drill Files: Leading to inability to determine hole positions and sizes

·Incomplete Solder Mask: Missing bottom or top solder mask layers in multilayer boards

·Outline Errors: Missing or duplicate board outlines causing incorrect PCB cutting

·Size Mismatches: Discrepancies between order input dimensions and Gerber file dimensions

Checking files against design rules helps prevent these problems by ensuring the layout meets manufacturing requirements. It is also crucial to verify all details, such as component specifications, model numbers, and size parameters, in the production files to ensure consistency with the design intent and avoid production delays.

Identifying Potential Production Issues

Professional PCB manufacturers perform Design for Manufacturability (DFM) checks during file confirmation to identify potential production issues in advance:

·Trace Width/Spacing: Whether it exceeds factory process capabilities (e.g., minimum trace width less than 3mil)

·Aspect Ratio: Whether it meets the requirement of hole diameter/board thickness ratio ≤ 8:1

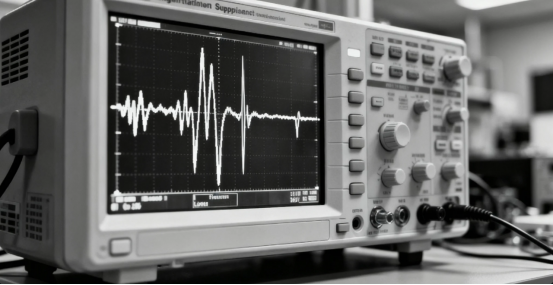

·Impedance Control: Whether differential impedance for high-speed signal lines (like USB, HDMI) meets requirements (e.g., 100Ω ± 10%)

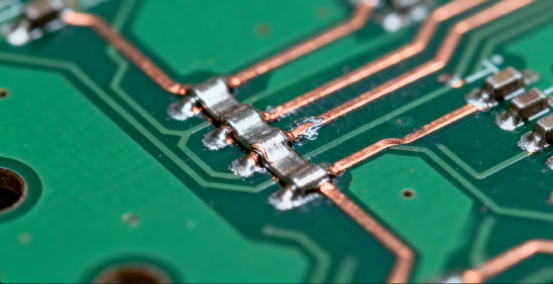

·Pad Design: Whether it may cause solder bridging or cold joints

·Processing Requirements: Whether all processing requirements, such as soldering or conformal coating specifications, are clearly documented in the files

Typical Problem Cases Discovered During File Confirmation

Case 1: Short Circuits Due to Missing Solder Mask

Engineer Zhang, rushing to prototype a smart home controller, skipped file confirmation and went directly to production. The entire batch of PCBs showed large-scale short circuits discovered during the test phase. Post-analysis revealed a setting error in the design software caused the bottom solder mask layer not to generate, exposing copper traces that contacted each other during assembly.

Had there been a file confirmation step, this issue could have been easily detected using a Gerber viewer before production. Proper file confirmation could have saved significant time and costs by preventing this problem.

Case 2: Incorrect Drill Files

An industrial equipment company, during mass production of industrial control boards, failed to provide clear distinction between plated and non-plated holes. This resulted in difficult installation of components, as unclear information in the drill files hindered proper component placement and verification, with a pass rate of less than 60%. Cross-referencing the drill files with the BOM file could have clarified component requirements and prevented this issue. The losses included not only PCB costs but more seriously, two weeks of project delay.

Case 3: Impedance Mismatch

Engineer Li’s high-speed data acquisition board worked fine in the lab but showed data errors during small-batch production. Investigation revealed that the differential pair trace width in the Gerber files didn’t match the impedance calculation, with actual impedance being 85Ω instead of the designed 100Ω. An accurate description of the trace width in the design files or BOM could have prevented this impedance mismatch.

PCB Production File Confirmation Checklist

To ensure smooth production, please verify the following checklist before board submission. It is essential to review all the files involved in the production process to avoid errors and delays.

Make sure to check different types of files, such as Gerber files, BOM, and assembly drawings, for completeness and accuracy.

File Completeness Check

·Gerber files include all layers (top/bottom/inner layers)

·Solder mask files (top and bottom)

·Silkscreen files (top and bottom)

·Drill files (NC Drill)

·Board outline file

·Solder paste layer files (if designed for SMT)

·Place files (component coordinates for automated pick-and-place assembly)

Version Consistency Confirmation

·Gerber file versions match the BOM

·Assembly drawings match actual design

·All files have identical date stamps

Make sure to plan for version control so all files remain consistent and up to date.

Key Parameter Review

·Board thickness and dimensional tolerances clearly marked

·Impedance control requirements clearly specified

·Special process requirements (like ENIG, HASL) clearly stated

·Review any specific notes included in the BOM or assembly drawings for special instructions, such as component program burn-in, installation requirements, or mounting details

Free Tools for PCB File Checking

Ensuring your printed circuit board (PCB) design files are error free before starting the manufacturing process is crucial for achieving high product quality and avoiding costly mistakes. Fortunately, there are a variety of free PCB file checking tools available that can help engineers and designers catch design rule violations and other issues early in the process.

One of the most widely used categories of free tools is the Gerber file viewer. These programs allow you to open and inspect your Gerber files—the industry standard format for PCB manufacturing—so you can visually verify each layer of your printed circuit, including copper traces, solder mask, and silkscreen. By reviewing your files with a Gerber viewer, you can spot missing layers, misaligned features, or other discrepancies that could impact the final boards.

In addition to Gerber viewers, many free design rule checking (DRC) tools are available. These tools automatically scan your PCB files for common design rule violations, such as minimum trace width, spacing errors, or incorrect drill sizes. By running your design files through a DRC tool, you can ensure your PCB meets the manufacturing requirements of most board houses, reducing the risk of delays or rejections during the manufacturing process.

Professional Advice: From "Confirmation" to "Prevention"

Prioritize Gerber Format

Although smarter formats like ODB++ and IPC-2581 are gaining popularity, Gerber remains the most universal and safest delivery format. Sending Gerber files can reduce software compatibility issues and provide manufacturers with a reliable production foundation. Before sending your files to the manufacturer, it is highly recommended to perform a comprehensive pcb file check to identify any potential manufacturing issues or design rule violations.

Utilize Modern Tools for Assistance

Many PCB manufacturers provide online DFM checking tools that automatically analyze potential issues after file upload. These tools can detect problems difficult for the human eye to spot, such as minimum spacing violations, acute angle traces, etc. In addition, many manufacturers offer a free PCB file check service to help identify issues before production.

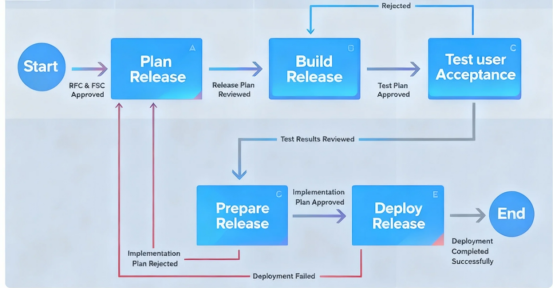

Establish Standardized Release Processes

Teams should establish internal PCB release checklists covering key points like Design Rule Check (DRC), Electrical Rule Check (ERC), and Design for Manufacturability (DFM). Incorporating file checks into the design process helps ensure higher first-pass success rates. Through systematic pre-release checking, first-pass PCB success rates can be increased to over 95%.

Fully Communicate with Manufacturers

For special requirements (like impedance control, special materials), proactively communicate with the manufacturer’s technical personnel. Clear communication with the customer is essential to ensure all requirements are met. Addressing the specific needs of different customers can help optimize the design and manufacturing process. Their experience can help optimize your design and avoid common pitfalls.

Conclusion

PCB production file confirmation isn’t a redundant step but a critical link in ensuring project success. It acts like a mirror, reflecting potential issues in the design, and like insurance, protecting your investment from minor oversights leading to major losses. Confirming files is essential for successful fabrication, pcb fabrication, and pcb assembly, as it ensures all requirements are met for each stage. Proper management of material and program files is also crucial for smooth production and quality control.

In the competitive electronics market, time-to-market is crucial. Rather than spending weeks on rework later, it’s better to invest a few hours carefully confirming production files. Wise engineers understand that each careful file confirmation safeguards the smooth implementation of their project.

Next time a PCB manufacturer asks you to confirm production files, don’t view it as a tedious obstacle but as a valuable quality control opportunity—as this might be the last chance to detect and fix costly errors before product mass production.

Do you have any project stories related to PCB file issues? Feel free to share and exchange in the comments section!

FAQs

Q. Why is production file confirmation necessary?

A.To mitigate risks of design-process mismatch, prevent scrap and delays, and ensure products meet specifications.

Q. What are the core files requiring confirmation?

A.Key documents include GERBER files, BOM, stackup structure, drill drawings, and solder mask/silkscreen specifications.

Q. What should be prioritized during file review?

A.Critical parameters (trace width, hole size, spacing), layer stackup, fiducial marks, solder mask clearance accuracy, and silkscreen legibility.

Q. How long does the confirmation process typically take?

A.Standard orders: 1–2 business days. Complex boards (e.g., HDI, RF boards): 3–5 business days.

Q. What if files deviate from requirements?

A.Engineers will provide modification requests. Clients must revise and resubmit until files meet production standards.

Q. Can files be modified after confirmation?

A.Revisions are permitted but require restarting the confirmation process, which may delay production. Thorough pre-checking is strongly advised.

Author: Jack Wang