PCBA Coating: What It Is and Why It Matters for Electronic Reliability

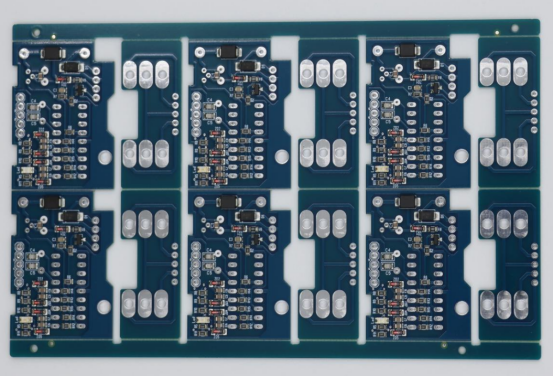

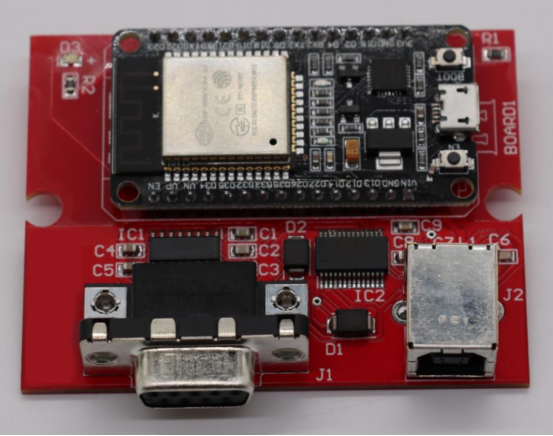

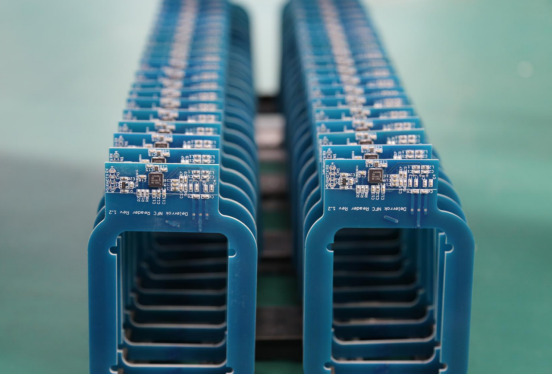

Modern electronic devices operate in demanding environments where heat, humidity, and contaminants can easily compromise delicate circuitry. To ensure long-term performance and reliability, every component on a printed circuit board assembly (PCBA) must be shielded from these external stresses. PCBA coating provides that invisible layer of protection—preserving signal integrity, preventing corrosion, and enabling electronics to perform consistently even under extreme conditions. Understanding how these coatings work and why they matter is key to designing electronics that last.

Introduction to PCBA Coating

What Is PCBA Coating?

PCBA coating refers to a thin protective layer applied to printed circuit board assemblies (PCBAs) to protect them from environmental and operational stress. This coating forms a barrier over electronic components and circuitry, preventing contaminants such as dust, moisture, chemicals, and corrosion from degrading performance.

The main purpose of PCBA coating is to enhance the durability and reliability of electronic assemblies. When a PCBA is exposed to humidity, salt spray, or vibration, uncoated circuits can short-circuit or corrode quickly. By applying a suitable coating, engineers can maintain consistent electrical performance and extend the operational life of the product.

PCBA coating is often compared to conformal coating and potting—two related but distinct protection methods. A conformal coating is a thin, uniform film that “conforms” to the shape of the PCB and its components, providing lightweight protection without adding bulk. Potting, on the other hand, encapsulates the entire assembly in resin, offering complete mechanical and environmental isolation but at a higher weight and cost. PCBA coating serves as an umbrella term encompassing both techniques, with the specific choice depending on performance requirements and design constraints.

Why PCBA Coating Is Important

The importance of PCBA coating lies in its ability to protect electronic assemblies against environmental, chemical, and mechanical threats that can lead to premature failure. A properly applied coating delivers several measurable benefits:

Moisture Resistance: Prevents water vapor or condensation from forming conductive paths that cause shorts.

Corrosion Protection: Shields metal traces and solder joints from oxidation and chemical attack.

Electrical Insulation: Reduces leakage currents and improves dielectric strength, ensuring stable signal transmission.

Extended Lifespan: Enhances long-term reliability, particularly in mission-critical systems.

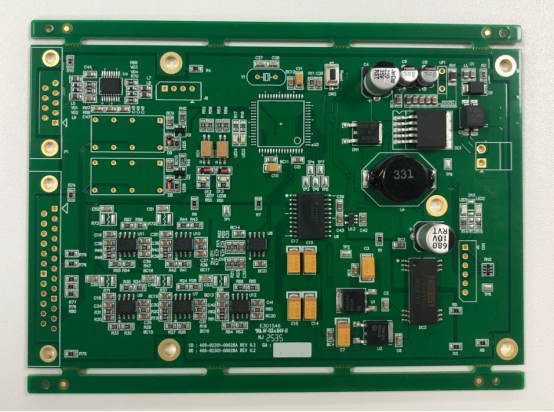

These advantages are essential in industries where electronics must perform flawlessly under stress. For instance, automotive ECUs are exposed to heat and vibration, aerospace systems face rapid temperature shifts, and medical devices demand long-term reliability in sterile environments. Industrial controls also benefit, as coatings help maintain consistent operation despite dust, oil, or humidity.

As coating materials and processes evolve, manufacturers now choose between options such as silicone, acrylic, epoxy, polyurethane, and parylene, each suited for specific applications. Later sections will explore how these materials and coating methods are selected to achieve optimal reliability and performance in modern electronics.

Types of PCBA Coating and Their Characteristics

Conformal Coatings

A conformal coating is a thin protective film that precisely follows the contours of a printed circuit board assembly (PCBA). Unlike thick encapsulating layers, conformal coatings form a light, uniform barrier—usually between 25 to 250 microns—that shields electronic components from moisture, dust, and chemical contamination while maintaining minimal weight and easy reworkability.

Common materials used for conformal coatings include acrylic, silicone, polyurethane, epoxy, and parylene. Each has unique performance characteristics suited to different applications:

Material Type | Advantages | Limitations | Typical Applications |

|---|---|---|---|

Acrylic (AR) | Easy to apply and remove; fast drying | Limited chemical resistance; moderate temperature tolerance | Consumer electronics, general-purpose assemblies |

Silicone (SR) | Excellent high-temperature and moisture resistance | Difficult to remove or rework | Automotive, aerospace, outdoor electronics |

Polyurethane (UR) | Strong chemical and solvent protection | Limited high-temperature performance | Industrial and chemical environments |

Epoxy (ER) | Exceptional mechanical strength and adhesion | Brittle; rework nearly impossible | High-stress or vibration-prone assemblies |

Parylene (XY) | Ultra-thin, pinhole-free barrier; superior dielectric strength | High cost; vacuum deposition required | Medical devices, aerospace |

Acrylic coatings are often chosen for low-cost applications that require quick turnaround, while parylene is favored in high-reliability systems demanding the highest insulation and moisture protection.

Potting and Encapsulation

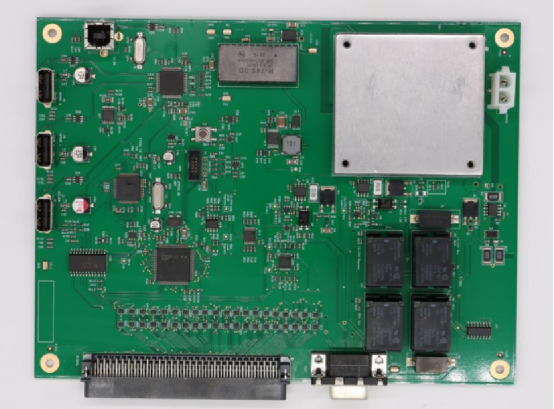

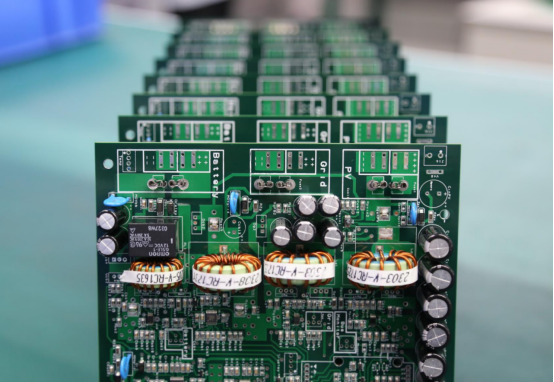

Potting and encapsulation involve enclosing the entire PCBA—or selected sections—in a solid resin compound. This method creates a thick, rugged barrier that protects components from mechanical shock, vibration, extreme temperatures, and chemical exposure.

The process typically fills a mold or casing with resin, completely surrounding the components. Once cured, the resin hardens into a permanent shell. Common potting materials include epoxy, polyurethane, and silicone, each offering varying degrees of hardness and flexibility.

Benefits of potting and encapsulation include:

Exceptional mechanical protection against vibration and impact.

Waterproofing for underwater or high-humidity environments.

Thermal stability for high-power or heat-sensitive designs.

When deciding potting vs. conformal coating, the choice depends on the level of protection and design constraints:

Use conformal coating when weight, reworkability, and board inspection are priorities.

Choose potting when the assembly must endure harsh mechanical stress or complete environmental isolation is required.

For example, automotive control units exposed to vibration and fluid contamination often rely on potting, while compact wearable electronics typically use conformal coatings to save space and weight.

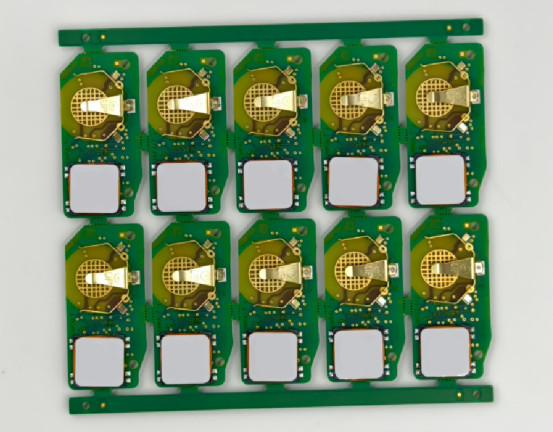

Selective Coating vs. Full Coating

In advanced manufacturing, selective coating allows engineers to apply protective layers only to specific areas of the PCBA, rather than covering the entire board. This is particularly valuable in high-density or mixed-technology assemblies, where some zones—like connectors, sockets, or heat sinks—must remain uncoated for proper function or heat dissipation.

A typical example is coating only the sensitive analog sections of a control board while leaving power connectors and test points exposed. Automated coating systems use precision nozzles or masking techniques to ensure accuracy and repeatability.

Key differences between selective and full coating include:

Cost: Selective coating reduces material usage but increases process complexity.

Process Control: Requires precise masking and automated application to avoid overspray.

Design Flexibility: Allows customized protection for critical components without hindering assembly access.

Selective coating is increasingly preferred in automotive and aerospace applications, where both protection and serviceability are critical. Full coating, however, remains the best choice when uniform coverage and simplicity outweigh precision needs.

In practice, engineers often combine these coating methods—such as applying conformal coating on most of the board and potting around high-voltage zones—to balance protection, cost, and manufacturability.

The PCBA Coating Process

Pre-Coating Preparation

Before any coating is applied, the PCBA must undergo careful surface preparation to ensure the coating adheres properly and performs as intended. Even small amounts of flux residue, dust, or oil can cause poor adhesion or voids in the protective layer.

Cleaning is the first and most critical step. Manufacturers use aqueous, solvent-based, or vapor-phase cleaning methods to remove flux residues and ionic contaminants left from soldering. Some high-reliability industries, such as aerospace and medical electronics, require ionic cleanliness testing (per IPC-TM-650 standards) to verify that no residue remains before coating.

Next comes masking, which protects areas that must remain uncoated—such as connectors, test points, edge contacts, or heat sinks. Masking materials include removable tapes, boots, or custom-fit caps designed to block coating overspray. Automated masking machines are often used in high-volume production to improve repeatability and reduce labor.

Surface cleanliness directly affects coating adhesion and long-term reliability. Contaminants trapped under the coating can lead to delamination, corrosion, or electrical leakage. Therefore, manufacturers often integrate plasma cleaning or ionized air treatment as a final preparation step before coating application.

Application Methods

There are several PCBA coating application techniques, each suited for specific production needs and precision requirements. The choice depends on factors such as board complexity, throughput, coating type, and desired film uniformity.

1. Brushing – The simplest manual method, ideal for small batches or rework. It offers full control over coating placement but is labor-intensive and inconsistent for large-scale production.

2. Spraying – Uses compressed air or atomizers to apply a fine mist over the PCB. It provides good coverage and moderate precision, but may require masking to prevent overspray.

3. Dipping – The entire assembly is submerged in coating material, ensuring complete coverage. This technique is cost-effective for simple geometries but unsuitable for dense or partially coated boards.

4. Automated Selective Coating – A computer-controlled process that applies coating only to designated areas using robotic nozzles. It delivers high precision, repeatability, and minimal material waste, making it the preferred choice for automotive and aerospace-grade PCBAs.

Step-by-step comparison:

Method | Precision | Throughput | Cost | Typical Use |

|---|---|---|---|---|

Brushing | Low | Low | Very Low | Prototyping, repair |

Spraying | Moderate | Medium | Medium | Consumer electronics |

Dipping | Low | High | Low | Simple geometries, low-cost boards |

Automated Selective Coating | Very High | High | High (initial setup) | Automotive, aerospace, high-reliability assemblies |

Example: In automotive-grade electronics, automated selective coating ensures consistent coverage on sensitive areas such as microcontrollers while leaving connectors and solder joints exposed for inspection and testing. This precision minimizes rework and supports compliance with stringent automotive reliability standards.

Curing and Inspection

Once the coating has been applied, it must cure to achieve full mechanical strength and chemical resistance. Curing is the process of transforming the liquid coating into a solid protective layer through heat, UV light, or ambient moisture.

Thermal curing uses controlled heat to accelerate solvent evaporation and polymer crosslinking. It’s common for epoxy and polyurethane coatings.

UV curing provides rapid hardening within seconds when exposed to ultraviolet light, ideal for high-speed production lines.

Moisture curing relies on atmospheric humidity, typically used for silicone-based coatings that require flexible, low-temperature processing.

After curing, each coated assembly undergoes inspection and quality verification to ensure uniform coverage and adhesion. Common inspection techniques include:

UV light inspection, as most coatings contain fluorescent tracers for easy visual detection.

Thickness measurement, ensuring the coating meets specified film requirements (usually 25–75 µm for conformal coatings).

Cross-section or X-ray analysis, used in failure analysis or process validation.

All inspections are conducted in line with industry standards such as IPC-CC-830, which defines the performance and qualification criteria for conformal coatings. Meeting these standards ensures that the coating provides consistent dielectric strength, chemical resistance, and long-term reliability across production batches.

A well-executed coating process—clean preparation, precise application, and controlled curing—forms the foundation of high-reliability PCB manufacturing, ensuring every assembly performs flawlessly in its intended environment.

How PCBA Coating Improves Electronic Reliability

Environmental Protection

One of the primary ways PCBA coating enhances electronic reliability is by providing a barrier against environmental contaminants. Moisture, dust, and corrosive chemicals are among the leading causes of PCB degradation and failure. When these contaminants reach exposed metal traces or solder joints, they can trigger corrosion, dendritic growth, or electrical leakage—all of which compromise circuit integrity.

A properly applied conformal coating or encapsulant seals the surface of the assembly, preventing moisture absorption and contamination. This protection is especially critical in marine, industrial, and humid environments, where condensation and salt spray can quickly corrode unprotected components.

Example: In marine navigation systems or offshore monitoring electronics, PCBA coatings prevent saltwater-induced oxidation, maintaining stable performance despite continuous exposure to moisture and airborne salts.

Electrical Stability

PCBA coatings also play a crucial role in maintaining electrical stability. By insulating conductive paths and components, coatings prevent short circuits and leakage currents that may occur due to humidity, ionic contamination, or condensation.

In high-voltage and high-density circuits, coatings increase dielectric strength—the ability of a material to resist electrical breakdown. They also improve insulation resistance, ensuring that signals remain isolated and that power distribution remains efficient.

For instance, in automotive control modules, silicone or parylene coatings protect microcontrollers and signal lines from transient voltage arcs and condensation, reducing the risk of unpredictable behavior or component failure.

In simple terms: PCBA coatings preserve the electrical integrity of a circuit, ensuring that each component performs within its designed parameters even under variable environmental conditions.

Mechanical and Thermal Durability

Beyond electrical and chemical protection, PCBA coatings provide mechanical reinforcement that helps assemblies withstand physical stress. Vibration, shock, and thermal cycling can fatigue solder joints or crack brittle components. The coating acts as a dampening layer, distributing mechanical stress and minimizing strain on delicate parts.

From a thermal perspective, coatings improve heat tolerance by protecting components from temperature fluctuations. Certain formulations, such as silicone-based coatings, remain flexible across a wide range of temperatures (from -60°C to +200°C), ensuring the PCB can operate reliably in both cold and high-heat environments.

Example: Aerospace electronics experience constant vibration and wide temperature shifts during flight. With high-performance conformal coatings, these assemblies maintain mechanical stability and continue functioning even under repeated stress cycles.

Long-Term Performance

Ultimately, the combination of environmental, electrical, and mechanical protection results in significantly extended product lifespan and reduced field failures. By preventing corrosion, short circuits, and fatigue damage, PCBA coatings ensure that electronics perform consistently throughout their service life.

Studies and industry experience show that conformal coatings can extend the operational life of automotive ECUs by 30–50% compared to uncoated assemblies. This improvement translates to fewer warranty claims, reduced maintenance costs, and greater customer trust in product reliability.

For manufacturers, the long-term benefit of PCBA coating is clear: greater reliability equals higher product value and stronger brand reputation. Whether in consumer devices, industrial controllers, or aerospace systems, coating serves as an invisible safeguard that ensures performance long after deployment.

Material Selection and Design Considerations

Choosing the Right Coating Material

Selecting the right PCBA coating material is a crucial decision that directly impacts long-term reliability and manufacturability. The choice depends on several factors, including operating environment, temperature range, chemical exposure, and reworkability requirements.

Operating environment: Outdoor, automotive, or marine applications demand coatings with strong moisture and corrosion resistance.

Temperature range: Electronics exposed to high or fluctuating temperatures benefit from flexible materials that can absorb thermal expansion stress.

Chemical exposure: Harsh industrial settings require coatings that resist solvents, fuels, and corrosive gases.

Reworkability: Some coatings allow easier repair or component replacement, while others form permanent barriers.

The table below compares three commonly used coating materials—silicone, polyurethane, and parylene—to guide material selection:

Coating Type | Key Advantages | Limitations | Best For |

|---|---|---|---|

Silicone (SR) | Excellent flexibility; withstands extreme temperatures (-60°C to +200°C); good moisture and vibration resistance | Harder to remove for rework; longer cure time | Automotive, aerospace, outdoor electronics |

Polyurethane (UR) | Strong chemical resistance; durable finish; good electrical insulation | Limited high-temp tolerance; can yellow over time | Industrial, chemical, and consumer applications |

Parylene (XY) | Ultra-thin uniform film; exceptional dielectric strength and barrier properties; no solvent required | Higher cost; vacuum deposition needed | Medical devices, high-reliability systems |

Summary: Silicone is ideal for environments with thermal stress, polyurethane suits chemically harsh conditions, and parylene is the go-to for precision or mission-critical electronics. Matching coating properties to environmental and design needs ensures consistent reliability and performance.

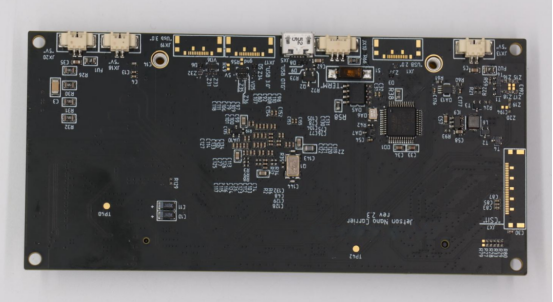

Design for Coating

Designing a PCB with coating in mind can greatly improve process efficiency and coating effectiveness. Design for Coating (DFC) ensures that the protective layer can be applied evenly without interfering with test points or mechanical interfaces.

Key PCB layout tips include:

Maintain sufficient component spacing to allow coating flow and prevent shadowing under tall parts.

Define keep-out zones around connectors, sockets, and heat sinks that must remain uncoated for electrical or thermal reasons.

Provide accessible test pads and fiducial marks for automated inspection systems.

Avoid sharp edges or deep recesses that may cause coating pooling or air entrapment.

Example: In high-voltage power boards, engineers often optimize coating thickness around components like transformers or MOSFETs to maintain dielectric strength while preventing excess buildup that could lead to cracking. Adjusting nozzle angles and flow rates ensures consistent coverage across uneven surfaces.

Good DFC practices reduce rework time, prevent coating defects, and improve overall process control—especially when scaling from prototyping to mass production.

Common Pitfalls and How to Avoid Them

Even well-chosen materials can fail if the coating process is not properly managed. Common PCBA coating issues include:

Bubbles or voids – trapped air during application or curing.

Peeling or delamination – poor adhesion due to contamination or incompatible surface energy.

Uneven coverage – caused by inconsistent spray parameters or shadowing beneath components.

Trapped moisture – residual humidity sealed under the coating, leading to corrosion over time.

To prevent these problems, manufacturers use several process control and environmental measures:

Maintain humidity below 60% during coating and curing to avoid moisture entrapment.

Perform thorough surface cleaning and plasma treatment before application for better adhesion.

Validate the process through thickness measurements, adhesion testing, and visual inspection per IPC-CC-830 or internal QA standards.

Use controlled dispensing and automated nozzles to ensure repeatable coverage across production batches.

By combining proper material selection, intelligent PCB design, and disciplined process validation, manufacturers can achieve consistent, defect-free coatings that maximize electronic reliability across a wide range of operating conditions.

Testing and Standards for PCBA Coating

Reliability Testing

To verify that a PCBA coating performs as intended, manufacturers conduct a series of reliability tests designed to simulate real-world operating conditions. These tests evaluate how coatings resist thermal stress, moisture, and mechanical vibration over time.

Common PCBA coating reliability tests include:

Thermal cycling: Repeated heating and cooling (e.g., -40°C to +125°C) to assess coating flexibility and adhesion under temperature expansion and contraction.

Salt spray testing: Exposes coated assemblies to a saline mist to measure corrosion resistance, especially for marine and automotive electronics.

Humidity testing: Maintains high relative humidity (typically 85% RH at 85°C) to evaluate moisture barrier performance.

Vibration testing: Simulates shock and vibration in transportation or aerospace conditions to confirm coating adhesion and mechanical stability.

Example: In an accelerated aging test, coated PCBAs may undergo 500 thermal cycles between extreme temperatures. After testing, engineers inspect for cracking, delamination, or loss of adhesion. High-performance coatings, such as parylene or silicone-based types, typically retain full protection with no visible degradation, confirming long-term reliability under harsh environments.

These tests provide quantifiable data that help manufacturers select appropriate materials and validate process consistency before production release.

Industry Standards

To ensure quality and consistency, PCBA coatings must comply with international standards that define performance, material properties, and testing protocols. The most widely recognized standards include:

IPC-CC-830: The primary industry specification for conformal coatings. It outlines test methods for dielectric strength, moisture resistance, flammability, and fungus growth. Meeting IPC-CC-830 ensures that coatings meet baseline performance for most commercial electronics.

MIL-I-46058C: A standard that specifies stringent qualification criteria and environmental durability requirements for coatings used in high-reliability electronic applications.

UL746E: Defines electrical insulation and flammability performance for polymeric coatings used in power electronics and high-voltage assemblies. Compliance ensures coatings can safely withstand electrical stress and high temperatures.

Why compliance matters: Meeting these standards supports OEM (Original Equipment Manufacturer) and EMS (Electronics Manufacturing Services) certification requirements. It also demonstrates to customers and regulatory bodies that the product meets verified safety and reliability levels. In many cases, OEMs mandate IPC-CC-830 or MIL-I-46058C certification as a prerequisite for supplier approval, especially in aerospace, automotive, and medical industries.

Failure Analysis

Even with controlled processes, coating failures can occur, often due to contamination, improper curing, or mechanical damage. Conducting a failure analysis helps engineers pinpoint the root cause and prevent recurrence.

Common coating defects include:

Delamination or peeling: Often caused by poor surface preparation or trapped moisture.

Bubbles and voids: Result from air entrapment during application or rapid solvent evaporation.

Cracking: Indicates excessive coating thickness or thermal stress during curing.

To diagnose these issues, engineers use advanced inspection and analysis techniques such as:

Cross-section microscopy: Examines coating thickness uniformity and adhesion to the substrate.

SEM (Scanning Electron Microscopy): Reveals micro-level defects, pinholes, or contamination residues.

EDS (Energy-Dispersive X-ray Spectroscopy): Identifies chemical contamination that may inhibit adhesion or promote corrosion.

Example: A failure investigation might reveal that a coating delaminated because residual flux was left on the PCB surface. In such cases, process improvements—like enhanced cleaning or longer curing times—eliminate future defects.

By combining rigorous testing, compliance, and failure analysis, manufacturers can ensure that every coated assembly meets both performance and safety expectations—ultimately leading to more reliable, longer-lasting electronic products.

Future Trends in PCBA Coating

Emerging Materials

The next generation of PCBA coating materials is focused on enhanced performance, miniaturization, and durability. Key innovations include nano-coatings, fluoropolymer coatings, and hybrid resins.

Nano-coatings leverage nanostructured materials to create ultra-thin, uniform films with superior moisture and chemical resistance.

Fluoropolymer coatings provide high dielectric strength and excellent chemical inertness, making them suitable for high-voltage or harsh chemical environments.

Hybrid resins combine multiple polymers to offer flexibility, mechanical strength, and self-healing properties, allowing minor scratches or micro-cracks to repair themselves over time.

Benefits of these emerging materials include thinner films that reduce weight, enhanced insulation and corrosion protection, and the ability to improve reliability without increasing board thickness. For example, a nano-coating applied at 10–20 microns can match or exceed the performance of traditional 50-micron layers, enabling more compact PCBA designs in aerospace and medical electronics.

Automation and Smart Inspection

Advancements in automation and AI-driven inspection are reshaping how PCBA coatings are applied and validated.

AI-powered visual inspection systems can detect coating defects such as voids, bubbles, or uneven coverage in real time, far faster and more accurately than manual inspection.

Data-driven coating thickness analysis allows predictive maintenance: engineers can track trends in process variability, anticipate adhesion or coverage issues, and adjust production parameters proactively.

Example: In automotive electronics, automated selective coating lines now integrate AI cameras that measure coating thickness on every board. Deviations trigger automatic adjustments, reducing scrap and ensuring consistent compliance with IPC-CC-830 standards.

This convergence of automation and smart inspection improves throughput, reduces errors, and ensures that high-reliability assemblies meet exacting quality standards.

Sustainability in Coating Processes

Environmental and regulatory pressures are driving sustainable PCBA coating practices. Manufacturers are increasingly adopting low-VOC (volatile organic compound) and solvent-free coatings to reduce environmental impact and improve worker safety.

Recycling and rework-friendly materials allow coatings to be partially removed or reworked without damaging the board, reducing electronic waste.

Advances in green chemistry enable high-performance coatings that meet the same electrical and mechanical standards while minimizing harmful emissions and energy consumption during curing.

Example: A water-based polyurethane coating can replace a traditional solvent-based system in consumer electronics, achieving similar corrosion protection and dielectric performance while reducing VOC emissions by over 90%.

Overall, the future of PCBA coating emphasizes high performance, intelligent production, and eco-friendly materials, enabling electronics that are more reliable, efficient, and sustainable across industries.

Conclusion

PCBA coating is a critical factor in ensuring electronic reliability. By providing protection against moisture, dust, chemical contaminants, mechanical stress, and thermal fluctuations, coatings help maintain consistent electrical performance and extend the service life of PCB assemblies. Without proper coating, even high-quality components can fail prematurely, leading to costly repairs or product recalls.

The key takeaway is that selecting the right coating material, application method, and design approach directly impacts product longevity and stability. Whether using conformal coatings, potting, or advanced hybrid resins, a well-planned process ensures that electronics perform reliably in demanding environments—from automotive and aerospace systems to industrial controls and medical devices.

For manufacturers seeking high-reliability solutions, partnering with experts is essential. Partner with PCBMASTER for high-reliability PCBA coating solutions and ensure your products deliver lasting performance and quality under the most challenging conditions.

FAQs

What is the difference between conformal coating and potting in PCBA protection?

Conformal coating is a thin protective layer that follows the contours of a PCBA, typically between 25–250 microns. It shields circuits from moisture, dust, and minor mechanical stress while allowing easy inspection and rework. Potting, in contrast, encapsulates the entire assembly in a thick resin, providing superior mechanical protection, vibration resistance, and waterproofing, but it adds weight and makes rework difficult. In short, conformal coating is lightweight and accessible, while potting offers full encapsulation for extreme environments.

How do I choose the best coating material for harsh environments?

Selecting a coating depends on several factors:

Operating environment: High humidity, salt spray, or chemical exposure.

Temperature range: Some coatings remain flexible across extreme heat and cold.

Mechanical stress: Vibration and thermal cycling tolerance.

Reworkability: Whether repairs may be needed later.

For harsh conditions:

Silicone coatings excel in high-temperature and vibration-prone environments.

Polyurethane coatings provide strong chemical and moisture resistance.

Parylene coatings deliver ultra-thin, pinhole-free protection for high-reliability applications like aerospace or medical devices.

What are the common causes of coating failure on PCBAs?

PCBA coating failures typically result from:

Contamination: Residual flux, oil, or dust prevents proper adhesion.

Improper curing: Insufficient heat, UV, or moisture curing can weaken the coating.

Application errors: Bubbles, uneven thickness, or overspray in masked areas.

Environmental stress: Excessive vibration, thermal cycling, or chemical exposure beyond design limits.

Preventing failure requires thorough surface cleaning, precise application, controlled curing, and quality inspections.

Can PCBA coatings be repaired or removed after curing?

Yes, but it depends on the coating type:

Acrylic coatings are relatively easy to remove with solvents or mechanical scraping, allowing component rework.

Silicone and epoxy coatings are harder to remove and may require specialized chemical strippers.

Parylene coatings are typically permanent and not removable, making careful application essential.

Repair strategies often include spot removal, re-coating, or selective rework to maintain protection without damaging the PCBA.

How do PCBA coatings meet IPC standards?

PCBA coatings comply with standards like:

IPC-CC-830: Defines conformal coating materials, adhesion, dielectric strength, and environmental performance for commercial electronics.

MIL-I-46058C: Specifies stringent requirements for high-reliability applications, including temperature cycling, moisture resistance, and mechanical durability.

UL746E: Covers insulation and flammability criteria for polymeric coatings in high-voltage applications.

Compliance ensures reliable performance, OEM approval, and quality assurance, demonstrating that coated PCBAs can withstand rigorous environmental and operational stresses.