PCB Buried Copper Block Embedded Technology Solutions and Process Analysis for High Heat Dissipation Requirements

With the trend of electronic devices moving towards high frequency, high speed, and high power, thermal management has become a critical factor affecting product performance and reliability. Whether it is 5G base station equipment, high-power LED lighting, industrial power supplies, or new energy vehicle electronic control systems, there are increasing demands for the heat dissipation capacity of printed circuit boards (PCBs). Embedded copper technology is compatible with multi layer board structure, making it suitable for complex and high-density designs. In this context, embedded copper PCB technology has emerged as an effective solution to address the problem of high heat accumulation and is gradually gaining prominence. This embedded copper PCB technology is a significant advancement in printed circuit board manufacturing, offering improved thermal management and integration.

What is an Embedded Copper PCB?

Embedded copper PCB, also known as a “copper-based embedded board” or “copper coin PCB,” refers to an advanced structure in which solid copper blocks are embedded into the PCB during the manufacturing process. Electronic components with high heat generation can be directly mounted on top of the embedded copper blocks, leveraging copper’s excellent thermal conductivity (with a thermal conductivity coefficient as high as 400 W/m·K) to rapidly transfer heat to heat sinks or the external environment, thereby significantly reducing the operating temperature of the components.

Compared to traditional heat dissipation methods, such as high-density thermal via arrays or externally attached metal substrates, embedded copper PCBs not only offer significant advantages in heat dissipation efficiency—approximately twice that of via arrays—but also save wiring space and improve integration. This focus on pcb heat dissipation makes embedded copper PCBs particularly effective in managing thermal challenges in modern electronic designs. This makes them particularly suitable for the trend toward “lighter, thinner, shorter, and smaller” electronic products.

At the same time, the rapid development of electronic devices and systems is driving continuous innovation in embedded copper PCB solutions to meet ever-increasing performance and thermal management requirements.

Introduction to Embedded Copper.

Embedded copper PCB, also known as a “copper-based embedded board” or “copper coin PCB,” refers to an advanced structure in which solid copper blocks are embedded into the PCB during the manufacturing process. Electronic components with high heat generation can be directly mounted on top of the embedded copper blocks, leveraging copper’s excellent thermal conductivity (with a thermal conductivity coefficient as high as 400 W/m·K) to rapidly transfer heat to heat sinks or the external environment, thereby significantly reducing the operating temperature of the components.

Compared to traditional heat dissipation methods, such as high-density thermal via arrays or externally attached metal substrates, embedded copper PCBs not only offer significant advantages in heat dissipation efficiency—approximately twice that of via arrays—but also save wiring space and improve integration. This focus on pcb heat dissipation makes embedded copper PCBs particularly effective in managing thermal challenges in modern electronic designs. This makes them particularly suitable for the trend toward “lighter, thinner, shorter, and smaller” electronic products.

At the same time, the rapid development of electronic devices and systems is driving continuous innovation in embedded copper PCB solutions to meet ever-increasing performance and thermal management requirements.

Embedded Copper Coin Applications

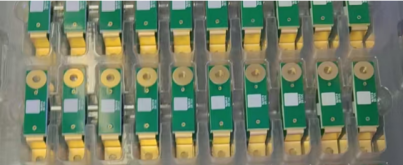

Embedded copper coin technology has become a cornerstone in the design of electronic systems that demand efficient heat dissipation. In the telecommunications sector, embedded copper coins are widely used in high-power devices such as 5G base stations, routers, and network switches, where they help prevent overheating and maintain stable signal transmission even under heavy loads. The ability of copper coins to rapidly conduct heat away from heat generating components ensures that these critical devices operate reliably and efficiently.

In automotive electronics, embedded copper coins play a vital role in electric vehicles (EVs) and modern cars, particularly in heat-intensive systems like electronic control units (ECUs), advanced driver-assistance systems (ADAS), and powertrains. By providing a direct and efficient heat dissipation path, copper coin technology helps improve the efficiency and reliability of these systems, reducing the risk of thermal failure and extending component life.

Industrial automation and medical devices also benefit from embedded copper coin solutions. In industrial settings, copper coins are used in power modules and motor drives to manage the heat generated during continuous operation. In medical equipment, where precision and reliability are paramount, embedded copper coins ensure that sensitive electronics remain within safe temperature ranges. Across all these applications, the use of embedded copper coins and copper coin technology delivers efficient heat dissipation, supporting the performance and longevity of heat generating components.

Solutions for High Heat Dissipation Requirements

Meeting the demands of high heat dissipation in modern electronics requires innovative design strategies, and embedded copper block design stands out as a highly effective solution. By embedding copper blocks directly beneath heat generating components, designers can create a rapid and direct heat transfer path to heat sinks, significantly reducing the risk of overheating. The use of high thermal conductivity materials, such as copper and advanced metal composite materials, further enhances the heat dissipation function of the PCB.

In addition to embedded copper blocks, incorporating thick copper foil circuits and local thick copper plating can dramatically improve the thermal performance of the board. These techniques increase the overall thermal conductivity, allowing for more efficient heat spreading and dissipation. Embedded copper block PCBs are particularly advantageous in applications with high power electronic components, such as power converters, LED lighting systems, and automotive power control units, where managing heat is critical to maintaining performance and reliability.

By combining embedded copper block design with high thermal conductivity materials and advanced copper plating techniques, engineers can develop PCBs that deliver high heat dissipation performance, ensuring that even the most demanding electronic systems remain cool and stable during operation.

Manufacturing Process and Quality Control

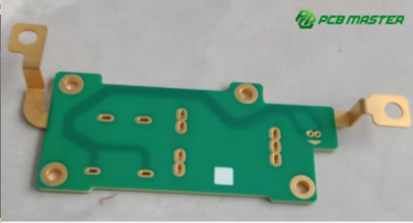

The manufacturing of embedded copper PCBs involves a series of precise and carefully controlled steps to ensure optimal heat dissipation and long-term reliability. The process begins with milling grooves in the PCB to accommodate the copper blocks, followed by the accurate placement of the copper block into the prepared slot. Achieving a strong quality and bonding force between the copper block and the surrounding PCB material is essential for effective thermal management and mechanical stability.

To guarantee the integrity of the embedded copper, manufacturers utilize advanced equipment such as controlled depth milling machines, which enable precise groove formation and copper placement. The choice of substrate materials, including high-performance epoxy resin and ceramic substrates, is also critical, as these materials must support both the mechanical and thermal requirements of the application.

Throughout the manufacturing process, rigorous quality control measures are implemented, including design verification, in-process inspections, and comprehensive final testing. These steps ensure that the embedded copper PCBs meet stringent standards for heat dissipation and reliability. By focusing on the quality and bonding force of the copper block, as well as the careful selection of materials and process controls, manufacturers can deliver embedded copper PCBs that provide superior thermal management for a wide range of applications.

Design and Procedure Considerations

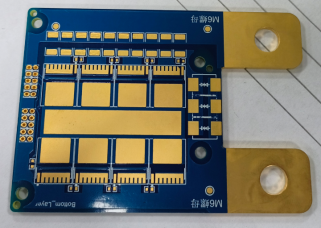

In addition to copper block design, the configuration of the PCB layers—including the inner layer core board, core board, and overall PCB stack-up—plays a crucial role in thermal management. The use of high-quality thermal interface materials between the copper block and heat generating components further enhances heat transfer, while careful layer design ensures that the heat is efficiently conducted away from critical areas.

By considering factors such as copper block thickness, copper block dimensions, heat dissipation path, and the integration of thermal interface materials, engineers can create embedded copper PCBs that deliver exceptional thermal performance. These design and procedure considerations are essential for meeting the rigorous demands of modern electronic devices, ensuring reliable operation and effective heat management in even the most challenging environments.

Conclusion

Embedded copper PCB technology successfully addresses heat dissipation challenges in high heat flux environments by heterogeneously integrating the high thermal conductivity of metal with the wiring capability of organic substrates. Its flexible design does not require additional space, enhancing product power capacity while improving reliability and service life. Although the manufacturing process demands high precision and process control, with equipment upgrades and accumulated industry experience, this technology is destined to become an indispensable part of high-end electronic devices.

FAQs

Q: What is the core distinction between buried copper blocks and embedded copper blocks?

A: Buried copper blocks are entirely concealed within the PCB stack-up with no surface exposure, primarily for inner-layer current transmission and heat dissipation; embedded copper blocks are partially exposed or connected to surface components, mainly used for direct heat dissipation and power supply of surface devices (such as processors).

Q: How do they enhance PCB performance?

A:balabHeat Dissipation: High thermal conductivity enables rapid heat transfer, preventing component overheating;

Electrical Conductivity: Low resistance optimizes high-current transmission (e.g., EV power supply), reducing losses;

Anti-Interference: Buried copper blocks can also function as shielding layers, reducing signal interference.

Q: Are they suitable for all PCBs?

A:No. They are more suitable for high-power, high-density applications (e.g., EVs, 5G equipment).

For low-power, simple PCBs (e.g., ordinary household appliance control boards), their use is cost-ineffective.

Q: What should be considered during design?

A:First, clarify the heat dissipation/current requirements of components to determine whether to use buried or embedded copper blocks;

Reserve space for copper blocks and match their size to power requirements;.

Use professional software to plan stack-up and connection points to ensure alignment accuracy.