What Is SMT A Guide to Surface-Mount Technology in Electronics Assembly

Introduction

Surface-Mount Technology (SMT) is a method for placing electronic components directly onto the surface of printed circuit boards (PCBs). This approach simplifies manufacturing and enhances performance by avoiding the need for drilled holes. This article will explain what is SMT, its evolution, key components, and its impact on modern electronics.

Key Takeaways

·Surface-Mount Technology (SMT) enables compact electronics design by directly mounting components on PCB surfaces, enhancing efficiency and performance compared to traditional methods.

·The SMT assembly process includes crucial stages such as solder paste application, component placement using automated machines, and reflow soldering, all of which contribute to the reliability of electronic assemblies.

·While SMT offers advantages like higher component density and cost efficiency, it also presents challenges including repair difficulties and quality control issues that must be addressed to ensure optimal assembly performance.

Understanding Surface-Mount Technology (SMT)

Surface-Mount Technology (SMT) is a revolutionary method for mounting electronic components directly onto the surface of printed circuit boards (PCBs). This technique allows for higher density and reliability in electronic assemblies, replacing the traditional through-hole technology by eliminating the need for drilling holes for component leads. Mounting components directly onto the PCB surface with SMT streamlines design while enhancing performance and efficiency in electronics manufacturing.

SMT plays a pivotal role in modern electronics by enabling the miniaturization of devices, allowing the development of smaller, more powerful, and efficient gadgets. We’ll explore the definition, historical evolution, and key components that make SMT indispensable.

What is SMT?

Surface Mount Technology (SMT) involves mounting electronic components directly onto the surfaces of printed circuit boards (PCBs). This approach is integral to the development of miniaturized microchips and other PCB components, essential for modern electronics manufacturing.

SMT components can range from tiny chips to larger capacitors, resistors, and inductors, allowing for a diverse array of applications. A major advantage of SMT is the reduction in material handling costs by eliminating the need for drilling holes, as required in traditional through-hole technology (THT).

History and Evolution of SMT

Surface-Mount Technology (SMT) began with Planar Mounting, the initial version of this innovative approach. Early adopters like IBM significantly contributed to its implementation and evolution in the electronics sector.

By the 1980s, SMT was widely adopted across the industry, transforming manufacturing techniques and paving the way for the miniaturized, high-performance electronics we use today.

Key Components in SMT

Surface Mount Devices (SMDs), central to SMT, are designed for direct mounting on PCB surfaces. They include a variety of electromechanical, passive, and active elements such as:

·Resistors

·Capacitors

·Inductors Unlike traditional components, SMDs do not have wire leads and are designed to fit directly on the surface, simplifying the assembly process.

Solder paste and pick-and-place machines ensure precise positioning and securing of components in pcb assemblies, enhancing the efficiency and effectiveness of modern electronics assembly.

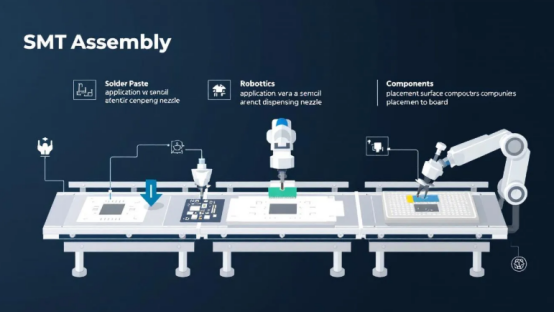

The SMT Assembly Process

The SMT assembly process begins with solder paste application, followed by precise component placement using automated machines, and concludes with reflow soldering to secure the components in the pcb assembly process.

Each stage is crucial in ensuring the reliability and performance of the final electronic assemblies.

Solder Paste Application

Solder paste application is an essential step in the SMT assembly process, using a stencil to apply the paste onto the solder pads of the PCB. This step ensures effective bonding between the components and the printed circuit board, laying the foundation for reliable solder joints.

Precise solder paste application is crucial as it directly impacts the integrity and performance of the final assembly.

Component Placement

Component placement in SMT relies heavily on precision pick-and-place machines, which:

·Accurately position surface mount components on PCBs

·Are programmed to place components at predetermined coordinates, ensuring high accuracy and efficiency

·Use vision systems to enhance placement precision

·Can place up to 100,000 components per hour, significantly enhancing assembly speed and precision

Pick-and-place machines are game-changers in SMT assembly, enabling rapid and accurate placement of smaller components, crucial for high component density. This automation not only accelerates the production line but also ensures consistent quality and performance across all electronic assemblies. The pick and place machine enhances efficiency in the process.

Reflow Soldering

Reflow soldering is a pivotal stage in the SMT assembly process, where components are secured by melting solder paste through controlled heating during the reflow process. The temperature must be carefully managed to ensure the molten solder melts and forms solid electrical connections as it cools. This method eliminates the need for traditional leads, streamlining the assembly process and enhancing the overall performance of the final product.

Reflow soldering not only secures components but also ensures the reliability and durability of the solder joints. Proper temperature control during reflow soldering is essential to prevent thermal stress and ensure the longevity of the electronic assemblies.

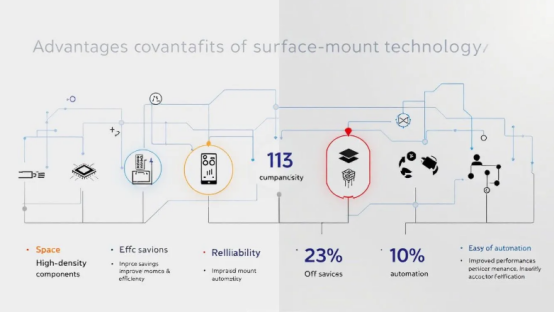

Advantages of SMT

Surface Mount Technology (SMT) offers numerous advantages that make it a preferred choice in modern electronics manufacturing. These benefits include higher component density, cost efficiency, and improved performance, which collectively contribute to the enhanced functionality and reliability of electronic devices.

High Component Density

One of the primary advantages of SMT is its ability to achieve higher component density, allowing for more components per square inch on a PCB. This compact arrangement facilitates more complex circuit designs and contributes to the development of smaller, more efficient devices.

Surface mount components are typically lighter than traditional components, further enhancing the overall efficiency and performance of electronic devices due to their lower component density.

Cost Efficiency

SMT is known for its cost efficiency, reducing production setup and operation costs compared to traditional methods. Although SMT components can be more expensive due to their size and complexity, overall savings in assembly processes and reduced labor costs make SMT highly economical, especially for high-volume production.

The automation inherent in the SMT manufacturing process significantly decreases labor costs and production time, allowing manufacturers to scale their operations efficiently with automated machinery, ultimately leading to lower manufacturing costs.

Improved Performance

SMT improves electrical performance by minimizing lead length, enhancing signal integrity and reducing interference. This results in better overall performance and reliability of electronic devices, making SMT an ideal choice for modern, high-frequency applications.

Challenges and Limitations of SMT

Despite its numerous advantages, SMT also presents several challenges and limitations, including:

Quality control issues

Repair and rework difficulties

Environmental sensitivity All of these can impact the reliability and efficiency of SMT assemblies.

Quality Control Issues

Quality control in SMT is vital since assembly reliability heavily depends on solder joint quality. Inspecting solder paste application and ensuring proper positioning are vital steps in preventing defects. However, detecting defects in SMT assemblies can be problematic, often leading to delays and increased waste.

Additionally, moisture and contaminants can significantly impair the performance and reliability of surface-mounted devices.

Repair and Rework Difficulties

Repairing SMT assemblies is often time-consuming and requires skilled technicians due to component density. Specialized equipment is essential for replacing SMT components because of their intricate designs and placement, making the repair process more complex.

Environmental Sensitivity

SMT components are sensitive to environmental factors like thermal stress, physical stress, and mechanical stress. Thermal shock can lead to performance degradation or failure if not managed properly, while absorbed moisture can cause issues during soldering processes.

Contaminants like dust and chemical residues can also impair the function of SMT components, making cleanliness an essential aspect of the assembly process.

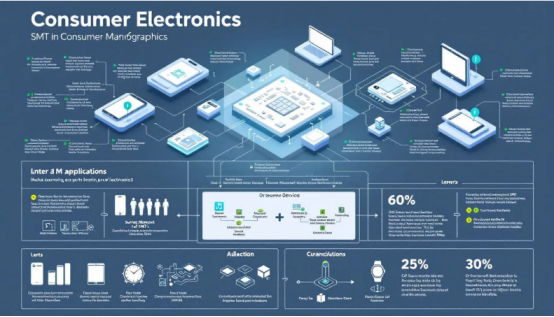

Applications of SMT in Electronics

Surface-Mount Technology (SMT) has wide-ranging applications in various fields of electronics. From consumer electronics to industrial systems, SMT plays a critical role in the development and production of modern electronic devices.

Its ability to accommodate high component density and enable compact designs makes it indispensable in today’s electronics industry.

Consumer Electronics

In consumer electronics, SMT drives the development of ultra-thin smartphones, smartwatches, and wearable technology. These devices use SMT to fit numerous components in a compact design, enabling advanced features while maintaining high performance.

Miniaturized components, SMT components, and integrated circuits are crucial for creating lightweight, sophisticated electronic devices that enhance user comfort and experience.

Industrial Electronics

In industrial applications, SMT is preferred for devices requiring high reliability and precision, such as programmable logic controllers (PLCs) and control modules. For instance, SMT in automotive electronics enables the production of lightweight, high-density control and sensor modules, improving vehicle performance and safety features.

SMT enhances the performance, reliability, and compactness of electronic devices, making it a valuable technology in both industrial and automotive sectors.

High-Volume Production

The scalability of SMT makes it ideal for high-volume production runs, ensuring fast and efficient component mounting. Automated pick-and-place machines and the efficient assembly process significantly reduce production cycle times, allowing manufacturers to produce large quantities of electronic devices efficiently.

SMT’s speed, efficiency, and scalability make it suitable for high-volume manufacturing across various industries.

Comparing SMT with Other Technologies

Comparing Surface-Mount Technology (SMT) with other technologies requires understanding each one’s unique characteristics, advantages, and disadvantages. SMT and Through-Hole Technology (THT) each have specific applications, and the choice of assembly method significantly impacts efficiency and performance.

Application requirements, component availability, and certain components of the assembly process characteristics play crucial roles in determining the most suitable technology.

SMT vs. Through-Hole Technology

Surface-Mount Technology (SMT) mounts components directly onto the PCB surface, while Through-Hole Technology (THT) inserts component leads into drilled holes. SMT enables more compact and complex assemblies, often preferred for high-density, high-frequency applications.

Conversely, THT provides strong mechanical connections, ideal for heavier components and easier rework and repair compared to SMT.

SMT vs. Traditional Components

Surface Mount Technology (SMT) enables higher component density on PCBs, allowing for more compact and lighter designs compared to traditional through-hole components. SMT components typically offer better electrical connections and reduced signal interference, enhancing overall performance.

However, SMT assemblies can be more complex to repair and rework than through-hole assemblies, posing challenges in maintenance and troubleshooting. Despite these complexities, the efficiency gains in space and performance make SMT superior for most modern applications.

Hybrid Approaches: Combining SMT and THT

Combining SMT and THT components in electronic assemblies leverages the strengths of both technologies, particularly in tht assembly. Mixed technology assemblies accommodate diverse component types on the same PCB, enhancing design flexibility and functionality.

This hybrid approach reduces unwanted electrical noise and minimizes the need for decoupling capacitors, thereby improving the reliability and performance of electronic devices. By integrating both SMT and THT, manufacturers can create more efficient and robust electronic assemblies.

Design Considerations for SMT

Effective SMT design requires careful consideration of various factors to ensure optimal performance and reliability. Key aspects include component layout, thermal management, and material selection, each crucial for the success of SMT assemblies.

Addressing these design considerations is essential for optimizing performance and ensuring the reliability of electronic assemblies during both manufacturing and operation.

Layout and Footprint Design

Proper layout and footprint design are critical in SMT for reliable component placement and solder joint integrity. The PCB footprint includes:

·Pads

·Obstacles

·Text

·Origins All these elements contribute to accurate component positioning on the circuit board.

Automated solder paste printing machines apply solder paste through stencil apertures onto the PCB pads, ensuring precise transfer and strong electrical connections. Effective solder paste application is vital for SMT assembly reliability and performance.

Thermal Management

Thermal management is crucial in SMT assemblies due to the high susceptibility of SMD components to high temperatures and thermal stress. Proper heat dissipation is necessary to prevent damage and ensure component longevity. The thickness and quality of PCB materials directly impact thermal performance, affecting heat management within the assembly.

Selecting materials with good thermal conductivity and low-loss dielectrics is essential for maintaining signal integrity and overall thermal performance in SMT applications.

Material Selection

Choosing the right PCB materials is paramount, as it affects the durability and performance of the assembled components in pcb manufacturing. Factors like thermal conductivity, dielectric properties, material costs, and compatibility with soldering processes must be considered during material selection.

The right materials enhance thermal conductivity and overall reliability of SMT applications, ensuring the final product meets performance and durability standards.

Summary

Surface-Mount Technology (SMT) has revolutionized electronics manufacturing, offering significant advantages in terms of component density, cost efficiency, and performance. Despite its challenges, such as quality control and repair difficulties, SMT remains a cornerstone of modern electronics. By understanding the assembly process, benefits, limitations, and design considerations, manufacturers can optimize their use of SMT to produce reliable and high-performance electronic devices. As technology continues to advance, SMT will undoubtedly play an increasingly vital role in the development of innovative and sophisticated electronic products.

Author: Jack Wang