Advanced PCB Manufacturing for Automotive and 5G Radar

High-frequency circuit boards are essential to the advancements in 5G communication, autonomous driving, and satellite communication. As these technologies evolve, the need for reliable, high-performance circuit boards becomes critical. Millimeter-wave radar, for example, plays a key role in autonomous driving by providing long-range detection and high resolution, while in 5G, it supports the massive data bandwidth required for fast, stable connections.

However, producing these circuit boards is challenging. Issues such as signal integrity, heat management, and precision control must be addressed to ensure optimal performance. Even small errors can disrupt communication, making it crucial to use advanced manufacturing techniques and materials. Companies like PCBMASTER are overcoming these challenges to meet the growing demand for high-frequency circuit boards in these cutting-edge technologies.

PCBMASTER's Technological Breakthrough: Overcoming Challenges in Millimeter-Wave Radar Circuit Board Manufacturing

Core Capabilities Overview

PCBMASTER has overcome key challenges in millimeter-wave radar PCB manufacturing through advanced technologies:

Laser Drilling: PCBMASTER’s laser drilling process achieves precise hole diameters (50–150μm) to ensure signal integrity at high frequencies.

Electroplating: The company ensures uniform copper layer thickness (18–35μm) for consistent signal transmission.

Precision Circuit Patterning: PCBMASTER achieves ±15μm tolerance in antenna patterns and ±0.013mm impedance control, critical for radar and communication systems.

These technologies address manufacturing difficulties and ensure high-performance PCBs for millimeter-wave applications.

Application Fields: PCBMASTER’s Technology Across Industries

PCBMASTER’s technology is used in several key industries:

Automotive Radar: Custom-designed PCBs for 77GHz radar, supporting features like collision avoidance and autonomous driving.

5G Communications: High-precision PCBs for 28GHz base station antennas, ensuring low loss and high-speed data transmission.

Satellite Communications: Millimeter-wave PCBs used in Ka-band transceivers, ensuring reliable data transmission for satellite systems.

PCBMASTER’s innovations cater to the specific needs of these high-frequency industries.

Manufacturing Innovation Highlights

Precision Breakthrough: PCBMASTER achieves ±15μm tolerance in antenna patterns and ensures precise impedance control, essential for millimeter-wave signal integrity.

Material Innovations: The use of high-performance materials like RO3003 and R-5515 enhances signal stability and reduces loss, making them ideal for automotive radar (RO3003) and cost-sensitive applications (R-5515).

PCBMASTER’s advancements in precision and materials ensure optimal performance in demanding high-frequency applications.

PCBMASTER's Process Capabilities: A Deep Dive into Core Technologies

Product Structure and Layer Configuration

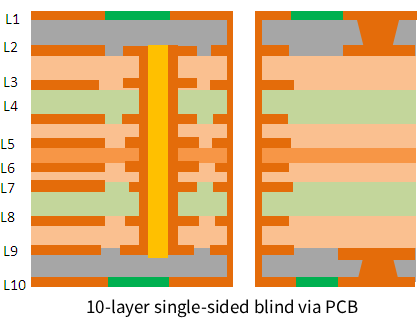

PCBMASTER specializes in the production of multi-layer, high-frequency PCBs, supporting complex structures with 4-10 layers. These boards are ideal for applications where high-performance and compact design are critical, such as automotive radar and 5G communication systems. The company’s manufacturing process includes HDI (High-Density Interconnect) technology, allowing for higher layer density and smaller component sizes, which are essential for advanced electronics.

Additionally, material selection plays a key role in PCBMASTER’s process. The company uses high-performance materials like RO3003 and R-5515, which are optimized for high-frequency applications. RO3003 is used for applications requiring low signal loss and high stability, especially in radar systems operating at 77GHz. R-5515, on the other hand, offers a more cost-effective option while maintaining good performance for applications like 24GHz radar. This combination of advanced materials and multi-layer configurations ensures the boards can handle the demanding performance needs of modern communication and radar technologies.

Key Process Capabilities

Laser Drilling Technology

Laser drilling is a critical process for creating microvias in high-density PCBs. PCBMASTER uses advanced laser technology to drill holes with diameters ranging from 50μm to 150μm, ensuring precise and reliable connections between different PCB layers. This process is particularly important when working with materials like RO3003 and R-5515, as these materials have specific laser parameters that must be optimized to achieve clean hole walls and minimal signal distortion. Laser drilling not only allows for small via sizes but also improves overall signal integrity, which is essential for millimeter-wave applications where precision is key.

Blind Hole Electroplating and Filling Technology

For blind hole applications, PCBMASTER offers electroplating and filling technology to ensure high-quality connections between PCB layers. The company is capable of precisely controlling the hole diameter and depth, ensuring there are no defects such as indentations, or if present, maintaining them at a controlled ≤15μm. This level of precision is crucial for high-frequency applications where any imperfections can cause signal losses or transmission errors. The blind hole plating process also ensures high reliability, which is vital for applications like automotive radar and 5G communication infrastructure.

Precision Circuit Patterning

PCBMASTER's expertise in precision circuit patterning ensures that all components, including traces and antennas, are manufactured with high precision. The company achieves ±15μm tolerance in patterning, ensuring that signal paths are accurate and consistent. Additionally, impedance control is maintained within ±0.013mm precision. These capabilities are essential for high-frequency signal integrity, especially in applications like automotive radar and 5G base stations, where any deviation in the circuit pattern can lead to signal distortion and performance degradation.

Electroplating Process Control

PCBMASTER excels in electroplating processes to ensure uniform copper coating on PCBs. The company maintains strict control over copper thickness—with surface copper thickness kept to ≤18μm—while also ensuring plating uniformity across the entire surface of the board, achieving ≥90% uniformity. This is particularly critical for high-frequency applications, where signal integrity depends on the consistent quality of the copper layer. Uniform copper plating also ensures reliability and durability, especially in high-stress environments such as automotive radar systems and 5G communication networks.

Materials and Process Advantages: How to Choose the Most Suitable High-Frequency Material

Advantages of RO3003 Material

Performance Characteristics:

RO3003 is a high-performance high-frequency PCB material that stands out due to its excellent dielectric constant stability (3.00±0.04), making it ideal for 77GHz applications. This stability is crucial in millimeter-wave technologies, where signal loss must be minimized. RO3003 also features extremely low high-frequency loss (as low as 0.0010 at 10GHz), ensuring efficient signal transmission even at high speeds. The material has outstanding thermal stability, with a low coefficient of thermal expansion (CTE) of 24 ppm/°C, ensuring that the material's expansion rate matches that of copper foil. This reduces the risk of thermal expansion mismatches and ensures reliability in extreme conditions, such as high-temperature automotive environments.

Applications:

RO3003 is particularly well-suited for high-performance radar systems, such as forward radar and long-range radar, where low signal loss and high reliability are crucial. For example, it is commonly used in automotive radar systems for autonomous driving and collision avoidance systems, where consistent signal transmission at high frequencies is a must.

Advantages of R-5515 Material

Cost-Performance:

R-5515 offers a more cost-effective solution compared to RO3003 while still maintaining strong performance characteristics. Its dielectric constant (3.1 at 10GHz) is very close to that of RO3003, making it suitable for many of the same applications, though at a lower cost. Additionally, R-5515 features good thermal stability, ensuring reliable operation in environments with temperature variations. The loss factor (0.0015 at 10GHz) is also comparable to RO3003, but the overall cost benefits make R-5515 an excellent choice for budget-conscious projects.

Applications:

R-5515 is well-suited for mid- to short-range radar applications such as corner radar and blind-spot detection systems, where cost sensitivity is more important without compromising too much on performance. Its balance of cost and performance makes it ideal for applications that require good thermal stability but do not demand the extreme precision of higher-end materials like RO3003. R-5515 is also used in 5G communications and satellite systems where performance can be slightly less stringent, but the material cost is a critical factor.

How to Choose the Right Material

Selection Guidelines:

Choosing the right material depends on performance needs and cost considerations. Here’s how to decide:

1. For High-Performance Applications:

If your application demands maximum performance, such as 77GHz radar systems or other high-frequency applications requiring low signal loss, RO3003 is the preferred material. Its exceptional dielectric stability and low loss make it ideal for demanding environments, such as automotive radar and high-performance satellite communications.

2. For Cost-Sensitive Applications:

When cost efficiency is a priority, R-5515 offers a solid alternative, delivering good thermal stability and performance close to RO3003, but at a much lower cost. It is well-suited for mid-range radar systems, such as blind-spot detection and corner radar, where performance can be slightly more flexible.

3. Mixed-Design Approach:

In some cases, a hybrid approach using both RO3003 and R-5515 materials within the same design can optimize both cost and performance. For example, you might use RO3003 in the most critical areas of the PCB, such as the antenna regions, where performance is paramount, and use R-5515 for less critical areas, such as the supporting circuitry.

By considering the specific performance and cost requirements of your application, you can select the material that best meets your needs, ensuring both high performance and cost-effectiveness.

Customer Application Cases: Real-World Performance of PCBMASTER Technology

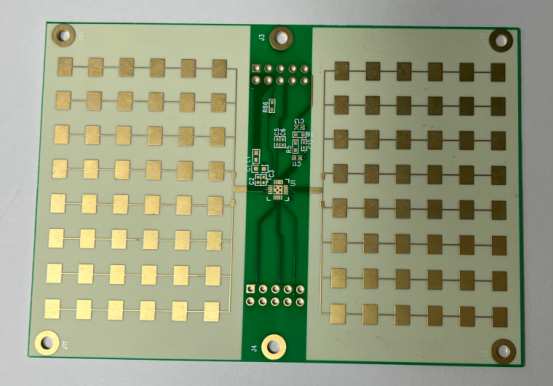

Automotive Radar: 77GHz Radar PCB with RO3003 Material

Customer Case: PCBMASTER’s 77GHz radar PCB, made with RO3003 material, has been successfully validated by customers in the automotive radar sector. The RO3003 material is known for its low loss and high dielectric stability, making it ideal for high-performance radar systems used in autonomous driving and collision avoidance technologies. The 77GHz radar systems demand ultra-precise signal transmission, and RO3003 ensures minimal signal degradation, even at these high frequencies.

Performance Validation: The 77GHz radar PCBs have undergone reliability testing and met the rigorous performance requirements for automotive radar applications. Customers have praised the signal integrity and thermal stability of the PCBs, which are crucial in the high-temperature environments of vehicles.

Real-World Benefits: By using RO3003, PCBMASTER ensures that the radar system’s performance remains consistent and reliable, even under challenging conditions, contributing to safer and more reliable autonomous driving features.

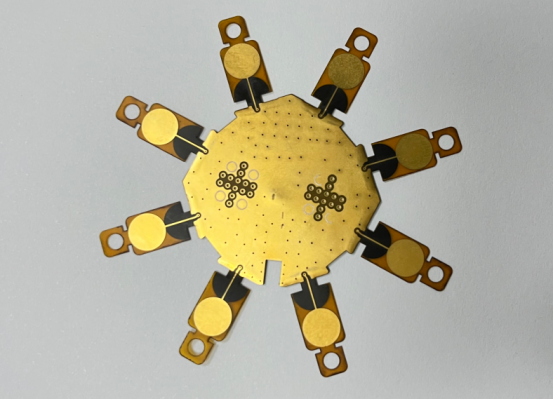

5G Communication: 28GHz Base Station Antenna PCB with R-5515 Material

Customer Case: PCBMASTER provided a 28GHz base station antenna PCB, using R-5515 material, to a leading customer in the 5G communication sector. The R-5515 material offers good dielectric stability and low loss factor, making it ideal for high-frequency communication systems like 5G.

Performance Highlights: The 28GHz PCB designed with R-5515 material exhibited superior insertion loss and return loss (S11) performance, outperforming industry standards. Insertion loss refers to the reduction in signal strength as it passes through the PCB, and return loss indicates how much of the signal is reflected back. Minimizing both of these metrics is critical for maintaining signal quality in 5G networks, where data needs to travel at high speeds with low latency.

Real-World Benefits: The 28GHz PCBs helped ensure high-quality signal transmission for the 5G base station, allowing for faster data speeds and more reliable connections. Customers have reported improved performance in their 5G networks, resulting in better coverage and more efficient communication.

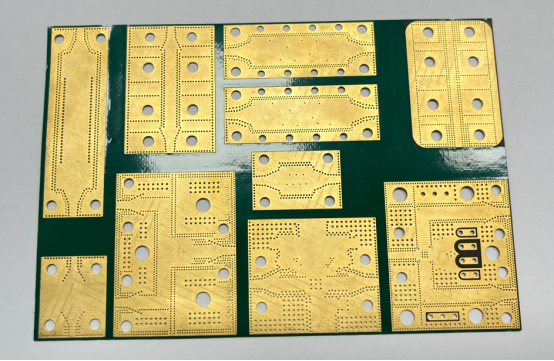

Satellite Communication: Ka-Band Transceiver Module with Hybrid Material Design

Customer Case: In the satellite communication sector, PCBMASTER designed a Ka-band transceiver module using a hybrid material design combining RO3003 and R-5515. This design optimizes both cost and performance for the high-frequency demands of satellite communications, where precise signal transmission is crucial.

Performance Highlights: The Ka-band PCB met all the customer’s performance requirements in terms of signal integrity and thermal stability. The hybrid material design ensured that the high-performance RO3003 material was used in critical areas, like the antenna regions, while the more cost-effective R-5515 material was used for supporting structures. This mixed-material approach successfully balanced the high-frequency performance with a cost-effective solution, making it ideal for large-scale manufacturing.

Real-World Benefits: The hybrid design allowed for cost-effective production without compromising on performance. The Ka-band transceivers were successfully delivered in bulk while meeting the stringent performance requirements for satellite communications. Customers have successfully integrated these modules into their satellite communication systems, ensuring stable and high-quality data transmission.

Technological Innovation and Future Outlook

Precision and Process Innovation

PCBMASTER has made significant breakthroughs in precision control and process optimization, particularly in high-frequency PCB manufacturing. A key achievement is the ±15μm tolerance in antenna patterning and circuit layout, which is crucial for applications such as automotive radar and 5G communications. This level of precision ensures that the signal integrity remains intact, even at high frequencies, where small deviations can lead to performance degradation.

In terms of material processing, PCBMASTER has continually refined its ability to work with advanced materials like RO3003 and R-5515. By optimizing laser drilling parameters, plating processes, and circuit design, the company has minimized signal loss and improved the overall performance of high-frequency PCBs. These innovations allow for more compact, efficient, and reliable products that meet the stringent requirements of next-generation technologies.

Quality Assurance System

PCBMASTER has established a robust quality assurance system that spans the entire production process, from material procurement to final delivery. This system ensures consistency and stability in every batch of PCBs, critical for high-frequency applications where even the smallest variations can impact performance.

The quality assurance process involves continuous monitoring at each step of production, including material testing, production inspections, and final performance validation. With automated testing and real-time monitoring systems, PCBMASTER can guarantee that each PCB meets its strict performance standards, ensuring reliability in demanding environments like automotive radar or satellite communication.

Future Development

Looking ahead, PCBMASTER remains committed to continuous technological innovation. The company plans to expand its R&D capabilities, focusing on the development of new materials and processes that will enhance signal integrity, thermal management, and cost-effectiveness. With the growing demand for 5G, autonomous driving, and satellite communications, PCBMASTER is positioning itself to serve an increasingly broad range of high-frequency PCB markets.

The company aims to not only meet the current needs of high-frequency circuit board applications but also to drive the evolution of the industry. By investing in new technologies, such as AI-driven manufacturing processes and advanced material research, PCBMASTER plans to stay ahead of industry trends and provide cutting-edge solutions for future challenges.

Conclusion

PCBMASTER's commitment to precision, innovation, and quality assurance sets it apart as a leader in high-frequency PCB manufacturing. With continuous advancements in materials and processes, the company is well-equipped to meet the growing demands of 5G, autonomous driving, and satellite communications. As the industry evolves, PCBMASTER remains dedicated to providing cutting-edge solutions that ensure reliability, performance, and cost-effectiveness.

If you have any questions or need assistance with your high-frequency PCB needs, feel free to reach out to PCBMASTER. We’re here to help!

FAQs

Why is millimeter-wave technology critical for automotive radar?

Millimeter-wave (mmWave) technology is crucial for automotive radar because it offers higher resolution and longer detection range, which are essential for the performance of autonomous vehicles. This technology enables radar systems to detect objects at greater distances and with more precise detail, even in challenging environments such as fog, rain, or low light. For autonomous driving and collision avoidance systems, millimeter-wave radar ensures accurate tracking of nearby vehicles, pedestrians, and obstacles, which is vital for safe navigation.

How should one choose between RO3003 and R-5515 materials?

The choice between RO3003 and R-5515 depends on the specific performance and cost requirements of the application:

RO3003 is best suited for high-performance applications, especially in the 77GHz radar systems used in automotive radar and high-frequency communications. It offers superior dielectric stability, low signal loss, and excellent thermal stability, making it ideal for long-range radar applications where precision is paramount.

R-5515, on the other hand, is more suitable for applications with cost sensitivity, such as 24GHz blind-spot detection radar. While it offers slightly lower performance than RO3003, it still provides good dielectric stability and low loss, making it an excellent choice for mid-range radar systems where performance demands are more moderate but cost-effectiveness is a priority.

In which fields are PCBMASTER's technological advantages most prominent?

PCBMASTER excels in high-frequency PCB manufacturing, particularly in industries like automotive radar, 5G base stations, and satellite communications. The company's key technological advantages lie in its ability to produce precise and stable PCBs that meet the rigorous requirements of high-frequency applications.

In the automotive radar sector, PCBMASTER specializes in producing 77GHz radar PCBs with exceptional signal integrity and thermal stability.

For 5G communications, PCBMASTER provides 28GHz antenna PCBs with minimal insertion loss and high signal quality.

In satellite communications, the company’s hybrid material designs deliver reliable performance for Ka-band modules, balancing cost and performance.

These capabilities are especially crucial for next-generation technologies, where reliability and precision are non-negotiable.

How does PCBMASTER ensure the production quality of millimeter-wave PCBs?

PCBMASTER maintains a stringent quality assurance system throughout every phase of the production process, ensuring the consistent and reliable performance of its millimeter-wave PCBs. Key elements of the system include:

Rigorous material testing to ensure that only the best raw materials are used.

Automated inspections and real-time monitoring at each production stage, including laser drilling, circuit patterning, and electroplating.

Comprehensive performance validation of the finished product, ensuring that the PCBs meet the exacting standards for signal integrity, thermal stability, and mechanical reliability.

With this full-spectrum approach to quality control, PCBMASTER guarantees that its products consistently meet customer specifications and industry standards, ensuring reliability and performance in critical applications.

How does PCBMASTER drive technological innovation and market applications?

PCBMASTER is committed to continuous technological innovation to meet the ever-evolving demands of high-frequency PCB applications. The company drives innovation through:

Ongoing R&D: PCBMASTER continually invests in new material research and advanced manufacturing technologies to improve the performance, cost-efficiency, and reliability of its PCBs.

Process optimization: The company constantly refines its production processes, including laser drilling, electroplating, and precision patterning, to enhance signal integrity and yield.

Customer-driven development: By working closely with customers, PCBMASTER tailors its solutions to meet specific application needs, ensuring the successful integration of its PCBs in industries like automotive radar, 5G communications, and satellite communications.

This focus on technology development and customer satisfaction allows PCBMASTER to be at the forefront of millimeter-wave PCB applications, supporting the growth of next-generation technologies worldwide.