5 Top Advantages of Using a Copper Printed Circuit Board in Electronics

Copper printed circuit boards (PCBs) are an essential part of modern electronics. You’ll find them in smartphones, laptops, LED lights, and industrial machines, where they make circuits work efficiently and reliably.

Their widespread use comes from a set of key advantages. Copper PCBs conduct electricity well, manage heat effectively, offer mechanical strength, and can be used in compact or complex designs.

Next, we’ll explore these main benefits, showing why copper PCBs are the preferred choice for engineers and designers.

Advantage 1: Superior Electrical Conductivity

Copper printed circuit boards (PCBs) are highly valued for their low electrical resistance, which allows signals to travel quickly and efficiently across the board. This property is critical for electronics that demand fast and stable signal transmission, such as smartphones, Wi-Fi routers, and networking devices. By enabling efficient conductivity, copper ensures that both data and power reach all components reliably, reducing voltage drops and maintaining consistent performance even when multiple circuits operate simultaneously.

Copper also provides precise signal control in high-frequency circuits. In applications like radio frequency (RF) modules or high-speed data lines, even small resistance or interference can weaken signals. Using copper traces, engineers can maintain strong signal integrity, which is essential for smooth connectivity and rapid data transfer. For example, in a smartphone’s RF module, copper PCBs help keep Wi-Fi and Bluetooth connections stable even under heavy usage. Continuous copper pathways allow electrons to flow smoothly, preventing bottlenecks and minimizing energy loss, which in turn reduces heat generation and improves both device performance and reliability.

Advantage 2: Excellent Thermal Management

Copper PCBs are highly effective at dissipating heat, which is essential for keeping electronic components safe and maintaining stable operation. When components generate heat during operation, the copper layers absorb it and distribute it evenly across the board. This prevents localized hotspots that could otherwise damage sensitive components or reduce performance.

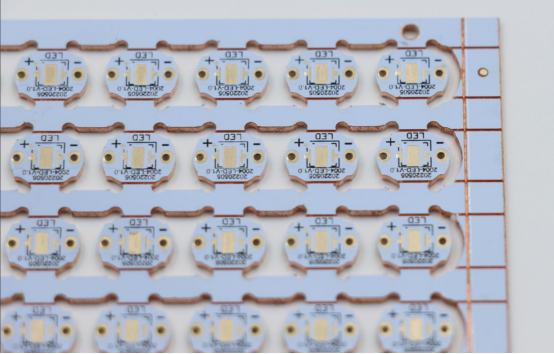

Thermal management is particularly important in high-power applications. Components such as CPUs, GPUs, LED drivers, and industrial control units generate significant heat during operation. Copper’s high thermal conductivity allows this heat to spread across the PCB, ensuring that components operate within safe temperature ranges. Copper also supports high-current applications, where the heat produced by electrical flow can be substantial. Using thicker or multiple copper layers spreads the heat evenly, preventing hotspots and protecting nearby components. For instance, in LED driver circuits, copper PCBs prevent individual LEDs from overheating, maintaining consistent brightness and prolonging their lifespan. Similarly, in power supply boards, copper layers help keep the board cool even under heavy electrical loads, ensuring reliable and long-term operation.

Advantage 3: Mechanical Strength and Durability

Copper PCBs are mechanically robust, which helps electronic devices endure physical stress without failure. The copper layers act as a reinforcement, distributing pressure and stress across the board, which prevents cracks in both the PCB itself and the solder joints that connect components. This rigidity is especially important in devices that experience vibration, bending, or repeated handling.

By maintaining structural integrity, copper PCBs ensure that components remain securely in place and continue to function correctly even under harsh conditions. Industrial sensors, automotive control units, and drones rely on this mechanical strength to survive constant vibration and shocks, which are common in transportation and industrial environments. For handheld or wearable electronics, the reinforced structure allows devices to stay durable without adding extra weight, making them lightweight yet resilient.

In addition, multi-layer copper designs further improve mechanical durability. Each additional copper layer distributes stress more evenly, reducing the likelihood of warping or deformation during assembly or use. Protective surface coatings also enhance resilience against scratches and minor impacts, prolonging the board’s operational life.

Advantage 4: Reliability in Harsh Environments

Copper PCBs maintain performance even in extreme environmental conditions, including high or fluctuating temperatures, humidity, and exposure to dust or corrosive elements. Copper’s resistance to oxidation and its stable thermal expansion properties ensure that electrical connections remain intact, preventing signal loss or circuit failure.

This reliability is critical for devices that operate continuously in demanding environments. Outdoor communication equipment, industrial automation systems, and renewable energy controllers rely on copper PCBs to maintain stable operation despite heat, moisture, or airborne particles. In high-power electronics, the combination of copper layers and heat dissipation ensures that circuits do not degrade over time, reducing downtime and maintenance costs.

Copper PCBs can also be enhanced with protective coatings and laminates, which shield the board from corrosion and improve long-term reliability. These features allow manufacturers to deploy electronics in outdoor, automotive, or industrial applications without worrying about environmental damage affecting performance.

Advantage 5: Design Flexibility and Miniaturization

Copper PCBs provide engineers with the flexibility to design compact, high-density circuits without sacrificing performance. Their excellent electrical conductivity allows signals to travel efficiently even in tightly packed layouts, while effective heat management ensures that closely spaced components do not overheat.

This design flexibility is essential for modern electronics, where devices are expected to be smaller, lighter, and more feature-rich. For instance, smartphones, smartwatches, and wearable fitness trackers rely on copper PCBs to integrate powerful processors, memory modules, sensors, and batteries into limited space. In industrial controllers and medical devices, multi-layer copper PCBs allow complex routing of high-current and signal lines in a compact footprint, enabling advanced functionality while maintaining thermal and electrical stability.

Engineers also leverage fine-pitch copper traces, multi-layer stackups, and flexible copper PCBs to create innovative shapes and layouts. These design possibilities support emerging technologies like foldable devices, wearable sensors, and compact IoT modules, where space is at a premium but performance cannot be compromised.

Applications of Copper PCBs in Electronics

Copper PCBs are widely used across various electronics sectors due to their excellent electrical, thermal, and mechanical properties. Their ability to handle high currents, dissipate heat efficiently, and maintain signal integrity makes them indispensable in modern devices.

In consumer electronics, copper PCBs are found in smartphones, tablets, laptops, and smart home devices. These devices require compact, high-density circuit boards that can reliably transmit signals while managing heat from processors, memory, and wireless communication modules. Copper PCBs ensure that data flows efficiently, components remain cool, and devices operate smoothly even under heavy usage.

In industrial and power electronics, copper PCBs play a critical role in motor controllers, LED lighting systems, and power supply units. These applications often involve high currents and continuous operation, which generate significant heat. Copper layers help distribute heat evenly, prevent hotspots, and allow circuits to carry large currents safely. This ensures reliable performance and extends the operational lifespan of industrial equipment and high-power electronics.

Copper PCBs are also increasingly important in emerging technologies. IoT devices, wearable technology, and high-frequency communication boards require compact, flexible, and highly reliable PCBs. Copper’s conductivity and thermal properties enable these miniaturized circuits to perform consistently, even in space-constrained designs or devices exposed to variable environmental conditions. By supporting high-speed data transfer and stable operation, copper PCBs help bring innovative electronic products to market with high reliability and efficiency.

Conclusion

Copper printed circuit boards (PCBs) offer a combination of advantages that make them a reliable choice for modern electronics. Their excellent electrical conductivity ensures fast and stable signal transmission, while superior thermal management keeps components cool and prevents overheating. Mechanical strength and durability allow devices to withstand vibration, bending, and repeated handling. At the same time, copper PCBs provide design flexibility for compact, high-density layouts, supporting both miniaturized consumer electronics and complex industrial circuits. These features together make copper PCBs a foundation for building efficient, long-lasting, and high-performance electronic devices.

For designers and engineers working on new electronic projects, considering copper PCBs can significantly enhance device reliability and performance. Companies like PCBMASTER specialize in producing high-quality copper PCBs, including advanced solutions such as Thermoelectrically Separated Copper-based PCBs with thermal conductivity up to 3 W/mK. By leveraging these high-performance boards, developers can create electronics that are not only compact and powerful but also durable and thermally efficient, meeting the demands of today’s fast-evolving technology landscape.

FAQs

How does copper thickness affect PCB performance?

The thickness of the copper layer directly influences a PCB’s current-carrying capacity and thermal performance. Thicker copper allows higher currents to flow without overheating, reducing voltage drops and minimizing the risk of hotspots. It also improves heat dissipation, which protects components and ensures stable operation. For example, power supply boards or high-power LED circuits often use 2 oz or 3 oz copper layers to safely handle larger currents, whereas standard signal boards may use 1 oz copper.

Can copper PCBs handle high-frequency signals better than aluminum PCBs?

Yes. Copper has lower electrical resistance than aluminum, which reduces signal loss and distortion, especially at high frequencies. This ensures better signal integrity, less interference, and more reliable data transmission. Aluminum PCBs, while lighter, have higher resistance and are less suitable for RF modules, high-speed data lines, or networking equipment where precise signal control is required.

What are the environmental benefits of using copper in PCBs?

Copper is highly recyclable and has a long lifecycle, making it environmentally friendly compared with other metals like aluminum or tin-plated traces. Recycled copper can be reused in new PCBs without losing conductivity or performance. Additionally, copper PCBs improve device efficiency by reducing energy loss, which lowers power consumption and helps reduce the carbon footprint of electronic devices over time.

How do multilayer copper PCBs improve miniaturization?

Multilayer copper PCBs allow engineers to route complex circuits in a compact footprint. By stacking multiple copper layers separated by insulating materials, designers can fit more connections and components in a smaller area. This supports miniaturization for smartphones, wearables, IoT devices, and other compact electronics, while maintaining signal integrity, thermal management, and reliability. Multi-layer designs also allow separation of power, ground, and signal planes, which reduces interference and improves overall performance.

Are copper PCBs more expensive upfront, and is the investment justified?

Copper PCBs typically have a higher initial cost than standard or aluminum PCBs due to the material and manufacturing requirements. However, the investment is justified because copper provides higher current capacity, better thermal performance, mechanical strength, and long-term reliability. These advantages reduce failure rates, maintenance costs, and device downtime, making copper PCBs cost-effective over the product’s lifetime, especially in high-performance, industrial, or high-power applications.