The Complete Guide to FPC Coverlay Colors Selection and Application

Introduction

If you work in electronics design, manufacturing, or procurement, you've likely encountered Flexible Printed Circuits (FPCs). These lightweight, bendable components are essential for modern devices like smartphones and medical equipment. While the flexibility and compact size of FPCs get most of the attention, a crucial element is often overlooked: the coverlay, or protective covering.

This thin insulating layer shields the FPC's conductive traces from moisture, dust, and physical damage. More than just a cover, its color can significantly impact the product's performance, aesthetics, and even cost.

So, why do FPC coverlays come in different colors? And how do you choose the right one? From the ubiquitous yellow to the sleek black and the highly functional white, each color serves a purpose far beyond mere decoration. This guide delves into the most common FPC coverlay colors, their unique properties, ideal applications, and key selection criteria to help you make an informed decision for your next project.

Understanding the Basics: What is an FPC Coverlay?

Before exploring colors, let's define the coverlay and its role. A coverlay is a protective film laminated onto the surface of an FPC. Think of it as the circuit's armor—without it, the board is vulnerable to short circuits, corrosion, and damage from repeated flexing or environmental exposure.

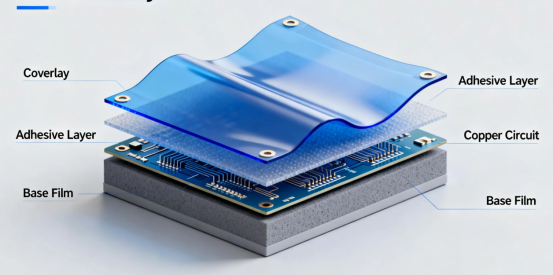

A typical FPC coverlay has a three-layer structure

·Base Material: Usually Polyimide (PI), a high-performance polymer known for excellent heat resistance, flexibility, and electrical insulation.

·Adhesive Layer (AD): Bonds the coverlay securely to the FPC substrate.

·Release Liner: Protects the adhesive during storage and handling, removed before application.

The coverlay is precisely cut to create "pad openings," exposing areas for soldering components or connectors. Its color comes from pigments added to the base material or a surface coating. While color doesn't alter the core PI/Adhesive performance, it has critical practical implications.

Common FPC Coverlay Colors: Properties and Applications

While various colors exist, yellow, black, and white are the most prevalent. Special colors like green, transparent, or custom hues serve niche requirements.

Yellow Coverlay: The Versatile Workhorse

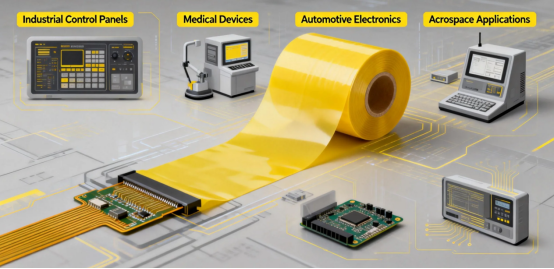

Yellow is the industry standard for FPC coverlays. Its dominance stems from an optimal balance of performance, cost, and ease of use, making it the ideal general-purpose choice.

Key Properties

·Cost-Effective: Typically the most economical option due to minimal pigment use and no need for extra coating processes.

·Moderate Light Transmission: Its slight translucency allows technicians to inspect underlying copper traces for defects without removing the coverlay, speeding up quality control.

·Easy Processing: Can be cleanly cut with lasers or die-cut tools and laminates uniformly without special curing requirements.

·Reliable Performance: Offers excellent electrical insulation, heat resistance (withstanding short-term temperatures up to 260°C), and strong adhesion.

Ideal Applications

A true all-rounder, suitable for most indoor, mid-to-low complexity FPCs.

·Consumer Electronics: Smartphone flex cables, tablet connectors, laptop keyboard circuits.

·Home Appliances: Internal wiring for smart speakers, sensor cables in refrigerators.

·Industrial Controls: Basic sensors, low-power control modules.

Pros & Cons Summary

·Pros: Low cost, facilitates inspection, fast processing, compatible with most designs.

·Cons: Limited UV resistance (may fade with prolonged sun exposure), offers no trace hiding.

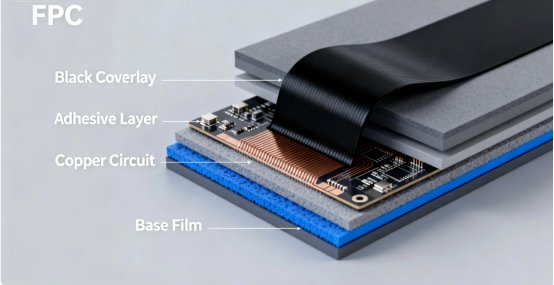

Black Coverlay: The Premium, High-Performance Choice

Black coverlay is synonymous with high-end, professional-grade FPCs. Valued for its sleek look, light-blocking ability, and security, it's the first choice for demanding applications.

Key Properties

·Excellent Light Blocking: Absorbs almost all light, preventing glare or interference with sensitive components like sensors or displays.

·Trace Confidentiality: Its opacity completely hides the circuit layout, protecting proprietary designs from reverse engineering—crucial for aerospace, defense, or competitive tech.

·Superior UV Resistance: The dark pigment inherently blocks more UV radiation, often paired with UV-stabilized PI for extended outdoor life.

·Aesthetic Appeal: Provides a professional, high-end finish for visible or semi-visible components.

Ideal Applications

Excels in high-performance, light-sensitive, or premium products.

·Automotive Electronics: Dashboard displays, LED headlight controls, in-cabin sensors.

·Advanced Consumer Tech: Flagship smartphone camera flex cables, internal wiring for VR/AR devices.

·Aerospace & Defense: Proprietary control systems, satellite components.

·Medical Devices: Endoscopes, wearable monitors (where blocking stray light is key).

Pros & Cons Summary

·Pros: Reduces glare, protects IP, high UV resistance, premium appearance.

·Cons: Higher cost than yellow, opaque (hinders visual inspection), may absorb marginally more heat (usually negligible).

White Coverlay: The Specialized Reflectivity Expert

Less common than yellow or black, white coverlay is indispensable for applications requiring light reflection or high visibility.

Key Properties

·High Reflectivity: White pigment reflects 80%-90% of light, enhancing brightness in LED applications or improving performance for light sensors.

·Increased Thickness: Requires an added white coating on the PI base, adding ~0.1-0.2mm. This boosts reflectivity but must be accounted for in compact designs.

·Complex Processing: The coating can challenge laser cutting precision, and lamination may require specialized equipment to avoid bubbles or misalignment.

·Stain Resistance: More resistant to discoloration from oils or chemicals than lighter colors like yellow.

Ideal Applications

Designed specifically for light-related or high-visibility uses.

·Lighting: LED strips, backlit displays (smartphone screens, watch faces).

·Medical Devices: Dental tools, surgical lights (reflectivity improves visibility).

·Industrial Sensors: Light-dependent resistors (LDRs), optical encoders.

Pros & Cons Summary

·Pros: Excellent reflectivity, stain-resistant, ideal for optical components.

·Cons: Higher cost, greater thickness, more challenging to process, opaque.

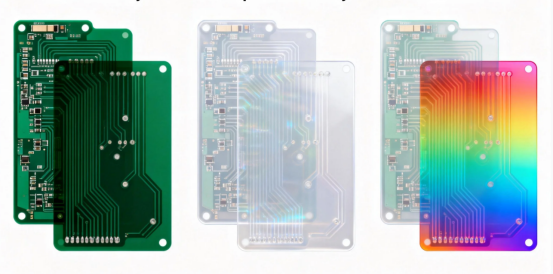

Special Colors: Green, Transparent & Custom

Special-color coverlays meet unique needs, playing vital roles in specific industries or design concepts.

·Green Coverlay: Offers a balance between yellow's inspectability and black's UV resistance. Common in automotive infotainment or industrial panels.

·Transparent Coverlay: Made with pure PI, it allows complete visual inspection of circuits. Ideal for prototyping, testing, or medical devices requiring visual verification.

·Custom Colors (Blue, Red, etc.): Achieved with custom pigments, primarily used for brand identity or color-coded systems in complex assemblies like aerospace. Performance matches standard colors, but cost is higher.

How to Choose: 5 Key Selection Factors

Selecting the right coverlay color is about matching properties to your project's specific needs.

1.Define the Application Environment: Is it indoors or outdoors (needs UV resistance)? Are there extreme temperatures or humidity? Is it near light sources (needs reflection or blocking)?

2.Prioritize Performance Needs: Is visual inspection during production/maintenance crucial (favor yellow/transparent)? Is circuit confidentiality a concern (requires black)? Is light reflection essential (mandates white)?

3.Consider Manufacturing Constraints: What is the budget volume (yellow for high volume)? Does your manufacturer have the equipment to handle thicker, coated materials like white coverlay?

4.Evaluate Aesthetic & Brand Requirements: Is the FPC a visible component (black/custom colors enhance look)? Can color coding simplify assembly in a complex device?

5.Check Industry Standards & Compliance: Some sectors have de facto standards (e.g., black for critical auto parts, white for medical optics). Ensure the chosen coverlay meets all relevant safety and environmental certifications (UL, RoHS).

Dispelling Common Myths

Myth: "Black coverlay is more durable than yellow."

Truth: Durability depends on PI/adhesive quality, not color. A high-quality yellow coverlay lasts as long as a black one in the same environment.

Myth: "White coverlay has better insulation."

Truth: Insulation is determined by PI thickness and adhesive, not color. All standard coverlays meet FPC insulation requirements.

Myth: "Colored coverlays are more expensive because they're higher quality."

Truth: The price difference comes from pigment costs and processing complexity, not superior base quality.

Conclusion

The color of an FPC coverlay is far from a mere cosmetic choice—it's a functional decision affecting performance, manufacturability, and cost. By understanding the distinct advantages of yellow, black, white, and special colors, you can specify the optimal coverlay for any project, from cost-sensitive appliances to cutting-edge aerospace components.

Remember, the core performance lies in the PI base and adhesive quality, not the color. Always partner with a reputable supplier to ensure consistency and reliability.

FAQs

Q. What is an FPC Coverlay?

A. It is a crucial insulating and protective material for Flexible Printed Circuits (FPCs). Typically composed of an insulating base film (PI/PET), an adhesive layer, and a release liner, it serves to insulate, protect against corrosion, resist flexing, and act as a solder mask. It is often referred to as the "protective armor" of an FPC.

Q. What are the main structural layers of a coverlay?

A. There are three primary layers: ① The insulating base film (PI or PET, providing support and insulation); ② The adhesive (epoxy or acrylic-based, bonding the film to the FPC); ③ The release liner (protects the adhesive layer and is peeled off before use).

Q. What are the two common base film materials, and how do they differ?

A. 1) PI (Polyimide): Offers high-temperature resistance (Tg > 300°C) and excellent flex endurance. Suitable for high-temperature soldering processes (e.g., SMT) and used in high-end FPCs (e.g., foldable displays, automotive electronics).

2) PET (Polyester): Lower cost but has inferior temperature resistance. Used only for standard applications not requiring high-temperature processing.

Q. What are the key performance indicators for a coverlay?

A. Critical metrics include:

Thermal Performance: High glass transition temperature (Tg > 300°C), resistance to heat during soldering (e.g., 280°C for 10 seconds).

Mechanical Performance: High flex endurance (≥200,000 cycles), tensile strength (>150 MPa).

Electrical Performance: High insulation resistance (>1×10¹⁶ Ω・cm), low dielectric constant (Dk) and dissipation factor (Df).

Chemical Resistance: Resistance to acids, alkalis, and solvents.

Q. How is coverlay thickness selected?

A. Total thicknesses are commonly 27.5µm, 37.5µm, and 50µm. Ultra-thin variants (<25µm total) are chosen for high-frequency or ultra-slim designs. FPCs with heavy copper (e.g., 2OZ) often require a 50µm coverlay for enhanced protection.

Q. What are the advantages of adhesive-less coverlay films?

A. They eliminate thermal stability issues associated with the adhesive layer, improve dimensional accuracy, reduce signal loss at high frequencies, and are well-suited for advanced applications like 5G and foldable displays.

Q. Are there special requirements for coverlays used in medical or automotive electronics?

A.

Medical: Requires biocompatibility and resistance to sterilization fluids.

Automotive: Must withstand extreme temperatures (≥150°C) and resist vibration, making them suitable for harsh environments like engine compartments.

Q. What is the difference between a coverlay and a flexible solder mask ink?

A.

Coverlay (PI film + Adhesive): Offers superior weatherability and flex endurance. Higher cost. Ideal for high-reliability applications.

Solder Mask Ink: Lower cost and simpler application process. Has poorer resistance to moisture and chemicals. Typically used for standard FPCs.

Q. What are the key requirements for selecting a coverlay for 5G applications?

A. Materials must have a low dielectric constant (Dk < 3.2) and a low dissipation factor (Df < 0.003). Base films like LCP (Liquid Crystal Polymer) or PPS (Polyphenylene Sulfide) are commonly used to minimize signal transmission loss.

Q. What is the mainstream manufacturing process for coverlays?

A. The primary method is the coating process. Key steps include: ingredient mixing → PI unwinding + corona treatment → adhesive coating → drying at 180°C → laminating with release film → curing (120-150°C) → slitting/ cutting. A core control point is ensuring uniform adhesive thickness (±1µm).

Author: Jack Wang