Printed Circuit Board Assembly (PCBA) vs. PCB: Key Differences Explained

If you're new to electronics manufacturing, you might find yourself confused by the terms PCB and PCBA. While both refer to circuit boards, there’s a significant difference between the two. Let’s break it down and explain how they differ.

What Are PCB and PCBA?

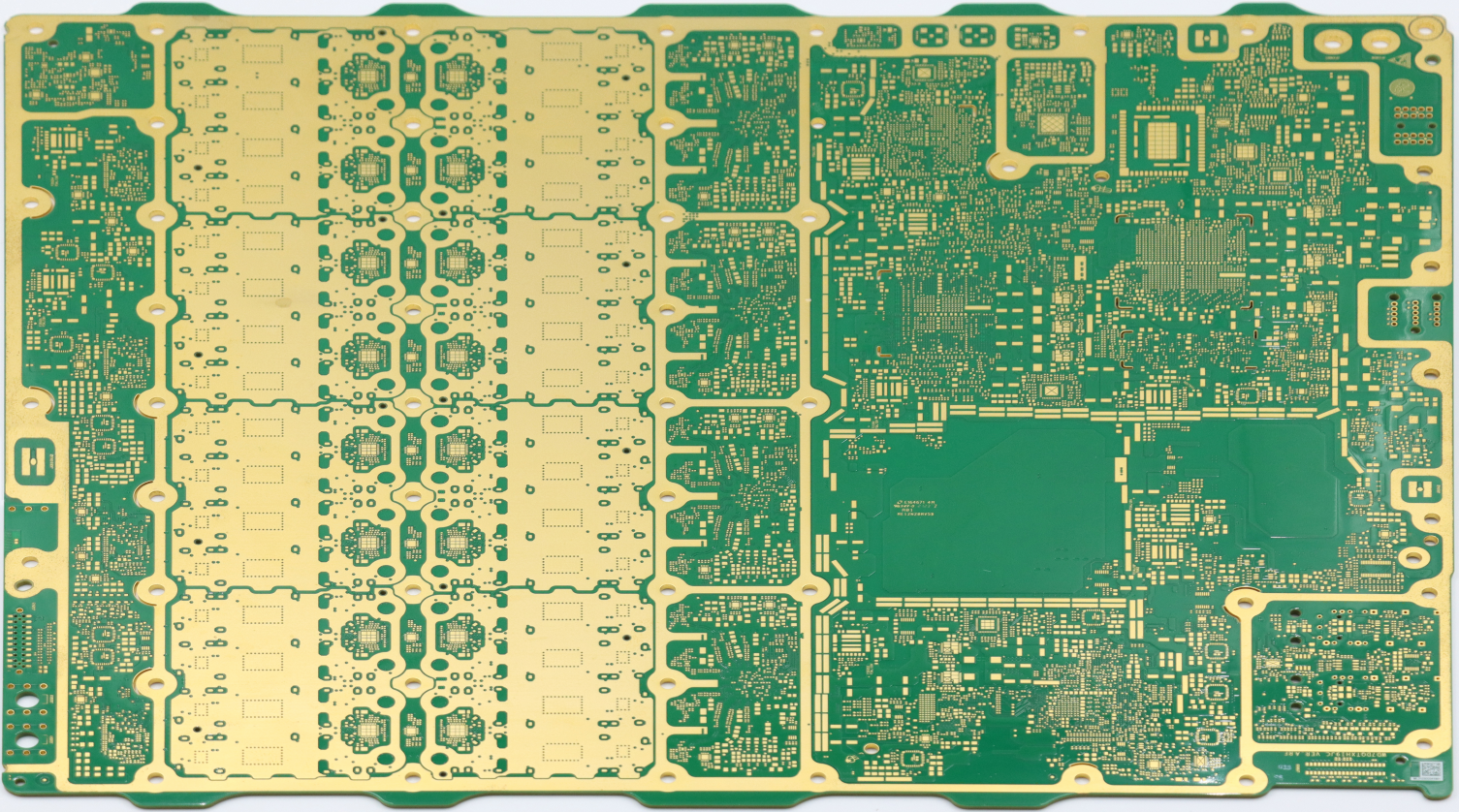

1. PCB (Printed Circuit Board)

A PCB is the foundation of all electronic devices. It’s typically made from insulating materials like fiberglass or resin and has a copper layer that allows electrical signals to travel across the board. To put it simply, think of a PCB as the "skeleton" of the circuit board — it provides the structure but doesn’t yet have any active components. Essentially, a PCB is the "platform" that enables different electronic parts to connect and communicate.

2. PCBA (Printed Circuit Board Assembly)

A PCBA is the fully assembled version of a PCB. Once the basic PCB is created, various electronic components like resistors, capacitors, diodes, and integrated circuits (ICs) are placed and soldered onto the board. At this point, the PCBA is fully functional and capable of performing specific electrical tasks according to its design.

Key Differences Between PCB and PCBA

1. Structure and Composition

PCB: A PCB only includes the circuit pattern and pads, with no electronic components on the surface. It is made from insulating materials like fiberglass or resin, with a copper layer that forms the electrical pathways. Essentially, a PCB acts as the "skeleton" of a circuit board — it provides the framework but does not contain any active electronic components. It’s the platform that allows different electronic parts to connect and communicate.

PCBA: A PCBA is a fully assembled circuit board. In addition to the basic PCB layout, it includes electronic components such as resistors, capacitors, diodes, and integrated circuits (ICs), all of which are soldered onto the board. Once assembled, the PCBA is fully functional and can perform the electrical tasks it was designed for.

2. Functionality

PCB: A PCB is essentially a blank circuit board, meaning it can't perform any electronic functions by itself. It’s just a base that provides the necessary electrical pathways and physical support for components, so it doesn’t do anything on its own until the components are added.

PCBA: A PCBA, on the other hand, is fully functional. After the components are placed and soldered, the PCBA is capable of performing tasks like signal transmission, power conversion, data processing, and more, depending on the design. It's the fully operational version of the PCB.

3. Manufacturing Process

PCB: The production of a PCB involves several steps, including circuit design, printing the circuit layout, and etching. These steps result in the creation of the basic electrical paths on the board.

PCBA: A PCBA takes the PCB a step further. After the PCB is manufactured, components are placed on the board using methods like surface-mount technology (SMT) or through-hole technology. The components are then soldered in place, and the board undergoes various tests to ensure it functions as intended. This process involves more complexity and precision, and results in a fully operational circuit board.

4. Cost and Production Time

PCB: Producing a PCB is quicker and more cost-effective because it only involves designing the electrical pathways and basic connections.

PCBA: The production of a PCBA takes longer and is more expensive due to the additional steps required — such as component sourcing, placement, soldering, and testing.

5. Quality Control

PCB: Quality control for PCBs focuses mainly on ensuring the integrity of the circuit and the quality of the copper traces. This includes checks for continuity, proper copper thickness, and ensuring no shorts or open circuits.

PCBA: In addition to the PCB’s quality checks, PCBA requires more rigorous testing, such as inspecting the soldering quality, component placement, and electrical functionality. Tests like automated optical inspection (AOI), X-ray inspection, and functional testing are commonly used to ensure the board is performing as expected.

6. Applications

PCB: PCBs are primarily used during the development phase or when designing custom circuit boards.

PCBA: Once fully assembled, PCBAs are used in a wide range of electronic devices, including consumer electronics, computers, automotive electronics, medical equipment, and more. These fully functional assemblies are essential in modern devices, carrying out everything from power control to complex signal processing.

How to Choose PCB and PCBA

Now that you understand the difference between PCB and PCBA, how do you go about selecting the right PCB and PCBA for your project? Whether you're working on prototype development, mass production, or custom designs, choosing the right PCB and PCBA is crucial as it directly impacts your product's performance, cost, and production efficiency. Here are some key factors to consider when selecting both:

1. Choosing a PCB

The right PCB ensures that the final product will provide stable electrical connections and solid physical support for your components. Here’s what to consider when selecting a PCB:

Material Selection:

Common PCB materials include FR4 (fiberglass resin), CEM-1 (composite material), and higher-performance options like Polyimide (PI) and ceramics. Choosing the right material optimizes electrical performance, heat resistance, and mechanical strength.

Layer Count:

Single-layer PCBs are cost-effective and used for simple designs, while double-layer PCBs are suitable for more complex circuits. Multilayer PCBs (commonly 4 layers, 6 layers, or more) are used for high-density circuits and high-speed signal applications.

Size and Thickness:

Smaller PCBs are ideal for portable devices, while larger PCBs are better for industrial equipment or high-power applications. The thickness of the PCB affects its mechanical strength and heat dissipation ability.

Surface Finish:

Common finishes include OSP (Organic Solderability Preservative), metal spraying, and gold plating. Choosing the right surface finish is essential for ensuring reliable electrical connections and high-quality soldering.

Signal and Power Requirements:

For high-speed signals or high-power applications, it’s essential to choose the right PCB design. Consider factors like signal integrity, EMI (Electromagnetic Interference), PCB layout, and trace routing to ensure the best performance for your application.

2. Choosing a PCBA

A PCBA is a fully assembled PCB, which means it’s not just about selecting the right PCB but also involves choosing the right electronic components, soldering processes, and product testing. When selecting a PCBA, consider the following factors:

Component Selection:

The quality and performance of these components directly influence the overall performance of the final product. Special requirements, like low power consumption or high-frequency support, may further narrow down the selection.

Soldering Process:

Common soldering methods include hand soldering, wave soldering, reflow soldering, and selective soldering. Reflow soldering is the most common for surface-mount devices (SMDs), while hand soldering is used for special components in smaller or more complex production runs.

Assembly and Testing:

Ensuring each component is properly installed and conducting thorough testing is key. Testing methods include Automated Optical Inspection (AOI), X-ray inspection, and functional testing. It’s important to choose an assembly manufacturer with strong quality control to guarantee the PCBA functions as expected.

Production Volume and Customization:

Small batches often have lower initial costs but may come with higher unit prices. For large-scale production, the per-unit cost is typically lower, but this requires a more complex production and testing process. Additionally, if your application requires customization (e.g., for the medical, automotive, or aerospace industries), ensure the manufacturer can accommodate these specific needs.

Functionality and Reliability:

Depending on the product’s intended function, reliability and stability are paramount when selecting a PCBA. Applications like automotive, medical devices, and industrial electronics demand higher reliability and more rigorous testing and certification, such as ISO9001 or ISO14001 certifications.

3. Key Considerations When Choosing PCB and PCBA

When selecting both PCB and PCBA, it’s important to balance various factors such as the product's end-use, budget, production timeline, and functional requirements. Here are some tips to keep in mind:

Understand the Design Requirements:

The first step in selecting the right PCB and PCBA is to fully understand the design needs. Will the product need to support high-frequency signals or high power, or is it just for basic signal transmission? These requirements will influence the material, process, component choice, and manufacturing steps.

Consider Long-Term Supply Chain and Quality Control:

Ensure that the supplier has the capacity to deliver consistently high-quality products with tight production schedules, and that they have a strong quality control system in place for long-term consistency.

Balance Cost and Performance:

In mass production, the goal is to avoid overly high costs that could impact product quality and functionality. By choosing the right materials, processes, and assembly techniques, you can optimize cost without sacrificing quality.

Consider Production Lead Time and Delivery Schedules:

For time-sensitive projects, it’s important to choose a supplier who can meet shorter production timelines and deliver on time. For non-urgent projects, you might opt for suppliers who offer cost-effective solutions but may have longer lead times.

Conclusion

In summary, understanding the difference between PCB and PCBA is crucial for anyone involved in electronics manufacturing. While a PCB serves as the foundation — providing the necessary structure and electrical pathways — a PCBA takes it a step further by assembling the board with electronic components to create a fully functional circuit. Choosing the right PCB and PCBA involves considering factors such as material, layer count, size, functionality, and production processes. Whether you’re designing a prototype, mass-producing a product, or customizing for a specific industry, making informed decisions about both PCBs and PCBAs will help optimize performance, reduce costs, and improve the overall efficiency of the manufacturing process. By taking into account the unique needs of your project and balancing cost with quality, you can ensure the success of your electronic products.

If you'd like to learn more about PCBs or PCBAs, please contact us.

FAQs

1. Why is it important to understand the difference between PCBA and PCB?

Understanding the difference between PCBA and PCB helps in making informed decisions during the design and production process. It ensures that you select the right option, avoiding mistakes and unnecessary costs. A PCB is useful for early development and prototyping, while a PCBA is required when a functional, fully assembled board is needed. Recognizing these differences improves product quality and prevents production errors, ultimately resulting in a smoother manufacturing process.

2. Why is the production cycle for PCBA longer?

The production cycle for PCBA is longer because it involves several additional steps beyond PCB production, including component placement, soldering, and thorough testing. Each component must be correctly placed and soldered, and the assembled board must undergo quality checks like automated optical inspection and functional testing. These extra processes ensure the board performs correctly, making the overall production timeline for PCBA longer than that of a simple PCB.

3. When should you choose a PCB and when should you choose a PCBA?

Choose a PCB when you're in the early stages of design or need a basic platform for connecting components. It’s perfect for prototyping and custom circuit board creation. Opt for a PCBA when you need a fully functional, tested assembly that’s ready to perform specific tasks, like in final product manufacturing. Essentially, PCBs are for development, while PCBAs are for production-ready, functional solutions.