A Complete Guide to PCB Quality Standards: Understanding IPC, IATF, and ISO Requirements

Introduction

A Complete Guide to PCB Quality Standards: Understanding IPC, IATF, and ISO Requirements

That green circuit board inside electronic devices is far more complex than it appears, and its quality is directly tied to the success or failure of the entire product.

Printed Circuit Boards (PCBs) are universally regarded as the ‘mother of electronic products,’ as nearly every electronic device relies on them. In today’s global manufacturing landscape, uniform quality standards are essential for ensuring PCB reliability. Whether for consumer electronics, automotive systems, or medical devices, different applications demand distinct PCB quality levels. For example, Class 1 PCBs are often used in products that only require basic functions and limited reliability. This guide provides a comprehensive overview of key standards like IPC-6012 Class 2/3, IATF 16949, and ISO 13485, helping you navigate the critical requirements for PCB quality.

IPC Standards: The Common Language of the PCB Industry

Developed by the Association Connecting Electronics Industries, IPC standards have become the most widely accepted technical specifications in the global PCB industry. The IPC classification system divides electronic products into three general classes, providing a framework for understanding different PCB quality requirements across applications.

·Class 1—General Electronic Products: Suitable for limited-life or basic-function products like remote controls and children’s toys. Focus is on core functionality, with less stringent cosmetic requirements. These products are only required to meet basic performance requirements, such as minimum copper thickness and solder mask quality.

·Class 2—Dedicated Service Electronics: Intended for dedicated service electronic products requiring reliable, stable, and ongoing operation for non-critical applications, such as computers and communication equipment. These products should function consistently but aren’t critical; some cosmetic imperfections are acceptable.

·Class 3—High-Reliability Electronics: Applied to mission-critical systems where performance is essential, including life support systems and flight controls. No downtime is permitted, and operation must be guaranteed when needed.

Notably, IPC-6012 Class 3/A represents a newer category for the most demanding applications, including space and military avionics, establishing the highest benchmark for printed circuit boards.

Deep Dive: IPC-6012 Class 2 vs. Class 3

Key Differences: Applications and Stringency

IPC-6012 Class 2 and Class 3 represent different quality tiers, primarily distinguished by their intended applications and requirement strictness.

Class 2 applies to dedicated service electronics requiring strong reliability and extended lifespan, though not for extreme environments. Class 3 targets high-performance electronics where continuous operation is mandatory, and system failure is not an option. The stricter standards in Class 3 are specifically designed to minimize defects that could affect electrical performance and reliability.

Technical Requirements Comparison

Class 3 imposes significantly tighter tolerances and more rigorous requirements than Class 2. Taking PCB warpage as an example: according to IPC standards, boards for component assembly must have warpage ≤0.75%. Warpage exceeding this limit is considered defective. For boards requiring only plug-in components (without surface-mount devices), the requirement relaxes to ≤1.5%.

In addition to warpage, adherence to IPC-specified minimum conductor width and minimum dielectric spacing is critical. These requirements ensure the integrity, performance, and reliability of both Class 2 and Class 3 PCBs, especially in high-density and high-reliability applications.

Some high-end applications demand even stricter controls, with warpage specifications as tight as ≤0.5% or even ≤0.3%.

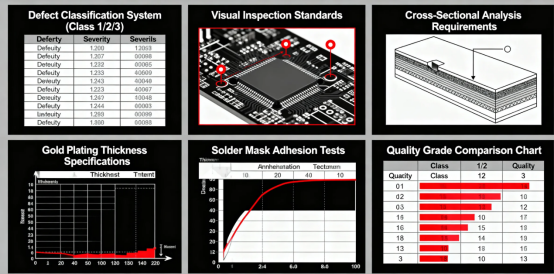

The table below summarizes the primary differences between Class 2 and Class 3:

| Characteristic | IPC-6012 Class 2 | IPC-6012 Class 3 |

|---|---|---|

| Application Field | Dedicated Service Electronics (computers, communication devices) | High-Performance Electronics (life support, military systems) |

| Quality Requirements | High reliability and lifespan; some cosmetic defects allowed | Extreme reliability; zero downtime; strict cosmetic and performance standards |

| Tolerance Control | Standard tolerance requirements | Tighter tolerance controls |

| Inspection Standard | Standard inspection and testing | Enhanced inspection and testing protocols |

Universal PCB Quality Requirements

Regardless of classification, PCB quality inspection typically covers these core areas:

·Dimensional Checks: Including outline dimensions, board thickness, hole size, trace width, and warpage

·Visual Inspection: Covering substrate white spots, delamination, conductor pinholes, hole blockages, and foreign materials

·Reliability Testing: Including solderability, peel strength, thermal shock resistance, and ionic contamination. As part of quality assurance, copper traces are specifically tested for adhesion and electrical conductivity to ensure reliable performance.

High-quality PCBs are essential for the reliable operation of electronic components, as they directly impact signal transmission and overall device performance.

For specialized applications like high-frequency PCBs, additional stringent requirements apply, such as impedance control tolerances typically within 2%.

Quality Control Measures in PCB Manufacturing

Inspection Techniques and Testing Protocols

In the world of PCB manufacturing, quality control is the backbone of delivering reliable, high-performance circuit boards that meet the rigorous demands of today’s electronics industry. From consumer electronics to military and medical applications, ensuring consistent quality throughout the manufacturing process is essential for both product quality and customer satisfaction.

A critical focus of quality control is the precise management of copper thickness and copper plating. During the manufacturing process, PCB manufacturers must verify that the plating thickness—especially in plated holes and on external layers—meets the strict requirements set by IPC 6012. For example, Class 2 PCBs typically require a minimum copper plating thickness of 0.8 mil, while Class 3 boards, used in high-reliability applications, demand at least 1 mil. This attention to detail ensures the structural integrity and electrical performance of the finished product.

Another vital inspection point is the detection of plating voids. These small gaps in the copper plating can compromise the board’s ability to conduct electricity and withstand mechanical stress, making their identification and elimination a top priority. Inspectors also check the minimum annular ring size—the copper ring surrounding a drilled hole—to ensure it meets the specified dimensions, typically no less than 0.005 inches. This is crucial for maintaining reliable connections, especially in densely packed or high-layer-count PCBs.

The inspection process extends to evaluating the solder mask for proper coverage, verifying plating separation to prevent short circuits, and assessing the quality of each drilled hole. The copper foil used in the board’s construction is scrutinized for uniformity and adherence to standards, while edge plating and exposed copper areas are checked for defects that could affect performance or durability.

To guarantee consistent quality, manufacturers implement rigorous testing protocols. Thermal cycling and vibration testing simulate real-world stresses, revealing potential weaknesses that could lead to failure in the field. Electrical testing is performed to confirm that all circuits function as intended, and thermal shocks are applied to assess the board’s resilience to rapid temperature changes.

IPC 6012 also sets out requirements for internal layer copper thickness, which is essential for the reliability of multilayer PCBs. Careful control of dielectric material, drill diameter, and annular ring dimensions further ensures that each board meets the necessary standards for finished copper ground fill and finished copper ground connections.

By adhering to these comprehensive quality control measures, PCB manufacturers can deliver products that not only meet but exceed industry expectations. This meticulous approach reduces the risk of defects, minimizes the need for rework or repair, and supports the production of high-quality PCBs for applications ranging from everyday consumer electronics to mission-critical medical devices and military systems.

Ultimately, robust quality control—guided by the standards of IPC 6012—is the key to achieving high reliability, consistent quality, and long-term customer satisfaction in the fast-evolving electronics manufacturing industry.

IATF 16949: Special Requirements for the Automotive Industry

Relationship with ISO 9001

IATF 16949 represents the automotive industry's specific quality management system standard, building upon the ISO 9001 foundation with automotive-specific additions. Importantly, IATF 16949 is not a standalone standard but rather a supplement to ISO 9001.

Core Requirements and Certification Path

IATF 16949 emphasizes defect prevention, reduction of supply chain variation and waste, and continuous improvement. Compared to ISO 9001, it enhances several areas:

·Product Safety: Requires documented product safety management processes. Testing for mechanical properties, such as resistance to thermal stress and physical deformation, is a key part of ensuring automotive PCB reliability.

·Supplier Management: Includes supplier selection, development programs, monitoring processes, and second-party audits

·Risk Management: Detailed risk management processes incorporating lessons from product recalls and field returns

·Customer-Specific Requirements: Integration of customer-specific requirements into the QMS

To achieve IATF 16949 certification, organizations must meet eligibility criteria: producing automotive materials, having active automotive customer contracts, and maintaining 12 months of production data records.

Recent Updates: IATF Rules 6th Edition

Notably, the IATF has published the 6th Edition Rules, with full implementation required by January 1, 2025. The new rules impose stricter distance limitations for Extended Manufacturing Sites (EMS)—they must be within 10 miles (16 km) or 60 minutes travel time from the primary manufacturing site.

ISO 13485: Quality Assurance for Medical Devices

Scope and Key Characteristics

ISO 13485 is the internationally recognized QMS standard for the medical device industry, providing a consistent framework to ensure the safety and effectiveness of medical devices throughout their lifecycle. Unlike ISO 9001’s focus on customer satisfaction and continuous improvement, ISO 13485 prioritizes regulatory compliance and patient safety.

This standard applies to the design, development, production, installation, servicing, and disposal of medical devices, including relevant service providers like contract sterilizers, logistics suppliers, and component manufacturers. In the construction of medical device PCBs, materials such as epoxy resin are commonly used in laminate and prepreg layers to provide structural support and electrical insulation, which enhances the electrical strength, reliability, and overall performance of the printed circuit boards.

Key Differences from ISO 9001

ISO 13485 exhibits several distinct characteristics compared to ISO 9001:

·Mandatory risk management across all stages

·Rigorous process validation requirements

·Enhanced focus on traceability and documentation

·Greater emphasis on regulatory reporting and data integrity

Global Regulatory Alignment

Another critical aspect of ISO 13485 is its alignment with major global regulatory frameworks:

·EU MDR/IVDR: Complies with QMS obligations under Article 10 and Annex IX

·US FDA QMSR: The FDA will replace its current QSR with the QMSR, which references ISO 13485

·Health Canada: Requires ISO 13485 certification for device licenses

·MDSAP: Serves as the audit basis accepted by multiple regulatory authorities

Special Considerations for Medical Devices

For medical devices, RoHS 2 (Restriction of Hazardous Substances Directive) includes specific provisions. Considering technical feasibility, the use of lead solder in printed circuit boards for mobile medical equipment is temporarily exempt. The exemption deadline for Class IIa mobile medical devices was June 30, 2016, and for Class IIb, December 31, 2020.

Selecting the Appropriate PCB Quality Standard

Choosing Based on End Application

The primary consideration for selecting a PCB quality standard is the product’s final application field:

·Consumer Electronics: Typically conform to IPC Class 1 or Class 2

·Automotive Electronics: Require compliance with IATF 16949, often with IPC Class 2 or higher

·Medical Devices: Must meet ISO 13485, with PCBs typically needing IPC Class

·Military/Aerospace: Require IPC-6012 Class 3/A, the highest standard

High-quality PCB assembly is essential for meeting the stringent requirements of each application, especially in automotive, medical, and aerospace electronics, where adherence to industry standards is critical.

Balancing Cost and Quality

It’s important to recognize that higher standard levels correlate with increased manufacturing costs. For instance, Class 3/A boards command premium pricing as they approach near-perfection. Therefore, selecting a standard requires balancing quality requirements with budget constraints. Choosing a default surface finish, such as ENIG, can also help optimize both cost and performance in PCB manufacturing.

Supply Chain Integration Considerations

For products requiring IATF 16949 or ISO 13485 compliance, supply chain integration becomes critical. The automotive and medical industries impose strict controls on suppliers, making full supply chain compliance essential for successful certification.

Summary

As electronic products grow more complex and application environments diversify, PCB quality standards continue to evolve. From reliability-focused IPC standards to industry-specific requirements like IATF 16949 and ISO 13485, these frameworks collectively form the foundation for ensuring electronic product quality and safety.

Selecting the right PCB quality standard requires considering not only current needs but also anticipating future technological trends. Emerging fields like 5G, IoT, and automotive electronics demand increasingly higher PCB quality. Only through a deep understanding of these standards can organizations maintain a competitive edge.

Author: Jack Wang