Copper-Aluminum Mixed PCB: The Game-Changer in Modern Electronics

Introduction

In the fast-paced world of electronics, innovation never stops. From smartphones that fit in our pockets to complex industrial machinery, every device relies on printed circuit boards (PCBs) to function. Among the latest advancements in PCB technology, Copper-Aluminum Mixed PCBs have emerged as a revolutionary solution, offering a unique blend of performance, cost-effectiveness, and versatility.

What is a Copper-Aluminum Mixed PCB?

Let’s start with the basics. A Copper-Aluminum Mixed PCB, as the name suggests, is a circuit board that combines both copper and aluminum layers in its structure. Traditional PCBs typically use only copper for their conductive layers, but this new design leverages the strengths of both metals to create a more efficient and versatile product. Compared to aluminum PCBs, which are widely used for their lightweight and excellent thermal management in applications like LED lighting, and copper-based PCBs, which are preferred for their superior electrical conductivity and use in high-power devices, copper-aluminum mixed PCBs offer a balanced solution for applications requiring both efficient heat dissipation and strong electrical performance.

Think of it as a team where copper and aluminum each bring their best skills to the table. Copper is an excellent conductor of electricity, while aluminum excels at dissipating heat. By combining them, manufacturers can create PCBs that handle electrical signals efficiently while keeping temperatures in check – a crucial factor in today’s high-performance devices. Over time, the evolution of PCB materials has included the development of aluminum based PCBs, which play a significant role in thermal management for energy-efficient and lightweight electronic designs.

Structural Features of Copper-Aluminum Mixed PCBs

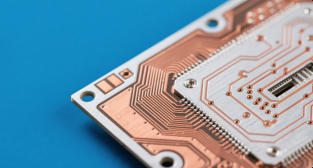

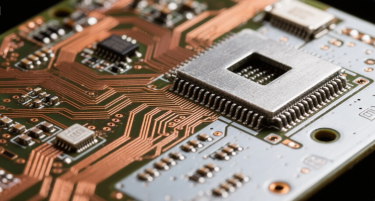

Copper-Aluminum Mixed PCBs are engineered to maximize both electrical performance and thermal management by leveraging the unique properties of their layered structure. At the heart of these PCBs is a robust aluminum core, which acts as the base material and provides outstanding mechanical durability and efficient heat dissipation. On top of the aluminum core lies a dielectric insulation layer, designed to electrically isolate the conductive copper layer from the aluminum substrate while still allowing for effective thermal conduction. This insulation layer is critical for maintaining electrical safety and reliable operation, especially in high-power applications.

The copper layer, typically made from high-quality electrolytic copper foil, forms the conductive pathways for electronic signals and power distribution. This layer is optimized for component assembly, ensuring excellent electrical conductivity and compatibility with a wide range of electronic components. The combination of copper foil and aluminum substrates results in better thermal conductivity compared to traditional PCBs, making these boards ideal for applications where heat management is crucial, such as power supplies, automotive electronics, and LED lighting.

Copper-Aluminum Mixed PCBs can be manufactured as single-sided, double-sided, or even multi-layered boards, offering flexibility in PCB design to meet diverse application requirements. Whether used in compact LED modules or complex automotive control systems, the structure of these PCBs ensures efficient heat dissipation, enhanced mechanical properties, and reliable performance under demanding conditions.

How Do Copper-Aluminum Mixed PCBs Work?

To understand how these hybrid PCBs work, let’s break down their structure. Most Copper-Aluminum Mixed PCBs consist of:

·Copper layers: These are used for the actual circuit traces that carry electrical signals. Copper’s high conductivity ensures minimal signal loss and efficient power transmission.

·Alumium layers: These form the aluminum base, functioning as a heat conduction layer underneath the copper and PP layers, aiding in the dissipation of heat from electronic components.

·Insulating layers: These are made from dielectric material, separating the copper and aluminum layers to ensure electrical isolation while allowing thermal transfer from copper to aluminum.

The magic happens in how these layers interact. When electrical current flows through the copper traces, some energy is converted to heat – this is normal in any electronic device. The heat generated by electronic components is managed by the PCB structure: in traditional PCBs, this heat can build up, potentially damaging components or reducing performance. But in Copper-Aluminum Mixed PCBs, the heat quickly transfers to the aluminum layers, which spread it out and release it into the surrounding environment.

Circuit Board Materials in Copper-Aluminum Mixed PCBs

The choice of materials in Copper-Aluminum Mixed PCBs is fundamental to their superior performance and reliability. The copper layer is crafted from electrolytic copper foil, renowned for its excellent electrical conductivity and resistance to corrosion. This ensures that electronic signals are transmitted efficiently and that the board can carry higher currents without degradation over time.

The insulation layer, often made from advanced dielectric materials such as aluminum oxide or ceramic, provides both electrical insulation and thermal conduction. This dielectric insulation layer is essential for preventing electrical shorts while enabling rapid heat transfer from the copper layer to the aluminum core. The result is a board with good thermal conductivity and robust electrical insulation, even at elevated temperatures.

At the core of the PCB is a high-purity aluminum alloy, chosen for its outstanding thermal conductivity, mechanical properties, and corrosion resistance. The aluminum core not only acts as a heat sink, promoting efficient heat dissipation, but also enhances the structural integrity and mechanical durability of the board. This makes Copper-Aluminum Mixed PCBs a preferred choice for high power applications where both electrical and thermal performance are critical.

All materials used in these PCBs are non-toxic and environmentally friendly, aligning with modern industry standards for safety and sustainability. The synergy between copper and aluminum substrates delivers a balance of electrical conductivity, thermal management, and mechanical strength, making these PCBs ideal for demanding environments and applications that require long-term reliability and energy conservation.

Advantages of Copper-Aluminum Mixed PCBs

Now that we know what they are and how they work, let’s explore why Copper-Aluminum Mixed PCBs are gaining popularity across various industries. The combination of copper and aluminum in these PCBs significantly improves the overall performance of electronic devices by enhancing thermal management and operational efficiency.

1. Superior Heat Dissipation

One of the biggest advantages of these hybrid PCBs is their ability to handle heat. As electronic devices become more powerful, they generate more heat. Excess heat can cause components to fail prematurely or operate less efficiently.

Aluminum’s thermal conductivity is about 237 W/m·K, significantly higher than many other materials used in PCBs. When paired with copper’s electrical conductivity (59,600,000 S/m), the result is a PCB that can handle high-power applications without overheating. Copper thickness and line width both play crucial roles in determining the heat dissipation and current-carrying capacity of the PCB; increasing copper thickness or optimizing line width can further enhance performance. When comparing aluminum substrates and copper layers of the same thickness, aluminum substrates can carry higher currents and offer better thermal conductivity, while copper layers provide superior electrical conductivity, making the choice dependent on the specific application requirements.

This makes Copper-Aluminum Mixed PCBs ideal for devices like power supplies, LED lighting systems, and motor controllers – all of which generate substantial heat during operation.

2. Cost-Effectiveness

Copper is expensive, and as demand for electronics grows, its price can fluctuate significantly. Aluminum, on the other hand, is more abundant and less costly. By using aluminum for non-conductive, heat-dissipating layers, manufacturers can reduce the amount of copper needed without sacrificing performance.

This cost savings can be substantial, especially for large-scale production. It allows manufacturers to create high-quality PCBs at a lower price point, making advanced electronics more accessible to consumers and businesses alike.

3. Lightweight Design

Aluminum is much lighter than copper – about one-third the density. This makes Copper-Aluminum Mixed PCBs lighter than traditional all-copper PCBs. For applications where weight is a concern – such as aerospace components, drones, or portable devices – this can be a game-changer.

A lighter PCB means a lighter overall device, which can improve battery life in portable electronics and reduce fuel consumption in aerospace and automotive applications.

4. Improved Mechanical Strength

Aluminum offers better mechanical strength and durability compared to some other PCB materials. This makes Copper-Aluminum Mixed PCBs more resistant to physical stress, vibrations, and temperature changes.

In harsh environments – like industrial settings or outdoor equipment – this added durability can significantly extend the lifespan of electronic devices, reducing maintenance costs and downtime.

5. Design Flexibility

Copper-Aluminum Mixed PCBs offer greater design flexibility than traditional PCBs. Engineers can strategically place copper and aluminum layers based on the specific needs of the device.

Some designs feature dual component mounting sides, allowing components to be placed on both sides of the board, similar to FR4 PCBs, which enhances circuit complexity and heat transfer pathways. In contrast, single component mounting and single component mounting side configurations offer structural simplicity and thermal advantages, making them ideal for applications where efficient heat dissipation and straightforward manufacturing are priorities. Single sided aluminum substrate designs are suitable for basic electronic components due to their simple structure and effective thermal management.

For example, in an LED light, the copper layers can be designed to efficiently distribute power to the LEDs, while the aluminum layers can be optimized to draw heat away from these components, preventing them from burning out. Double-sided designs typically consist of two layers separated by an insulating material, further improving circuit complexity and heat dissipation.

This flexibility allows for more innovative and efficient device designs, pushing the boundaries of what electronics can achieve.

Applications of Copper-Aluminum Mixed PCBs

The unique combination of properties offered by Copper-Aluminum Mixed PCBs makes them suitable for a wide range of applications. Copper-aluminum mixed PCBs are commonly used in power equipment due to their superior heat dissipation, which is essential for high-power applications. Compared to metal core PCBs, which also provide excellent thermal management and are often used in high-performance electronics, copper-aluminum mixed PCBs offer additional versatility and can be tailored for specific design requirements. Let’s explore some of the most common uses:

1. LED Lighting

LEDs are energy-efficient, but they still generate heat. If this heat isn't properly managed, it can reduce the brightness and lifespan of the LEDs. Copper-Aluminum Mixed PCBs are perfect for LED lighting systems because they:

·Conduct electricity efficiently to power the LEDs

·Dissipate heat quickly to keep the LEDs cool

·Are cost-effective for large-scale production of lighting fixtures

From household bulbs to industrial lighting systems, these PCBs are helping to make LED technology more reliable and long-lasting.

2. Power Electronics

[Enter content text hereEnter content text here]

Devices like power supplies, inverters, and motor controllers handle high voltages and currents, making heat management critical. Copper-Aluminum Mixed PCBs excel in these applications because they can:

·Handle high power levels without overheating

·Reduce energy loss through efficient conduction

·Withstand the mechanical stress of high-power operation

This makes them essential components in renewable energy systems, electric vehicles, and industrial machinery.

3. Automotive Electronics

Modern cars are packed with electronics – from infotainment systems to advanced driver-assistance systems (ADAS). These components need to operate reliably in extreme temperatures and harsh conditions.

Copper-Aluminum Mixed PCBs are ideal for automotive applications because they:

·Can withstand wide temperature ranges

·Resist vibrations and physical stress

·Offer lightweight design to improve fuel efficiency

As electric vehicles become more popular, the demand for these PCBs is expected to grow, as they can handle the high-power requirements of EV batteries and motors.

4. Aerospace and Defense

In aerospace and defense applications, reliability is paramount. Electronic components must operate flawlessly in extreme conditions, including high altitudes, wide temperature ranges, and high levels of vibration.

Copper-Aluminum Mixed PCBs meet these demands by offering:

·Lightweight construction to reduce aircraft weight

·Excellent heat dissipation for high-performance components

·Durability to withstand harsh environments

From communication satellites to military equipment, these PCBs are playing a crucial role in advancing aerospace and defense technology.

5. Consumer Electronics

While smartphones and laptops might not generate as much heat as power electronics, they still benefit from the advantages of Copper-Aluminum Mixed PCBs. These include:

·Lighter weight for more portable devices

·Better heat management to prevent performance throttling

·Cost savings that can be passed on to consumers

As consumers demand thinner, lighter, and more powerful devices, manufacturers are turning to these hybrid PCBs to meet these expectations.

How Copper-Aluminum Mixed PCBs are Manufactured

The manufacturing process for Copper-Aluminum Mixed PCBs is more complex than for traditional PCBs, but the results are well worth the effort. Compared to the manufacturing of traditional copper PCBs and other based PCBs, such as copper-based PCBs and aluminium-based PCBs, this process involves additional steps to ensure optimal performance and integration of both metals. Here’s a simplified overview of the process:

·Material preparation: High-quality copper and aluminium sheets are selected based on their thickness and material properties, along with insulating materials that can effectively separate the layers while allowing heat transfer.

·Layer bonding: The copper and aluminium layers are bonded together with the insulating material in between. This requires precise temperature and pressure control to ensure a strong bond without damaging the materials.

·Circuit design transfer: The circuit pattern is transferred to the copper layers using a photolithography process. This involves coating the copper with a photosensitive material, exposing it to light through a mask of the circuit design, and then etching away the unwanted copper.

·Drilling and plating: Holes are drilled through the PCB to connect different layers, and these holes are plated with copper to ensure electrical conductivity between layers.

·Surface treatment: The PCB surface is treated to protect it from corrosion and improve solderability. This might include applying a thin layer of nickel or gold to the copper pads.

·Testing and quality control: Each PCB undergoes rigorous testing to ensure it meets performance standards. This includes checking for electrical continuity, insulation resistance, and thermal performance.

When selecting insulating materials, the dielectric constant is an important factor, as it affects signal propagation and overall transmission efficiency.

The entire process requires specialized equipment and expertise, but as demand for these PCBs grows, manufacturing techniques are becoming more efficient and cost-effective.

Choosing the Right Copper-Aluminum Mixed PCB for Your Project

If you're considering using Copper-Aluminum Mixed PCBs in your project, there are several factors to keep in mind:

·Power requirements: Consider the amount of power your device will handle. Higher power applications will require thicker copper layers and more extensive aluminum heat sinks.

·Heat generation: Estimate how much heat your components will generate. This will help determine the size and placement of the aluminum layers.

·Environmental conditions: Think about where your device will be used. Extreme temperatures, vibrations, or exposure to moisture will affect the type of materials and protective coatings needed.

·Cost constraints: While Copper-Aluminum Mixed PCBs can be cost-effective, the exact design will impact the final price. Work with your manufacturer to balance performance and cost.

·Manufacturing capabilities: Not all PCB manufacturers have experience with Copper-Aluminum Mixed PCBs. Choose a manufacturer with a proven track record in producing these hybrid boards.

By carefully considering these factors, you can select the perfect Copper-Aluminum Mixed PCB for your specific application.

Future Trends in Copper-Aluminum Mixed PCB Technology

As electronics continue to evolve, so too will Copper-Aluminum Mixed PCB technology. Here are some trends to watch for in the coming years:

·Improved bonding techniques: Researchers are working on better ways to bond copper and aluminum layers, which could improve thermal transfer and mechanical strength.

·Integration with other materials: We might see Copper-Aluminum Mixed PCBs combined with other materials, like carbon fiber or ceramics, to create even more specialized boards.

·Miniaturization: As devices get smaller, Copper-Aluminum Mixed PCBs will need to become more compact while maintaining their performance. This could lead to new design techniques and manufacturing processes.

·Increased use in renewable energy: With the growing focus on renewable energy sources like solar and wind power, Copper-Aluminum Mixed PCBs will play an increasingly important role in power management systems.

·Smart thermal management: Future PCBs might include sensors and active cooling elements integrated with the copper-aluminum structure, allowing for real-time temperature regulation.

These advancements will make Copper-Aluminum Mixed PCBs even more versatile and effective, opening up new possibilities in electronics design.

Common Misconceptions About Copper-Aluminum Mixed PCBs

Like any new technology, Copper-Aluminum Mixed PCBs have their share of misconceptions. Let's address some of the most common ones:

"They're not as reliable as traditional PCBs"

This couldn't be further from the truth. When properly designed and manufactured, Copper-Aluminum Mixed PCBs can be just as reliable – if not more so – than traditional PCBs, especially in high-heat or high-stress applications.

"They're too expensive"

While the initial cost might be slightly higher than for basic PCBs, the long-term savings in energy efficiency, reduced component failure, and extended device lifespan often make them a more cost-effective choice, especially for high-performance applications.

"They're difficult to work with"

While they do require some specialized knowledge for design and manufacturing, many PCB manufacturers now have experience with these hybrid boards. As the technology becomes more mainstream, working with them will become even easier.

"They're only suitable for large devices"

Copper-Aluminum Mixed PCBs come in all sizes, from large industrial boards to small components for portable electronics. Their versatility makes them suitable for a wide range of device sizes.

Conclusion:

Why Copper-Aluminum Mixed PCBs are Here to Stay

Copper-Aluminum Mixed PCBs represent a significant advancement in circuit board technology. By combining the best properties of copper and aluminum, they offer superior heat dissipation, cost-effectiveness, lightweight design, and improved durability – all qualities that are in high demand in today's electronics market.

From LED lighting to electric vehicles, these hybrid PCBs are already making an impact across various industries. As manufacturing techniques improve and costs continue to decrease, we can expect to see them used in even more applications in the years to come.

If you're involved in electronics design or manufacturing, it's worth exploring how Copper-Aluminum Mixed PCBs could benefit your projects. Their unique combination of properties might just be the solution you've been looking for to take your devices to the next level.

FAQs

Q. What is a copper-aluminum mixed PCB? How is it different from traditional PCBs?

A. A copper-aluminum mixed PCB is a circuit board that combines copper layers (for signal transmission) and aluminum layers (for heat dissipation), separated by insulating layers to transfer heat. Traditional PCBs use copper as the conductive layer and rely on external components (such as heat sinks) for heat dissipation, unlike the former, which integrates "conductivity + heat dissipation" for optimized performance.

Q. How much better is the heat dissipation compared to traditional PCBs? Is there data?

A. The thermal conductivity of aluminum (237 W/m·K) is much higher than that of traditional FR-4 substrates (0.2-0.4 W/m·K). Taking a 10W LED driver board as an example: without a heat sink, the component temperature of a traditional PCB can exceed 85°C, while a copper-aluminum mixed PCB can maintain temperatures between 55-65°C, improving heat dissipation efficiency by 30%-40%.

Q. Is the cost higher? Is it cost-effective in the long run?

A. The initial cost is 15%-30% higher than that of traditional PCBs, but it is more cost-effective in the long run: first, it eliminates the need for heat sinks and installation costs; second, it reduces device damage caused by overheating, extending the service life by 2-3 times and lowering maintenance/replacement costs.

Q. Can the copper and aluminum layers delaminate? How can this be avoided?

A. Delamination may occur due to differences in thermal expansion but can be prevented through three measures: using specialized bonding layers like modified epoxy resin as a buffer; precisely controlling lamination temperature (180-220°C) and pressure (20-30 kg/cm²); and applying edge-sealing protection to the PCB.

Q. Can components be soldered onto it? Will it damage the aluminum layer?

A. Soldering can be performed normally, as the solder joints are on the copper layer (the aluminum layer is non-conductive). The soldering process is the same as for traditional PCBs (SMT temperature: 250-260°C). The aluminum layer undergoes passivation treatment and can withstand temperatures above 280°C. During soldering, the temperature of the aluminum layer does not exceed 150°C, so it will not be damaged.

Author: Jack Wang